Grey Pro Resin

General Purpose

SLA

Fine Details

61 MPa

2,600 MPa

86 MPa

Select Printer Series and Resin Volume

| Bulk order quantity (L) | Discount % |

|---|---|

| 1 | 0% |

| 30 | 15% |

| 60 | 20% |

| 120 | 25% |

| 240 | 30% |

| 1,000 | 35% |

| 2,000 | 40% |

| 3,000 | 45% |

Grey Pro Resin is compatible with Form 2 and Form 3 Series printers. Grey Resin V5 on the Form 4 Series offers improved mechanical properties and three times faster print speed, replacing Grey Pro Resin.

Grey Pro Resin has been added to your cart.

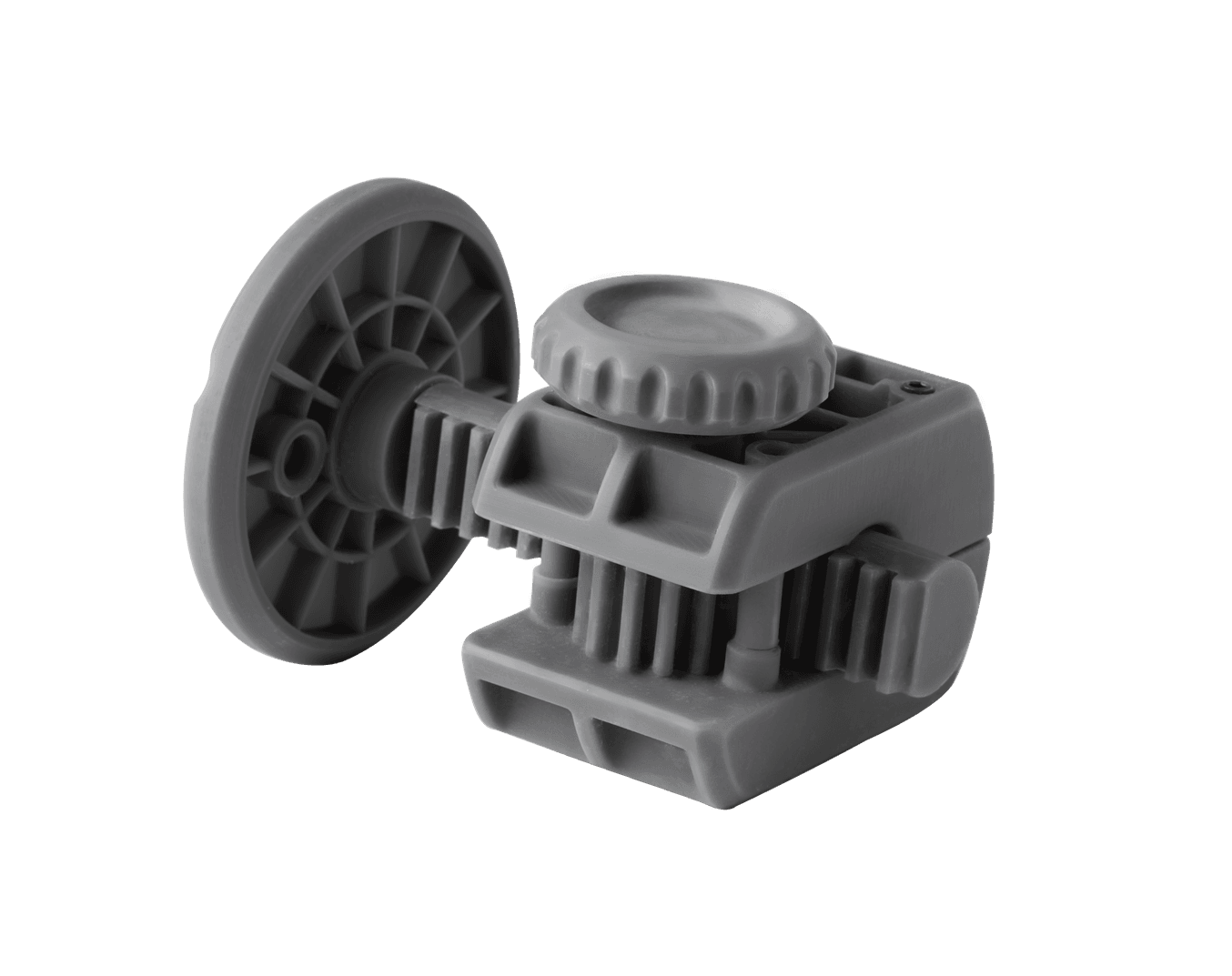

Why Choose Grey Pro Resin?

Grey Pro Resin is a tough and heat resistant material that has increased elongation and improved toughness compared to Formlabs Standard Resins.

Low Creep

Able to withstand high stress and hold its shape overtime.

High Heat Resistance

Allow hot air, gas, and fluid flow through your parts.

Tough

Handle parts repeatedly, knowing parts will absorb shock and impact energy without breaking.

High Precision

Create looks-like prototypes with smooth surfaces that show fine detail.

Applications

Grey Pro Resin is ideal for concept modeling and versatile and functional prototyping. It is a versatile material suitable for both looks-like prototypes and rigorous hands-on testing.

Consider Grey Pro Resin for:

Material Properties*

Grey Pro Resin

Ultimate Tensile Strength

Tensile Modulus

Elongation

Flexural Modulus

Notched Izod

Heat Deflection Temp @ 0.45 MPa

Thermal Expansion (0-150 ºC)

* Material properties may vary based on part geometry, print orientation, print settings, and temperature. Data was obtained from green parts printed using Form 2, 100 μm, Grey Pro Resin settings and post-cured with a Form Cure for 120 minutes at 80 °C.

Post-Processing

Washing

The foundational step in any SLA post-processing workflow is to remove any excess resin on the surface of the parts through an alcohol or ether wash.

Curing

Post-curing for General Purpose Resins is optional. However, Formlabs recommends a short post-curing to reduce surface tack and improve mechanical properties.