Throughout history, artisans have used molds to make everything from Bronze Age weaponry to modern-day consumer products. While early molds were commonly shaped in stone, modern science has given rise to materials that are far easier to work with, such as silicone.

Today, a vast array of industries rely on silicone molding. Product developers, engineers, DIY makers, and even chefs all make silicone molds to create one-off or smaller runs of parts.

In this practical guide to silicone mold-making, we’ll break down everything you need to know before getting started, provide a list of items you’ll need, and give you a step-by-step guide for incorporating silicone molds into any type of project.

Silicone Molding For Product Design

Download this report for case studies featuring OXO, Tinta Crayons, and Dame Products that illustrate three different implementations of silicone molding for product design and manufacturing, including overmolding and insert molding.

Why Make Silicone Molds?

Silicone is a strong choice for mold-making because it offers such a diverse array of benefits. You can easily create custom designs using silicone molding. The molds themselves are also quite durable, so you can use them repeatedly without fear of breakage. Silicone’s inorganic makeup—compared to rubber, its organic counterpart—makes it highly resilient to heat and cold, chemical exposure, and even fungus. Some of the benefits of silicone molds include the following:

Flexibility

Silicone’s flexibility makes it easy to work with. Silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a part is fully formed. Thanks to silicone’s high level of flexibility, both the mold and the fabricated part are less likely to break or chip. You can use custom silicone molds to shape everything from complex engineering components to holiday-themed ice cubes or confections.

Stability

Silicone withstands temperatures from -65° to 400° degrees Celsius. Additionally, it can have an elongation of 700%, depending on the formulation. Highly stable under a broad range of conditions, you can put silicone molds in the oven, freeze them, and stretch them during removal.

Durability

In most cases, you’ll get many runs out of a silicone mold. However, it’s important to note that the life span of molds can vary greatly. The more frequently you cast, and the more complex or detailed your design, the faster your mold might degrade. To maximize the life of your silicone molds, clean them with mild soap and water, dry them thoroughly, and store them flat without stacking.

Limitations

While there are a lot of benefits to working with silicone, there are also a few limitations to be aware of:

-

Silicone costs more than latex and organic rubbers. A quick comparison on Amazon shows a gallon of silicone regularly topping $100—almost twice as much as latex.

-

Though it’s flexible, silicone can tear if stretched too far.

-

Not all silicone is formulated equally. Always purchase silicone and any manufacturing materials from a reputable supplier.

Common Applications for Silicone Molds

Hobbyists and professionals alike rely on silicone molds because of their versatility and ease of use. Here are a few examples of industries and applications that make silicone molds to produce their products:

Prototyping

Silicone molding is used in prototyping and product development production across a wide range of industries. Because the cost for silicone molds is substantially lower than hard tooling for traditional manufacturing processes like injection molding, casting in silicone molds is ideal for prototyping product designs as well as creating beta units for testing the market and consumer response to a new product. While 3D printing is better suited for creating one-off parts quickly, silicone molding and urethane casting can be ideal for smaller runs of parts.

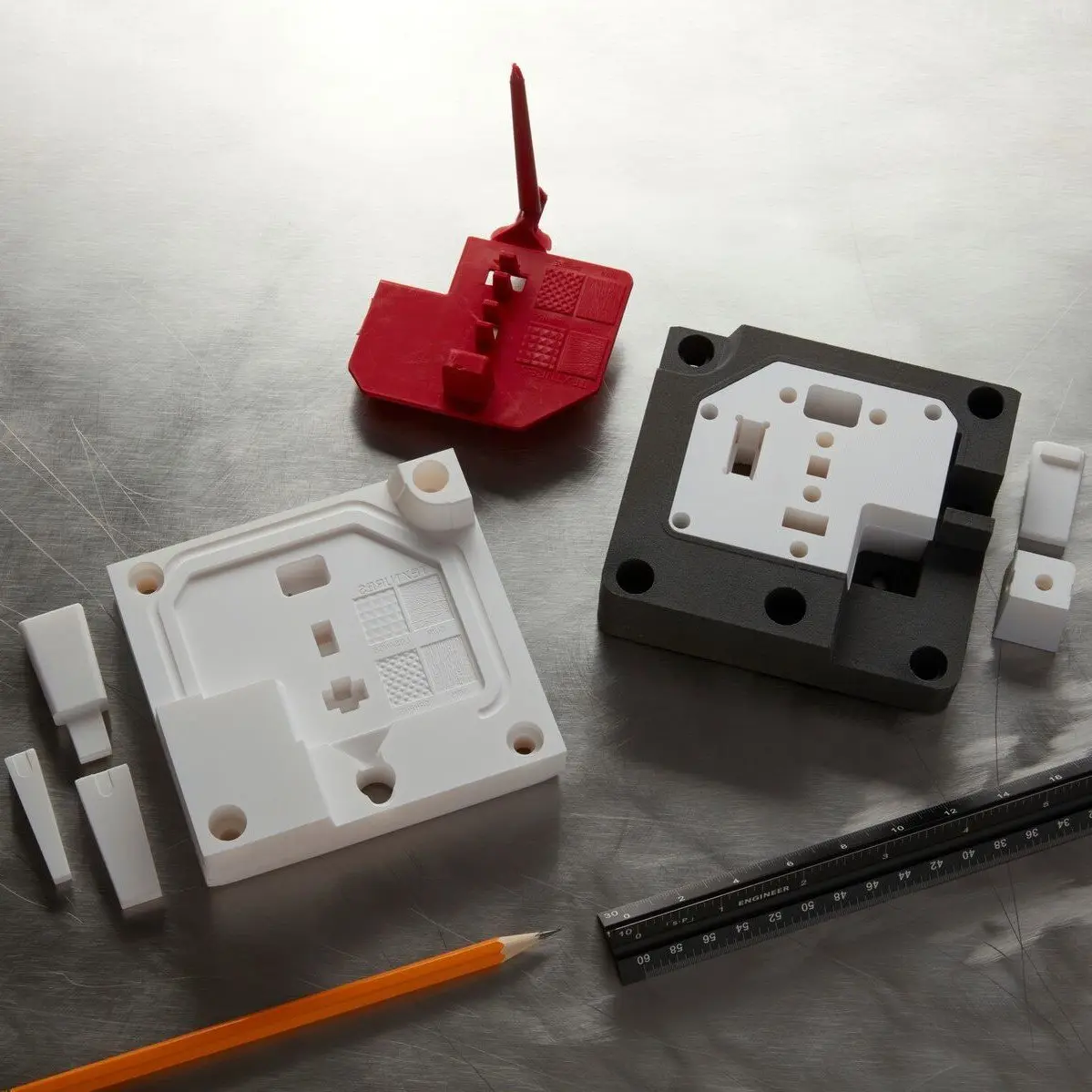

Bridging Production with 3D Printing and Urethane

Bridge production is faster than traditional manufacturing methods and is useful for products where the volumes are low or the design may need to change. Watch this webinar to learn how to switch from 3D printing to mid vol casting to injection molding.

Watch the WebinarJewelry

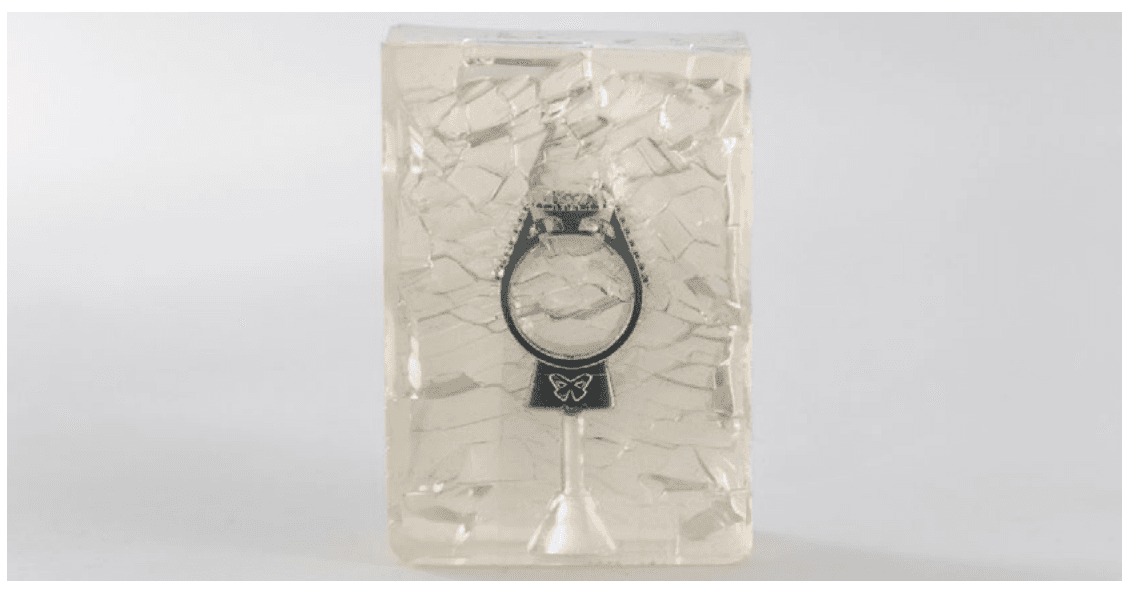

Jewelers use custom silicone molds to duplicate hand-carved or 3D printed patterns in wax, allowing them to phase out the time-consuming labor of creating wax-carved patterns for each new piece, but still continue to cast from wax. This offers a major leap in serial production, making it possible for investment casting to work at scale. Because silicone molds capture a fine level of detail, jewelers can produce pieces with ornate details and intricate geometries.

An RTV (room-temperature-vulcanized) silicone mold formed around the 3D printed master.

Vulcanized Rubber Molding with 3D Printed Masters

3D printing with high-performance materials allows designers and casters to leverage digital technology in their production processes. Read now to learn how 3D printing can be used in the production of small metal parts.

Download White PaperConsumer Goods

Creators use silicone molds to make many custom crafts such as soaps and candles. Even manufacturers of school supplies often use silicone molds to form items such as chalk and erasers.

For example, Tinta Crayons, a small Australia-based company, uses silicone molding to manufacture crayons with playful shapes and high surface detail.

Silicone-molded robot crayons from Tinta Crayons. (Image Source)

Food and Beverage

Food-grade silicone molds are used to form all sorts of whimsical confections, including chocolates, ice pops, and lollipops. Since silicone can handle heat up to 400° degrees Celsius, molds can be used in cooking, too. Small baked goods such as muffins and cupcakes rise nicely in silicone molds.

DIY Projects

Independent artists and DIYers often use silicone molding to craft unique creations. You can use silicone molds to form or replicate everything from bath bombs to dog treats—the possibilities are nearly endless. A fun silicone molding project for kids is to create a lifecast of their hand. Just make sure you choose a skin-safe silicone.

How To Make Patterns for Silicone Molding

A pattern—sometimes referred to as a master—is the part you use to create a precise negative in your silicone mold. If you are simply trying to replicate an existing object, it might make sense to use that object as your pattern. You’ll just need to be sure that the object can withstand the mold-making process.

To create a new design or prototype, you must first fabricate your pattern; you have several options for this. Here are a few ways to make patterns for silicone molding:

-

Sculpting – If you’re a talented sculptor or if you’re creating a relatively simple design, you can use clay to create a pattern. Sculpting a pattern is also a fun project for kids and a cost-effective option for DIYers.

-

Carving – You can make your pattern out of wood. Carved wood masters are an excellent choice for making tiles and flat designs.

-

3D printing – Many professionals and commercial designers choose to 3D print patterns. Desktop 3D printers offer many benefits, including design flexibility within CAD software, high accuracy, ease of prototype modification, and quick turnaround times.

Once you have a pattern, you can get started with making your silicone mold.

Guide to Rapid Tooling

In this white paper, learn how to combine rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or casting.

Getting Started with Silicone Mold-Making

Here’s everything you’ll need to build a basic silicone molding kit:

-

A master pattern

-

Liquid silicone, such as Smooth-On OOMOO 30

-

A box or nonporous container for the mold housing

-

Mold release, such as Smooth-On universal mold release

-

Wax, resin, or other end-use material

One-Piece vs. Two-Piece Silicone Molds

Before you start making your molds, you’ll need to determine which type of mold(s) you want to create.

One-piece silicone molds are like ice cube trays. You fill the mold and then let the material set. However, just as an ice cube tray creates cubes with a flat top, one-piece molds will only work with designs that have a flat side. If your master has deep undercuts, that also makes it harder to remove it and the finished parts from the mold once the silicone sets without damage.

When these are not a concern for your design, a one-piece silicone mold is an ideal way to create a seamless 3D reproduction of your master on all of its other surfaces.

One-piece silicone molds are ideal for designs that have a flat side and no deep undercuts.

A two-piece silicone mold is better for reproducing your 3D master without a flat side or has deep undercuts. The mold splits into two pieces that join back together, forming a fillable 3D cavity (similar to how injection molding works).

Two-piece molds leave no flat surfaces and are easier to work with than single block molds. On the downside, they are a bit more complex to create and seams may form if the two pieces aren’t perfectly flush.

Two-piece silicone molds can reproduce any master design. (image source)

How to Make Silicone Molds

First, you’ll need to decide if you want to use a one-piece or two-piece mold. The processes for making these molds are similar, but it will take a bit longer to create a two-part mold. You can use the following step-by-step instruction to create your own silicone molds.

One-Piece Silicone Mold

-

Create your product master: This is your final part design, which will be replicated in another material. When 3D printing on a stereolithography (SLA) 3D printer, use any Standard Resin with a layer height of 50 microns. Keep the detailed surface free of support marks. Wash the parts thoroughly with IPA—any residual tackiness on the surface can affect the silicone molding process.

-

Construct the mold housing: Coated MDF is a popular choice for constructing a containment box for the silicone mold, but even a simple premade plastic container will do. Look for nonporous materials and a flat bottom.

-

Lay out the master and apply mold release: Start by lightly misting the inside of the mold housing with mold release. Tile the masters inside the box with the detailed side up. Lightly spray these with mold release as well. This will need about 10 minutes to dry thoroughly.

-

Prepare the silicone: Mix the silicone rubber according to the package instructions. You can use a vibrating device like a handheld electric sander to remove air bubbles.

-

Pour the silicone into the mold housing: Gently pour the mixed silicone rubber into the containment box in a narrow stream. Aim for the lowest part of the box first (the base) and gradually come up the contours of your 3D printed master. Cover it with at least one centimeter of silicone. The curing process will take from one hour to one day to complete, depending on the silicone type and brand.

-

De-mold the silicone: When curing is complete, peel the silicone out of the containment box and remove the masters. This will serve as your ice cube tray-style mold for casting your end-use product.

-

Cast your part: Again, it’s a good idea to lightly spray the silicone mold with mold release and let it dry for 10 minutes. Pour your end-use material (wax or concrete, for example) into the cavities, and allow to cure.

-

Prepare the mold for the next casting: You can use this silicone mold multiple times. Return to step seven to repeat the process.

Two-Piece Silicone Mold

To create a two-part mold, start by following the first two steps above, which include creating a master and constructing the mold housing. After that, follow this process to create a two-part mold:

-

Lay out the masters in clay: Use the clay to form what will eventually be one half of your mold. The clay should be placed inside your mold housing with half of your master sticking out of the clay.

-

Prepare and pour your silicone: Follow the package instructions included with your silicone to prepare and gently pour the silicone into your mold housing on top of the clay and your masters. This layer of silicone will be one half of your two-piece mold.

-

Remove everything from the mold housing: Once your first mold has cured, you’ll need to remove the silicone mold, masters, and clay from the mold housing. It’s okay if the layers separate upon extraction.

-

Clean away the clay: Clean all of the clay away to reveal your first silicone mold and masters. Make sure your masters and your existing mold are completely clean.

-

Place the mold and masters back in the mold housing: Insert both your existing silicone mold and the masters (laid in the mold) back into the mold housing facing up instead of down.

-

Apply release agent: Apply a thin layer of release agent to the top of your master and existing silicone mold to make de-molding easier.

-

Prepare and pour the silicone for your second mold: Following the same instructions as before, prepare and pour the silicone into the mold housing to create your second mold.

-

Wait for your second mold to cure: Allow plenty of time for your second mold to cure before attempting to remove it from the mold housing.

-

De-mold your parts: Remove both silicone molds from the mold housing and gently pull them apart.

A World of Possibilities with Silicone Molding Techniques

At the end of the day, there’s no one right way to make products, whether they’re food, figurines, or commercial components. Various production methods are frequently used together to achieve the best results; understanding all of their unique advantages and disadvantages will help you make the best decisions for your project.

Want to discover more techniques and applications for silicone mold-making? Download our Silicone Molding for Product Design white paper.