One step in the painting process is the key to turning a 3D print into a professional product. Most beginners skip it, but all experienced model builders do it. This one simple step makes painting effortless and helps create a flawless final surface. That one step is priming.

Table of Contents

Applications

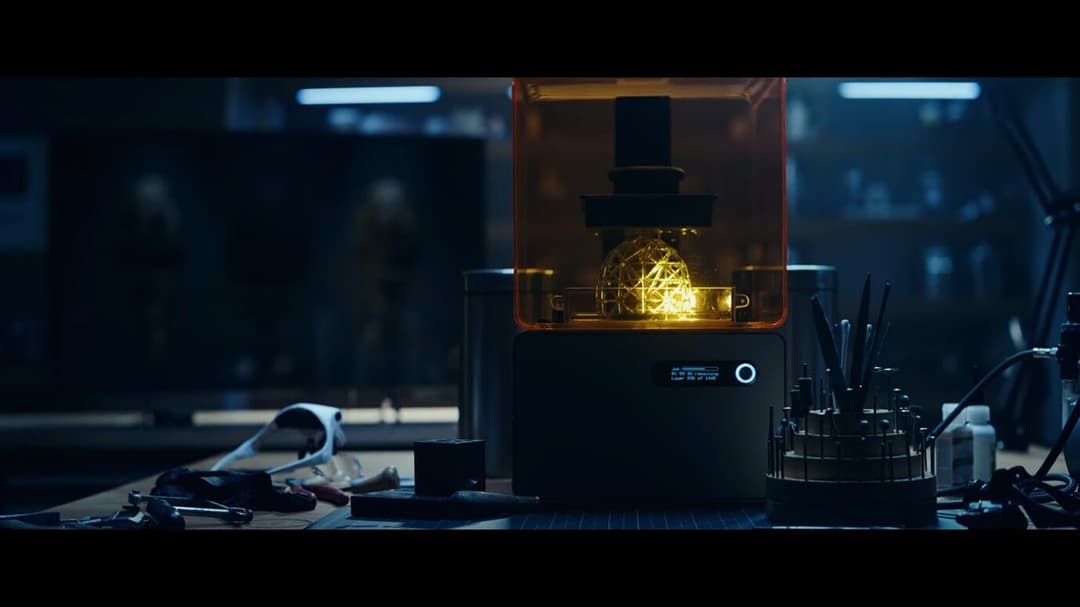

Whether you’re working in an industrial design shop, finishing a 3D printed character, or prototyping the next hit Kickstarter product, this how-to is for you.

Adding a final coat of paint to a part creates presence and polish. But anyone who builds 3D models for a living knows that paint hides no flaws. Without treatment, small step-marks or support marks will show through on the final surface, along with any large triangles visible in the 3D printed mesh. If the end goal is to create a show-stopping object, then primer is essential.

The goal of priming is to create a pristine surface before painting. The neutral gray of a primer highlights imperfections in a model and preps them to be sanded or filled with modeling putty. It makes the painting process much cleaner and the outcome more professional (especially with glossy surfaces).

Prior to priming, the surface should be smooth. While primer will fill in very small cracks and holes, using a thin coat of paint will retain surface details. After sanding and adding an initial coat of primer, inspect the surface again for imperfections. Most primers have an extremely flat finish that highlights details under direct light. Apply a final coat of primer and after the manufacturer specified drying time, the part is ready for painting (a quick, final polish is not a bad idea).

Request a Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Request a Free Sample PartMaterials

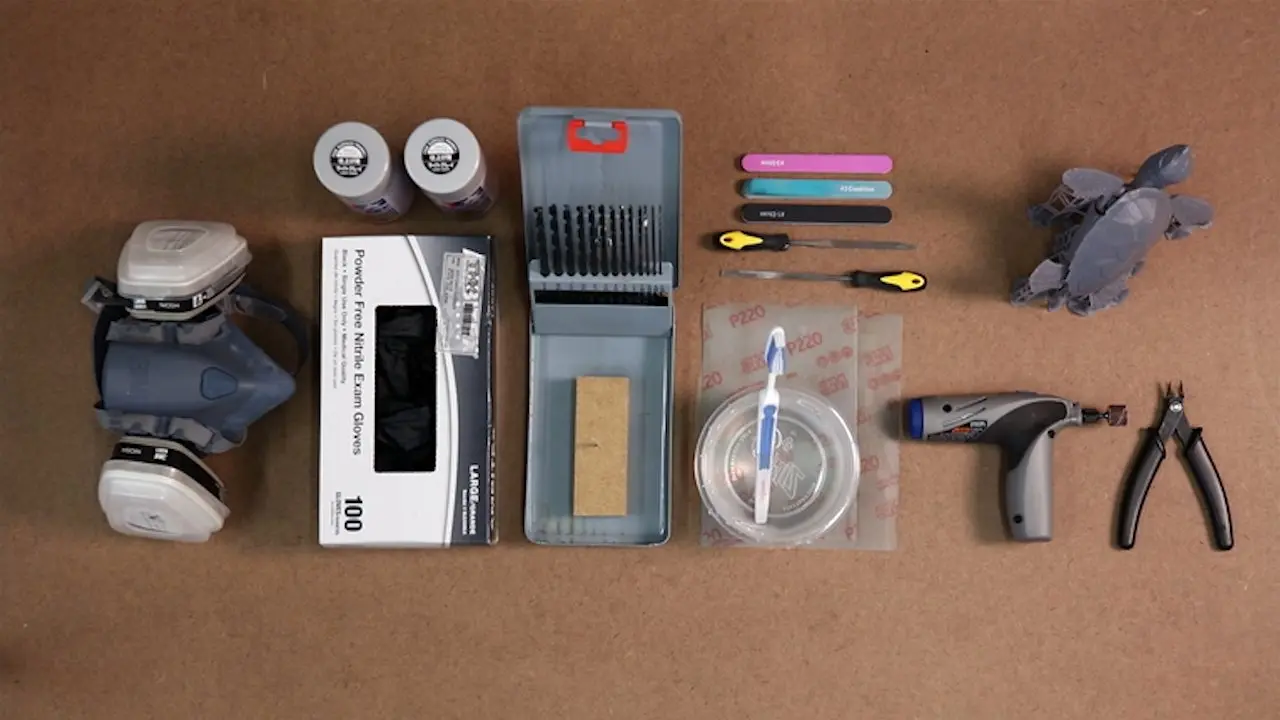

Primer

Primer is a special type of paint that adheres strongly to the part and provides a uniform surface for paint to bond with. Different primers have different uses. A spray-on primer is the best way to paint your printed parts because it quickly covers a surface with an even coating. Brush-on primers are available, but they are tricky to work with and better for fine touch ups. For best results, choose a primer and paint that are plastic compatible and from the same brand. We like Krylon and Montana (though both are thick formulas), but nothing really compares to Tamiya brand model paint - it goes on extremely thinly and evenly, preserving delicate surface details.

Rotary Tool

Because sometimes you want to sand fast. With interchangeable bits, rotary tools offer a variety of options for sanding and polishing parts. Drum sanding bits quickly sand down supports, while steel wire brushes smooth surface marks. Rotary tools are rough, so you will still need sandpaper for a smooth finish. There are plenty of great brands: Dremel and Craftsman are popular in the states, Proxxon in Europe. To avoid scorching your part, turn down the RPMs to the minimum (usually 500-1000) and use a light touch.

Hand Files

Not as clumsy or as random as a palm sander. A more elegant tool…for a more civilized age.

One of the most simple yet effective tools, a hand file removes supports and sands down surfaces. Using a firm grip, you can remove marks with more control than with a rotary tool. Keep a wire brush on hand and clean the file’s teeth often (otherwise plastic and resin will gum up teel). Like a rotary tool, a hand file will leave a rough surface, so it’s best for removing the larger support marks.

Sand Paper

The most unglamourous tool in the shop, sandpaper has come light years in the last decade with the release of flexible sanding sheets. Available at home improvement stores, flexible sanding sheets last 15 times longer than paper ones. They don’t curl, puncture or crease.., and they hey can be used wet, which reduces dust and prevents buildup in the sanding tooth. Because they flex, they can easily reach small interior spaces and rounded surfaces.

Dust Removal

Even after wet sanding, some dust will remain. Remove buildup with water and a soft scrub brush (an old toothbrush works). For serious cleanup, an inexpensive sonicator can quickly remove fine particles caught in corners and cracks of a surface. If you work in an area with hard water, using deionized or distilled water will prevent spotting between painting.

Tack Cloth

Tack cloth is a soft, slightly sticky cotton cloth designed to remove remaining dust and leave a clean surface for painting. Let your model dry before using the tack cloth — the waxy surface does not work well with water.

Painting Block, Dowels & Drill

This simple trick will save you grief in the spray booth (we were excited when we saw this technique in a modelmaking how-to video by Adam Savage). By mounting your 3D print on a dowel (often you can use a preexisting hole in the part), you can quickly maneuver while spraying, allowing you to get to all sides and into the nooks and crannies of the part without creating any fingerprints. When you want to add an even coat to all sides of your model, this is pretty essential. We recommend ordering a variety of size of dowels. To minimize the hole size on a part, start with a small size and work your way up until the model feels firmly seated. Drill a corresponding hole in a block of wood or MDF and insert the part with the dowel - now you can keep the model hands free while spraying.

Safety Equipment

Spraypainting means working with airborne particulates and solvents, both of which pose health hazards. Remember to use a NIOSH approved respirator and work in a well ventilated workspace. While painting, wear nitrile gloves to avoid spraying paint on your hands and and also protect your model from fingerprints.

Tool Checklist

- Tamiya primer

- Rotary tool

- Hand files

- Sandpaper or flexible sanding strips (220/320, 400/600 grit)

- Water

- Soft brush with fine bristles

- Tack cloth

- Wood painting block (sized slightly larger than model)

- Drill and drill bit

- Dowels to hold model

- Safety Equipment: gloves and mask

Steps

1. Remove supports from your part

Use a set of flush cutters to remove sections, or peel off supports by hand. With delicate pieces, an exacto knife or razor blade can be carefully used to cut away support tips.

2. Sand down support marks.

Using a rotary tool, hand file, or even 220 grit fine sandpaper, gently remove support marks from the model.

3. Sand and smooth surface.

The degree to which the surface is smoothed in this step will impact the finish of the final part. Beginning with 220 or 320 grit sandpaper or flexible sanding strips, gently sand the entire surface of the model to remove any filing or tooling marks. Follow up with 400 or 600 grit.

4. Mount the part.

Drill a starter hole in an inconspicuous spot and mount your part on a thin dowel, then insert the dowel into the paint block.

5. Wash the surface to remove dust.

Use a brush and water to wash away any dust. You may prefer to use deionized or distilled water (available from a grocery store) to thoroughly clean the surface without leaving any spots.

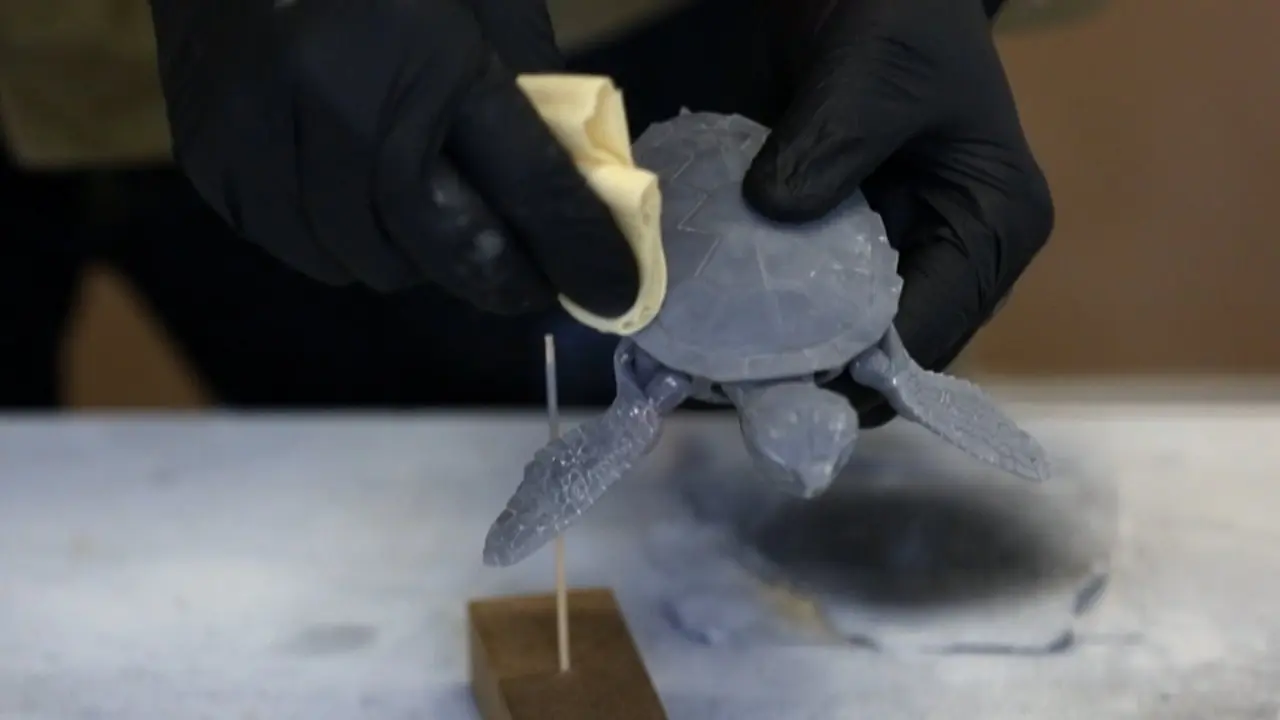

6. Wipe down the surface with a tack cloth.

While wearing nitrile gloves, gently run the tack cloth over the surface of the model using long, gentle strokes. Try to use a continuous direction, but don’t forget to wipe in the small cracks in the model.

7. Mix the primer.

Gently swirl the spray primer for 2 to 3 minutes in a circular motion. Avoid shaking as this can mix the propellant into the solvent, resulting in bubbles in the coat when sprayed. The goal is to fully dissolve the pigment within the solvent. After a minute of swirling, you should hear the mixing ball (called the “pea”) smoothly rolling around the inside of the can, indicating all the paint has mixed in.

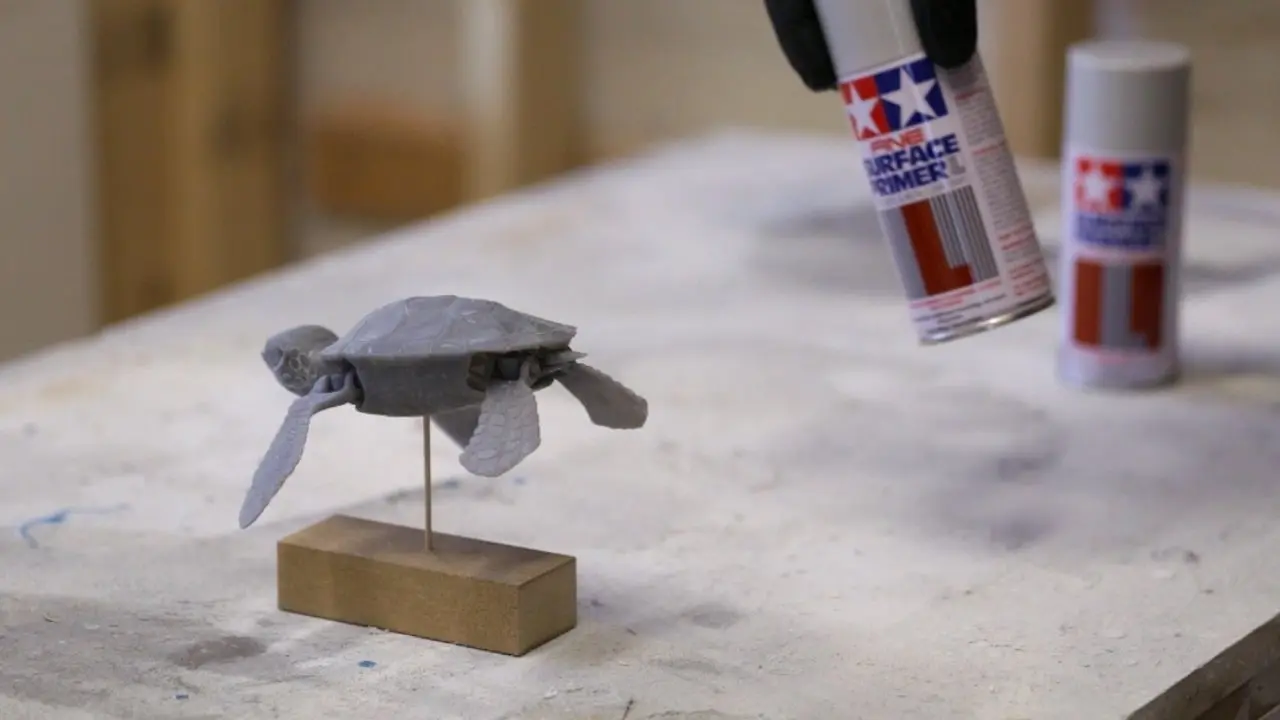

8. Spray the first coat of primer.

Spray in short, rapid strokes, 6-8” from the part. Start each stroke before the part and end the stroke after the part. Moving quickly, rotate the part while spraying, Avoid allowing spray to pool on the part - it’s better to start with a very thin initial coat and slowly build up opacity.

9. Inspect the first coat.

With the primer on, inspect for any areas that need additional sanding or filing. If necessary, rework and polish the part with fine (>600 grit) sandpaper. If sanding is necessary, be sure to repeat steps 5-6 to clean off dust before respraying.

10. Spray the final coat of primer.

Add another coat of paint using rapid strokes, making sure to keep the coat light and finish as soon as the color is opaque. Too much paint here will fill in your fine details, so make sure to avoid the tendency to add too thick of a coat.

With the final coat added, you’re ready to move on to spray painting your part! In the next installment of this guide, we’ll go over how to add a model-smooth paint job and finish with a clear coat to protect the paint job.

We’d like to thank our friend and colleague Brian Chan (@chosetec) for the incredible Articulated Baby Turtle model. Support his designs at his Shapeways shop.

Part 2: Painting

This article is Part 1 in our two-part “Guide to Painting 3D Printed Parts” series. Read the next part on “Painting”.