Draft Resin is the newest addition to our resin library and prints three to four times faster than other Standard Resins. The material is named for its ability to print large parts quickly and cycle through multiple design iterations (or “drafts”) within one day. With a 300 micron layer height, it’s accurate enough to meet prototyping needs while enabling faster design iterations.

While accuracy, reliability, and part quality are important, we know that time is valuable and sometimes, turnaround time is key. Using feedback from our customers, Draft Resin was developed specifically to balance speed with prototyping accuracy needs. Draft Resin is great for same day design iterations, jig and fixture prototyping, and quickly printing large parts.

Webinar: Draft Resin: How to 3D Print Multiple Iterations In the Same Day

Learn the pros and cons of using Draft Resin and how to use it to shorten your product development cycle.

Watch the Webinar NowBalancing Speed With Accuracy

3D printing has already significantly cut down prototyping time and costs by removing the need for expensive outsourcing or other costly traditional manufacturing techniques.

Today, engineers and designers often turn to FDM machines for initial concept prototyping, and use stereolithography (SLA) machines for higher fidelity models. Now, you can use Draft Resin for early prototypes and switch to Standard or Engineering Resins for detailed, functional models - all on the same machine.

Read our in-depth guide about FDM vs. SLA 3D printers to learn how they compare in terms of print quality, materials, applications, workflow, speed, costs, and more.

Jeremy Mikesell, Engineering Manager of Research at Cycling Sports Group

“While the Form 2 has always excelled in resolution we have never considered it to be as fast as our FDM printer. Draft Resin completely changes this. With Draft Resin, we are able to print parts 20% faster than FDM with low density infill and 40% faster than FDM with an equivalent solid infill.”

Even at 300 microns, Draft Resin is as accurate as other Formlabs Standard Resins in the X and Y axes, making it great for printing parts with flat surfaces. Draft Resin can print curved features and raised or embossed text, however some layer lines will be more visible. For any parts with fine surface details, Standard and Engineering Resins are still recommended.

Note: Draft Resin prints on the Form 3 Resin Tank, Form 2 Standard Resin Tank, and Form 2 Resin Tank LT.

Print in Hours Instead of Days

The impact of faster printing is more drastic when printing large parts or multiple parts on one build platform. Models that take up the entire build volume can take up to 20 hours to print in Standard Resin and may require printing overnight. Printing the same part at 300 micron layers with Draft Resin takes less than six hours.

Comparison of Draft Resin Speeds to Standard Resin

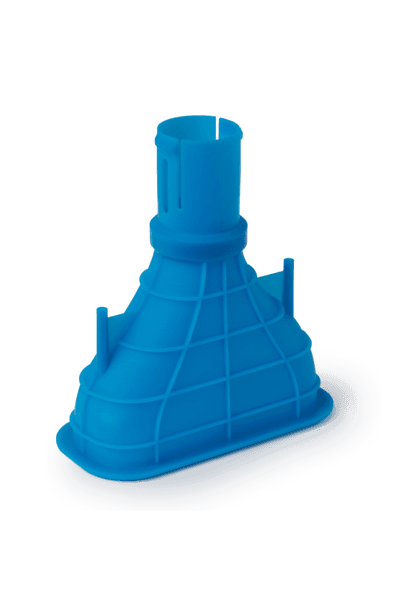

See the table below for an example of printing times for this manifold in both Draft Resin and Clear Resin.

| Draft Resin | Clear Resin |

|---|---|

| 2 h 5 min | 8 h 46 min |

Item Prints 4.2x Times Faster

Same Day Design Iterations

Building great products takes multiple iterations, which are often time-consuming.

If an engineer wants to create a new jig prototype, prints on the Form 3 or Form 2 can take up to 5 hours. Draft Resin can finish the same part in 1 hour and 20 minutes, a 73% speed improvement. This means less time printing and more time to iterate on product designs to create better products.

Read our “Using Draft Resin” support article for a deeper look at how to support and orient parts for printing with this material.

Start Printing Faster Today

With the launch of Draft Resin, we’re excited to continue our mission to increase the speed of 3D printing and enable faster designs and better products. Draft Resin is available globally from Formlabs starting today. Order Draft Resin now and start prototyping even faster.