Mass Customization With 3D Printing

The holy grail of producing customized products in large volumes is now a reality. With 3D printing, you can scale personalized products for mass-market opportunities without drastically increasing operational costs and delivery timelines.

Build Strong, Lasting, and Lucrative Relationships With Your Customers

Leverage mass customization to drive innovation and explore new direct-to-customer business models to increase margins and build a stronger relationship with your customers.

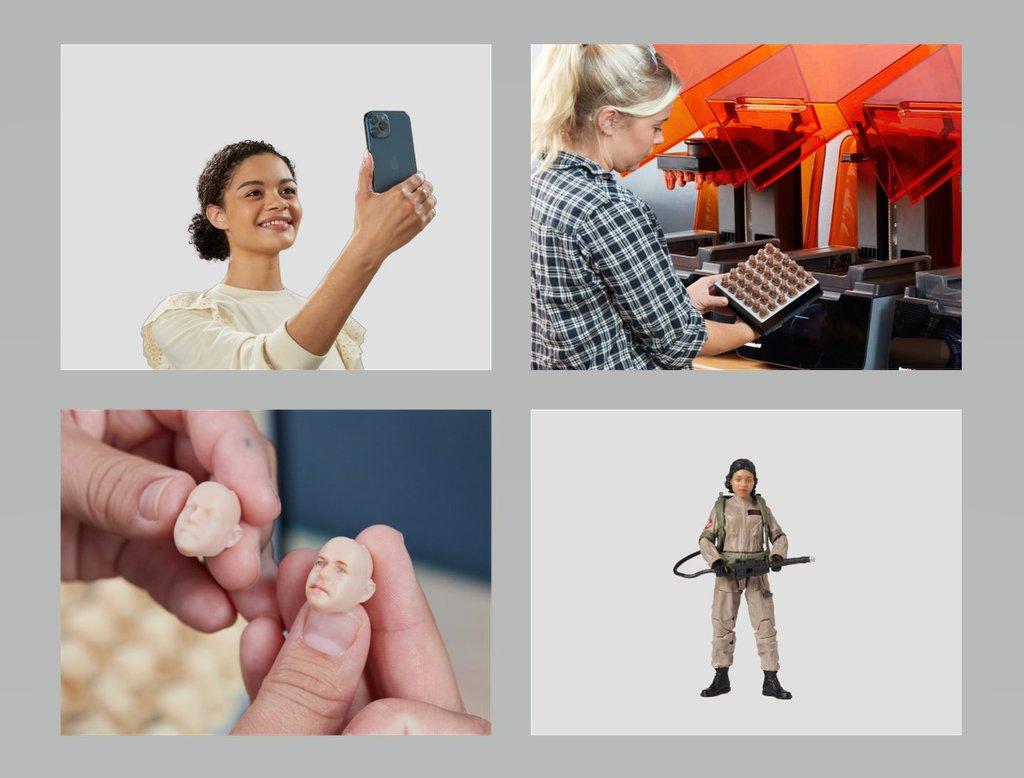

Hasbro Makes Anyone a Hero With 3D Printing

Learn about Hasbro's groundbreaking endeavor to use 3D printing to create personalized action figures, manufactured at scale.

Gillette Uses 3D Printing to Unlock Consumer Personalization

Gillette turned to 3D printing to launch Razor Maker™—a platform for designing and manufacturing customized and limited-edition razor handles.

How to Make Custom Fit Ear Tips With 3D Printing

Watch our video and learn how easy it is to create a custom-fit earpiece for a Bose in-ear headphone.

Workflows Just as Custom as Your Final Products

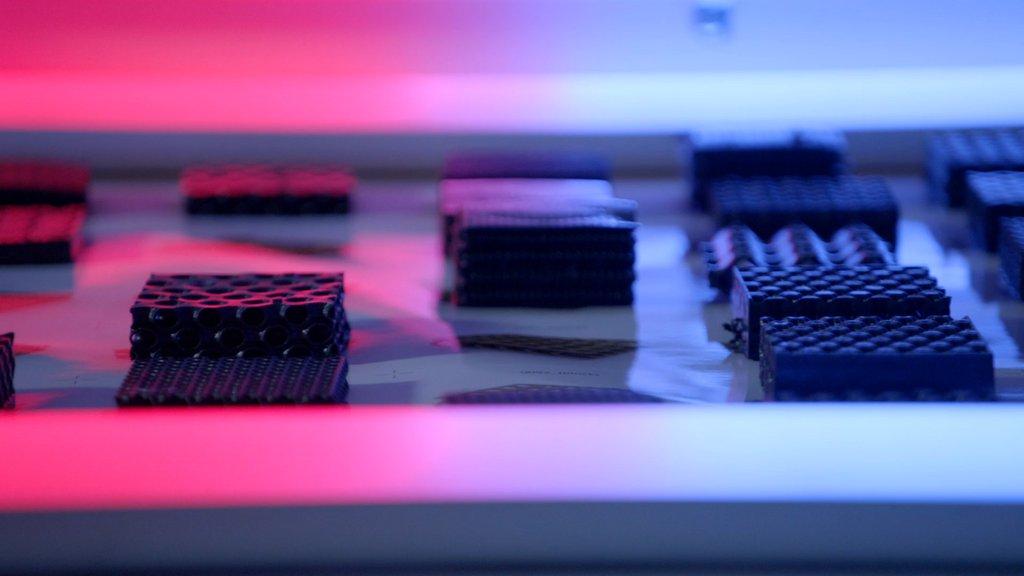

Mix and match innovative technologies like product configurators, 3D printing, and automation, and combine them with traditional tools and processes to manufacture mass customized products at an affordable cost.

Design

Manufacture

Assemble

Scale Up and Be Agile

Explore Mass Customization Applications

Consumer Products

Unlock mass customization and personalization for product innovation.

- Personalization

- Products tailored to the customer's body

- Complex designs

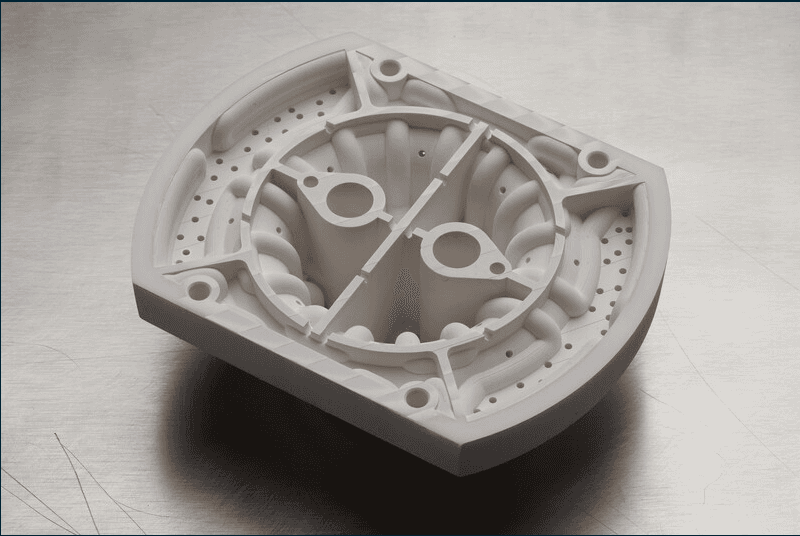

The Freedom to Design and Manufacture High-Performance Custom Products

Formlabs Factory Solutions is 3D printing reimagined to build the factory of the future for demanding industrial applications.

Build your factory the way you want it with intuitive tools, transparent pricing, and proven processes. Take control of your production infrastructure with additive manufacturing for high-throughput applications. With scalable hardware, world-class materials development, and a team of interdisciplinary experts, Formlabs is here to help you make the factory of the future an immediate reality.

Tools to Get Started 3D Printing End-Use Parts

Formlabs' ecosystem of accessible 3D printers and high-performance materials offers solutions for a wide range of end-use applications.

Tools for End-Use Parts

Form 4

High Performance SLA 3D Printer

The Form 4 produces parts with a high-quality surface finish and fine features, ensuring that your parts are created fast and true to design with minimal post-processing.

From 3D printing end-use parts to producing rapid tooling for traditional manufacturing techniques, the Formlabs ecosystem is easy to integrate into any production process.

Additional Resources About Mass Customization

Check out some additional resources to help you get started with mass customization.

Get Started With Mass Customization

Have an idea for leveraging mass customization at your business, but don’t know where to start? Get in touch with a Formlabs Solution Specialist to discuss how you can piece together an ideal workflow.