Engineering Resin Families

Our library of versatile, reliable Engineering Resins is formulated to help you reduce costs, iterate faster, and bring better experiences to market.

Tough and Durable Resins

Robust, functional, and dynamic materials that can handle compression, stretching, bending, and impacts without breaking.

TOUGHIMPACT RESISTANTDUCTILE

Rigid Resins

For strong and stiff, as well as thermally and chemically resistant parts that will be dimensionally stable under load.

STIFFSTRONGHEAT RESISTANT

Flexible and Elastic Resins

Produce flexible parts in-house in a matter of hours and replace outsourcing and molding of silicone, urethane, and rubber parts.

SOFTFLEXIBLECLEAR

Silicone Resins

100% silicone 3D printing materials to quickly fabricate functional prototypes and short runs in pure silicone.

SOFTPLIABLEDURABLE

Ceramic Resins

For affordable and high-performance technical ceramic 3D printed parts with exceptional thermal, mechanical, and conductive properties.

EXTREMELY STIFFHEAT RESISTANTCONDUCTIVE

Polyurethane Resins

Go beyond the limits of traditional plastic 3D printing and leverage materials that create true, high-performance polyurethane parts.

TOUGHDURABLELONG-LASTING

Specialty Resins

Functional materials optimized for unique features that unlock new applications.

HEAT RESISTANTFLAME RETARDANTESD-SAFE

Compare Properties Across Engineering Materials

Formlabs Engineering Resins are designed to simulate a wide range of end-use materials. Compare mechanical properties to find the resins that best match your product requirements.

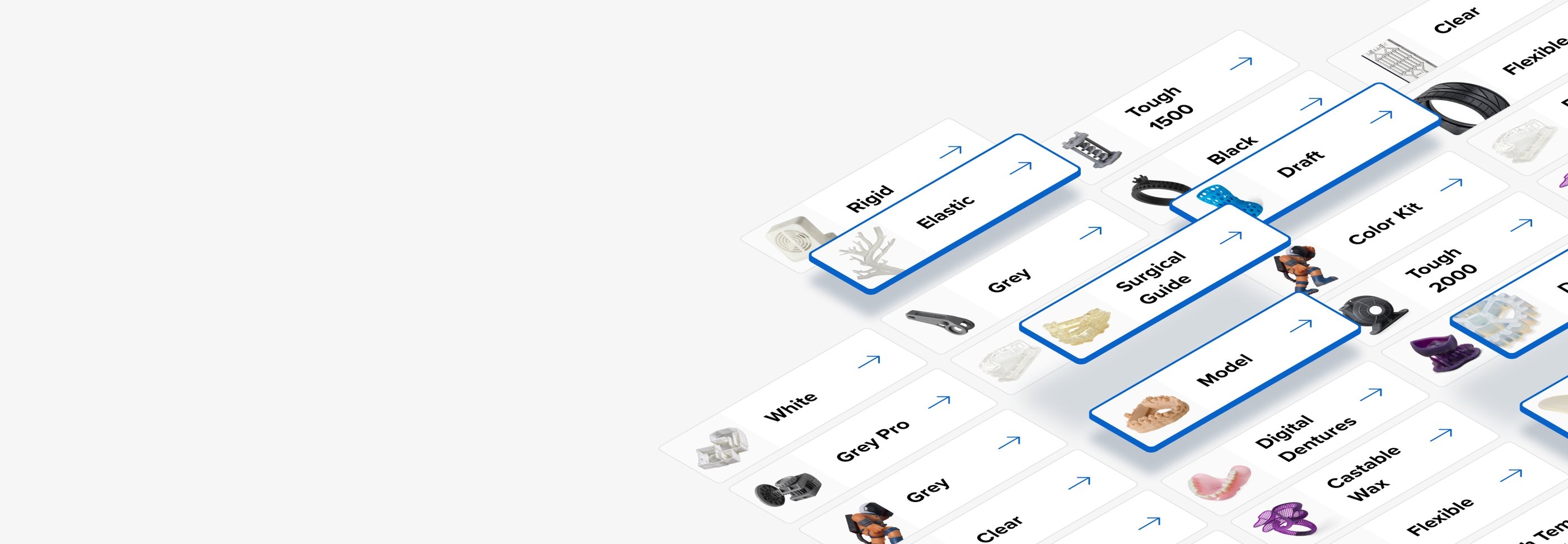

Material Selector

Find the Right Material for Your Application

Our interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of materials.

Sample Request

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.