Form 4 Design Guide

A successful 3D print starts with a well-designed model. Follow our best practices to optimize designs and reduce failures.

Form 4 Design Guide

Download as PDF

A successful 3D print starts with a well-designed model. Follow our best practices to optimize designs and reduce failures.

The recommended feature sizes listed below represent the intended feature size in your CAD model. The comparison table at the end of the article compares this to the measured value of the actual printed feature size found during Formlabs testing. The deviations are minimal and generally imperceptible to the human eye. The table also includes a comparison to Form 3 performance, showing that the Form 4 better matches the intended feature sizes.

The guidelines below were developed using Formlabs Grey Resin printing at 50 microns on the Form 4. You may experience slight variations with other Formlabs resins, different Formlabs printers, and various layer thicknesses.

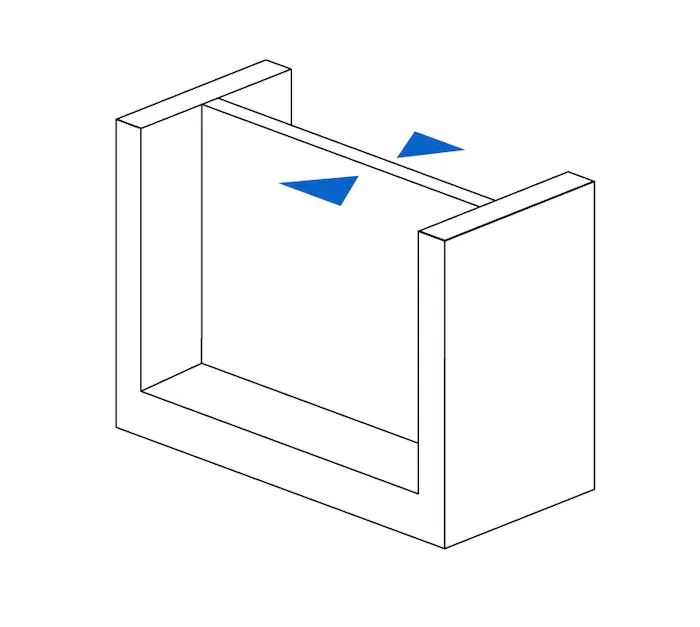

MINIMUM SUPPORTED WALL THICKNESS

Recommended: 0.2 mm/200 microns

A supported wall is one that is connected to other walls on two or more sides. A supported wall with a thickness of 0.2 mm or less may warp due to the peel forces exerted on the part during the peel process.

Take care when washing parts with thin walls, which may absorb solvents such as IPA during the washing process. Spending an extended duration in a washing solution can cause deformation of the part, so minimize how long the part is immersed in IPA to limit this effect.

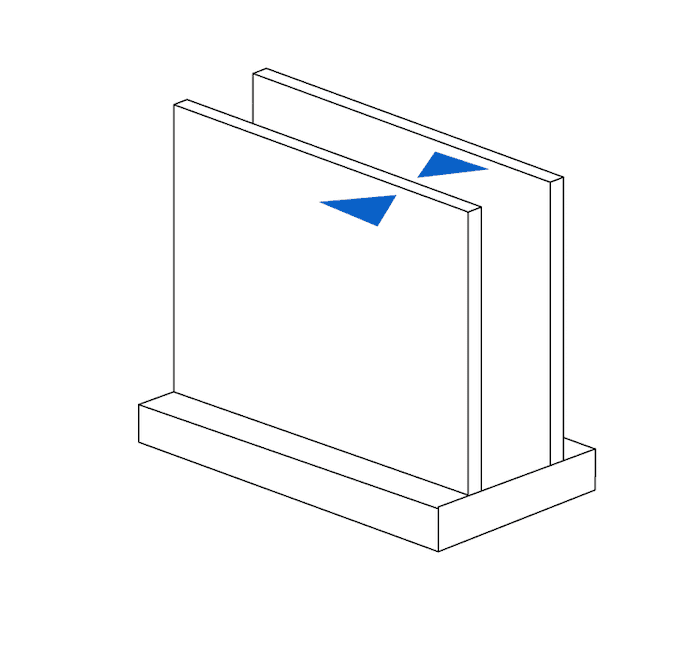

MINIMUM UNSUPPORTED WALL THICKNESS

Recommended: 0.2 mm/200 microns

An unsupported wall is one that is connected to other walls on fewer than two sides. An unsupported wall with a thickness of 0.2 mm or less may warp or detach from the model during printing.

Take care when washing parts with thin walls, which may absorb solvents such as IPA during the washing process. Spending an extended duration in a washing solution can cause deformation of the part, so minimize how long the part is immersed in IPA to limit this effect.

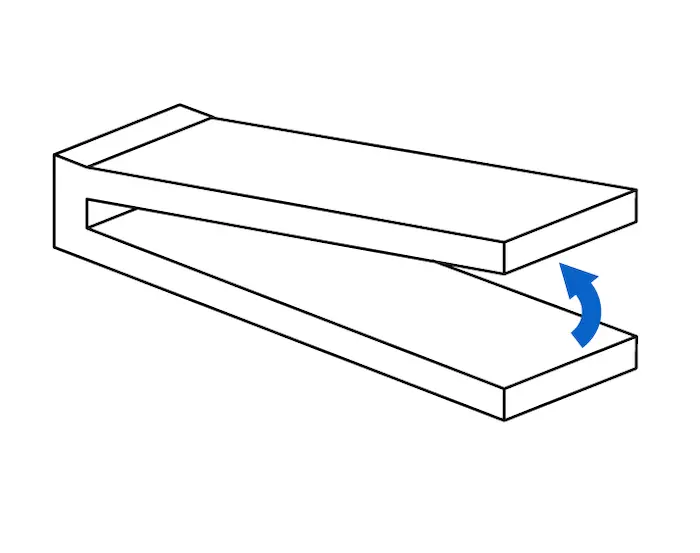

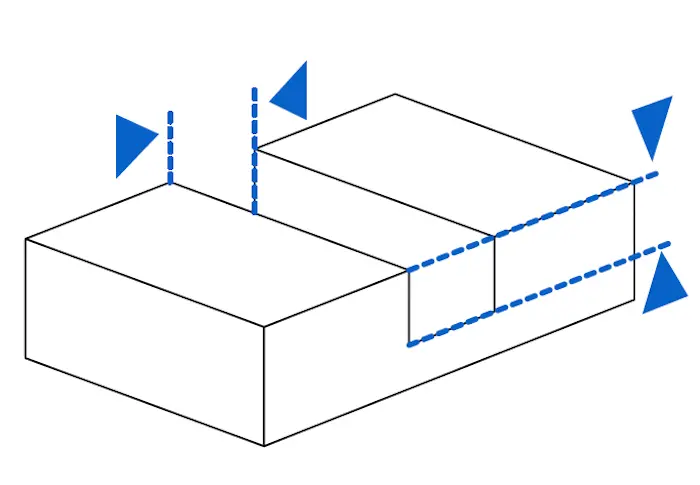

MAXIMUM UNSUPPORTED OVERHANG LENGTH

Recommended: 5.0 mm/5000 microns

An overhang refers to a part of the model that extends parallel to the build platform. Printing such features without support is discouraged, as layers that cannot maintain their structure often warp or detach. Horizontal overhangs beyond 5 mm do not completely form and become increasingly deformed as the length of the overhang increases. Change the orientation of the model, or click Supports and select Internal Supports in PreForm to ensure overhangs are supported.

MINIMUM UNSUPPORTED OVERHANG ANGLE

Recommended: 10 ° from level

(35 mm long x 10 mm wide x 3 mm thick)

An overhang set at an angle of 10 degrees or less can break off the model during the peel process. Refer to the support article Moving and rotating a model in PreForm to rotate flat surfaces to be more self-supporting.

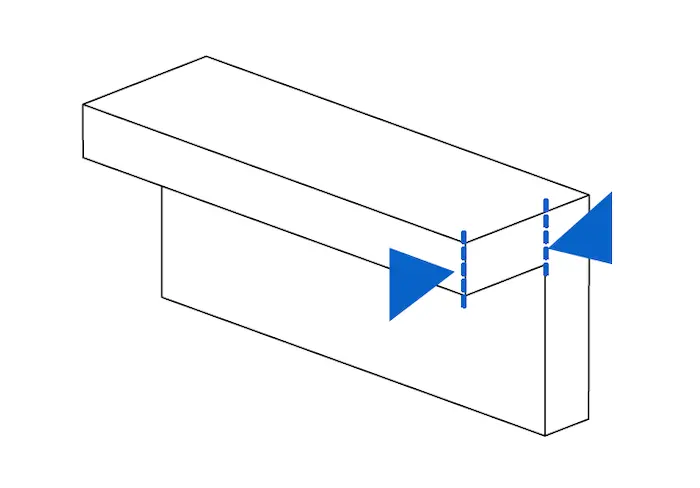

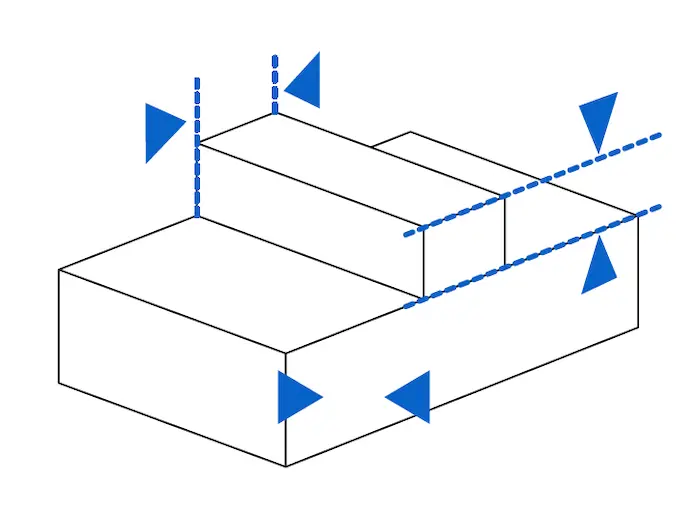

MAXIMUM HORIZONTAL SUPPORT SPAN/BRIDGE

Recommended: 29 mm/29,000 microns

(5 mm wide x 3 mm thick)

Span is the distance between two supports. Printing horizontal spans is discouraged, but certain geometries may print successfully. For a 5 mm wide and 3 mm thick beam, spans longer than 29 mm are more likely to fail. Wider beams must be kept shorter to avoid print failures.

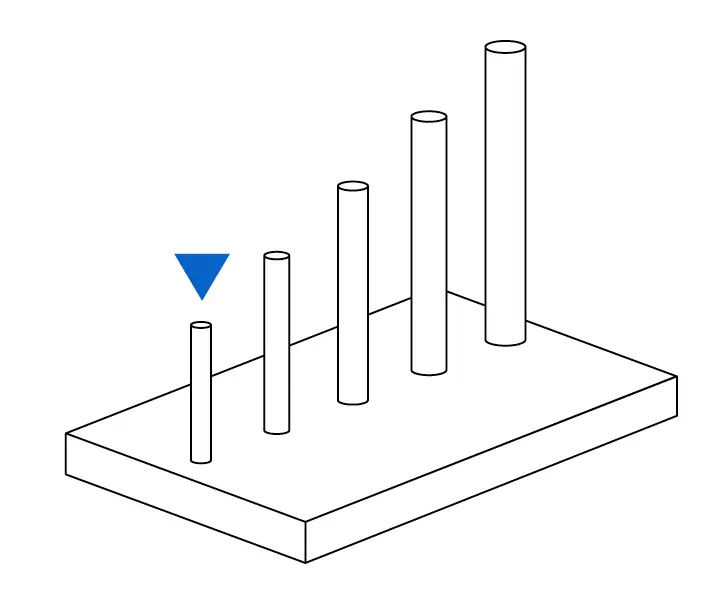

MINIMUM VERTICAL-WIRE DIAMETER

Recommended for a 7 mm-tall wire: 0.3 mm/300 micron diameter

Recommended for a 30 mm-tall wire: 0.6 mm/600 micron diameter

A wire is a feature whose length is at least two times greater than its width. A wire with a 0.3 mm width can be up to 7 mm tall before it begins to deform. Similarly, a wire with a 0.6 mm width can be up to 30 mm tall before it begins to deform.

Take extra care when washing thin wires, as they are weakened by IPA and can easily be damaged. Minimizing how long the part is immersed in IPA limits this effect.

MINIMUM EMBOSSED DETAIL

Recommended: 0.1 mm/100 microns

Embossed details are shallow raised features on the surface of a model like text. Details less than 0.1 mm thick and 0.1 mm tall may not be visible on the completed print.

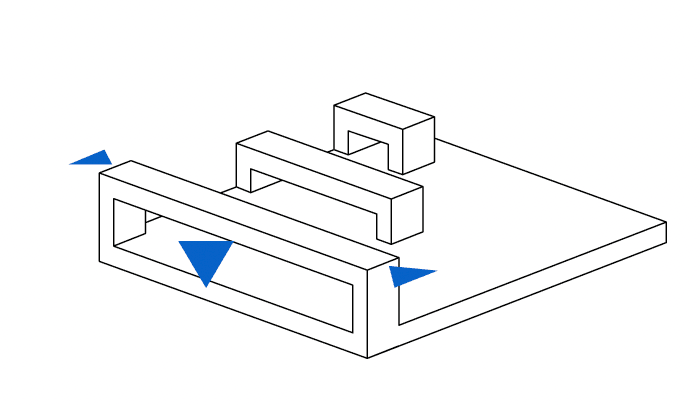

MINIMUM ENGRAVED DETAIL

Recommended: 0.15 mm/150 microns

Engraved details are imprinted or recessed features on the surface of a model. Details recessed less than 0.15 mm deep or 0.15 mm wide may fuse with the rest of the model during printing.

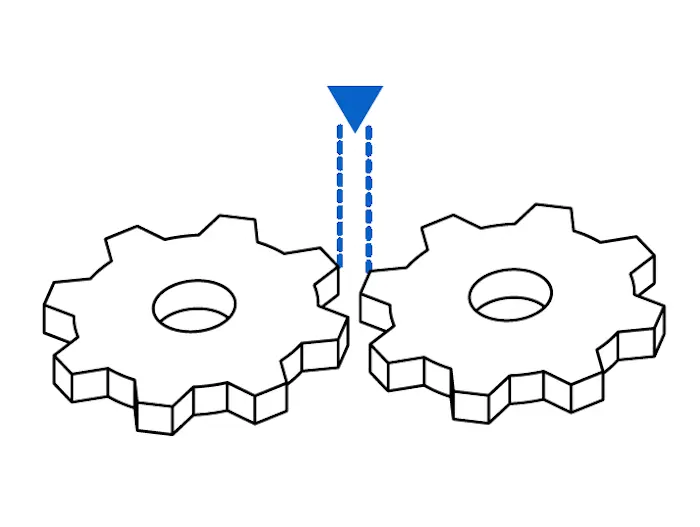

MINIMUM CLEARANCE

Recommended: 0.4 mm/400 microns

Clearance is the distance between two parts of a model (e.g., the distance between a pair of gears). Parts may fuse if clearance is less than 0.4 mm.

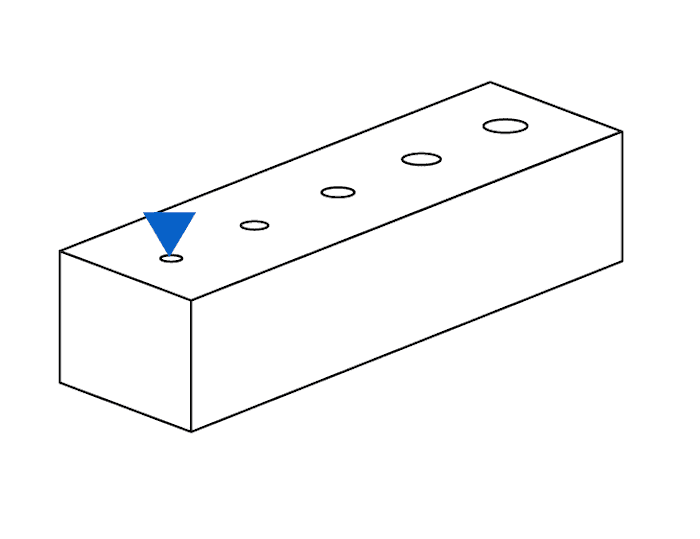

MINIMUM HOLE DIAMETER

Recommended: 0.5 mm/500 microns

Holes with a diameter of less than 0.5 mm in the X-, Y-, and Z-axes may close during printing.

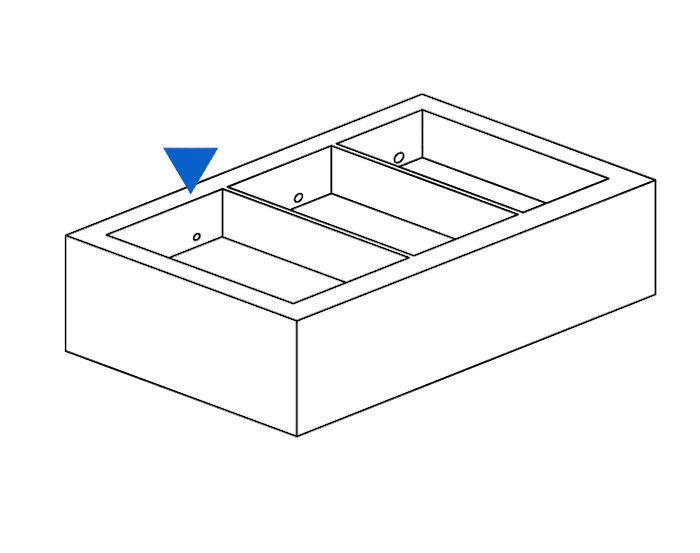

MINIMUM DRAIN HOLE DIAMETER

Recommended: 0.75 mm/750 micron diameter

Drain holes are recommended for resin to escape in models that are a fully enclosed cavity (like a hollow sphere or hollow cylinder printed directly on the build platform). Without drain holes of at least 0.75 mm in diameter, the part may trap resin or air and lead to a cupping blowout failure.

Book a Consultation

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.

Typical Dimensional Tolerances

For reference, please see a list of typical dimensional tolerances for Form 4 generation printers. One test model with various feature sizes 3D was printed on three different printers using Grey Resin and 100 μm layer height, post-cured for five minutes at room temperature.

• 1–30 mm features: ±0.15% (lower limit: ±0.02 mm)

• 31–80 mm features: ±0.2% (lower limit: ±0.06 mm)

• 81–150 mm features: ±0.3% (lower limit: ±0.15 mm)

Comparison Between Form 4 and Form 3

The following table compares the recommended design values or the intended CAD feature size to the measured value of the actual printed feature size found during Formlabs testing. The closer the printed feature size is to the intended CAD feature size, the more precise a printer is. The deviations in the intended CAD feature size and the printed feature sizes are minimal and generally imperceptible to the human eye. The following takeaways apply for the Form 4 and Form 3 generation printers:

- The recommended design values for minimum feature sizes between Form 4 and Form 3 did not change.

- The Form 4 prints the recommended design values or intended CAD feature sizes more precisely compared to Form 3 printers.

|

FORM 4 / FORM 4B GREY V5 AT 50 MICRONS (DEFAULT) |

FORM 3 / FORM 3B GREY V4 AT 50 MICRONS (DEFAULT) |

|||

|

Intended CAD feature size |

Actual printed feature size |

Intended CAD feature size |

Actual printed feature size |

|

|

Minimum supported wall thickness |

0.2 mm |

0.17 mm |

0.2 mm |

0.25 mm |

|

Minimum unsupported wall thickness |

0.2 mm |

0.18 mm |

0.2 mm |

0.26 mm |

|

Maximum unsupported overhang length |

5.0 mm |

5.00 mm |

5.0 mm |

5.03 mm |

|

Minimum unsupported overhang angle |

10° |

10° |

10° |

10° |

|

Maximum horizontal support span length |

29 mm |

29.00 mm |

29 mm |

29.00 mm |

|

Minimum vertical wire diameter |

0.3 mm (7 mm tall) 0.6 mm (30 mm tall) |

0.20 mm 0.59 mm |

0.3 mm (7 mm tall) 0.6 mm (30 mm tall) |

0.35 mm 0.68 mm |

|

Minimum embossed detail |

0.1 mm |

0.13 mm |

0.1 mm |

0.24 mm |

|

Minimum engraved detail |

0.15 mm |

0.15 mm |

0.15 mm |

0.14 mm |

|

Minimum clearance |

0.4 mm |

0.34 mm |

0.4 mm |

0.15 mm |

|

Minimum hole diameter |

0.5 mm |

0.42 mm |

0.5mm |

0.26 mm |

|

Minimum drain hole diameter |

0.75 mm |

0.91 mm |

0.75 mm |

0.90 mm |

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.