Fuse Blast Polishing System

PKG-FS1-FB-PS-01

Estimated delivery: Mar 5 - 10The Fuse Blast Polishing System is a drop-in upgrade to the Fuse Blast that allows users to add a smooth, semi-gloss, scuff-resistant, and dye-ready surface finish to their SLS printed parts.

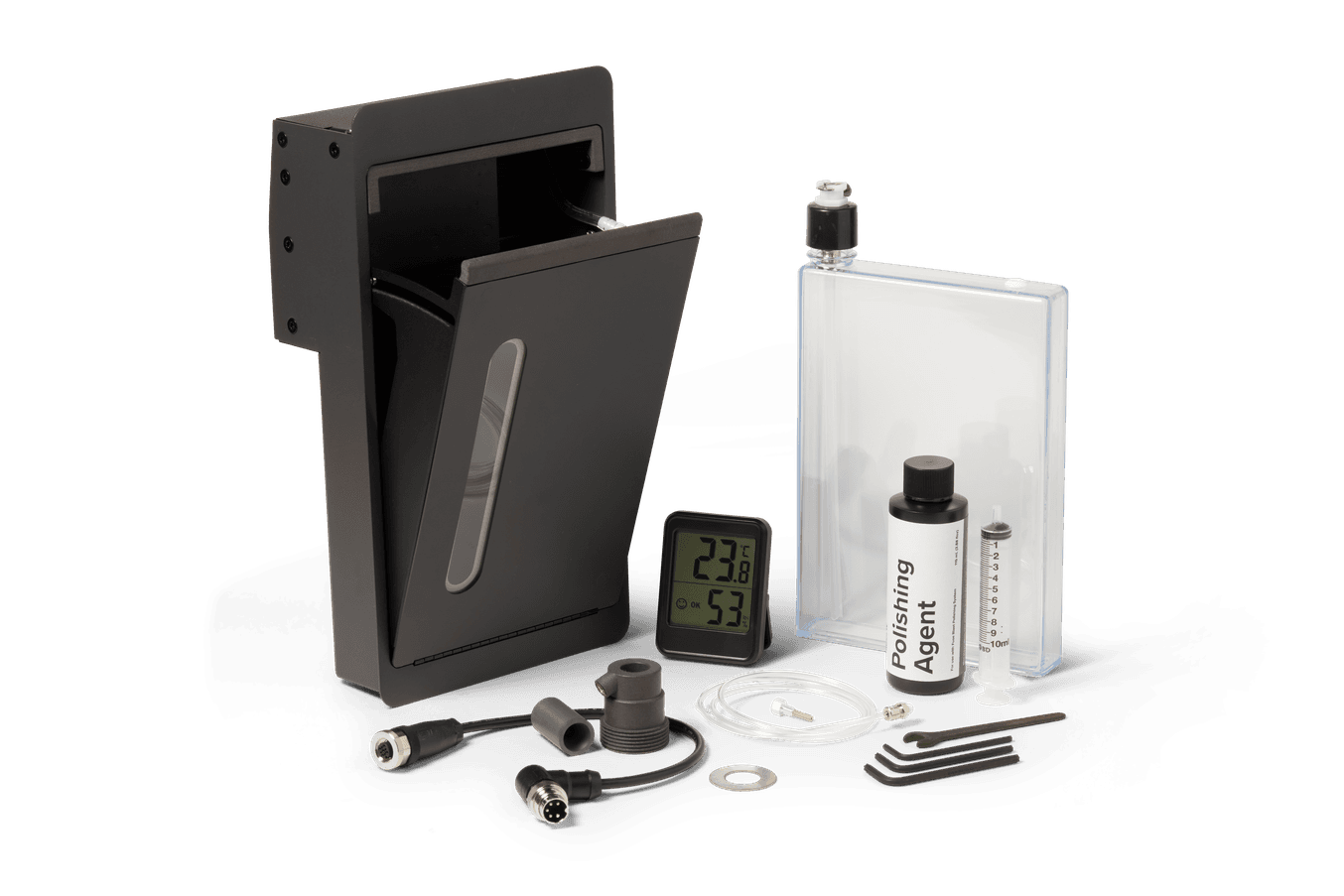

This single-step add-on to the Fuse Blast both cleans and polishes your parts straight from the Fuse Sift without the need for another Blast. The Polishing System is compatible with any Fuse Blast and includes:

1 - Fuse Blast Polishing Module

2 - Fuse Blast Polishing Media Jugs

1 - Fuse Blast Polishing Agent Bottle

- Fuse Blast Polishing Module

- Fuse Blast Polishing Media

- Fuse Blast Polishing Agent

- Fuse Blast Polishing Mesh

Why Choose Fuse Blast Polishing System

Consumer-Ready Parts

Produce professional SLS parts with a smooth, semi-gloss, and dye-ready surface finish for customer facing applications.

All-In One

Upgrade any Fuse Blast to clean and polish parts in a single step, straight from Fuse Sift.

Reliable Outcomes

By compacting the surface with polishing media, as opposed to abrasive smoothing or chemical surface melting, surface roughness is reduced without removing material.

Cost-Effective Solution

The most affordable solution for SLS surface finishing, in a simple and intuitive UX compared to competitive systems that require standalone units and/or specialized training.

How It Works

While standard glass-blasting leaves a rough, matte surface, the Polishing System cleans and smooths parts in one step through impact polishing. The Polishing Module doses and aerosolizes a small amount of Polishing Agent solution in the blast stream to condition the Polishing Media. This media compacts the part surface, achieving a smooth, semi-gloss finish without removing material, similar to shot peening.

A minimum blasting pressure of 60 PSI is recommended for best results. Fuse Blast’s Adaptive Airflow feature enables lower-capacity compressors to handle this increased airflow requirement by pausing the cycle while the compressor recharges. This delivers an uninterrupted, hands-off experience for cleaning and polishing your consumer-ready, SLS parts.

Technical Specs

Fuse Blast Polishing System

Blast Polishing Time

Polishing Media Lifetime

Blasting Pressure

Polishing Agent Lifetime

Recommended Flowrate

Water Tank Volume

Compatibility