The Fuse Series selective laser sintering (SLS) 3D printers enable customers to fabricate industrial quality parts in-house, gaining more control over their supply chains, accelerating time to market, shortening their iterative cycles, and reducing cost per part.

One major feature of the Fuse Series that helps companies achieve these goals is the adjustable refresh rate. Refresh rate refers to the ratio of new to recycled powder that each new Fuse Series build needs in order to efficiently print parts of the highest quality. It is adjustable because, though each Formlabs SLS Powder has a recommended refresh rate, customers can slightly tweak their refresh rate to best match their own workflows and priorities.

In this article, we’ll detail what refresh rate is, what it means for your print process on the Fuse Series printers, and how the Fuse Sift and PreForm make powder recycling easier than ever.

What Is Refresh Rate in SLS 3D Printing?

SLS 3D printers are able to print with a mix of fresh, new powder and recycled powder from previous prints. The recommended refresh rate is the percentage of the new cartridge that is ‘refreshed’ with new, unused powder. For example, every user’s first print will be entirely new powder, with a refresh rate of 100%, while a print made of entirely recycled powder would have a refresh rate of 0%.

Recycling used powder is a good way to reduce waste and increase the efficiency of your process. While it is true that the lower the refresh rate, the lower the cost per part, using recycled powder over too many cycles can create a degradation in material properties. Therefore, each user needs to determine the refresh rate for each new cartridge based on multiple factors.

Choosing the Right Refresh Rate

When deciding which specific refresh rate to use within the recommended range, there are multiple factors to consider.

The packing density, or how closely parts are arranged within the build chamber, affects how much powder is left unsintered. Whatever is not sintered will then be recycled during post-processing, ready to be mixed into a new cartridge.

To ensure that there is as little waste as possible, packing density and refresh rate should be as close as possible. For instance, if the print packing density reported in PreForm is 30%, then a refresh rate of 30% would result in no excess used material. In this case, the powder that was sintered into parts would be replaced with new, fresh powder for your next print. Paying attention to both the powder refresh rate and the packing density of your prints will allow you to make the most out of your powder and minimize cost per part.

Example Build Chambers With Nylon 12

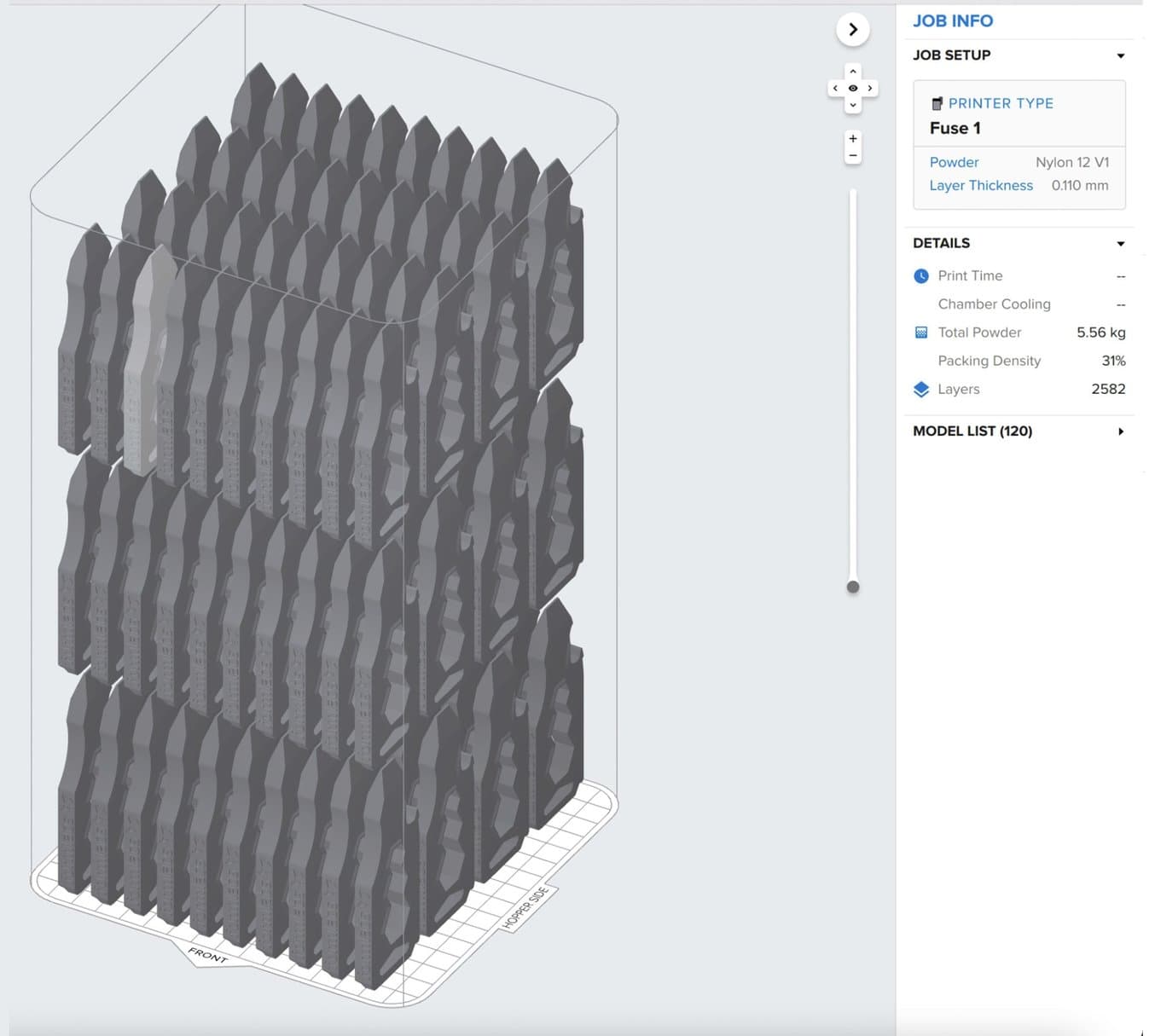

Packing Density: 30%

Refresh Rate: 30%

Advantages

- Refreshing with the same amount of powder that was sintered

- Most cost efficient

- No waste

Disadvantages

- No major disadvantages, this is the high quality setting for PA12

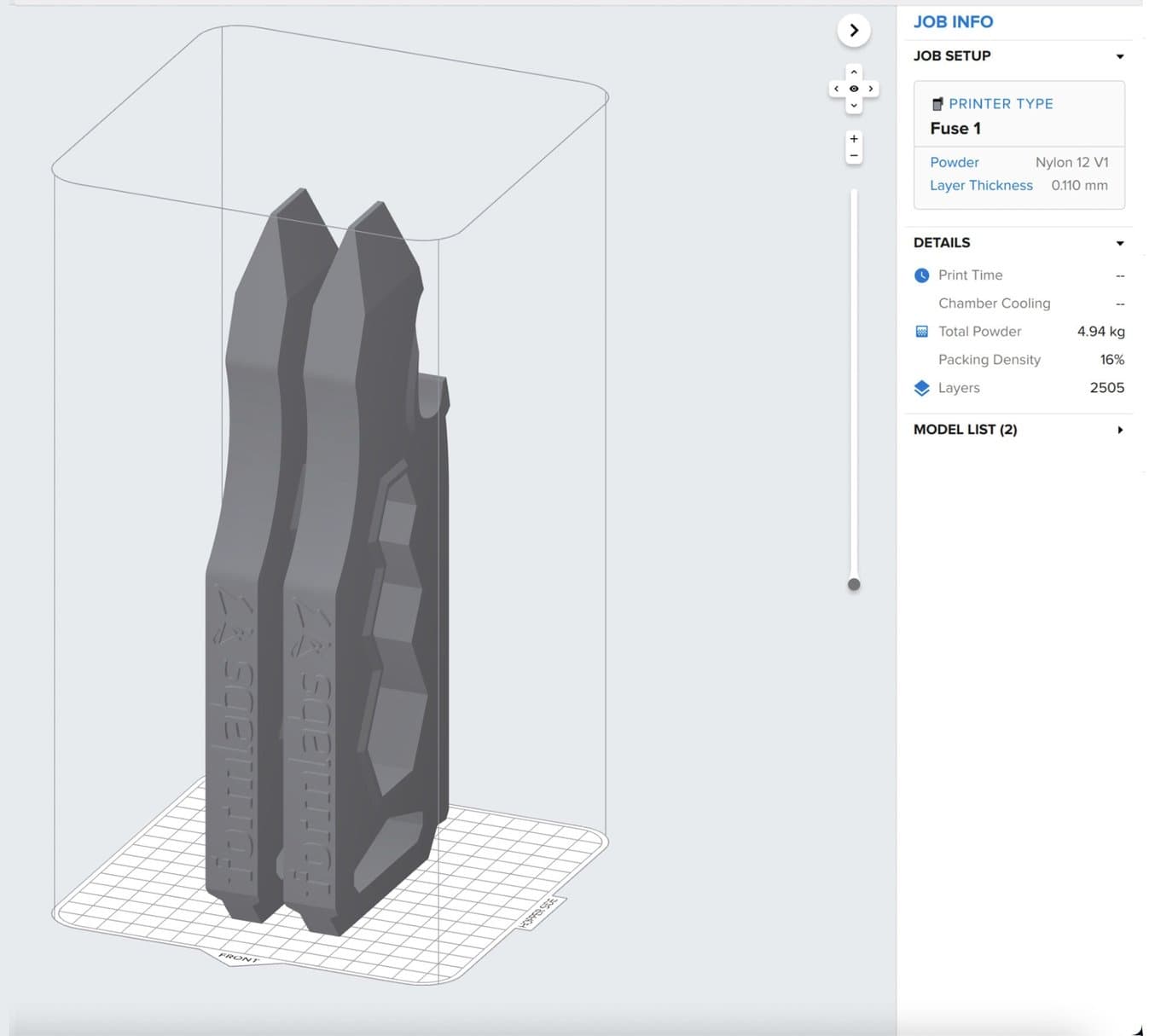

Packing Density: 15%

Refresh Rate: 30%

Advantages

- Faster time to part

Disadvantages

- Sub optimal use of powder, resulting in more waste and higher cost per part

Packing Density: 15%

Refresh Rate: 20%

Advantages

- Lower amount of waste

Disadvantages

- Risk of surface finish defects over multiple prints

Refresh rate also impacts some cosmetic details. If powder is recycled many times, and builds are programmed at lower than recommended refresh rates, there can be surface variations on the parts. Consistently smooth surface finish and fine detail will be more repeatably achieved with a higher refresh rate.

For parts that need to have high visual appeal, fine detailing, or perfectly smooth surfaces, users should not deviate from the recommended refresh rate.

If the goal is to produce mechanically sound parts that aren’t cosmetically flawless, it’s possible to experiment with multiple re-use cycles at a slightly lower refresh rate to recycle more powder and reduce cost per part.

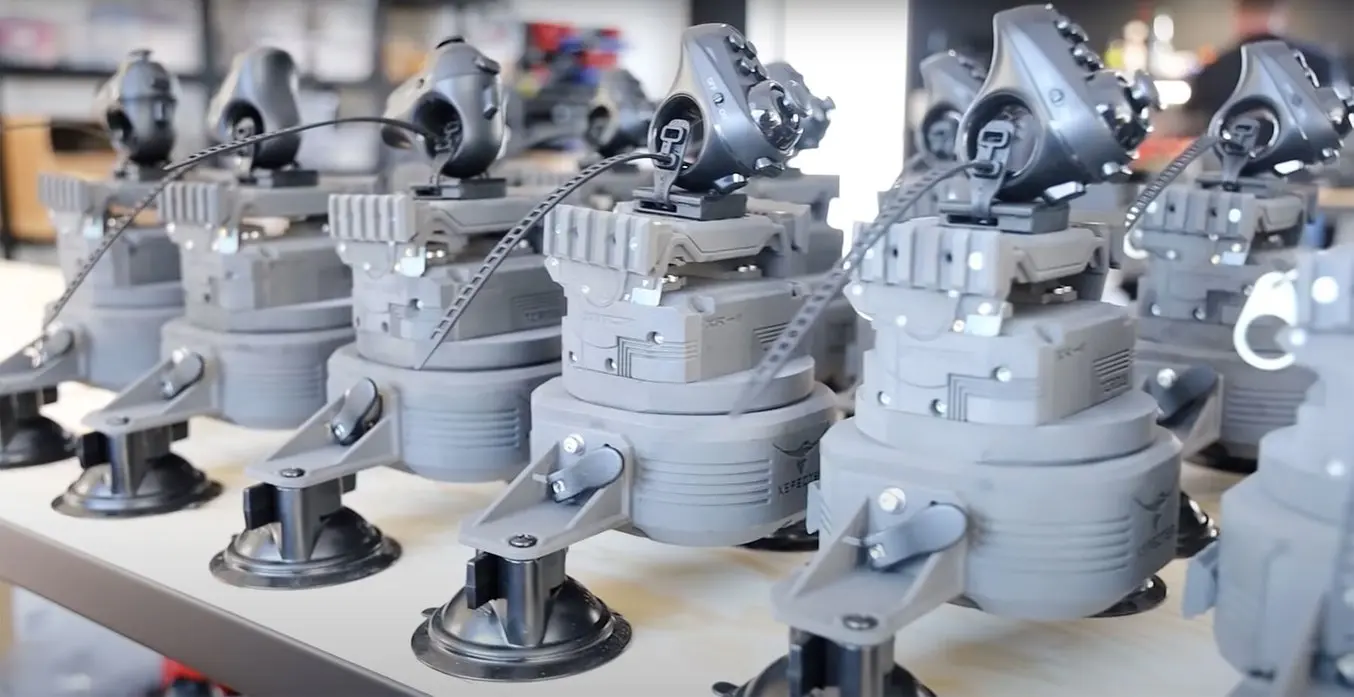

SLS for End-Use Production

3D printing for end-use production is not only possible, it's more affordable, agile, and scalable than ever with the Fuse SLS Ecosystem. Visit our SLS for Production page to compare production methods, learn about bulk powder pricing, and see production in action for 15 different manufacturers currently using the Fuse Series.

Case by Case

This customizable refresh rate means that users in different industries can choose the workflow that works best for them. An engineer creating hundreds of small magnet covers as part of a regular production run will have a high packing density, and can choose a higher refresh rate (more new powder than recycled) because he or she won’t have much unsintered powder left over from previous runs, so there won’t be any waste involved in creating a new cartridge.

In a different scenario, a product designer might need to only print one large item each week. The packing density is low (there is a lot of unsintered powder left around the part), and he or she only needs a rough prototype. Choosing a lower refresh rate (more recycled powder than new powder) means that they will get the material properties they need, use all the recycled powder they had from a previous print, and aren’t worried about any cosmetic issues that can be fixed in post-processing.

| Low volume, infrequent printing (e.g. prototyping), consistently low packing density | Users can experiment with slightly lower refresh rates. |

|---|---|

| Mid volume (prototyping & production), variable packing density | Users can choose to use lower refresh rates if needed, but should aim to use recommended refresh rates. |

| High volume (production), consistently high packing density | Users should not deviate from the recommended refresh rate. |

Recommended Refresh Rates

Formlabs recommends a minimum refresh rate for each SLS material to ensure high quality prints, every time. Customers can experiment with slightly lower refresh rates in order to optimize cost per part for their specific workflow.

The following table shows results from different refresh rates with each Formlabs SLS material. While it is never recommended to use entirely recycled powder (i.e. 0% refresh rate), users can vary their refresh rate with a deviation of 10%-20% from the recommended ratio.

PreForm, Packing Density, and Refresh Rate

Determining the right refresh rate for your workflow can be difficult, and can change over time according to the needs of different projects. Formlabs has created tools to help in PreForm, Dashboard, and on the Fuse Sift itself.

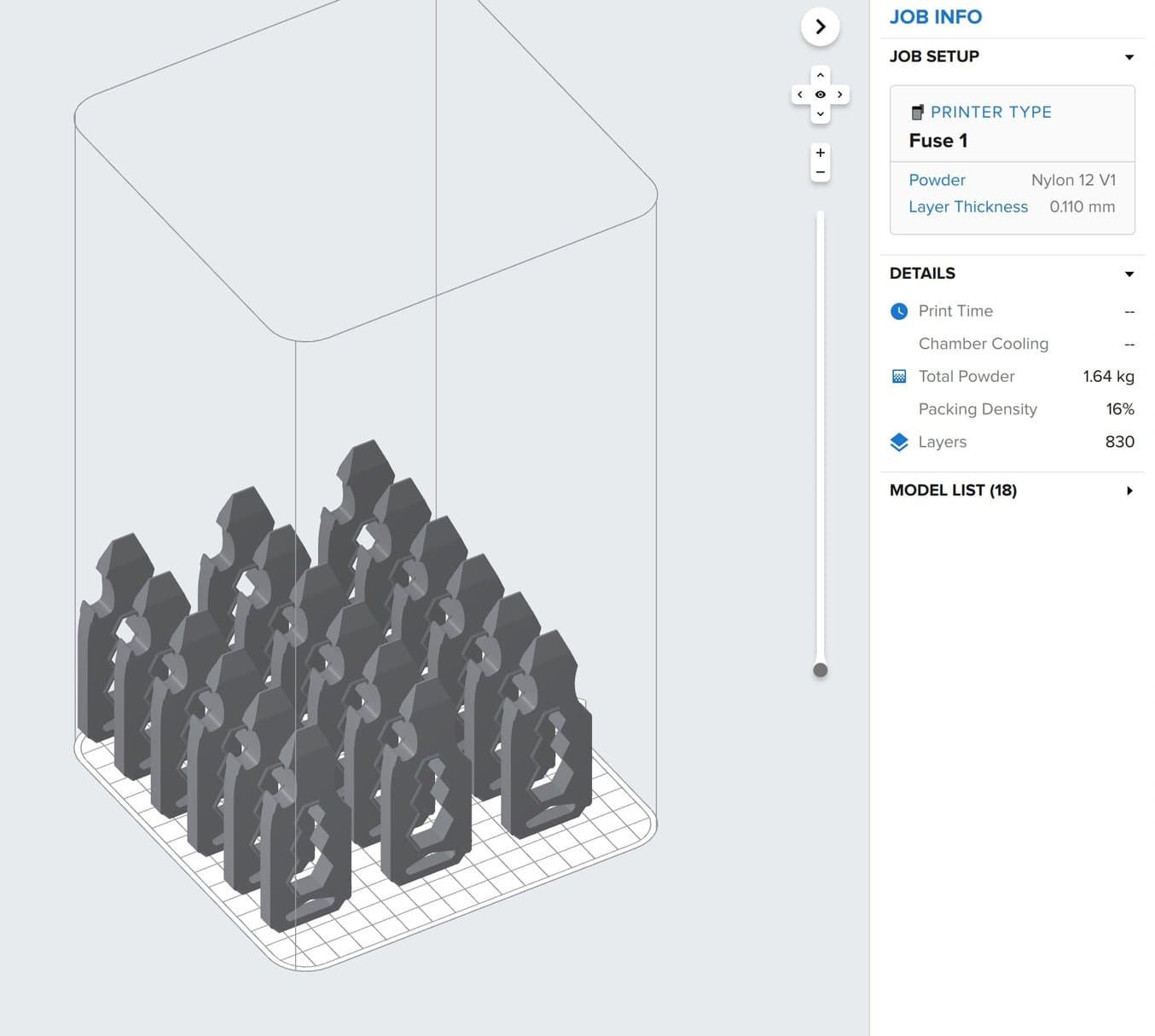

After loading a file into PreForm, the software will show you a breakdown of sintered powder, unsintered powder, and estimated packing density for your job. Packing density is calculated as the mass fraction of consumed powder compared to the total powder required for the print, not the part volume. Using that breakdown, you can change the packing density, wait to add more parts to your build, estimate your cost per part, or change your refresh rate to account for more, or less, recycled powder.

Formlabs is committed to making the Fuse Ecosystem workflow as efficient as possible, and has continuously made updates to the packing algorithm in order to pack parts faster and as densely as possible. In comparisons to popular third-party softwares like Materialise Magics, PreForm's packing function outperformed the competitor 23 out of 25 times, delivering more densely packed builds in less time.

The Fuse Sift Workflow

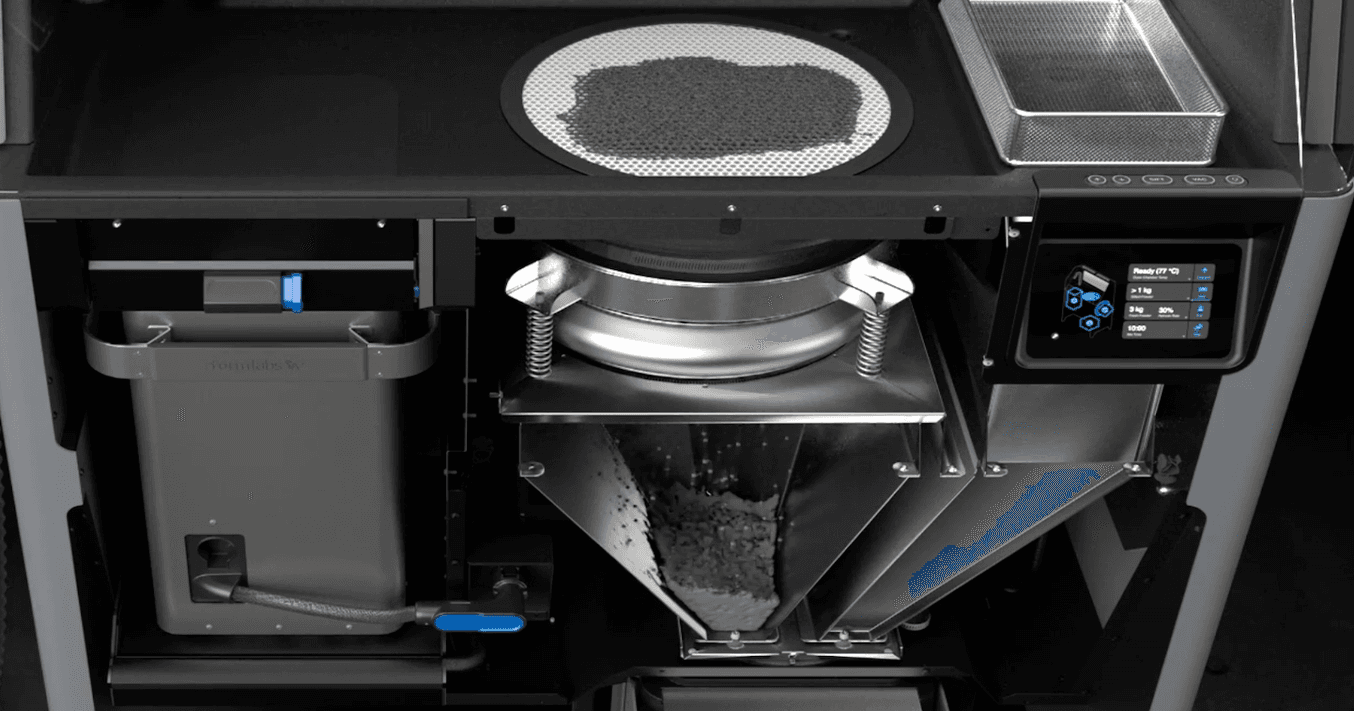

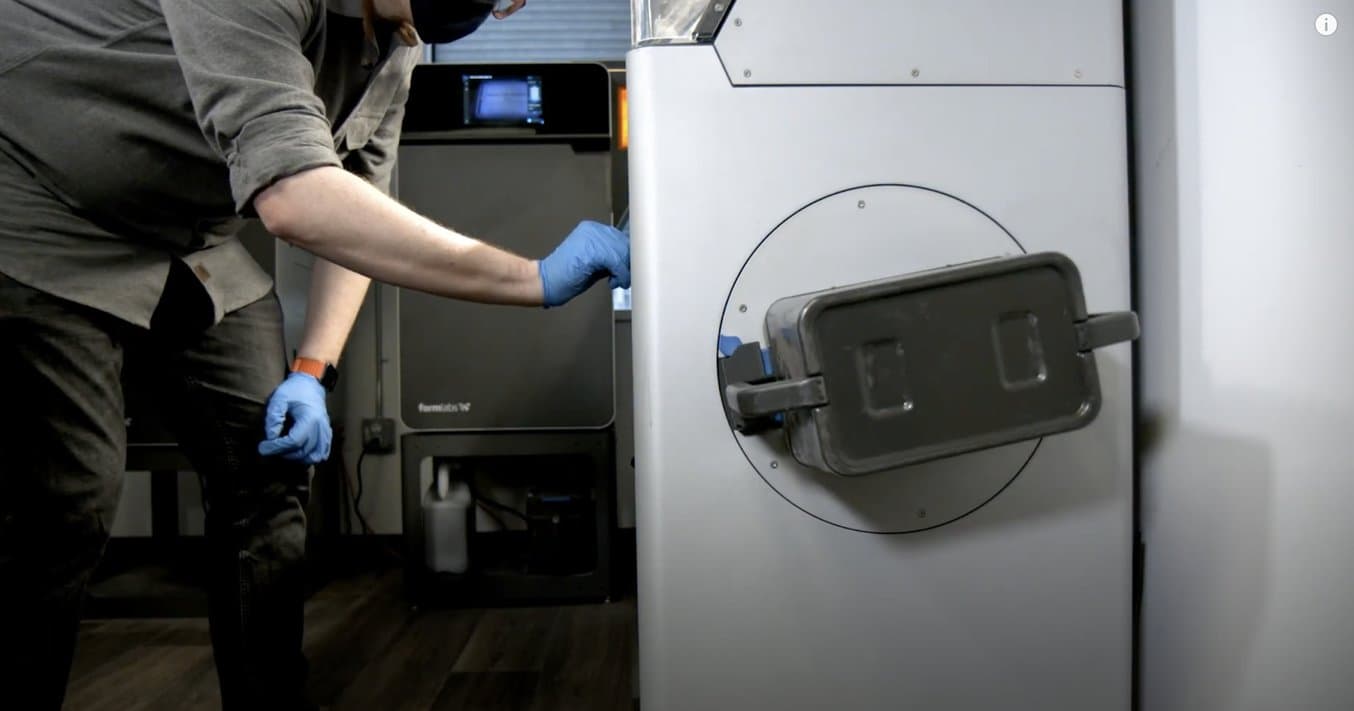

With many traditional SLS systems, users are required to manually weigh and sort powder to the desired ratio before printing. Any gains in efficiency created by the powder recycling process are thus wasted by this labor intensive and time consuming weighing process. Formlabs created an end-to-end solution with the Fuse Sift, the powder recovery station for the Fuse Series SLS 3D printers, and the Fuse Blast, a part cleaning and media blasting solution that completes the SLS workflow.

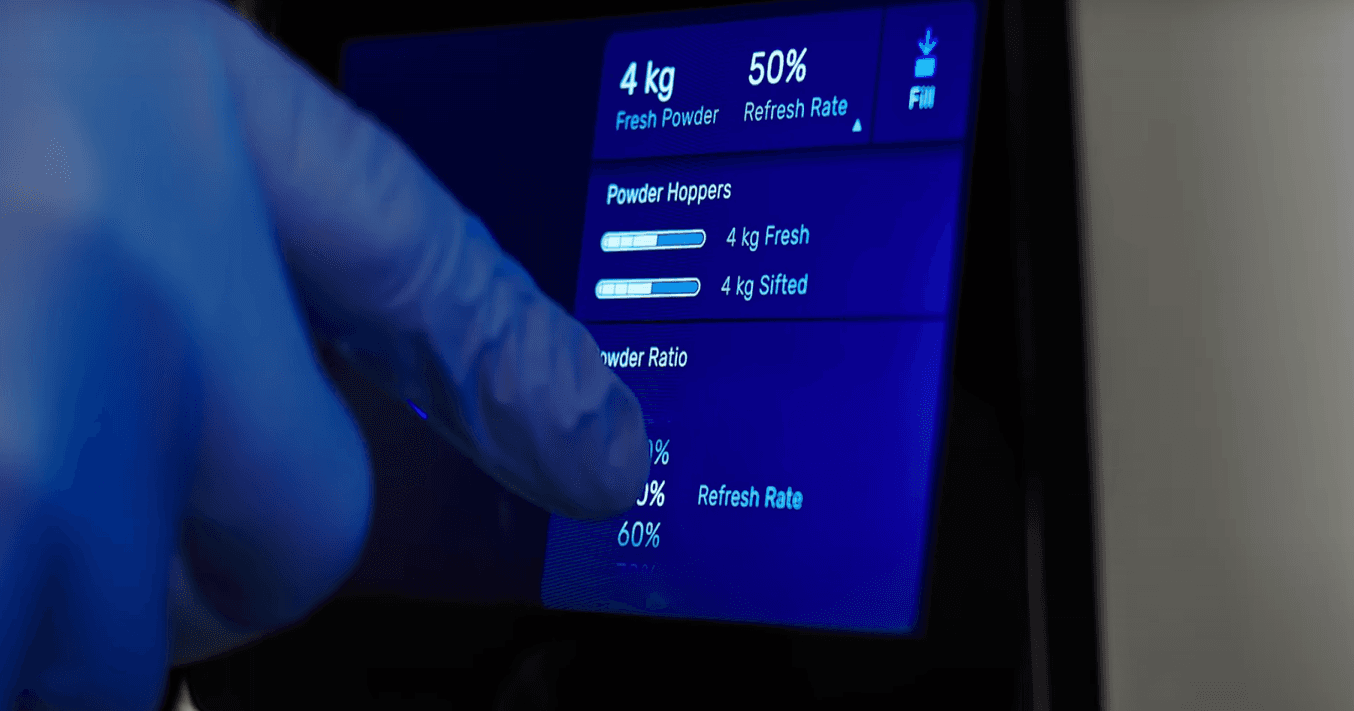

After finishing a print on a Fuse Series printer, users remove the build chamber and insert it into the Fuse Sift, where it dispenses the powder cake onto a hooded work surface. Unsintered powder is sifted down into a hopper to await the mixing stage. Users set their desired refresh rate on the Fuse Sift touchscreen, and new and used powder are dosed automatically into the new powder cartridge. The mixer on the side of the Fuse Sift can then be loaded with a freshly dosed cartridge and automatically mixed, ready to transfer to a Fuse Series printer.

Though using a mix of new and recycled powder is not unique to the Fuse Series workflow, Formlabs has made the process simpler and more efficient than with any other SLS printer. At each step of the printing and post-print process users can see the amounts of sintered and unsintered powder and packing density, allowing them to make informed decisions when choosing a refresh rate that fits their needs.

Formlabs recommends refresh rates for each material, but has also provided a range of slightly lower refresh rates and guidelines on how to use them appropriately. With these guidelines and the automated power of the Fuse Sift, Fuse Series users are prepared to print at production levels in an efficient and cost-effective manner.