Safety With Formlabs SLS Products: Air Quality and Dust Hazard Analysis

This report summarizes two studies performed at Formlabs SLS facilities: an air quality assessment in accordance with OSHA regulations and a combustible and dust hazard analysis in accordance with NFPA regulations. The results show that the normal use of the Fuse Series ecosystem at Formlabs facilities does not represent a risk of respiratory adverse health effects nor fire or explosion hazards.

Safety With Formlabs SLS Products: Air Quality and Dust Hazard Analysis

This report summarizes two studies performed at Formlabs SLS facilities: an air quality assessment in accordance with OSHA regulations and a combustible and dust hazard analysis in accordance with NFPA regulations. The results show that the normal use of the Fuse Series ecosystem at Formlabs facilities does not represent a risk of respiratory adverse health effects nor fire or explosion hazards.

Executive Summary

Formlabs selective laser sintering (SLS) ecosystem is designed and manufactured to ensure a safe and easy-to-use 3D printing experience. Refer to Formlabs machine manuals and powder safety data sheets as a primary source of safety information. Additional documentation, such as workspace preparation and a quick start guide, can be found on the Formlabs support page.

In order to provide further health and safety information related to the handling of SLS powder, Formlabs requested an air quality assessment from U.S. Compliance as well as a combustible and dust hazard analysis from Stonehouse Process Safety. Both studies took place at the Formlabs SLS research and development (R&D) facility in Somerville, MA, which has about 60 SLS printers and 15 post-processing machines.

The study at Formlabs R&D SLS facilities indicates the following:

• Even with a large number of printers, the average airborne powder concentration of total particulate matter is below 2% of the OSHA permissible exposure limit.

• The likelihood of powder ignition and explosibility is considered to be very low, given the safeguards that have been incorporated inside the printing equipment.

• The overall risk from an employee safety perspective is considered to be negligible.

Based on the results of the studies, no special personal protective equipment, respirators, or goggles are required at Formlabs facilities for operating the Fuse ecosystem. The only requirements are adherence to a regular housekeeping program and the use of safety glasses and nitrile gloves when handling powders.

This document summarizes the results and key findings of each report and provides guidance on good SLS housekeeping practices.

Air Quality Assessment from U.S. Compliance

U.S. Compliance is a leader in environmental, health, and safety (EHS) compliance management, delivering Occupational Safety and Health Administration (OSHA) compliance and EHS consulting solutions. Read more about OSHA requirements on this page.

Procedure

U.S. Compliance conducted an air quality assessment at Formlabs' MA R&D facilities to determine the level of employee powder exposure. The parameter considered was the eight-hour time-weighted average (TWA): the employee’s average airborne exposure in an eight-hour work shift. Two types of air sampling were performed continuously from 9:00 AM to 5:00 PM.

Room Sampling:

Monitors were staged on tripods throughout multiple workspaces. Eight rooms were measured, including engineering labs, print production farms with a large fleet of printers, and media blasting rooms. The workspace varies from a 190 m² room with over 20 Fuse printers and four Fuse Sifts to smaller rooms of 35 m² size with about 10 printers and four Fuse Sifts.

All Formlabs SLS rooms are equipped with HVAC systems providing at least three full air exchanges per hour. In some cases the air exchange was increased, without having to change the HVAC systems in place, by adding exhaust fans in windows.

Formlabs R&D SLS materials lab in Somerville is about 37 m² (180 m³) with over 10 Fuse printers and four Fuse Sifts.

Employee Sampling

A group of employees wore monitors throughout a workday and performed all job tasks for managing a large fleet of Fuse printers, similar to a service bureau:

- General lab activities

- Normal Fuse Series printer operation

- Normal Fuse Sift operation

- Bead blasting parts

- Pouring powder into hoppers

- Switching powder

- Waste consolidation

- Emptying a vacuum used for cleaning in and around the Fuse Series ecosystem

- The tests were carried out with air sampling cassettes using pumps calibrated at 2.0 L/mn and 2.5 L/mn flow rates. They considered the following concentrations:

- The total particulate matter associated with all powders

- The respirable particulate matter associated with all powders

- The Carbon black associated with all powders (some SLS powders used in the Fuse ecosystem contain 0.1% to 1% of respirable carbon black, by mass)

The TWA concentration experienced over an eight-hour period should be less than the permissible exposure limit (PEL) defined by OSHA or equivalent regulatory entity. The PEL TWA is established as the highest level of exposure an employee may be exposed to without incurring the risk of adverse health effects, while the annotated occupational exposure limit (OEL) TWA is the recommended concentration not to exceed.

Results

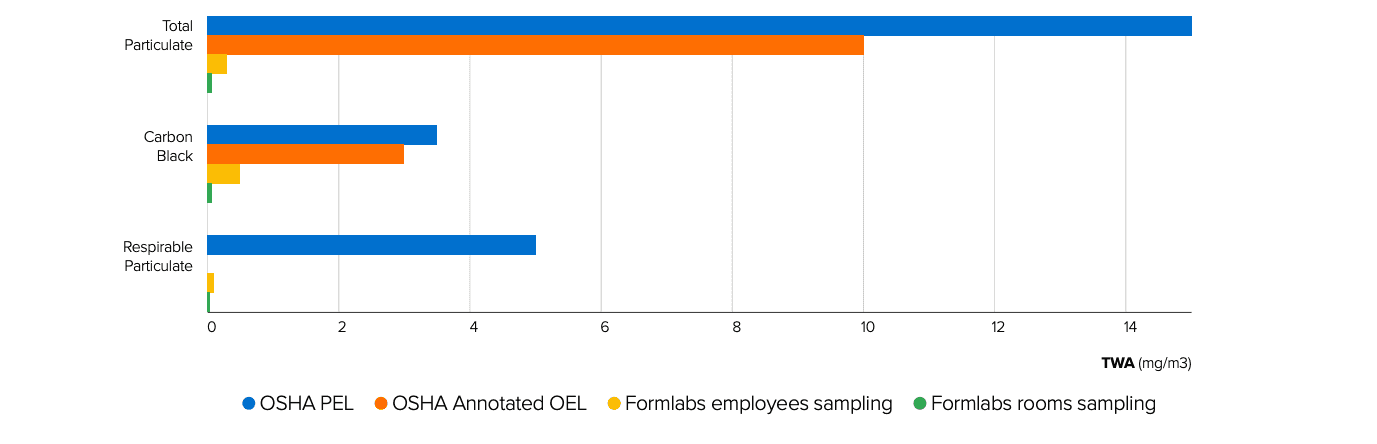

Average airborne powder concentrations associated with the normal use of the Fuse ecosystem are below 2% of the OSHA permissible exposure limit for the total particulate matter and respirable particulate matter, and below 15% of the OSHA permissible exposure limit for carbon black. Even with more than a dozen printers in one room, the normal use of the Fuse ecosystem does not represent a risk of respiratory adverse health effects and complies with OSHA dust exposure regulations.

Averaged TWA concentrations of particulates measured at Formlabs SLS R&D facilities and TWA OSHA exposure limits.

Combustible and Dust Hazard Analysis from Stonehouse

Stonehouse Process Safety (Stonehouse) is an industry leader in preventing explosions, fires, and accidental material releases. They deliver quality-assured test data and process safety management solutions.

Scope

Stonehouse conducted a combustible and dust hazard analysis (DHA) at Formlabs' SLS R&D facility in December 2022. The goal of this study is to help Formlabs identify potential powder fire and explosion hazards associated with the use of the SLS ecosystem. This assessment follows the guidance of the National Fire Protection Association (NFPA) consensus codes and standards for the processing and handling of combustible particulate solids.

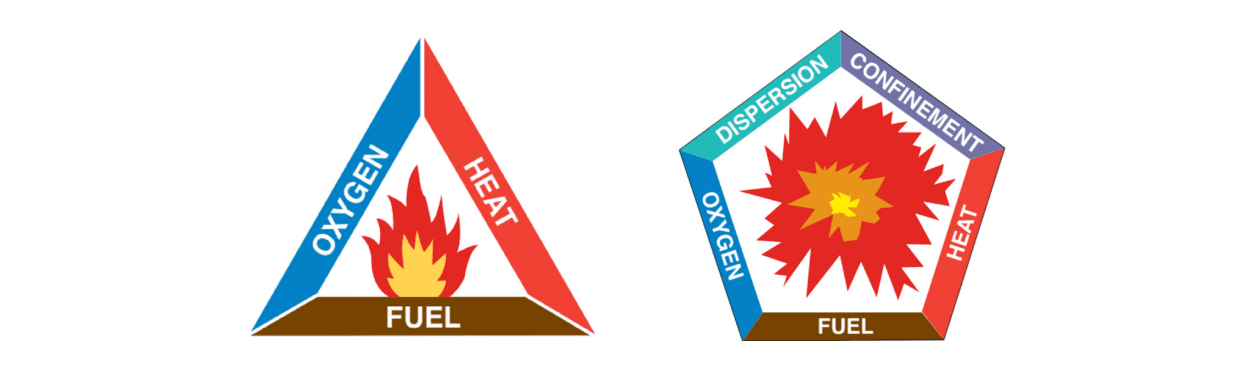

SLS powders, along with many other materials such as sawdust and flour, are combustible and can catch on fire under certain conditions. Three elements are required for a fire to occur: oxygen, fuel (combustible), and an ignition source. For an explosion involving a combustible powder to occur, two additional conditions are needed: the components must be confined in a contained volume and the dispersion or concentration of powder in air should be above the minimum explosive concentration (MEC).

The Fire Triangle and Explosion Pentagon.

Based on this understanding, Stonehouse evaluated dust explosion hazard potential by checking oxidizing atmosphere, credible ignition source, and credible suspension mechanism from Formlabs SLS ecosystem. They evaluated both the equipment and the building that are used to house the process, including the SLS powders, the Fuse Series printer, the Fuse Sift, the powder handling and processing areas, and the facilities’ housekeeping process.

DHA Methodology

Stonehouse experts ran laboratory tests on samples from six Formlabs powders to evaluate the associated explosivity data, including Nylon 12 Powder, Nylon 11 Powder, Nylon 11 CF Powder, Nylon 12 GF Powder, TPU 90A Powder, and a powder in development.

The tests included:

- Screening test (go/no-go) to determine if the particulates are at risk of explosion.

- Measures of the minimum ignition energy and temperatures to initiate a fire.

- Measure of the minimum concentration of suspended dust to cause an explosion (MEC).

Stonehouse conducted an investigation of spaces where combustible dust was present or in use and inspected equipment used in those spaces for processing combustible dust such as the Fuse Printers and post-processing equipment.

DHA Results - Equpiment

Powders Explosibility: Stonehouse evaluated the powders' ignitability properties. The table below summarizes the results of their tests and data interpretation.

| Test | Result | Interpretation |

|---|---|---|

| Explosivity screening (go/no-go) | Go | The powders are explosible. |

| Minimum ignition energy (MIE) (mj) | High 300 < MIE < 1000 | The powders present a low risk of autoignition. |

| Minimum ignition temperature (cloud) (MITcloud) (°C) | High 400 < MITcloud < 440 | The powder clouds present a low risk of autoignition. |

| Minimum explosible concentration (MEC)(g/m3) | High MEC = 40 | The powder clouds present a low risk of explosion. |

- The powders present a low risk of ignition by sparks and electrostatic discharges. The minimum ignition energy (MIE) of all the powders is considered to be high, ranging from 300 to 1000 mJ. Even strong spark discharges from ungrounded equipment would not be expected to generate this type of energy.

- The powder clouds present a low risk of autoignition when exposed to a heated environment, hot surfaces, and friction sparks. The minimum ignition temperature (MITcloud) is greater than 400°C for all the tested samples, which is considered to be very high. Additionally, the minimum ignition temperature of the dust layer on a hot plate (MITlayer) is greater than 350°C. This shows that the powders will only ignite in the event of a fire.

- Extremely dense powder clouds must be generated in order for the cloud to be ignitable. This is given by the relatively high value for the minimum explosible concentration (MEC) when compared to most organic products.

As a result, Formlabs SLS powders are considered to be difficult to ignite and explode. Only extremely dense powder clouds exposed to open flames could cause an explosion. Stonehouse observed that the nature of the printing operations is such that significant quantities of powder, in layers or suspended dust clouds, would not be expected.

Fuse Series Printers and Fuse Sift DHA

- The Fuse Series printers utilize a laser to selectively fuse the powder layer by layer. The Fuse Sift is an enclosed system for removing and recycling excess powder from printed parts.

- The heating sources' temperatures inside the equipment are well below the powders' MIT, MITcloud, and MITlayer, and show that the powders will not ignite inside the equipment.

- All electrical components inside the equipment are well isolated from the powder and not considered to be potential ignition sources.

- The volume of dust clouds inside the Fuse Sift for cleaning operations is judged to be small in comparison with the overall internal volume of the sifting equipment.

Any additional electrical equipment used to support the cleaning operation inside the Fuse Sift should be intrinsically safe and suitable for Class II Division 1 atmosphere. For instance, using an electric brush tool with a rechargeable lithium battery could be a potential ignition source.

The likelihood of ignition is considered to be very low, given the safeguards that have been incorporated into the printing and sifting equipment. For example, Fuse Series printers have thermal sensors and shut down at high temperatures. The consequences of ignition, in terms of employee safety, are also considered to be very small. The overall risk from an employee safety perspective is considered to be negligible.

DHA Results - Building

In order to prevent flash fire or explosion hazards within the facility, Stonehouse recommends establishing a housekeeping plan using either the NFPA layer depth criterion method or Mass Method A to establish powder levels of accumulation that will trigger cleanup activities. Vacuuming is the preferred cleaning method to avoid the generation of powder clouds and settling the dust again at higher elevations.

Stonehouse did not observe any significant accumulations of fugitive dust in the Formlabs SLS R&D areas and considered that a dense dust cloud is not likely to happen in the facility. This is explained by the nature of the printing operations as well as the impact of the simple housekeeping program described below. Formlabs’ SLS workspace is classified as a Non-Hazardous Area.

DHA Takeaways

SLS powders are combustible. However, Stonehouse DHA shows that given the nature of the Formlabs powders, the safety features incorporated in the hardware, and regular housekeeping to avoid dust accumulation, the risks of powder fire and explosion are negligible.

Formlabs Housekeeping Program

The Formlabs R&D team conducts weekly simple housekeeping to ensure the facilities are free from powder hazards. The main operation is to vacuum all surfaces in order to prevent dust accumulation. Because Formlabs facility was deemed to be a “Non-Hazardous Area”, the team uses a static dissipative vacuum that follows NFPA guidelines for combustible dust conveyance (ATEX Ex II 3 D in EU). Consult Formlabs' support page for all product documentation, such as workspace preparation. Here are a few additional best practices that Formlabs follows:

Rooms and General Equipment:

- Emergency equipment should be visible and available.

- Tools, ladders, and PPE should be available, organized, and stored.

- Fire extinguishers should be provided throughout all buildings in accordance with NFPA.

- Electrical panels should be closed, unobstructed, and free of potential ignition sources.

- Conductive components of process equipment must be bonded and grounded as per NFPA recommendations.

Flammable Materials:

- All flammable materials should have designated storage.

- If the Fuse equipment is in a workshop, designated hotwork areas should be free from combustibles and flammables, and a fire extinguisher should be present in the immediate area. A hot work program should be in place in accordance with NFPA.

Powders:

- Vacuum all surfaces and floors, including higher elevations such as HVAC ductworks or suspended ceilings. Avoid dust layers thicker than a paperclip (0.8 mm), or visible discoloration of equipment due to dust. Any powder spilt during use must be vacuumed up immediately.

- Close all powder containers.

- Build chambers must be cleaned first, then returned to the shelf when they are not in use. Uncleaned build chambers spread dust around the shop and risk cross-contamination with powder from different material build chambers.

- Excess used powder can be dosed out of the Sift by setting refresh rate to 0% and dosing into an empty cartridge. This powder should then be disposed of in the 55-gallon fiber barrels and refresh rate returned to default for future users.

- Follow Formlabs’ manual for powder care, storage, and disposal.

- Use conductive or static dissipative (SD) hoses for powder transport - as per NFPA recommendations.

Chemicals and Waste:

- Chemical containers should be closed when not in use, stored properly, and labeled with full chemical names and associated hazards.

- Trash and recycling containers should be emptied.

- Employees should follow safe work practices during housekeeping, use proper waste disposal streams, and require EHS assistance for unwanted waste.

Conclusion

U.S. Compliance and Stonehouse Safety Process ran an air quality assessment and dust hazard analysis at Formlabs SLS R&D facilities. Both studies were conducted in accordance with OSHA and NFPA regulations. The results show that the normal use of the Fuse ecosystem does not represent a risk of respiratory adverse health effects nor fire or explosion hazards, as long as the powder safety data sheets, hardware manuals, and a relevant housekeeping program are respected.

As noted, only the use of safety glasses and nitrile gloves are required for handling SLS powders at Formlabs facility. Formlabs recommends users to understand and comply with their local regulations, respect the product instructions and housekeeping, as well as evaluate their workspaces and practices to identify any potential safety hazards.

To learn more about how the Fuse Series ecosystem can fit into your workspace and to evaluate your workflow for safety, contact our team.