Eleven successfully crowdfunded projects, who collectively raised $2.5 million dollars, have used the Form 1+ SLA 3D printer to develop incredible products.

Kickstarter helped us introduce the Form 1 to the world, and with a high-resolution desktop printer by your side, there’s never been a better time to take advantage of crowdfunding platforms to launch your own product.

Successfully Funded Projects

Having been through the Kickstarter process, it's been rewarding to watch others using the Form 1+ 3D printer in pursuit of their own crowdfunding success.

- Ownphones- $767,472 - Custom-fit 3D printed earphones. Kickstarter, August 2014

- Novena Laptop - $591,212 - Open-source laptop. Crowdsupply, May 2014

- Eva - $539,963 - Intimate wearables for couples. Indigogo, December 2014

- TriggerTrap Ada - $445,573 - Modular camera trigger. Kickstarter, November 2013

- Ambi Climate - $114,892 - Smart AC management. Kickstarter, November 2014

- Sutrue - $46,058 - Automatic suturing device. CrowdBnk, November 2014

- GeMo - $24,442 - An army of 3D printed vases. Kickstarter, July 2014

- House of Monsters - $2,0218 - Stop-motion web series. Kickstarter, April 2014

- Squizmo - $6,506 - A self-sealing tube squeezer. Kickstarter, July 2014

- HbA1C Model - $5,050 - Teaching model for diabetes education. Rockethub, May 2014

- 3DPonics - $2,547 - 3D printable hydroponics system. Kickstarter, August 2014

The above projects are known to have used Formlabs printers during the development process, however several projects used other methods of 3D printing during the prototyping phase or as they moved to production. For the purpose of this article, funds raised in other currencies have been converted to USD.

Ambi Climate - Design in Distributed Teams

Ambi Climate launched their smart AC management system on Singapore-based Crowdtivate and US-based Kickstarter. As a globally distributed team, they had to decide where to locate their Form 1 3D Printer. Instead of shipping it to their designer in Japan, they found it more useful to have at the main office in Hong Kong.

“Our industrial designer can think in 3D. When he creates a CAD model, he knows what it looks like in his head. It was much more useful to be able to print things quickly at our office in Hong Kong, so that when reviewing designs, our engineering team, our marketing team, and our business team could see the product for themselves and articulate what we'd want to change.” - Julian Lee, founder of Ambi Climate.

Having a high-fidelity prototype early on in the process can help communicate ideas and help identify issues with fit or tolerances - before financially committing to tooling. For more on this project check out Ambi Climate’s blog post on prototyping with the Form 1.

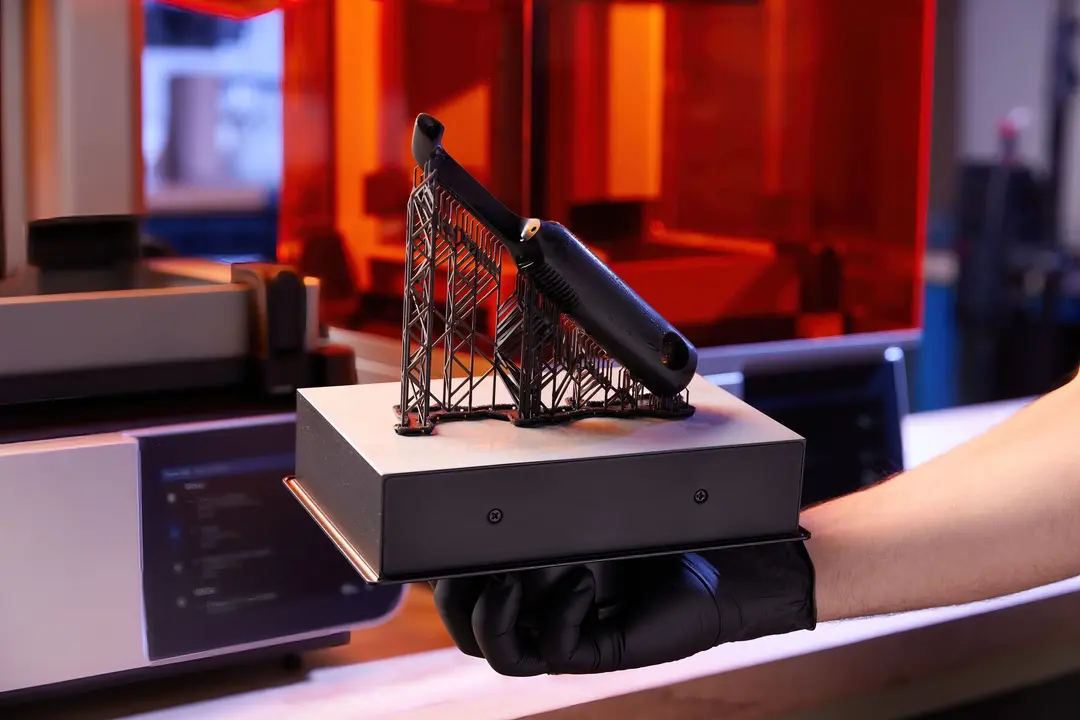

From prototype to injection molding tool. Ambi Climate prepares for production.

From prototype to injection molding tool. Ambi Climate prepares for production.

Biologic Models - Design for a Specific Market

We were inspired by Casey Steffen’s Glycated Hemoglobin A1C Model, which was successfully funded through RocketHub in 2014. Casey and action figure toy designer, Michael Gulen, created a model of Hemoglobin A1C, a protein that’s looked for in a common blood test given to every single diabetic. The physical model helped people better understand the test and their numerical test results.

The final production models were cast, however original prototypes were printed on the Form 1+.

The final production models were cast, however original prototypes were printed on the Form 1+.

Crowdfunding helped Casey get this model into clinics and practices around the world, while the Form 1 allowed him to take his illustration skills and create a physical model for the first time. Casey continues to explore new 3D printing projects through his work with Biologic Models.

Studio Integrate - Design for Engagement

Studio Integrate, a product/architecture studio in London, raised over $24,000 by allowing backers to support their ‘genetically modified’ vases on Kickstarter for their project, GeMo, an army of 3D Printed Vases. They offered backers the reward of an individual vase, created from a parametric design based on Islamic patterns. The final vases were displayed during London Design Week and then shipped to backers.

The final Army of vases on display at 100% Design 2014.

The final Army of vases on display at 100% Design 2014.

Studio Integrate used the Form 1+ 3D printer to test the designs produced by their algorithm, which occasionally had awkward voids, before printing in ceramics or metals which are more expensive processes. Crowdfunding seemed the only way to go with this project, allowing them get direct feedback, and to promote that the vases were to be exhibited at London Design Festival. They found that this high level of public engagement both before and after the exhibition itself was a unique and exciting experience.

“We created these through an emerging tool, an emerging fabrication, and we wanted to get it to people through an emerging platform.” - Mehran Gharleghi, Studio Integrate.