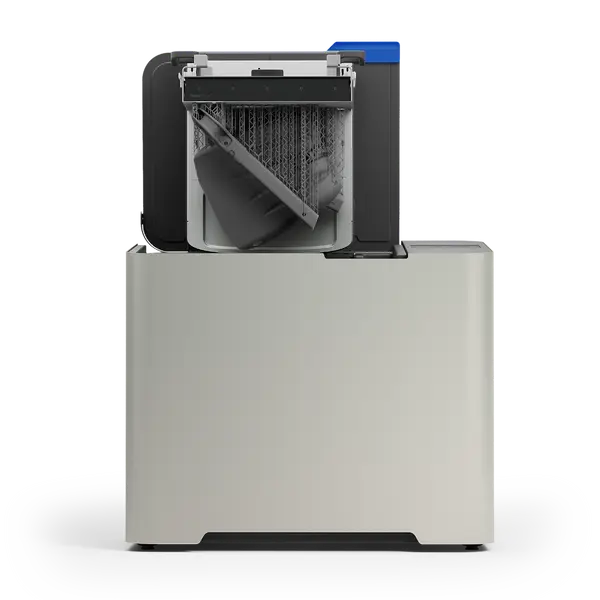

The Form 4L Ecosystem

Complete Your 3D Printing Experience

Learn how you can power your productivity, and improve part quality, workflows, and time efficiency, by upgrading from Form 3L to Form 4L.

Improvement

form 4 vs. form 3

2-4x faster print speeds across all materials for most large prints in under six hours for faster iterations and higher throughput.

“Form 4L allows us to print large parts fast. For example, we use the Form 4L to print setup parts for our weld cell in just hours instead of overnight.”

Matthias Schulz, Seat Division Prototyping Manager, Brose

13% larger build volume and 6% larger maximum part length for larger parts and increased throughput.

Six new resins provide higher performance, richer color, and crisper features – all at a fraction of the price of the Form 3L equivalents.

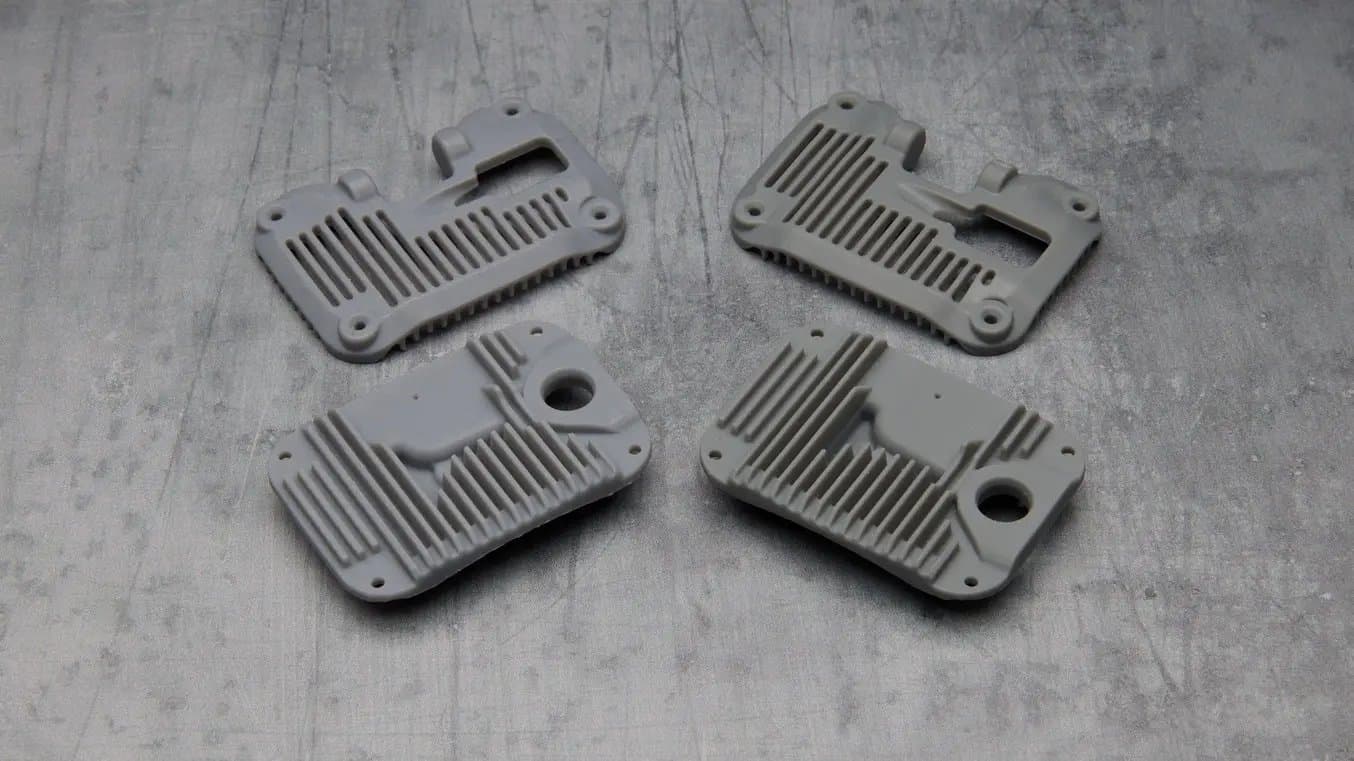

Surface finish that rivals injection molding for improved aesthetics and presentation-ready parts.

Improved Reliability and Consistency

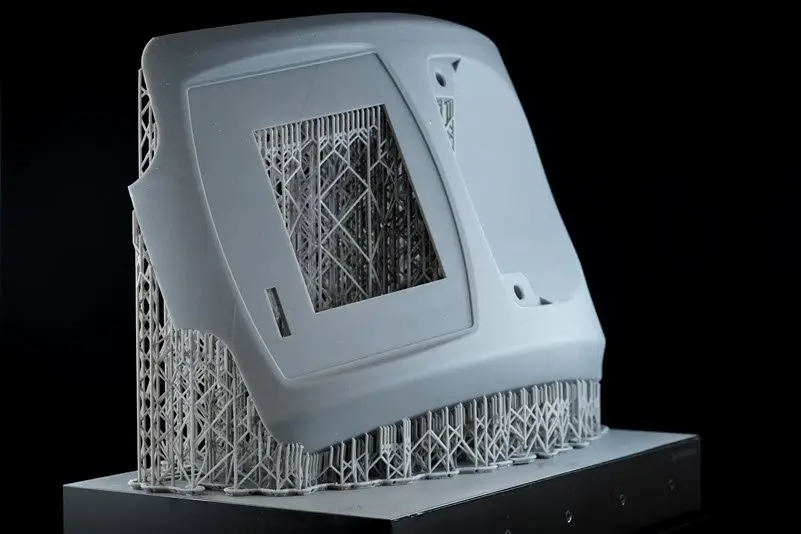

Sharpest details to produce parts with the finest and most intricate features, uniform finishes, and no seamline for less time spent finishing parts.

Improved tank lifetime and management to minimize upkeep costs and waste.

Cartridge redesign for hassle-free, efficient, and fast automatic resin dispensing.

Access images and timelapses online to remotely monitor your prints.

Post-Processing Improvements

Additional Specs

100 μm layer height

Form 4L

Technology

Display Holders

4 h 12 m

Scooter Cover

4 h 58 m

Build volume

35.3 x 19.6 x 35 cm

13.9 x 7.7 x 13.8 in

24.2 L

Fast Model Resin, Formlabs’ fastest printing resin, was designed to print on Form 4 Series printers.

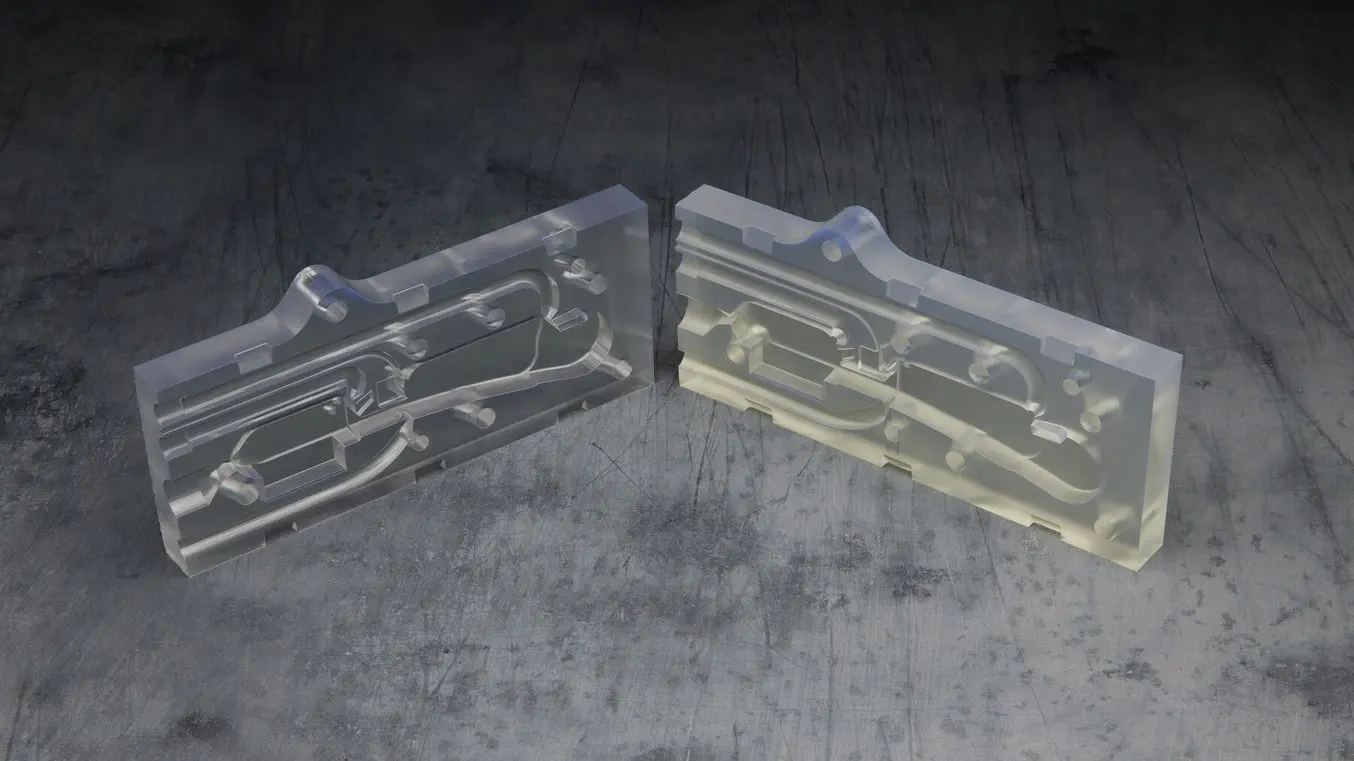

White Resin V5 (left, for Form 4L) is brighter and crisper in color than White Resin V4 (right, for Form 3L).

"We’ve pushed Form 4BL to its limits, and it hasn’t failed a single print. Its reliability under pressure has been outstanding."- Brian Albers, 3D Printing Engineer, St. Louis Children’s Hospital.

“As a dental lab, reliability is essential for us to deliver our products on time. With Formlabs’ ecosystem, our 3D print success rate is now close to 100%. Compared to other 3D printers we’ve used in the past, Formlabs shows much higher performance and reliability.” - Stephan Kreimer, MDT, Kreimer Dentallabor.

46 µm with pre-tuned anti-aliasing for subpixel resolution

Masked stereolithography (MSLA) prints have fine finishes with no seamline, like this ventilator enclosure printed in Grey Resin V5.

75,000+ layers with any Formlabs material.

For example: approximately 190 prints using an average height model (39 mm tall), any resin, and 100 µm layer height.

Integrated 5-megapixel camera, which can be disabled, covered, or removed

Ease of Use

form 4 vs. form 3

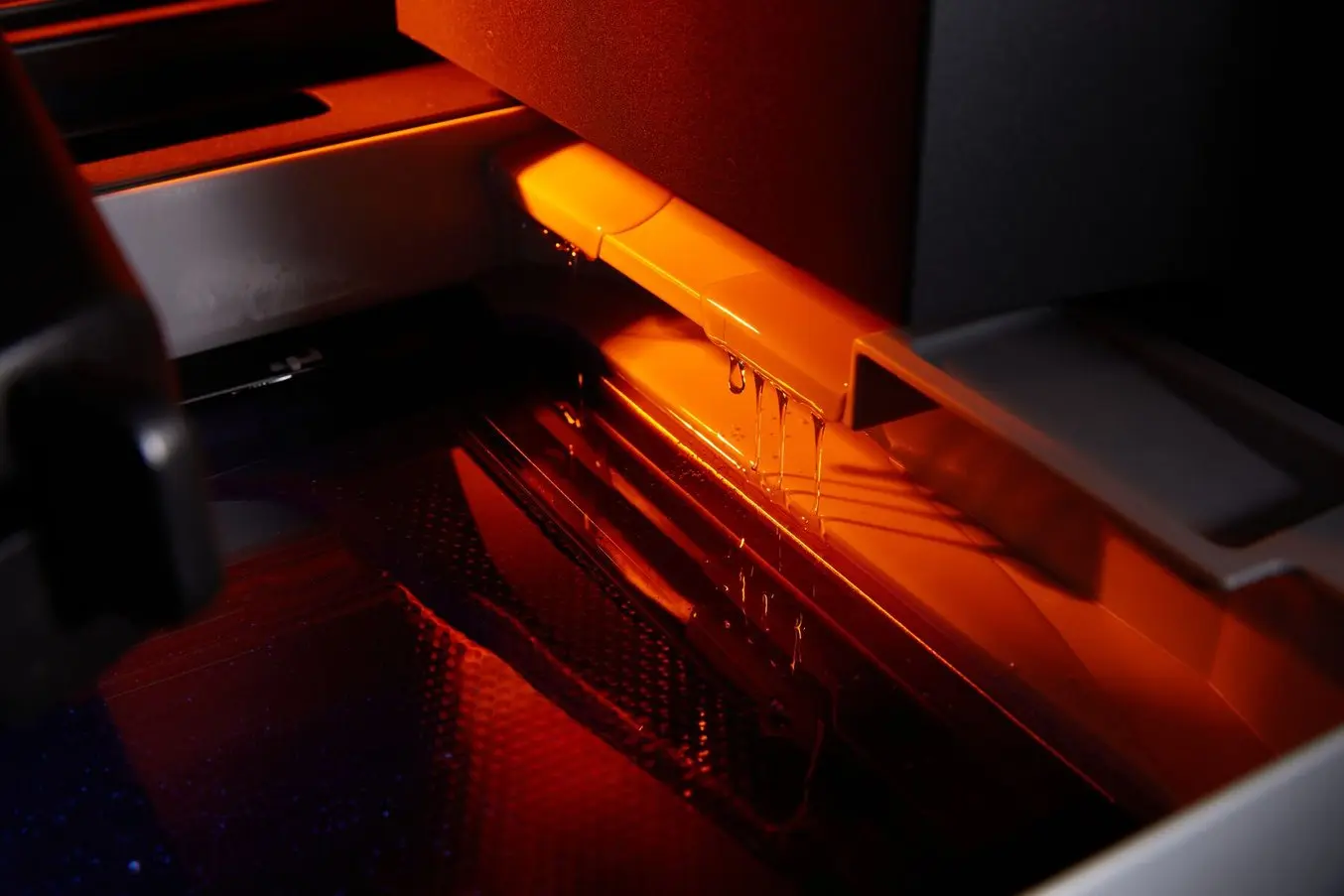

Backlight Unit

Light Processing Unit 4L (LPU 4L)

Release Texture

Flexible Film Resin Tank

Intelligent Control Systems

High-Speed Automatic Resin Handling

±0.15% XY dimensional tolerances so assemblies always fit

Average: 24 mm/h across all materials

Range: 20-35 mm/h depending on the material

80 mm/hr

3.1 in/hr

7” touchscreen

Languages: English, German, French, Spanish, Italian, Japanese, Simplified Chinese

58.5 kg

129 lb

66.4 x 52.8 x 79.4 cm

26.1 x 20.8 x 31.3 in

Form 3L

Technology

Display Holders

22 h 52 m

Scooter Cover

18 h 47 m

Build volume

33.5 × 20 × 30 cm

13.2 x 7.9 x 11.8 in

21.4 L

Clear Resin V5 (left, for Form 4L) vs. Clear Resin V4 (right, for Form 3L).

Grey Resin V5 (left, for Form 4L) is darker and richer in color than Grey Resin V4 (right, for Form 3L). It is also tougher, with a 30% higher impact strength, and prints 4x faster.

85 µm laser spot size, 25 µm XY resolution

Printing with two lasers on Form 3L causes a small seamline in parts. The seamline runs lengthwise from left-to-right through this ventilator enclosure printed in Grey Resin.

250-800 hours of printing and/or 10-35 weeks exposed to resin, depending on the material.

Approximately 70 prints using Grey Resin V4 and average print time (11 hours) or approximately 20 prints using Tough 2000 Resin and average print time (11 hours).

No camera

Ease of Use

form 4 vs. form 3

Laser

Light Processing Unit (LPU)

Flexible Film Resin Tank

Intelligent Control Systems

Automatic Resin Handling

Not measured

Average: 8 mm/h across all materials

Range: 1-14 mm/h depending on the material

23 mm/hour

0.9 in/hr

5.5” touchscreen

Languages: English

54.4 kg

120 lb

77 × 52 × 74 cm

30.3 × 20.5 × 29.1 in

The Form 4L Ecosystem

Complete Your 3D Printing Experience