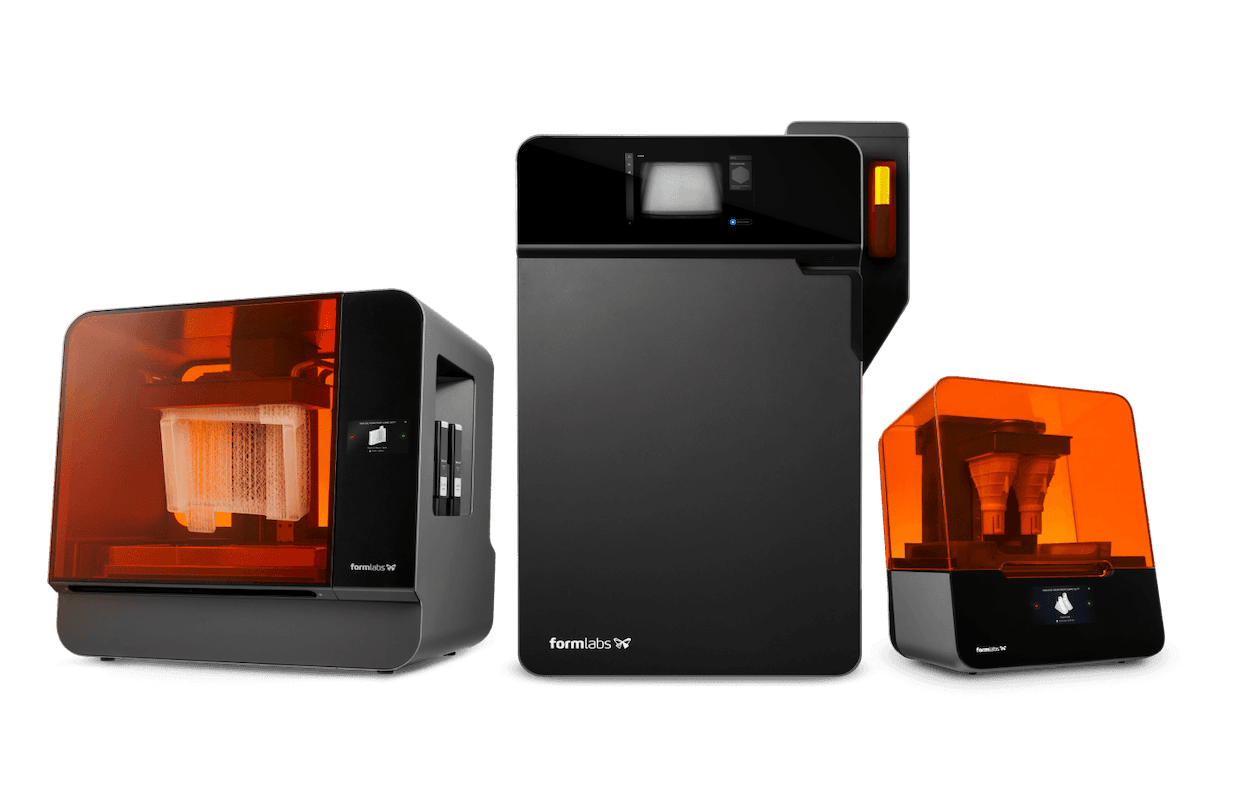

In order to maintain the elite quality of hardware performance our customers have come to expect, prices on some of our hardware products will increase, effective April 21, 2022.

The global cost of goods and services has risen more rapidly over the past two years than our supply chain predictions, or indeed global economists, could have foreseen. Shifts in exchange rates have also impacted our calculations. Though we have maintained the lean and agile manufacturing policies that allowed us to bring industrial quality 3D printing to an affordable entry-point in 2011, we, along with so many other companies, now face new challenges posed by the inflated costs of raw materials, labor, and shipping. We’re proud that since the release of the Form 1, the price of our flagship stereolithography (SLA) product has stayed under £3,500. The monumental changes impacting the global economy over the last two years have finally caused us to shift our pricing dynamics.

The products affected globally are the Form 3+ and Form 3B+ stereolithography (SLA) printers, the Form Wash and Form Wash L, the Form Cure and Form Cure L, and packages containing these items. Shifts in exchange rates have also impacted our calculations. In EMEA, the price for the Fuse 1 selective laser sintering (SLS) printer and packages will also be affected. The exact increase varies by product and by region, as we raised prices only to reflect the cost of producing that particular item, rather than averaging the increase out across every category.

We know customers rely on Formlabs for consistent and reliable printing, and to continue supporting them, we are not increasing the price on any of our resin or powder materials. Though this may not be the most profitable move, we believe that offering a broad variety of materials at accessible price points enables our customers to try new things, print at production levels, and elevate the entire 3D printing community. Being able to explore the entire materials library without huge expense is one of the biggest benefits of printing with Formlabs, and we’re looking forward to seeing our community continue to push the boundaries of what’s possible.

We hope to support each customer as they face new challenges presented by their own heightened cost of goods. We firmly believe that 3D printing is an ideal way to reduce costs to your business, insulate your supply chain, and become a more agile manufacturer, designer, or engineer. We’ve highlighted certain cost reduction measures our customers have taken using our 3D printers:

-

Increase your throughput by switching to faster Draft Resin.

-

Draft Resin prints up to four times faster than standard resins such as Grey Resin.

-

Run multiple iterations of your design each day.

-

-

Reduce your per part materials cost by optimizing each build with the Fuse 1 packing algorithm.

-

Insulate your supply chain by utilizing ESD Resin to protect electrical components from damage.

-

Switch from injection molding to SLS and eliminate the cost of metal tooling through short run production on the Fuse 1.

-

Manufacture cost-effective rapid tooling, such as injection molds, or manufacturing aids with your Form 3+ and Form 3L.

If you are curious about any of these applications, or would like to discuss your unique workflow and how 3D printing can reduce your costs, please contact our team here.