We’ve always believed that one of the most powerful advantages of stereolithography (SLA) 3D printing is the wide range of printing materials. That’s why Formlabs is excited to announce six new materials across the Form 3, Form 3B, and Form 2 SLA 3D printers. These new resins continue to challenge what's possible with 3D printing by further expanding use cases and design possibilities with our existing printers. Our latest resins support a wide range of industries and use cases within these industries, ranging from healthcare to manufacturing.

The new material families and resins address the following segments:

-

Engineering, Product Design, and Manufacturing: We are introducing a new family of Flexible and Elastic Resins consisting of Flexible 80A Resin, a reformulation of our current Flexible Resin, and Elastic 50A Resin.

-

Healthcare: Our new line of BioMed Resins that includes BioMed Clear Resin and BioMed Amber Resin brings biocompatible resins to healthcare professionals across the globe.

-

Dental: As part of our Materials Partnership Platform with BEGO, we’ve introduced a novel material for temporary restorations. We are also introducing a new resin for manufacturing custom impression trays, as well as improving our long-term clear material indicated for splints and occlusal guards. These two resins were developed at our in-house ISO 13485 facility.

Read on to learn more about these new resins and how they’re tailored to meet your needs.

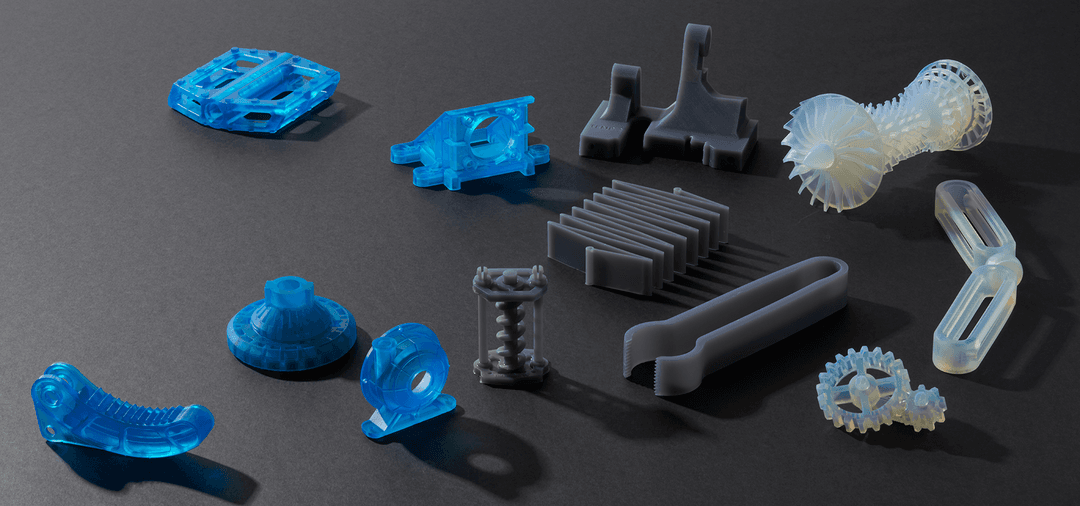

Flexible and Elastic Resins for Streamlining In-House Production

We are excited to announce our new family of Flexible and Elastic Resins, our second engineering resin family. Manufacturers have long expressed the desire to replace outsourcing and molding of silicone, urethane, and rubber parts in order to reduce long turnaround times and additional labor. With the launch of our family of Flexible and Elastic Resins, we are expanding our library of high performance, easy-to-use soft materials, and making it possible to produce flexible parts in-house within hours. These resins are well suited for consumer goods prototyping, compliant features for robotics, and special effects props and models.

Tune in on July 8 for a live webinar led by our Applications Engineer who will walk you through Flexible 80A Resin.

Deep Dive on Flexible 80A and Elastic 50A with our Materials Product Manager

In this webinar, a Formlabs Product Marketer will walk through our family of Flexible and Elastic Resins and deep dive into our latest material, Flexible 80A Resin.

Flexible 80A Resin

The Flexible 80A Resin is a reformulation of our current Flexible Resin (V2). It is the most stiff soft-touch material in our library of Flexible and Elastic Resins, with an 80A Shore durometer to simulate the flexibility of rubber or TPU. Balancing softness with strength, Flexible 80A Resin can withstand bending, flexing, and compression, even through repeated cycles. Choose this resin for:

-

Handles, grips, and overmolds

-

Seals, gaskets, and masks

-

Cushioning, damping, and shock absorption

-

Cartilage, tendon, and ligament anatomy

Elastic 50A Resin

Elastic 50A Resin is a new name for our existing Elastic Resin. With a 50A Shore durometer, this is our softest Engineering Resin. It is suitable for prototyping parts normally produced with silicone. Choose Elastic 50A Resin for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing, and spring back quickly to their original shape. Elastic 50A Resin applications include:

-

Wearables, such a straps

-

Compressible buttons

-

Stretchable enclosures and casings

-

Soft tissue anatomy

Find the Right Material for Your Application

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

BioMed Resins for Expanding Medical Applications

3D printing continues to make great strides in the medical space but there is still a lot of room for innovation, encouraging creative new solutions to age-old problems. How does 3D printing fit into the healthcare industry? Diversifying the types of medical resins can help healthcare professionals with an array of important tasks: creating medical devices, planning surgical procedures, developing custom implants, and conducting research. Our new line of BioMed Resins is a group of biocompatible materials targeted towards use in healthcare applications.

BioMed Clear Resin

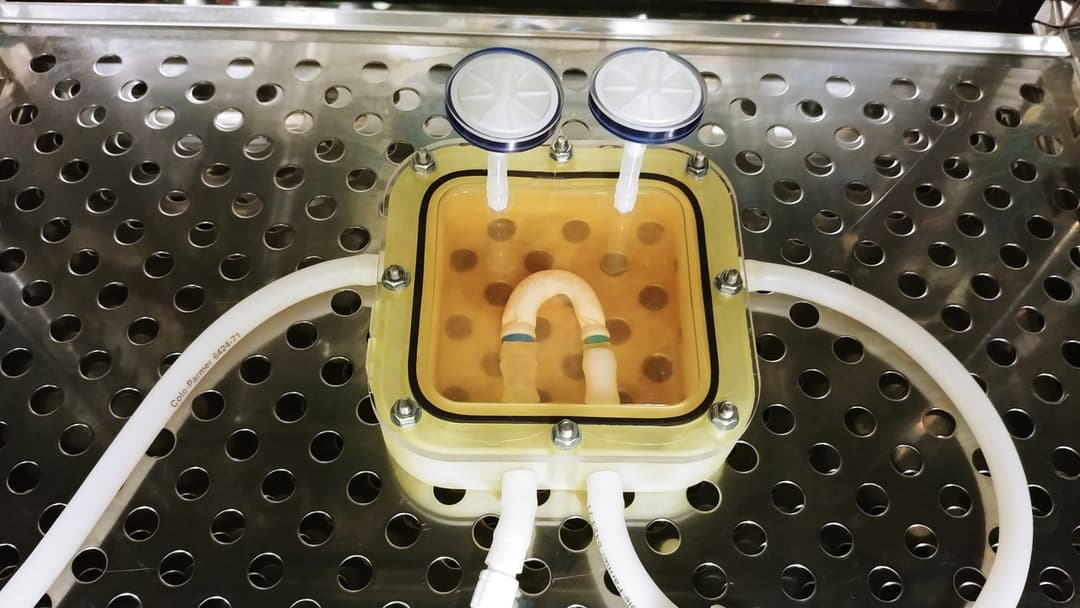

BioMed Clear Resin is a strong, hard resin for biocompatible applications requiring long-term skin or mucosal membrane contact. This USP Class VI certified material is suitable for applications that require wear resistance and low water absorption over time. Parts printed with BioMed Clear Resin are compatible with common sterilization methods and can be sterilized to CDC standards.

BioMed Clear Resin is manufactured in our ISO 13485 facility and is supported with an FDA Device Master File. This material is well suited for the following:

-

Medical devices and device components

-

Jigs and fixtures

-

Surgical planning and implant sizing tools

-

Drug delivery devices

-

Bioprocessing equipment

-

Research and development

BioMed Amber Resin

BioMed Amber Resin is a rigid material ideal for biocompatible applications requiring short-term skin or mucosal membrane contact. Parts printed with BioMed Amber Resin are compatible with common solvent disinfection and sterilization methods.

BioMed Amber Resin is manufactured in our ISO 13485 facility. Use this material for the following:

-

Medical devices and device components

-

Surgical planning and implant sizing tools

-

Implant guides and drilling templates

-

Research and development

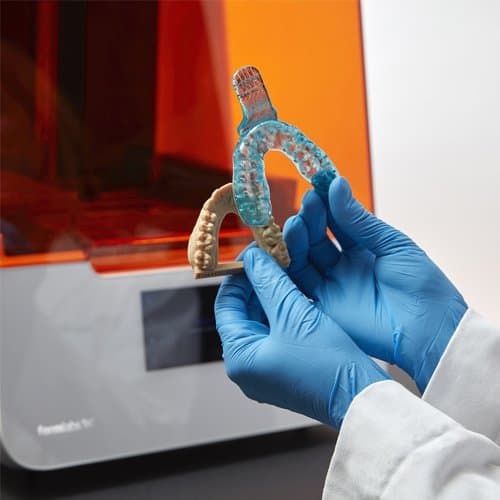

Dental Resins for Custom Trays, Splints, and Temporary Crown and Bridge Restorations

We’re also excited to announce three new Dental Resins to our expanding library of dental materials. If you’d like to learn about the new dental materials in detail, head over to our dental website or register for our upcoming webinar.

Dental Materials Launch: A Deep Dive Into Our Three New Dental Materials

In this webinar, learn about the key features of our new dental resins and how you can use them to produce dental parts and biocompatible appliances in your practice or lab.

Dental LT Clear Resin (V2)

In order to further improve Dental LT Clear Resin, we brought development in-house to fully reformulate the resin. We are pleased to launch our second-generation, long-term biocompatible material for splints and occlusal guards. Durable and resistant to fracture, this color-corrected material prints clear, polishes to high optical transparency, and resists discoloration over time for a finished appliance you’ll be proud to deliver.

*Dental LT Clear Resin (V2) is currently shipping in the US and other select countries. View the full regional availability list. While we’re working on expanding the availability, consider using our legacy Dental LT Clear Resin in other regions.

Custom Tray Resin

Custom Tray Resin is a new in-house developed material indicated for custom impression trays. It is designed for direct printing of custom trays used for taking highly accurate definitive impressions, making it ideal for crown and bridge, implant, dentures, and comprehensive cases. This fast printing resin creates one tray in less than one hour, reducing labor time and enabling higher throughput.

Temporary CB Resin

Available in four VITA shades and developed in partnership with BEGO, a leader in restorative dental materials, Temporary CB Resin is designed for directly printing temporary crowns, bridges, inlays, onlays, and veneers. This durable resin can produce up to 7 unit bridges and temporary restorations for up to 12 months use and enables a digital workflow for collaborative processes between dental technician, dentist, and patient.