Formlabs’ New General Purpose Resins Make 3D Prints Faster, Stronger, and More Affordable

Since Formlabs’ Grey Resin was announced in 2011 and shipped with the first iteration of Form 1, Formlabs customers have relied on General Purpose Resins for the majority of their printing. Over a decade and 400 million parts later, that still holds true; Formlabs General Purpose Resins are the backbone of workflows, from prototyping to production.

The release of Form 4 opened up the opportunity to develop resins optimized for printing on the new hardware. Six updated resins are now available, including our four General Purpose Resins, Fast Model Resin, and Precision Model Resin.

Our new General Purpose Resins for Form 4 — Grey Resin V5, Clear Resin V5, White Resin V5, and Black Resin V5 — are now available with enhanced aesthetics, improved mechanical properties, and faster print speeds, all at $99 a liter.

Form 4 Materials Guide

Learn more about all the high performance materials available on Form 4 and how to leverage the right material for your application.

Advancements to General Purpose Resins

We collected extensive feedback on our popular General Purpose Resins to develop new formulations that are designed to both leverage the Form 4 hardware for improved performance and deliver more value to our users.

General Purpose Resins are versatile materials with a wide range of user applications including form and fit prototyping, models and props, 3D printed masters or molds, and more. They offer a balance of fast print speed, high accuracy, aesthetics, strong mechanical properties, and an easy, reliable workflow — all with extremely low-odor printing for a pleasant and comfortable user experience.

Improved Material Properties

All General Purpose Resins have improved toughness, with up to 30% more impact strength than V4 resins, and up to two times the elongation at break. The improved material properties of General Purpose Resins make them even more suitable for prototyping parts generally produced with injection molding, and even for some end-use applications.

Formlabs General Purpose Resins vs. Injection Molded Thermoplastics

| Post-cured at room temperature | Post-cured 15 min at 60 °C | Polystyrene (Injection Molded) | PET (Injection Molded) | PMMA (Injection Molded) | |

|---|---|---|---|---|---|

| Material | Grey Resin V5 | Grey Resin V5 | INEOS Styrolution PS 3600 | Eastman 9921 | Trinseo Plexiglas V825 |

| Ultimate Tensile Strength | 54 MPa | 62 MPa | 42.7 MPa | 58 MPa | 70 MPa |

| Tensile Modulus | 2500 MPa | 2675 MPa | 3170 MPa | 2400 MPa | 3100 MPa |

| Elongation at Break | 15% | 13% | 2% | 120% | 6% |

| Flexural Strength | 91 MPa | 103 MPa | 76.5 MPa | 84 MPa | 103 MPa |

| Flexural Modulus | 2450 MPa | 2750 MPa | 3310 GPa | 2500 MPa | 3100 MPa |

| Notched Izod | 34 J/m | 32 J/m | 21.4 J/m | 40 J/m | 16 J/m |

| Heat Deflection Temp. at 0.45 MPa | 62 ℃ | 71 °C | 98 ℃ | 69 °C | 105 °C |

For the detailed properties of each General Purpose Resin, view the technical data sheets.

Print Speed

Leveraging the Form 4 ecosystem, print speeds of General Purpose Resins are three to four times faster compared to the Form 3 generation, with additional time savings during post-processing, for an overall faster workflow.

Holley’s LED Light Bar and Mount can be printed in Black Resin V5 in 2 h 49 min on Form 4.

| Printer | Time to print LED Light Bar and Mount |

|---|---|

| Form 4 | 2 h 49 min |

| Benchmark FDM printer | 4 h 28 min |

| Benchmark SLA printer | 6 h 52 min |

| Form 3+ | 10 h 35 min |

Workflow Optimization

The time from hitting print to a finished part is faster than ever. After washing for five minutes in Form Wash, printed parts can be used with no post-curing. However, we recommend post-curing with either a 5-minute room temperature cure for improved surface and mechanical properties or a 15-minute cure in Form Cure at 60 °C for the highest strength, stiffness, and heat deflection temperature.

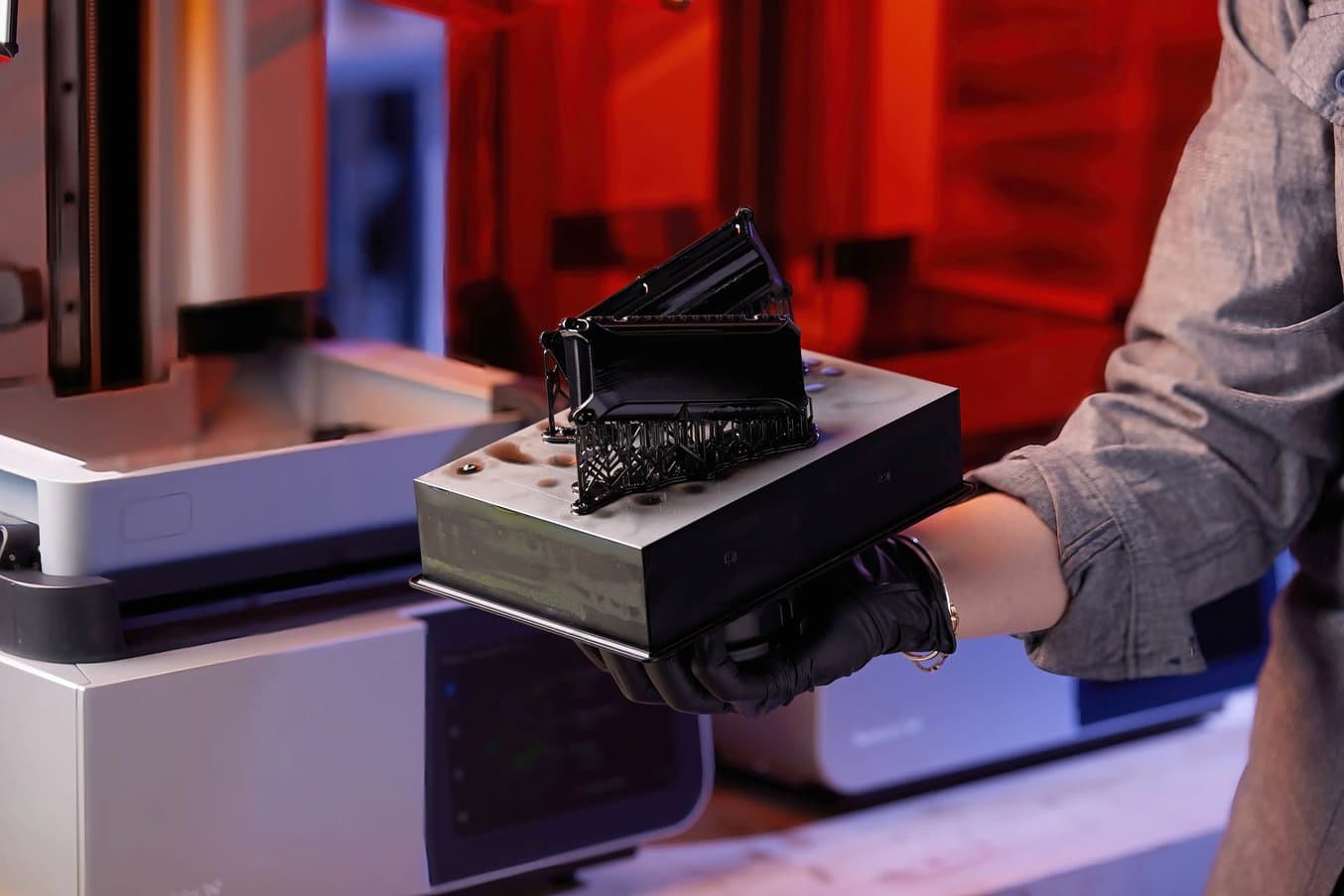

Print Reliability

General Purpose Resins have a higher green strength, achieved by higher resin polymerization and curing in Form 4, for improved print reliability. Additionally, parts are less prone to warping during post-cure, for finished parts with precise tolerances and fine features.

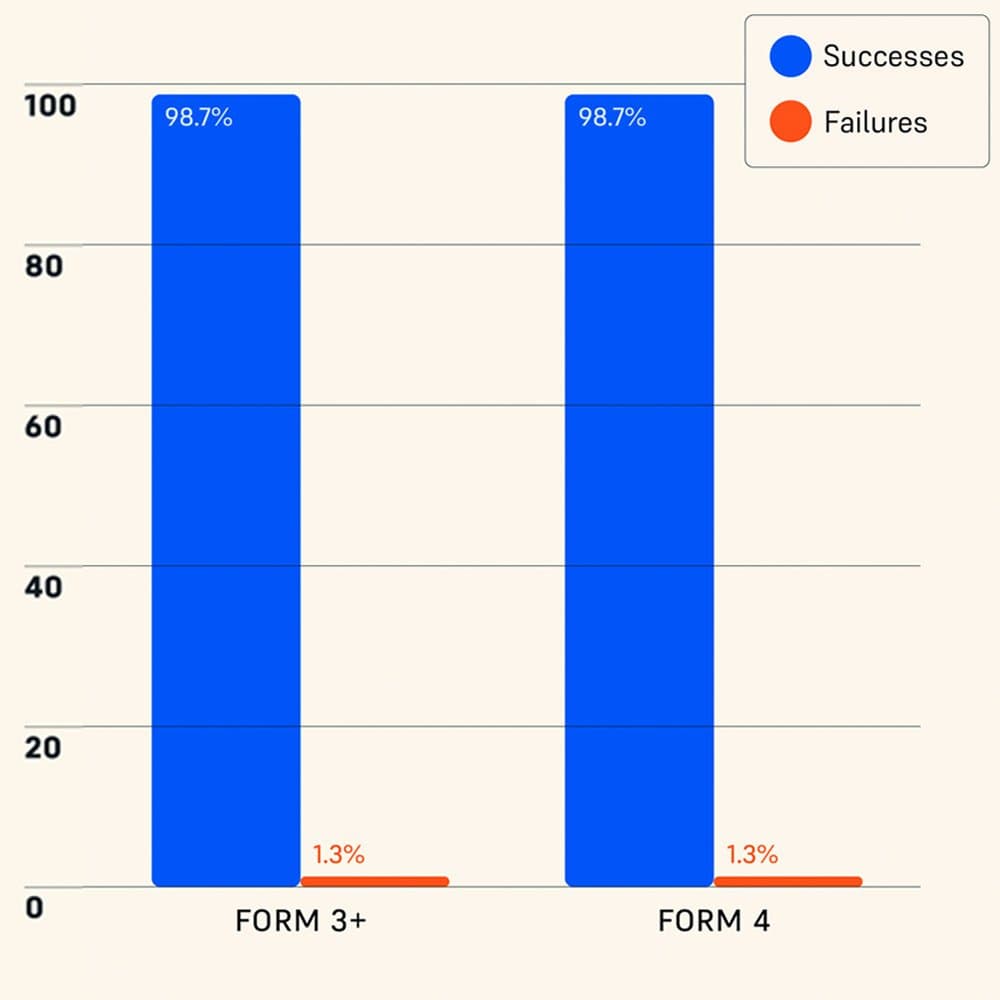

Independently Tested Reliability of Form 4 and Other Resin 3D Printers

Formlabs Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Dimensional Accuracy

The new General Purpose Resins are low-shrinkage materials that, when used with Form 4's optimized exposure settings, achieve superior green strength. This advantage, combined with the reduced need for post-curing, facilitates extremely precise dimensional accuracy, with parts achieving up to ±0.15% XY dimensional tolerances. This level of precision ensures a consistent and reliable fit for assemblies.

Aesthetics

Grey Resin V5, White Resin V5, and Black Resin V5 have a richer, more matte color with a finish that rivals that of injection-molded parts. Clear Resin V5 is closer to acrylic in appearance, with improved clarity and transparency.

White Resin V5, on the left, is brighter and crisper in color than White Resin V4 on the right. This part was printed in two hours and 36 minutes on Form 4.

Optimized for streamlined workflows, improved aesthetics, peak mechanical properties, and print reliability — all at $99 a liter —- new General Purpose Resins allow users to unlock more applications.

Below, we detail some of the updates that enable printed parts in General Purpose Resins on Form 4 to rival injection-molded parts in both speed of production and quality.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Grey Resin V5: Visualize Fine Features

Grey Resin V5, on the left, is darker and richer in color than Grey Resin V4 on the right. It is also tougher, with a 30% higher impact strength, and prints four times faster than Grey Resin V4.

Grey Resin V5 offers great dimensional accuracy and print reliability for the widest range of parts. With a 30% higher impact strength than Grey Resin V4, Grey Resin V5 is a versatile resin for form and fit prototyping and printing jigs and fixtures.

“We need parts to match the original CAD design, to fit smoothly into assemblies, and to print multi-part molds that fit together tightly. Grey Resin V5 molds have been fitting perfectly.”

Matt Tetzl, Prototyping Manager, Black Diamond

The improved grey color of Grey Resin V5 is richer than Grey Resin V4, with a matte surface that captures fine features accurately. These aesthetic improvements make it ideal for printing general dental models and presentation models where surface quality and fine details are important.

Black Diamond was able to run three different iterations of this headlamp component (left) in Grey Resin V5 on Form 4 in a single day.

The design team at Black Diamond Equipment has to make sure that their products are up to the challenge of helping a new climber get comfortable or a professional hit a new record. Detail and accuracy are important, as is extensive testing — millions of cycles for some products.

Product Design Lab Manager Matt Tetzl has been printing the new General Purpose Resins on Form 4 and says, “The surface finish has been really good. The team is really impressed with all the parts we’ve printed off for them on Form 4 in Grey Resin and Clear Resin.”

This set-up for fatigue testing a trekking pole uses fixtures printed on Form 4 in Grey Resin V5 (left) and on Fuse 1+ 30W in Nylon 12 Powder (right).

But it’s not just the aesthetics that are impressive. Tetzl put Grey Resin V5 to the test with a 3D printed fixture that controls the telescoping action of a trekking pole. During fatigue testing, Tetzl was impressed by the durability of the new resin formulation, saying, “For 55 pounds per cycle, we completed 2.5 million cycles, and it showed no wear or deformation.”

Clear Resin V5: Exceptional Clarity

Clear Resin V5 on the left is more translucent and less yellow than Clear Resin V4 on the right.

Clear Resin V5 is exceptionally clear and color-neutral, offering an optimal balance of fast print speed, high accuracy, transparency, strong mechanical properties, and an easy, reliable workflow.

With improvements to transparency and color, Clear Resin V5 now offers the ability to make high-clarity, transparent parts with smooth surface finishes that require no additional sanding or polishing. For applications with higher transparency requirements, the printed parts can be polished to near optical transparency, for a result that rivals acrylic. Print parts requiring transparency and accuracy, including those that showcase internal features, such as fluidic devices, as well as transparent enclosures, optical components, and lighting prototypes.

Parts printed with Clear Resin V5 are highly transparent, stiff, and strong. Enhancements to mechanical properties include increased toughness, with two times the elongation at break and 25% higher impact strength than Clear Resin V4, for parts that can withstand use as models, masters, and molds for rapid tooling.

Desktop Millifluidics With SLA 3D Printing

This report delves into the implementation of millifluidic geometries using stereolithography (SLA) 3D printing. What 3D printed chips bring to the table are improved performance, while reducing the cost of customized design.

White Resin V5: Brighter and Tougher

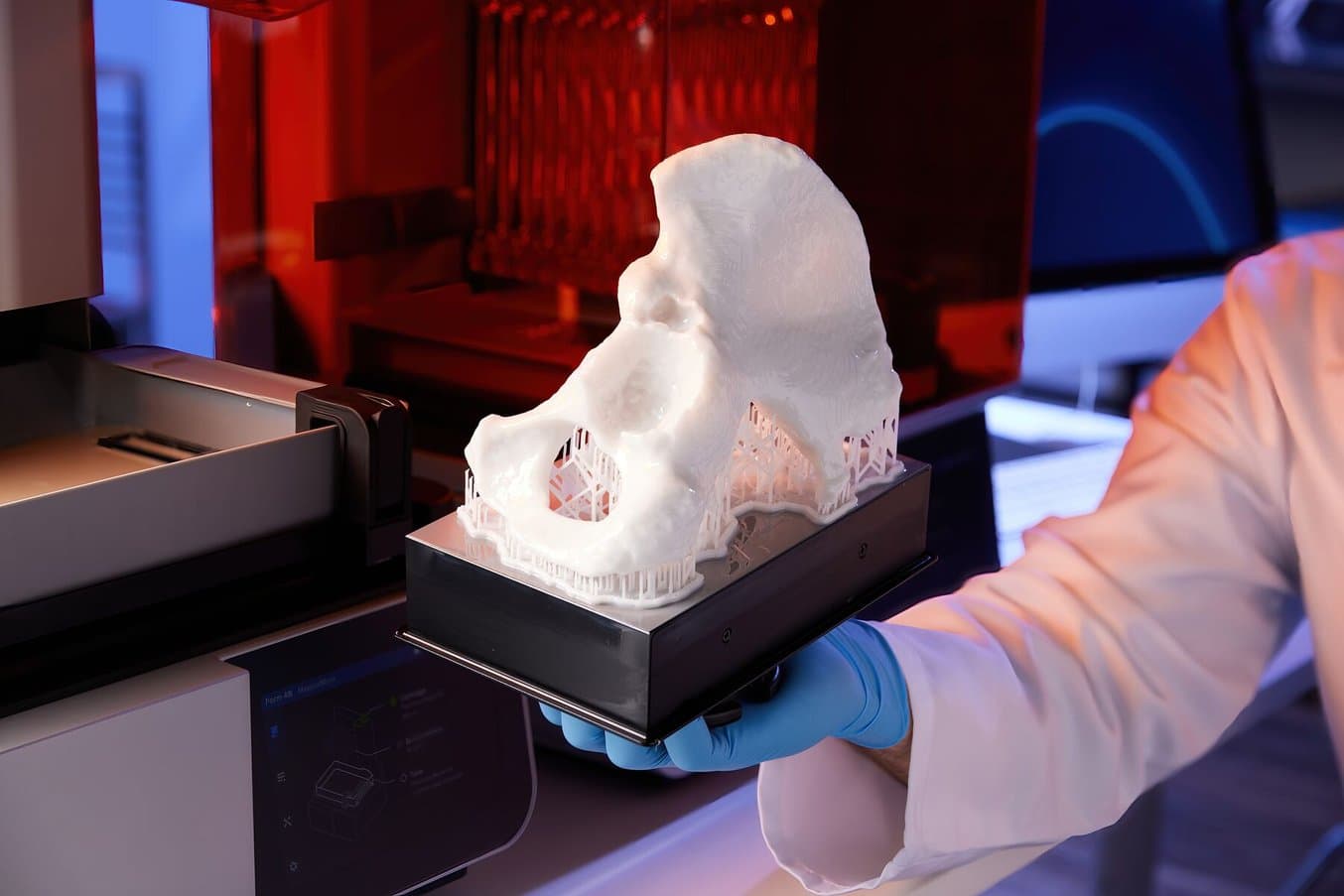

Print highly accurate anatomical models three times faster with White Resin V5 on Form 4.

The bright, crisp color of White Resin V5 makes it optimal for printing anatomical models with crisp details and high dimensional accuracy. Like Grey Resin V5 and Black Resin V5, White Resin V5 has better toughness and accuracy, with two times the elongation at break and 25% higher impact strength than White Resin V4.

With a presentation-ready appearance and a surface finish that rivals injection molding, White Resin V5 can be used for the printing of parts including form and fit prototypes, anatomical models, and presentation-ready models with fine features and intricate details.

Black Resin V5: Aesthetics That Rival Injection Molding

Black Resin V5 on the left has a richer, more matte color to help visualize fine details compared to Black Resin V4 on the right.

Updates to Black Resin V5 make it an exceptionally rich, deep black resin that captures fine features for parts that are stiff and strong with a surface finish that rivals injection molding. Improved aesthetics are ideal for presentation-ready models.

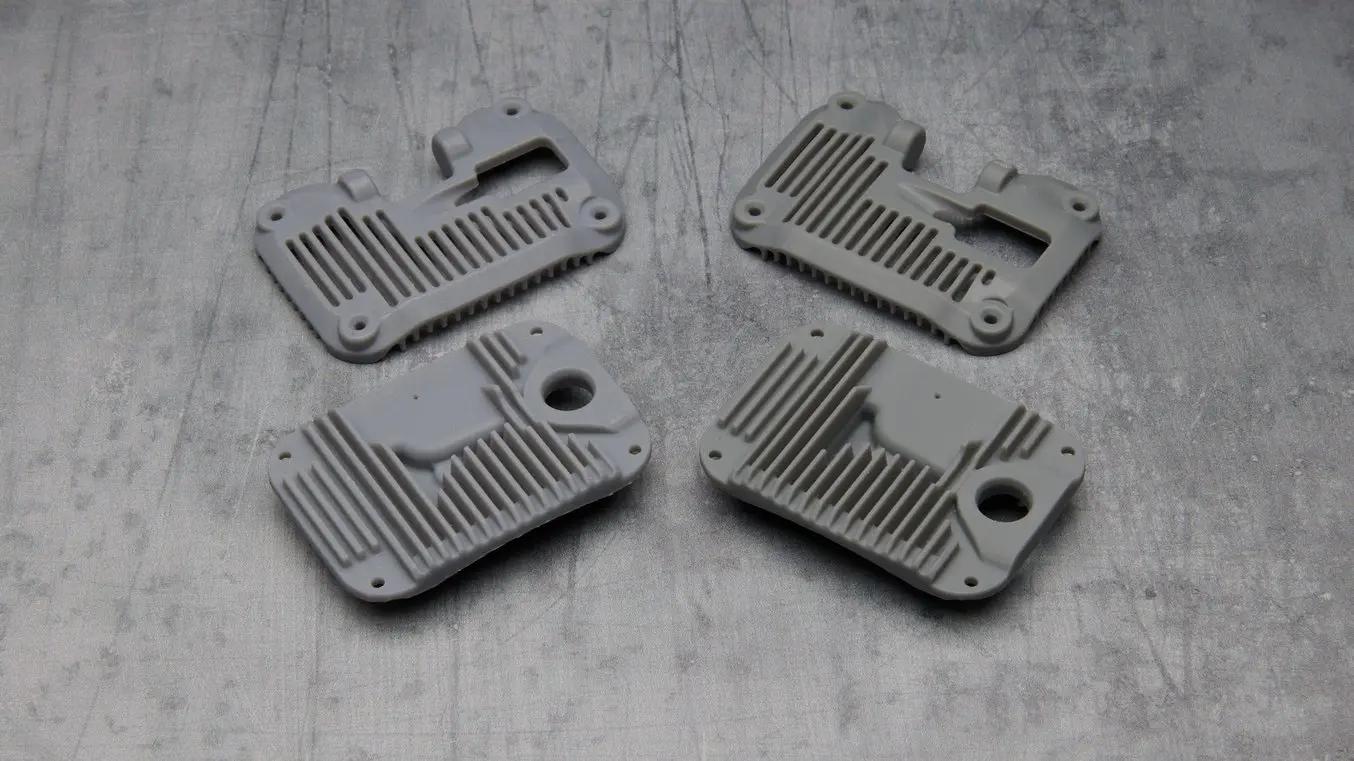

With increased toughness, two times the elongation at break, and 25% higher impact strength than Black Resin V4, Black Resin V5 has the balance of strength, toughness, and stiffness required for a wide range of applications including form and fit prototyping, enclosures, housings, and jigs and fixtures. Black Resin V5 printed on Form 4 also significantly improves on print reliability and dimensional accuracy compared to Black Resin V4 printed on Form 3+.

We used Black Resin V5 when we put Form 4 to the test, pitting four Form 4 3D printers against injection molding. The result? 3D printing outpaced traditional injection molding in both speed and quality.

Start Printing Faster and at Lower Costs

Whether you’re looking to print accurate anatomical models, exceptionally clear fluidic devices, presentation-ready models, or jigs and fixtures, there’s a General Purpose Resin for your application.

The Form 4 hardware enables you to print General Purpose Resins at blazing new speeds, opening up potentials for rapid prototyping, production, and new applications — all at $99 per liter of resin. Additional discounts are available for resin purchases over 30 L. Contact a sales representative to learn more.

To start printing with General Purpose Resins, visit our store, or request a free sample part to evaluate the material advancements for yourself.