‘Agility’ is the manufacturing industry’s favorite buzzword — but even the most agile hardware manufacturer would have something to learn from Polish graphic design firm ARTNOVA. When faced with a drop in customer demand for 3D visualizations, ARTNOVA’s Director Artur Dmochowski didn’t just develop a new approach to his work — he pivoted into an entirely different field.

“With the rapid development of AI, I started to worry that 'desk jobs' — graphic designers, programmers, UX designers — may sooner or later lose a significant part of their work. I wanted to start selling physical products — something you can actually hold in your hand — rather than only providing services.”

ARTNOVA Director Artur Dmochowski

The best way to make something physical, without the legacy infrastructure of most manufacturers? A reliable 3D printing ecosystem capable of delivering end-use products.

ARTNOVA brought on the Fuse Series selective laser sintering (SLS) 3D printer with Nylon 12 Powder and a Form 4 stereolithography (SLA) 3D printer for carbon fiber molds to start their new venture, BeSmart Bike.

Request a Free Nylon 12 Powder Sample Part

See and feel the quality of our general-purpose nylon powder firsthand. We’ll ship a free sample part to your office.

Facing Off With AI

Dmochowski knew that to stay profitable in a rapidly changing market, Artnova needed to diversify its offerings. With AI tools becoming more capable of producing high-quality renderings, visualizations, and graphic designs, he needed to find an alternative product with a new customer base. The idea came to him as he looked to customize his own bike and had difficulty sourcing the right parts and attachments. “I thought, ‘Why not design and print them ourselves?’" says Dmochowski.

The team was used to 3D printing, and after designing the first prototypes in Plasticity, they printed them on a large-format fused deposition modeling (FDM) 3D printer, the Prusa XL. Though they were able to find customers via Etsy nearly right away, the feedback on the FDM parts wasn’t positive. “Customers often complained about surface finish on FDM parts,” says Dmochowski.

Functionality was only part of the problem — for end-use parts, aesthetic appeal and high-quality surface finish are nearly as important. The negative feedback from those initial customers prompted the ARTNOVA team to look for an option that could deliver end-use functionality, weather-resistance, long-term durability, and a slick surface finish that could blend in with a high-end bike frame.

Fuse Series for In-House Manufacturing

The end-to-end workflow of the Fuse Series ecosystem made it simple to learn and operate for the entire ARTNOVA team.

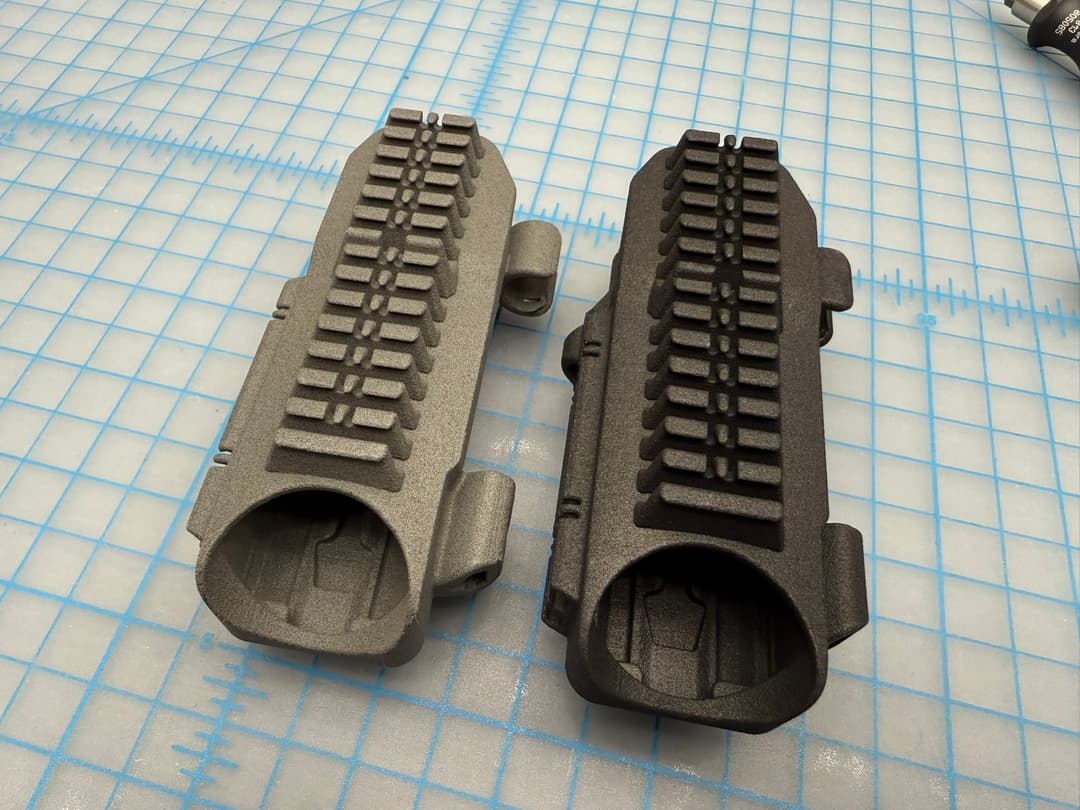

With help from Formlabs’ Polish partner CADXPERT, ARTNOVA expanded their 3D printing capabilities and added a Fuse 1+ 30W. Right away, the difference in surface finish and functionality was worth it. “SLS offers much better surface quality and far more design freedom. You don’t have to worry about supports or post-processing them. Customers noticed the difference immediately,” says Dmochowski.

The choice to bring the Fuse Series in-house as a manufacturing method was in part due to ARTNOVA’s penchant for well-designed tools. As designers and artists themselves, the team prefers to work with fabrication technologies that are simple and streamlined.

The SLS 3D printed bike component (round part, underneath seat) enables customers to further customize their bikes for added comfort and functionality.

The accuracy and dimensional reliability of the Fuse Series make it easy to fabricate components that have to fit onto existing structures. SLS 3D printing makes in-house manufacturing of aftermarket parts like these possible.

“Formlabs designs beautiful machines and accessories that create a consistent ecosystem — visually and in terms of UX. I genuinely appreciate good design. Maybe it’s not the most “engineering-driven” selection criterion, but I like using well-designed tools and having nice things around me.”

ARTNOVA Director Artur Dmochowski

The integration process was easy — with technologically capable engineers on staff, both the printer installation and the first prints went smoothly. Learning was easy, Dmochowski told us, “We have a very competent team and we learn quickly, so the learning curve wasn’t a major problem for us.”

Moving Forward With Carbon Fiber Molds and More

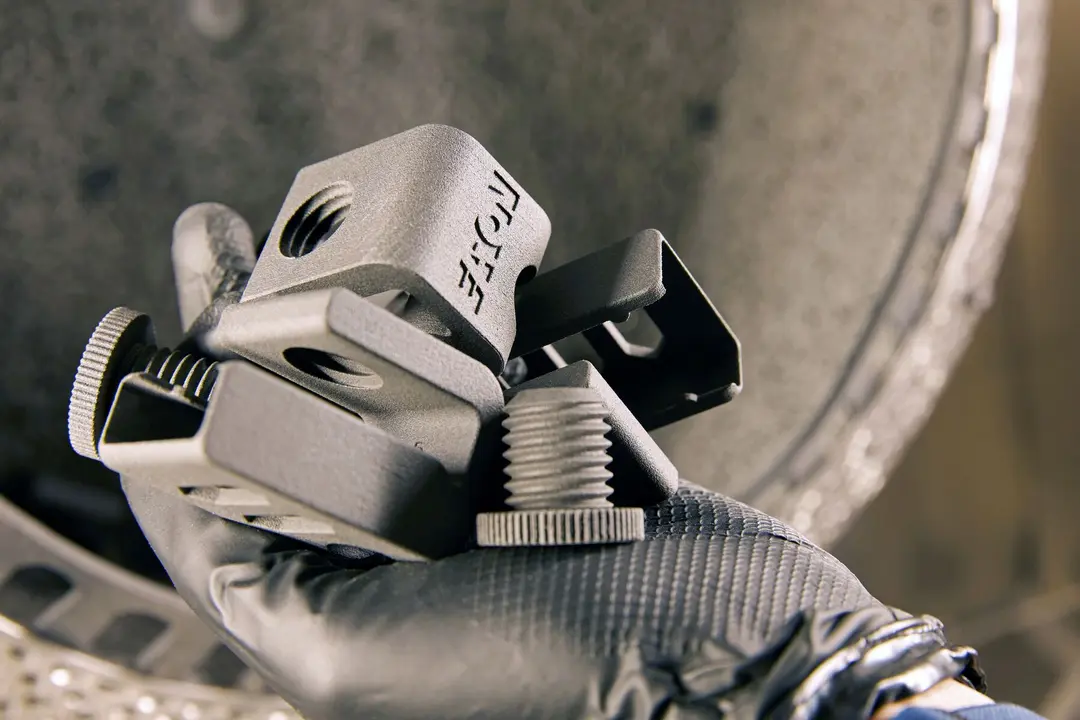

With minimal time spent post-processing SLS parts, the team can focus on developing new product designs and working on accessory workflows, like producing SLA 3D printed molds for carbon fiber parts.

ARTNOVA’s production continues to increase as their customer base grows. Competitors, both large manufacturers of bikes and bike components, as well as smaller, more local sellers, aren’t able to keep up with ARTNOVA’s ability to take customer requests and create new products nearly immediately.

Working with the Fuse Series in-house means that the team can produce low volumes of end-use parts cost-effectively; they don’t need to involve larger manufacturers or injection molding for anything. The entire workflow, from design to getting parts in the hands of customers, can be accomplished in just a few days. Their product catalog can remain extensive without causing an undue headache in terms of part storage and production planning — everything can be made on-demand with no lead time, thanks to the Fuse Series in-house.

Customization and single-person orders are possible too, helping ARTNOVA develop a strong and supportive customer base. From their first customers found on Etsy to their larger community today, SLS 3D printing helps them answer requests for everything from clips to custom accessories.

Moving forward, the ARTNOVA team purchased the Form 4 SLA 3D printer as well, to start making molds for carbon fiber parts. “We’re planning to produce molds for carbon-fiber parts, which we’ll use to manufacture certain types of mounts. SLS will absolutely remain part of our production — we expect strong demand from spring onward. We’re also considering a second Fuse printer and potentially a Form 4L. As I mentioned, I’m a big fan of Formlabs,” says Dmochowski.

To learn more about the Fuse Series, visit our page. To see the strength of Nylon 12 Powder for yourself, request a free SLS 3D printed sample.