Formlabs is excited to announce Tough 2000 Resin, a reformulation of our popular Tough Resin, as the newest addition to our library of materials for our line of desktop stereolithography (SLA) 3D printers, including the Form 3 and Form 2.

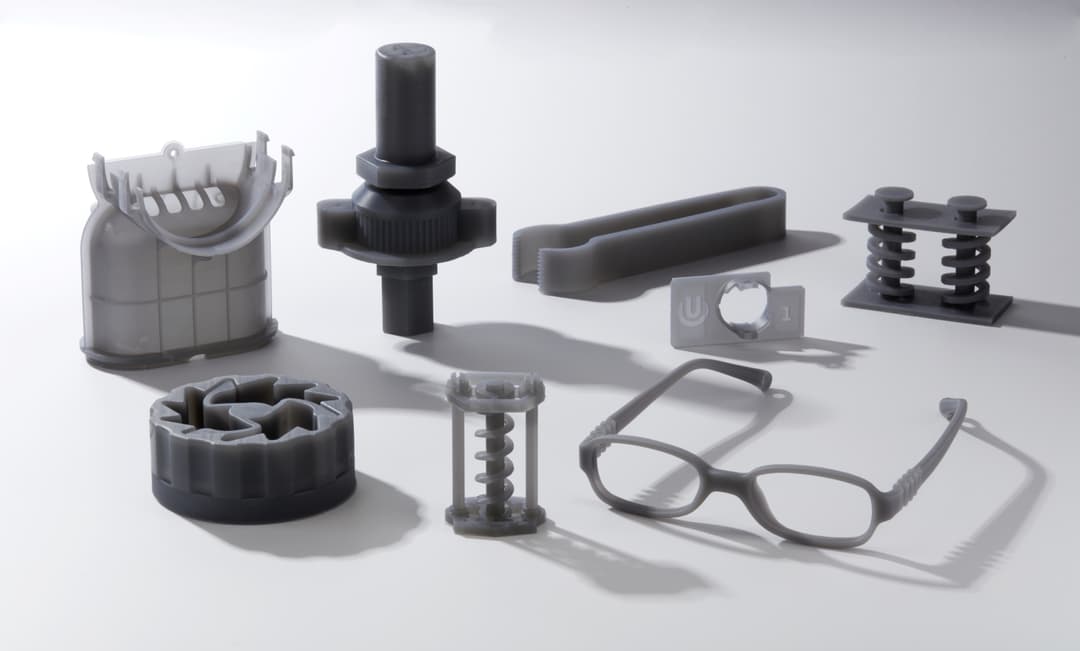

Tough 2000 Resin produces stiff and sturdy parts that are difficult to bend. This material is ideal for functional parts such as housings and enclosures, jigs and fixtures, mechanical connectors, and prototypes undergoing wear and tear.

Tough 2000 Resin is the strongest and stiffest material in our newly segmented family of Tough and Durable Resins. These materials, which include Tough 2000 Resin, Tough 1500 Resin, and Durable Resin, can all handle compression, stretching, bending, and impacts without breaking, but can be clearly differentiated by comparing key properties such as modulus (the property represented by the “2000” in this material’s name).

Of all Tough and Durable materials, Tough 2000 Resin most closely simulates ABS in terms of stiffness and strength.

Contact Sales Request a Sample Part

Introducing Tough 2000 Resin - An Improvement Over Our Popular Tough Resin

At Formlabs, we strive to develop materials that consistently push the limits of 3D printing and expand what is possible to create in-house. That's why we reformulated one of our most popular materials. Our new Tough 2000 Resin has improved mechanical properties and a new look compared to Tough Resin, the previous versions of this material, including:

-

Reduced brittle failures: Increased elongation by more than 100%.

-

Improved strength and stiffness: Increased flexural strength and flexural modulus by roughly 15%.

-

Better performance at elevated temperatures: Increased heat deflection temperature.

-

Professional-looking parts: New grey color.

Mechanical Properties Comparison

The improvements in elongation, strength, and stiffness enhance the material’s overall toughness, which can be measured by the area under a stress-strain curve.

| Elongation at Break | Flexural Strength | Flexural Modulus | |

|---|---|---|---|

| Tough 2000 Resin | 48% | 65 MPa | 1.9 GPa |

| Tough Resin | 23% | 57 MPa | 1.6 GPa |

| % Improvement | 109% | 14% | 19% |

Data was obtained from parts printed using Form 2, 100 μm and post-cured with a Form Cure according to our recommended settings.

Strength, stiffness, and elongation are typically opposing properties. Thanks to a complete reformulation, Tough 2000 Resin offers a net gain in properties over Tough Resin -- it is both less brittle, and more stiff and strong, than Tough Resin. Tough 2000 Resin uses higher performing components similar to those in Rigid Resin and Elastic Resin. These components mean Tough 2000 Resin requires a specialty tank like Form 2 Resin Tank LT or Form 3 Resin Tank V2.

<< The “2000” in Tough 2000 Resin represents its tensile modulus (in MPa). As Formlabs reformulates and develops new engineering materials, we will continue to use this “adjective + number” naming convention. If you are looking for a less stiff material, try Tough 1500 Resin or Durable Resin. >>

Thermal Properties Comparison

The improved HDT of Tough 2000 Resin enables parts made from this material to perform better in elevated temperatures, such as electronic enclosures or jigs and fixtures in manufacturing environments.

| Heat Deflection Temp. @ 1.8 MPa | Heat Deflection Temp. @ 0.45 MPa | |

|---|---|---|

| Tough 2000 Resin | 53 °C | 63 °C |

| Tough Resin | 43 °C | 47 °C |

| % Improvement | 23% | 34% |

Data was obtained from parts printed using Form 2, 100 μm and post-cured with a Form Cure according to our recommended settings.

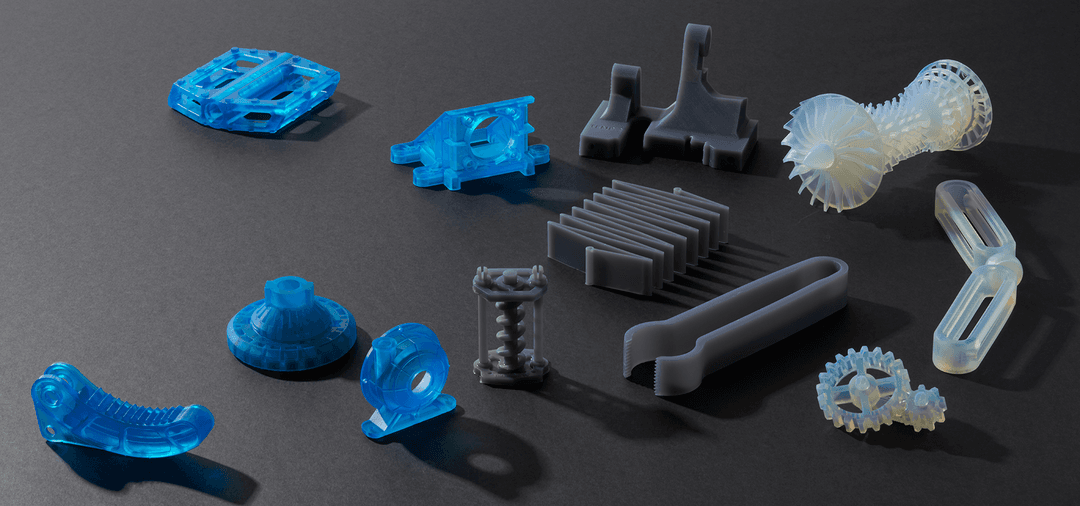

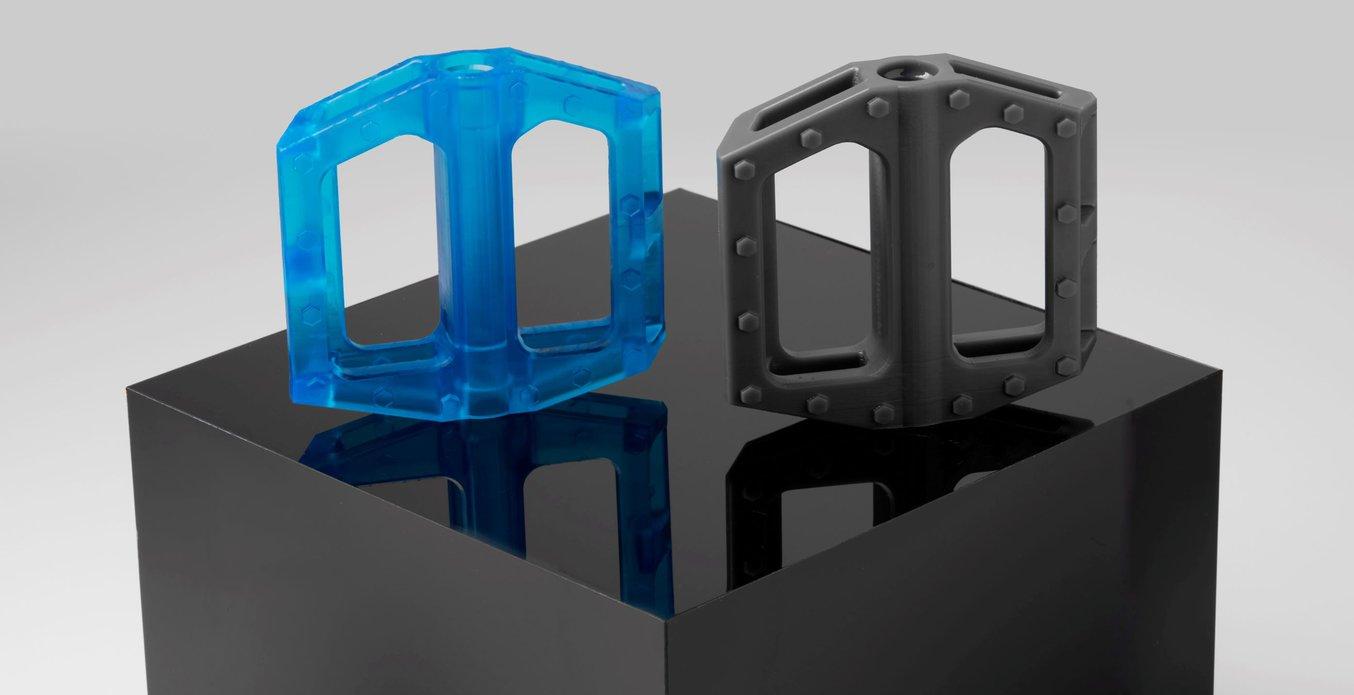

A More Professional Look

Surveys conducted with current Tough Resin customers highlighted that you would prefer a more neutral color in any future reformulations. Although the translucent blue color has been iconic for Tough Resin, we are confident that the dark gray color of Tough 2000 Resin will open up new opportunities to create professional-looking parts that blend seamlessly into their environment.

When to Use Tough 2000 Resin

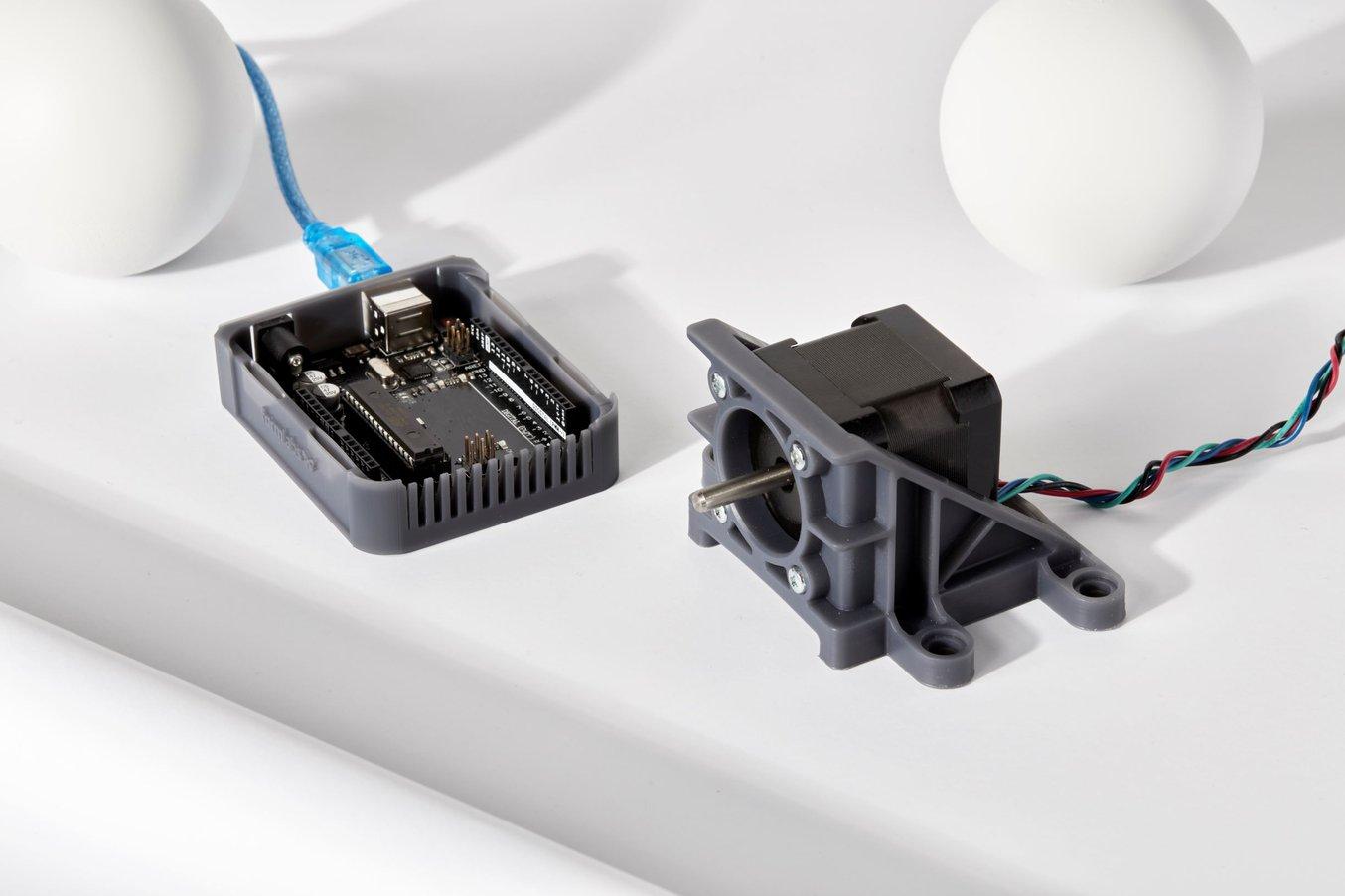

Tough 2000 Resin suits many applications across engineering, product design, and manufacturing settings. This includes prototypes undergoing wear and tear, mechanical connectors, and housing and enclosures such as the below motor mount. The improved strength, stiffness, and elongation allow engineers and product designers to iterate with higher confidence and reduce brittle failures.

Tough 2000 Resin is ideal for jigs and fixtures that require minimal deformation and overall robustness, such as the drill guide shown below. The improved Heat Deflection Temperature also increases Tough 2000 Resin’s ability to perform at elevated temperatures.

Prototype ABS Parts With Tough 2000 Resin

ABS is a common thermoplastic used in numerous consumer packaged goods products. Use Tough 2000 Resin to simulate the strength and stiffness of products that will be manufactured from ABS.

Experience Tough 2000 Resin

Tough 2000 Resin offers a unique balance of strength and stiffness that makes it difficult to bend. See it for yourself by requesting our Tough 2000 Resin pump housing sample part.

High Performance Engineering Materials For Everyone

Formlabs is dedicated to enhancing desktop 3D printing and the possibilities of in-house fabrication by developing advanced materials. Tough 2000 Resin is the latest material to be added to our family of Tough and Durable Resins. To view our complete library of engineering materials for the Form 3 and Form 2, visit our Engineering Resins page.

Webinar: Introducing Tough 2000 Resin

In this on-demand webinar, a Formlabs Product Marketer will walk through our family of Tough and Durable Resins at Formlabs and deep dive into our latest material, Tough 2000 Resin.