SLS Powders

3D print production-ready, end-use parts on our SLS printers with our family of SLS Powders. Our materials, hardware, and software are developed and validated together to deliver peak performance while optimizing cost per part.

nylon-12

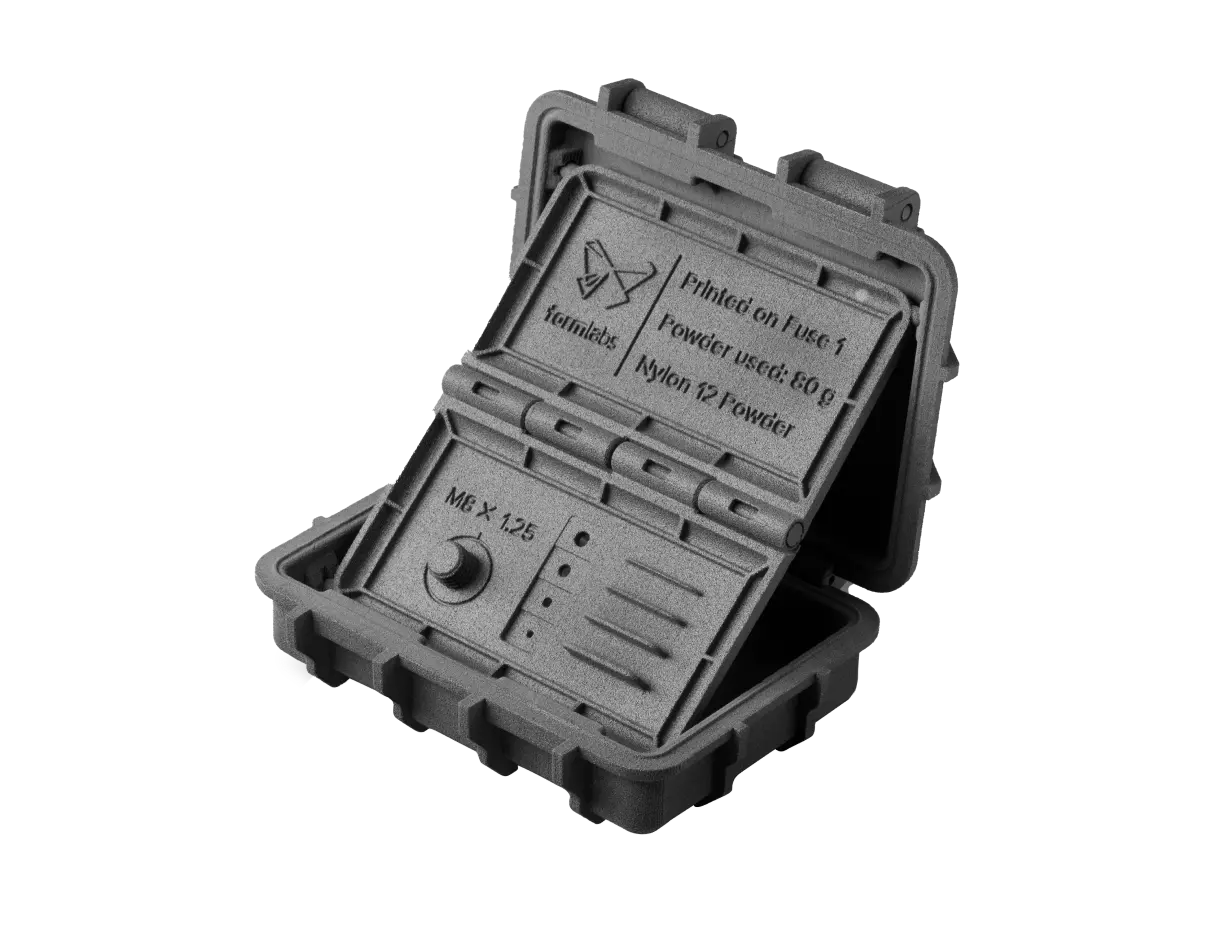

Nylon 12 Powder

A Material That Does It All

Balancing strength and detail, Nylon 12 Powder is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability. Our Nylon 12 Powder is specifically developed for use on the Fuse Series SLS 3D printers.

Nylon 12 Powder is ideal for:

* Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

nylon-11-cf

Nylon 11 CF Powder

Carbon Fiber SLS, for Strong and Lightweight Parts

Get the best of nylon and carbon fiber with this highly stable, high-performance material, perfect for end-use applications that require both high stiffness and superior strength. Choose Nylon 11 CF Powder to produce lightweight rigid parts that can withstand repeated impact and remain stable over time, even at high temperatures.

Nylon 11 CF Powder is ideal for:

Note: Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

Note: Nylon 11 CF powder can act as an irritant of skin and mucosal membranes. Please refer to the SDS and Support Article for usage guidelines.

nylon-12-gf

Nylon 12 GF Powder

Stiff, Stable, Functional Parts

A glass-filled material with enhanced stiffness and thermal stability for demanding industrial environments. Choose Nylon 12 GF Powder to produce stiff functional prototypes or end-use parts for applications where structural rigidity and thermal stability are critical.

Nylon 12 GF Powder is ideal for:

Note: Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

nylon-11

Nylon 11 Powder

High Performance, High Impact

For highly ductile, robust parts, Nylon 11 Powder is our higher performance nylon material for functional prototyping and small batch production. Compared to Nylon 12 Powder, our Nylon 11 Powder is more flexible, less brittle, and better at printing thin walls.

Nylon 11 Powder is ideal for:

*Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

pp-pump

Polypropylene Powder

Ductile, Lightweight, and Chemically Resistant

Leverage genuine polypropylene to produce works-like prototypes and durable end-use parts that are chemically resistant, weldable, and watertight. Polypropylene Powder offers high ductility, allowing for repeated bending and flexing while ensuring durability, without the need for inert atmospheric control.

Polypropylene Powder is ideal for:

*Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

tpu-90a

TPU 90A Powder

A Tough SLS Elastomer for Resilient, Skin-Safe Products

Create flexible TPU parts with unmatched design freedom and ease. Balancing high elongation at break and superior tear strength, TPU 90A Powder enables you to 3D print flexible, skin-safe prototypes and end-use parts that withstand the demands of everyday use – all at a low cost per part thanks to a 20% refresh rate.

TPU 90A Powder is ideal for:

*Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

Explore Material Properties

Make the most of your material with simple, efficient powder recycling.

What is refresh rate?

The ability of an SLS 3D printer to print with a mix of new and recycled powder. The powder refresh rate is the minimum ratio of fresh powder required to print and may vary based on the material used, packing density, and parts printed.

Refresh Rate

Recycled Powder

How it works

Just set the desired refresh rate on the touchscreen and the Fuse Sift powder recovery station will automatically mix and dose powder to be reused in future prints.

Request a free sample part printed with Formlabs’ SLS technology.

Request a Free Sample Part

A New Wave of Independent Manufacturing Starts Now

Rethink product development and take control of your own manufacturing. Configure your SLS setup today.

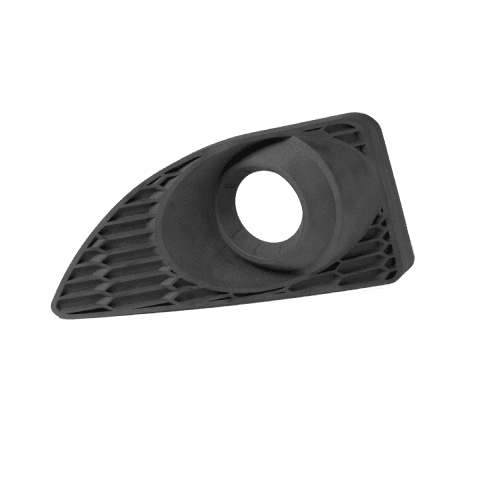

In automotive, it is important that you deliver the highest possible quality at the best price possible. At the moment, anything under 10,000 parts per year could be printed in SLS. With the Fuse 1, we have a very capable product, at a very competitive price.

Christian Kleylein, Technologist for AM Polymer Series Manufacturing, Brose