Model V3 Resin

General Purpose

SLA

Fine Details

48 MPa

2,300 MPa

4.8 %

Select Printer Series and Resin Volume

| Bulk order quantity (L) | Discount % |

|---|---|

| 1 | 0% |

| 30 | 15% |

| 60 | 20% |

| 120 | 25% |

| 240 | 30% |

| 1,000 | 35% |

| 2,000 | 40% |

| 3,000 | 45% |

Model Resin V3 is compatible with Form 3 and Form 2 Series printers. Choose Precision Model Resin on the Form 4 Series for better accuracy, three times faster print speed, and improved aesthetics.

An optional Fit Tuning Test on Form 3, Form 3B, and Form 3B+ allows you to dial in precise dimensional fit depending on your use case.

Read our Application Guide to learn the complete digital workflow and best practices for making 3D printed restorative models on your Formlabs 3D printer.

Model V3 Resin has been added to your cart.

Why Choose Model Resin?

Model Resin enables dental professionals to print models in high volume, easily handle rush cases, and deliver highly-accurate custom fixed prosthetics and implants.

Fast

Produce models in high volume and easily handle rush cases.

Consistent and Reliable

Don’t spend time troubleshooting or redoing cases, get it right the first time.

Accurate

Deliver high-quality results with models you can rely on.

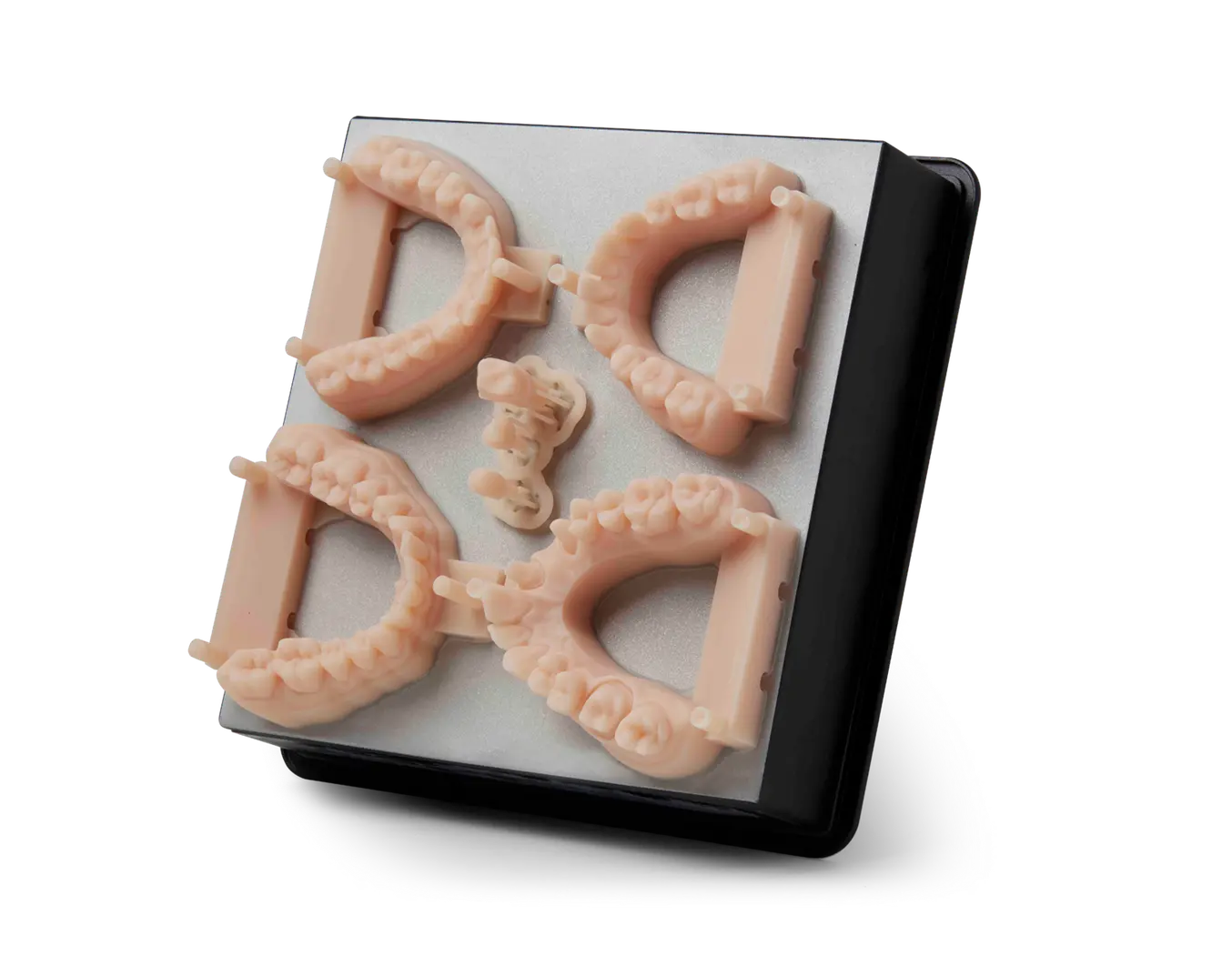

Applications

Formlabs 3D printers can quickly produce high-quality solid models, removable die models, and implant analog models with crisp margins and contacts.

Consider Model Resin for:

Material Properties*

Model Resin

Ultimate Tensile Strength

Tensile Modulus

Elongation

Flexural Modulus

Notched Izod

Heat Deflection Temperature at 0.45 MPa

* Material properties may vary based on part geometry, print orientation, print settings, and temperature. Data for post-cured samples were measured on Type IV tensile bars printed on a Form 3 printer with 100 μm Model Resin settings, washed in a Form Wash for 10 minutes in ≥99% Isopropyl Alcohol, and post-cured at 60°C for 5 minutes in a Form Cure

Post-Processing

Washing

The foundational step in any SLA post-processing workflow is to remove any excess resin on the surface of the parts through an alcohol or ether wash.

Curing

Post-curing for General Purpose Resins is optional. However, Formlabs recommends a short post-curing to reduce surface tack and improve mechanical properties.