Strength from Metal: Strategies and Use Cases for Electroplating SLA Parts

This white paper covers how engineers are adding metal to resin 3D prints, and why hybrid metal parts can open doors to a surprising range of applications, including (but not limited to) improving end-use strength and durability. We will cover new ways to apply electroplating, as well as design considerations and practical tips for using metal electroplating to amplify the performance of your stereolithography (SLA) parts.

Strength from Metal: Strategies and Use Cases for Electroplating SLA Parts

This white paper covers how engineers are adding metal to resin 3D prints, and why hybrid metal parts can open doors to a surprising range of applications, including (but not limited to) improving end-use strength and durability. We will cover new ways to apply electroplating, as well as design considerations and practical tips for using metal electroplating to amplify the performance of your stereolithography (SLA) parts.

Introduction

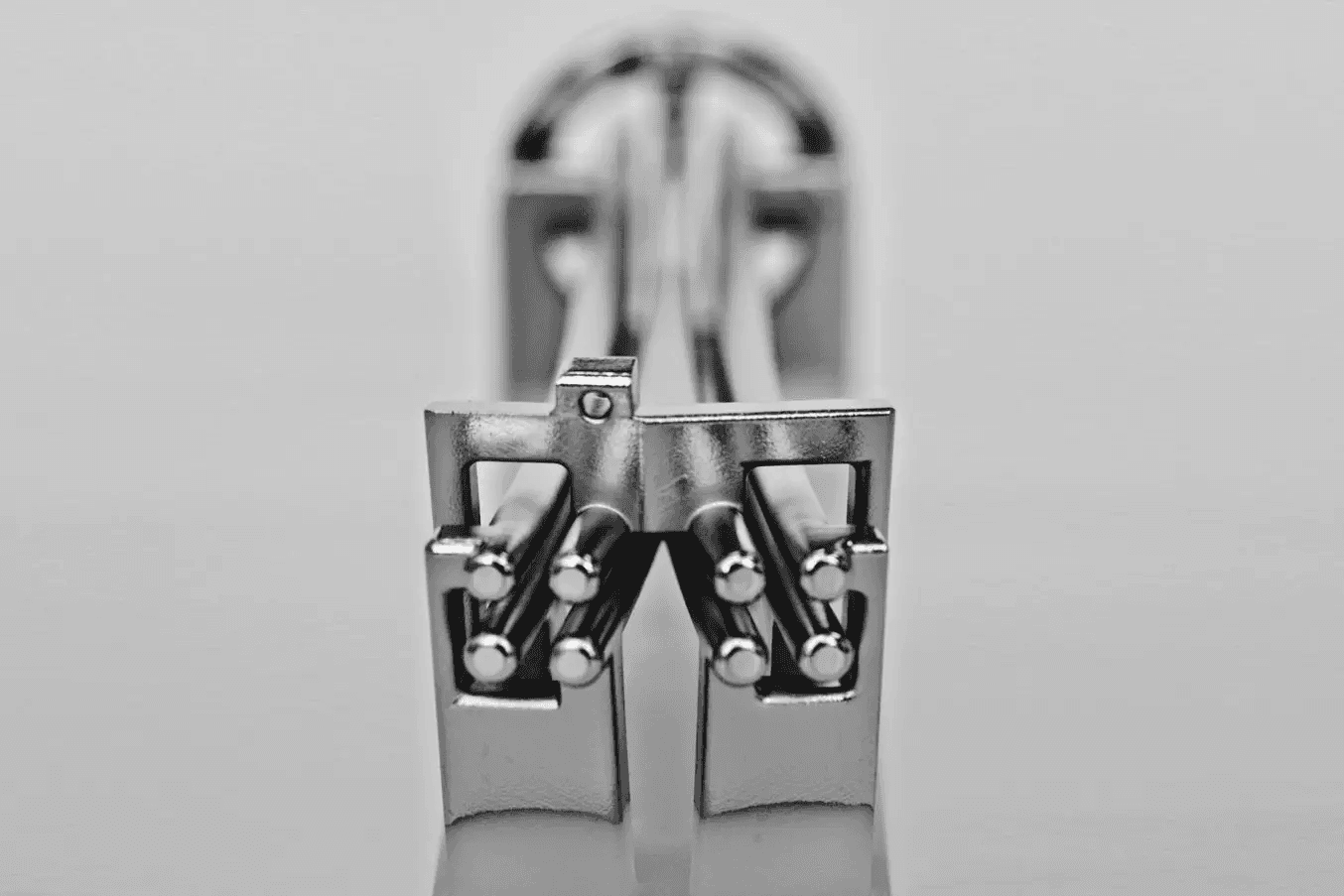

Plating is best known as a way to give metal parts a thin coating with different surface properties than the underlying material provides. Applications range from cosmetic (such as gold plated jewelry) to functional (such as the use of electroplated nickel or chrome to protect metal parts from corrosion). However, electroplating is not exclusively applied as a thin film over metal. Electroplating plastic 3D prints is becoming more common thanks to its unique ability to transform an easy-to-print resin part into a metal-like composite, with applications in the automotive industry, defense, and consumer product prototyping.

Electroplating resin creates conductive parts that enable high-performance radio frequency applications, like this part from Elliptika.

Metal electroplating can have a major impact on the mechanical performance of 3D printed parts. With a structural metal skin and a lightweight resin core, parts can be produced with surprisingly high flexural strength characteristics.

In addition to improving mechanical behavior, electroplating can be used to protect SLA resins from environmental degradation. In applications where SLA resin is exposed to chemical attack or ultraviolet light, plating provides a permanent barrier that can extend the life of your parts from months to years.

When used as an aesthetic treatment, plating offers an easy way to create prototypes that both look and feel like metal. Depending on the plate thickness, electroplated plastic can be thin and light, or add noticeable weight to a part. Thicker electroplated coatings can even be texturized or polished to achieve a variety of metal finishes, from cast aluminum to mirrored chrome. More complex textures can be achieved by 3D printing a textured resin substrate.

Given the potential combinations of 3D printable materials, a variety of plating metals, and plate thickness ratios, it’s easy to see how electroplating gives engineers a new field of design options to consider.

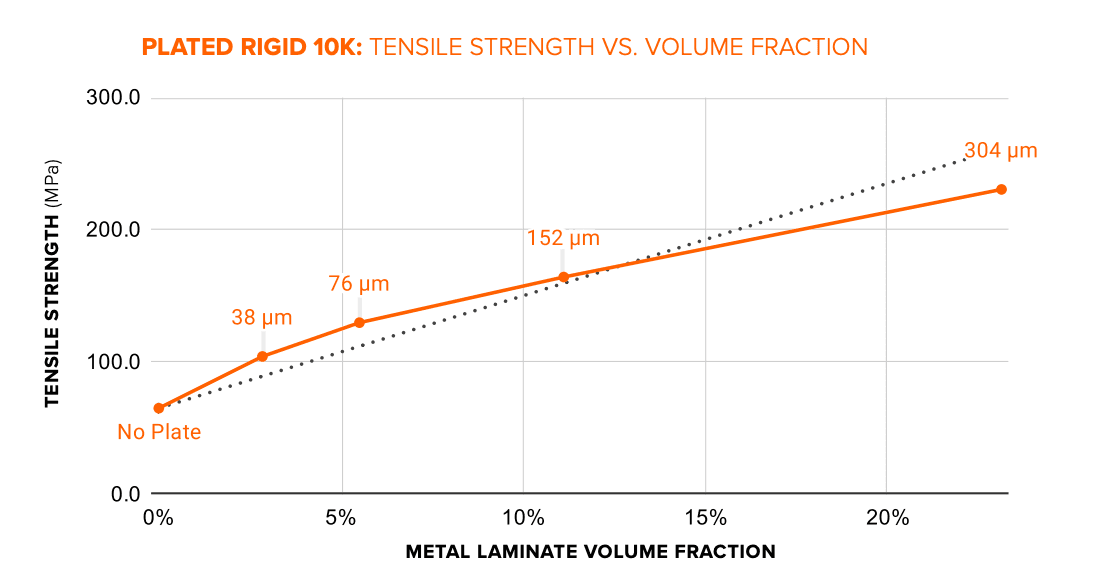

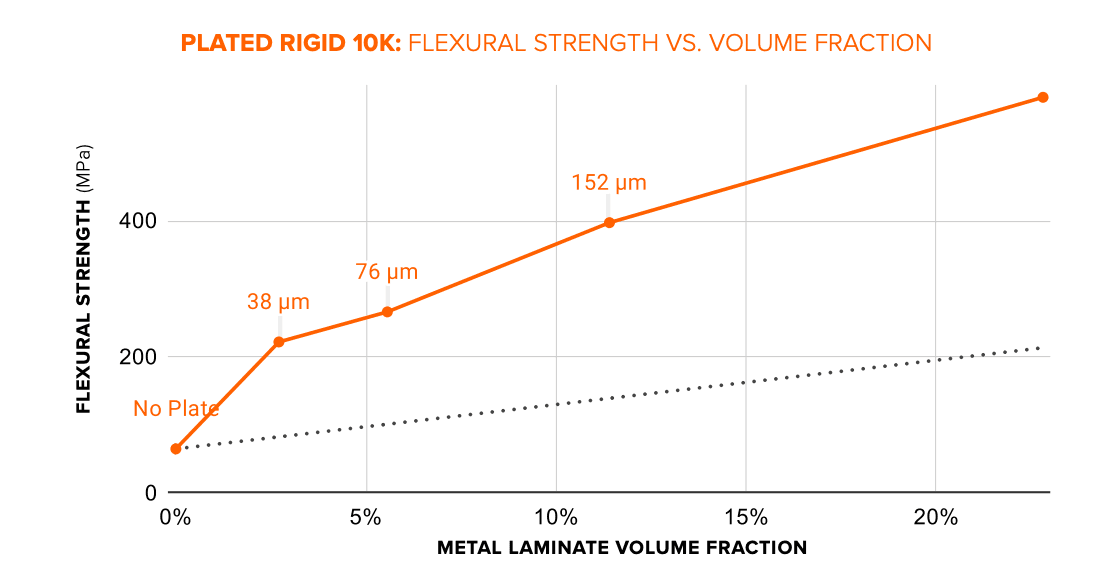

Formlabs partnered with electroplating service provider RePliForm to put data behind the claim that plated parts are significantly stronger than unplated 3D prints. We tested the tensile (ASTM D 638-14) and flexural (ASTM D 790-15) mechanical properties of plated samples produced with a range of ratios of metal to resin. The results show a significant improvement in tensile strength and a dramatic increase in stiffness.

How Plating Over Plastic Works

Electroplating is most commonly applied to metal parts because the basic requirement is that the underlying material (the substrate) is conductive. Although less common, autocatalytic pre-coatings have been developed which produce an ultra-thin conductive interface, allowing a variety of metals — most notably copper and nickel alloys — to be plated onto plastic parts.

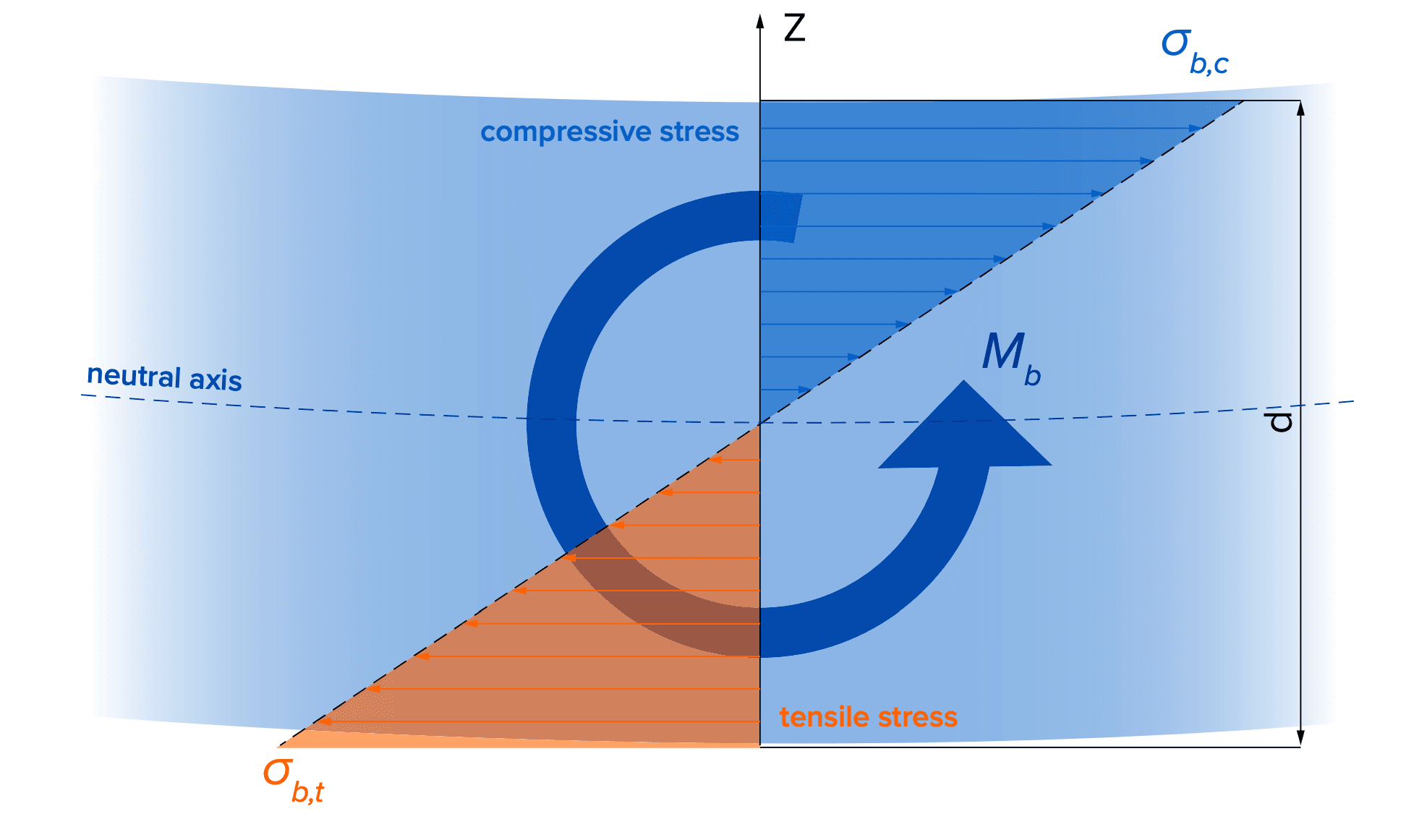

Strength and Properties of Electroplated Parts

When structures experience bending forces, tensile and compressive forces concentrate towards the surface. As a result, electroplating just the surface of a part with a high-strength metal tends to have a disproportionate effect on part strength. Depending on the geometry, structural electroplating typically improves bending and tensile strength, and increases part stiffness.

The mechanical characteristics of plated parts depend greatly on the specifics of how plating is applied; a plated part involves several different layers of metals and plastic, with different contributions to strength, stiffness, and weight depending on their relative thicknesses. In many cases, both copper and nickel are used in tandem to produce a strong coating, where ductility can be adjusted based on the plating composition and sequence of metals applied.

Used as a weight-saving measure, hybrid plastic-metal parts can provide enough strength and stability to be a viable, efficient, and less expensive alternative to more labor-intensive methods such as fiber layup manufacturing. In fact, the stiffness-to-weight ratio of hybrid metal parts can even surpass fiberglass parts. Further on, we will explain how to estimate the mechanical properties of electroplated parts to aid you in the design and selection of plating composition.

By the Numbers

Formlabs partnered with electroplating service provider RePliForm, to put data behind the claim that plated parts are significantly stronger than unplated 3D prints. We tested the tensile (ASTM D 638-14) and flexural (ASTM D 790-15) mechanical properties of plated samples produced with a range of ratios of metal to resin. The results show a significant improvement in tensile strength and a dramatic increase in stiffness.

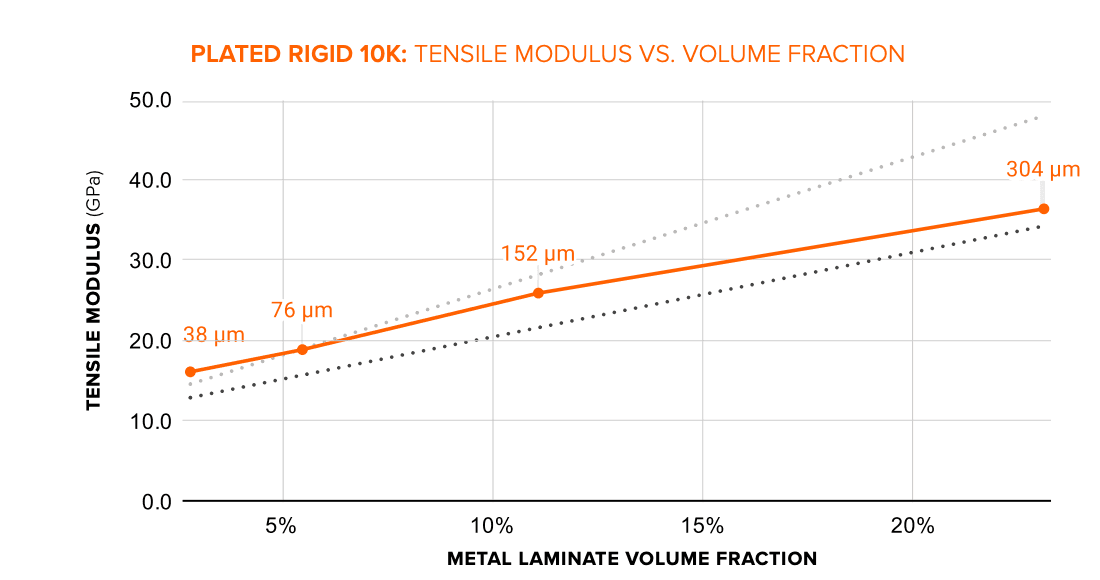

Electroplated Rigid 10K Resin Composite

Plate composition: ⅓ copper, ⅓ soft nickel, ⅓ hard nickel

| Volume Fraction | Tensile Modulus (GPA) | Modulus (%) Increase | Tensile Strength (MPA) | Strength % Increase |

|---|---|---|---|---|

| 0% | 10.0 | 0 | 65.0 | 0 |

| 3% | 16.2 | 62% | 104.1 | 60% |

| 6% | 19.0 | 90% | 129.6 | 99% |

| 11% | 26.0 | 160% | 164.1 | 152% |

| 23% | 36.5 | 265% | 230.3 | 254% |

We can see that the ultimate tensile strength of the plated Rigid 10K Resin part with 11% volume fraction metal has increased by 150% from the tensile strength of un-reinforced resin. Electroplating Rigid 10K Resin moves its properties into a range of mechanical properties that is sparsely occupied, but 30% glass-fiber filled polyester (207 MPa) may be the closest analog, especially when using higher volume fractions of metal (10-20%).

Materials Compared

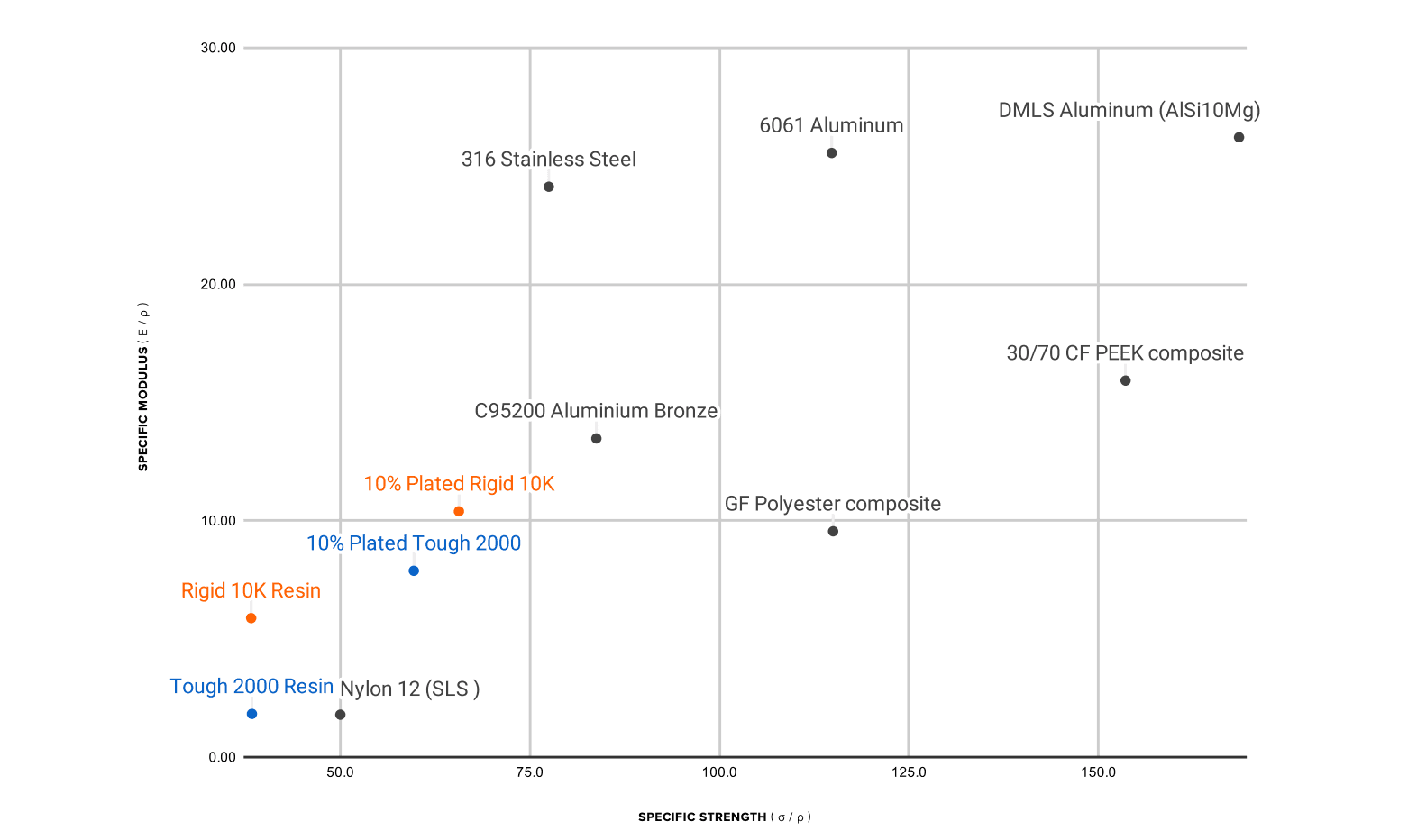

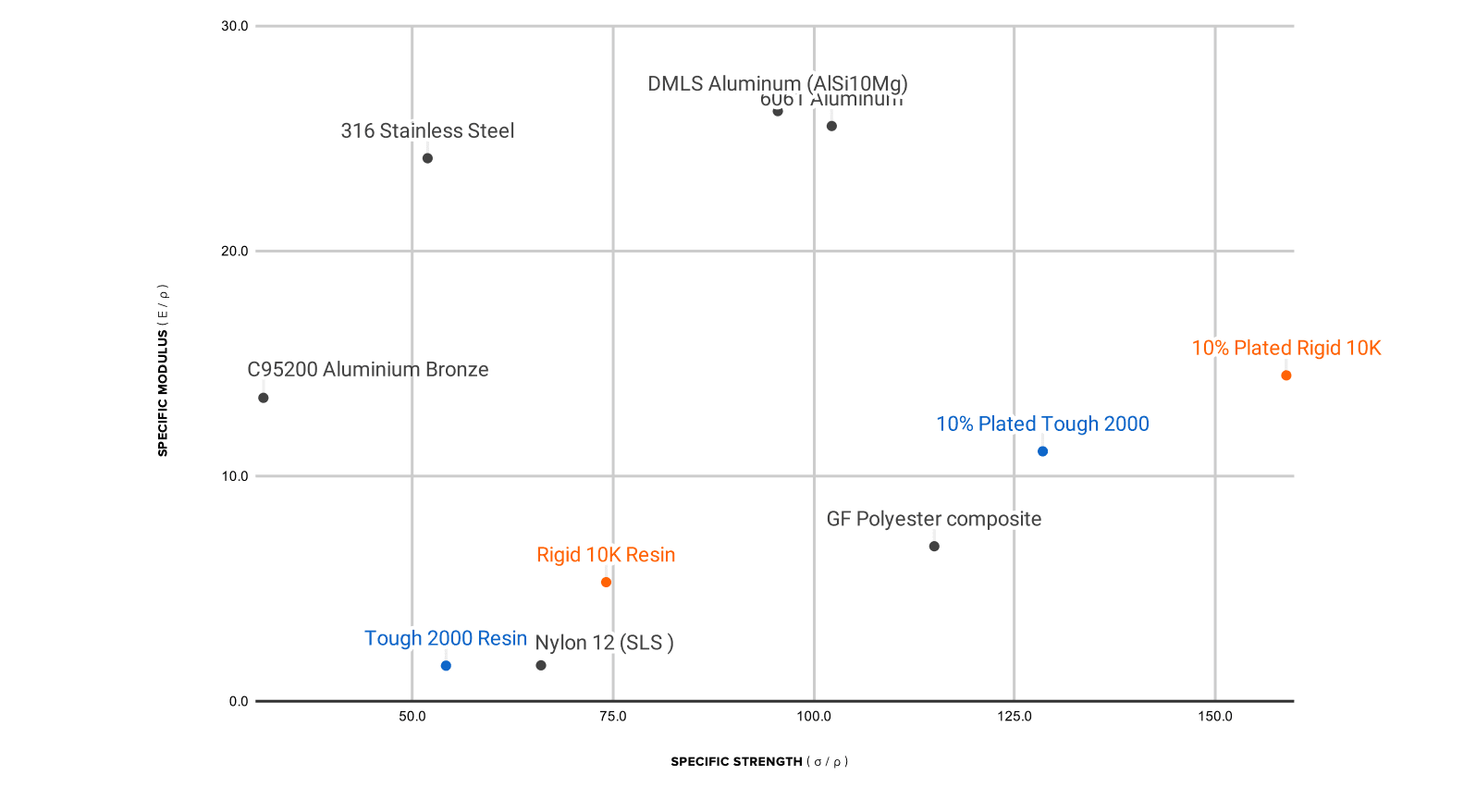

Specific strength and specific modulus are measures of a material’s strength-to-weight and stiffness-to-weight ratios. In order to compare electroplated parts to more familiar materials, we have plotted both specific strength and specific modulus for two plated materials, along with a few others that are nearby in the world of engineered materials.

The first thing we noticed is that plating either resin causes it to more than double in strength-to-weight compared to Nylon 12. Unsurprisingly, the tensile strength-to-weight ratio of oriented composites greatly exceeds that of plated, laminated composites. However, the story gets more interesting when we look at flexural properties. After all, we know that one of the weak points of plastics is their tendency to deform over time when they are subjected to long-term bending forces.

Definitions: A material with a high specific modulus will be stiff for its weight. A material with a high specific strength will be strong for its weight.

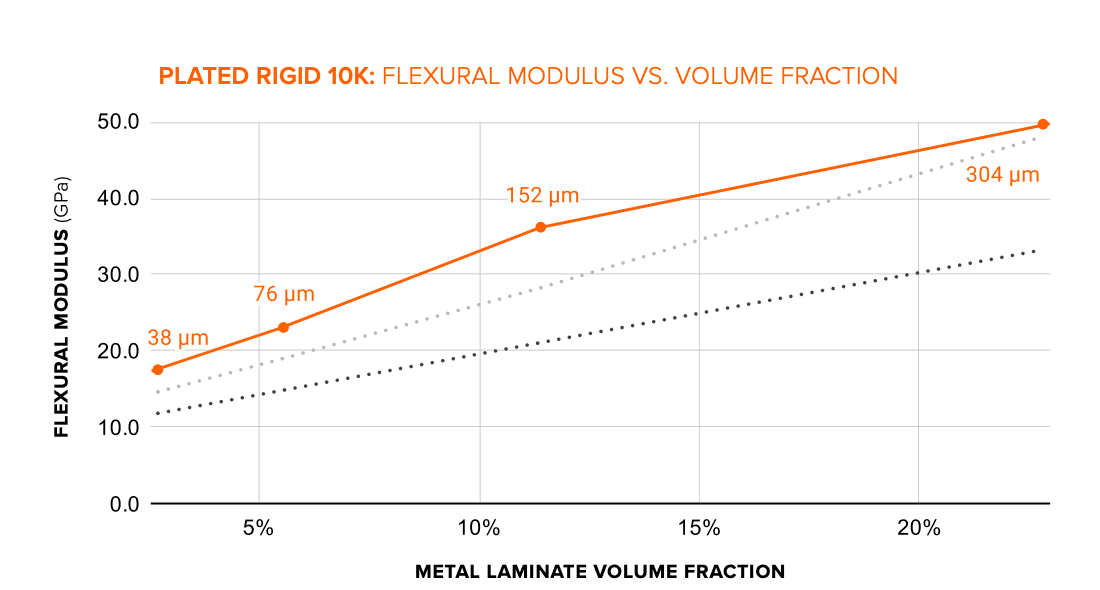

On the horizontal axis, we can see that the specific flexural strength of the 10% Plated Rigid 10K Resin surpasses some glass fiber composites and exceeds the strength-to-weight ratio of some metals, including aluminum, in bending conditions. If you need a lightweight, rigid, and strong material that will resist deformation, 10% plated Rigid 10K Resin is an interesting choice.

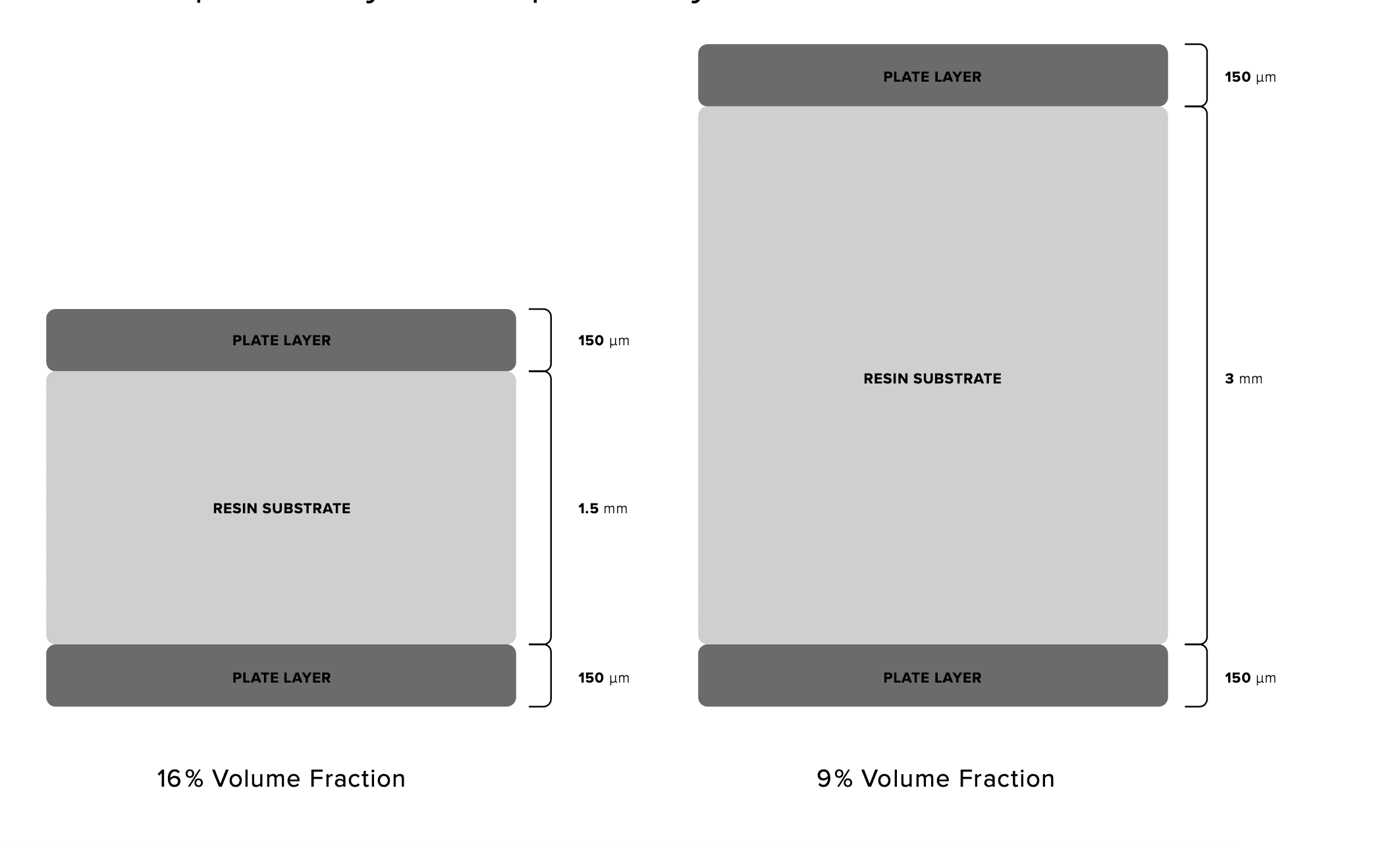

Volume Fraction of Metal Explained

It’s important to understand that “volume fraction of metal” in plated parts is not the same as “plated metal thickness.” Thick parts require a thicker plate to achieve the same volume fraction compared to thin ones. In absolute terms, thicker plate layers also tend to have a greater impact on dimensional accuracy (even when compensated for in CAD). Considering the effort, time, and added expense of electroplating, we see a volume fraction of about 10% as the sweet spot between improved mechanical properties, controllable part accuracy, and production efficiency.

In most cases, if your parts have a roughly constant wall thickness of between 3 and 5 mm - common for SLA resin parts and injection molded plastic - you will probably need between 150 and 300 microns of plate thickness to achieve a volume fraction of metal of around 10%.

Later on, we’ll show you how the volume fraction of metal relates well to tensile and flexural modulus, why it’s the right starting point for estimating the properties of your final part, and how to calculate the necessary plate thickness to achieve a desired part stiffness.

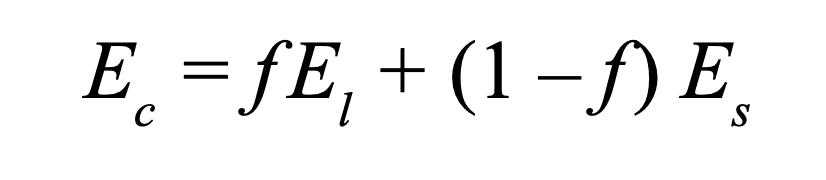

Estimating Mechanical Performance With ROMa

A basic but useful way to estimate the mechanical properties of a plated part is to use the “general rule of mixtures.” The rule of mixtures (ROM) is simple: the overall properties of a composite will be close to the volume-weighted average of the substrate and laminate’s properties.

Where:

Ec is the Modulus of Elasticity of the composite

f is the volume fraction of the laminate in the composite

El is the Modulus of Elasticity of the electroplated laminate

Es is the Modulus of Elasticity of the 3D printed resin substrate

This method was developed to be used with matrix composites with dispersed fillers (e.g., glass-reinforced plastic), but our results below show that the ROM also gives an acceptable approximation of the stiffness characteristics of electroplated composites.

Different methods of electroplating will produce metal layers with different mechanical properties, which may cause properties of the composite to differ based on who does the plating. As a whole, electrodeposited metal has slightly different properties from the bulk metal (e.g., cast copper or nickel).

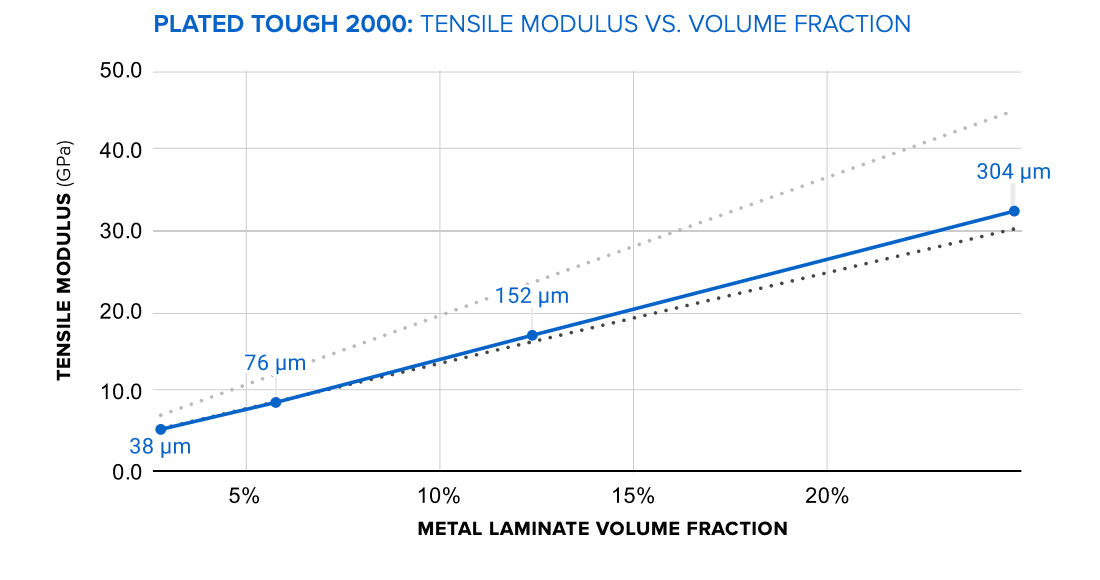

The lower dotted line represents the ROM calculated with values for electroplated copper and nickel found in engineering literature, while the upper dotted line corresponds to ROM from the bulk metals. We have found that for predicting tensile modulus, the electrodeposited metal values serve as a relatively accurate lower bound.

In order to apply the rule of Mixtures, we recommend using the following values for electroplated composites:

| Tensile Modulus (GPA) | Yield Strength (MPA) | Ultimate Tensile Strength (MPA) | |

|---|---|---|---|

| Electrodeposited Hard Nickel | 146 | 1288 | 1558 |

| Electrodeposited Soft Nickel | 140 | 607 | 860 |

| Electrodeposited Copper | 60 | 253 | 328 |

Note: Values given for electrodeposited metals provided by RePliForm, Inc.

Does the rule of mixtures work to estimate the effect of plating on tensile (or flexural) strength as well? In general, yes, at least in the case of our simple tensile test.

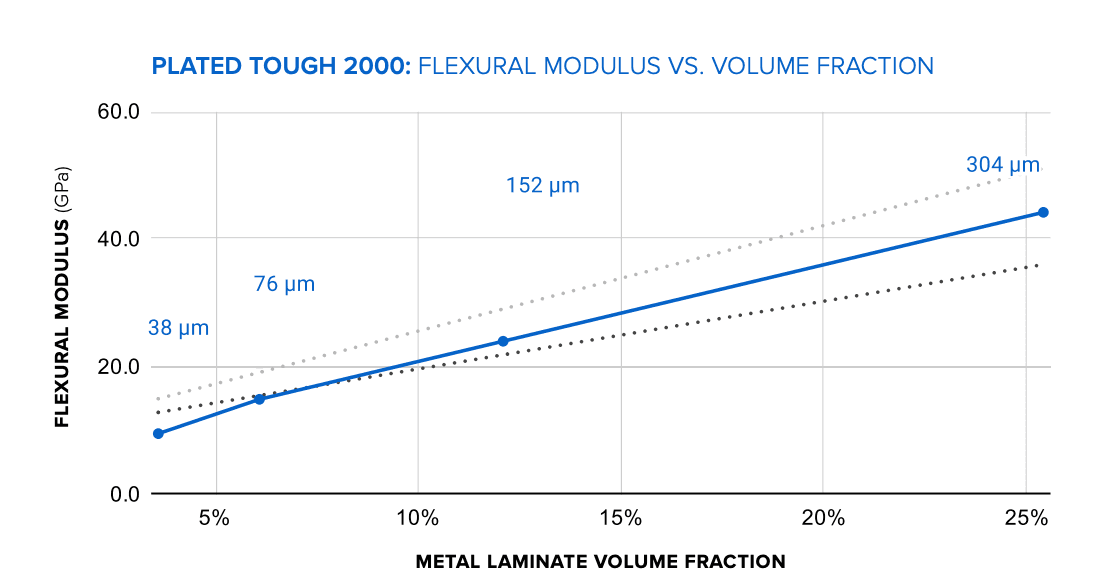

In the graph on the left, the slope of the Rule of Mixtures prediction tracks reasonably well with the actual results, providing a conservative estimate for volume fractions under 10%. We can see that flexural yield strength is even more dramatically improved over the unplated part. A modest 6% volume fraction of metal increases flexural strength by 4x.

The real-world flexural strength of the test parts greatly exceeded the Rule of Mixtures prediction. We speculate that, because copper has a higher elongation before break than the resin substrate, the substrate may have failed or delaminated while the metal was still intact, which could allow the sample to experience higher peak stress than would be expected if the two were acting in perfect unison. In flexural load applications, ROM can provide an even more conservative baseline for maximum yield strength, but is less useful for estimating peak load at failure.

Avoiding Part Failure

Real-world electroplated parts aren’t always a constant wall thickness, which means the volume fraction of metal is also rarely completely uniform across a part. Furthermore, ultimate failure modes in plated composites can sometimes be related to less-predictable mechanical effects such as delamination, rather than as a direct result of tensile strain. As a result, it is more difficult to predict the ultimate yield stress of plated parts as accurately as with homogenous materials.

Tip: You can minimize the chance of unexpected mechanical failure by using a substrate resin that has similar properties to the plated metal composition.

Since structural electroplating usually aims to improve stiffness characteristics, we recommend Rigid 10K Resin as the most predictable substrate material to use for most static applications. However, if your application requires higher impact resistance (or tolerance to higher strain), we suggest using a substrate such as Tough 2000 Resin or Tough 1500 Resin, which has a lower flexural modulus. The Tough & Durable Resin family of materials should be functionally matched with a thicker copper plate, and a thin nickel outer layer if necessary for corrosion or wear resistance.

The surface texture of the Formlabs Nylon 12 substrate is visible through a structural nickel plate in this aero fairing prototype (right).

In addition to substrate selection, it’s also wise to add radii to internal corners. Radiused edges reduce stress concentrations that might contribute to delamination, but also help in other ways; radiused internal corners clean more easily, and therefore metallize more reliably. Plating thickness is also more uniform in radiused corners than in a perfectly sharp corner.

It’s also a good idea to build in a larger factor of safety than you would with a homogenous material, to avoid stressing plated parts near their predicted limits. This can be done very easily via generative design, where surface area and volume density can be parametrized.

Leveraging Generative Design

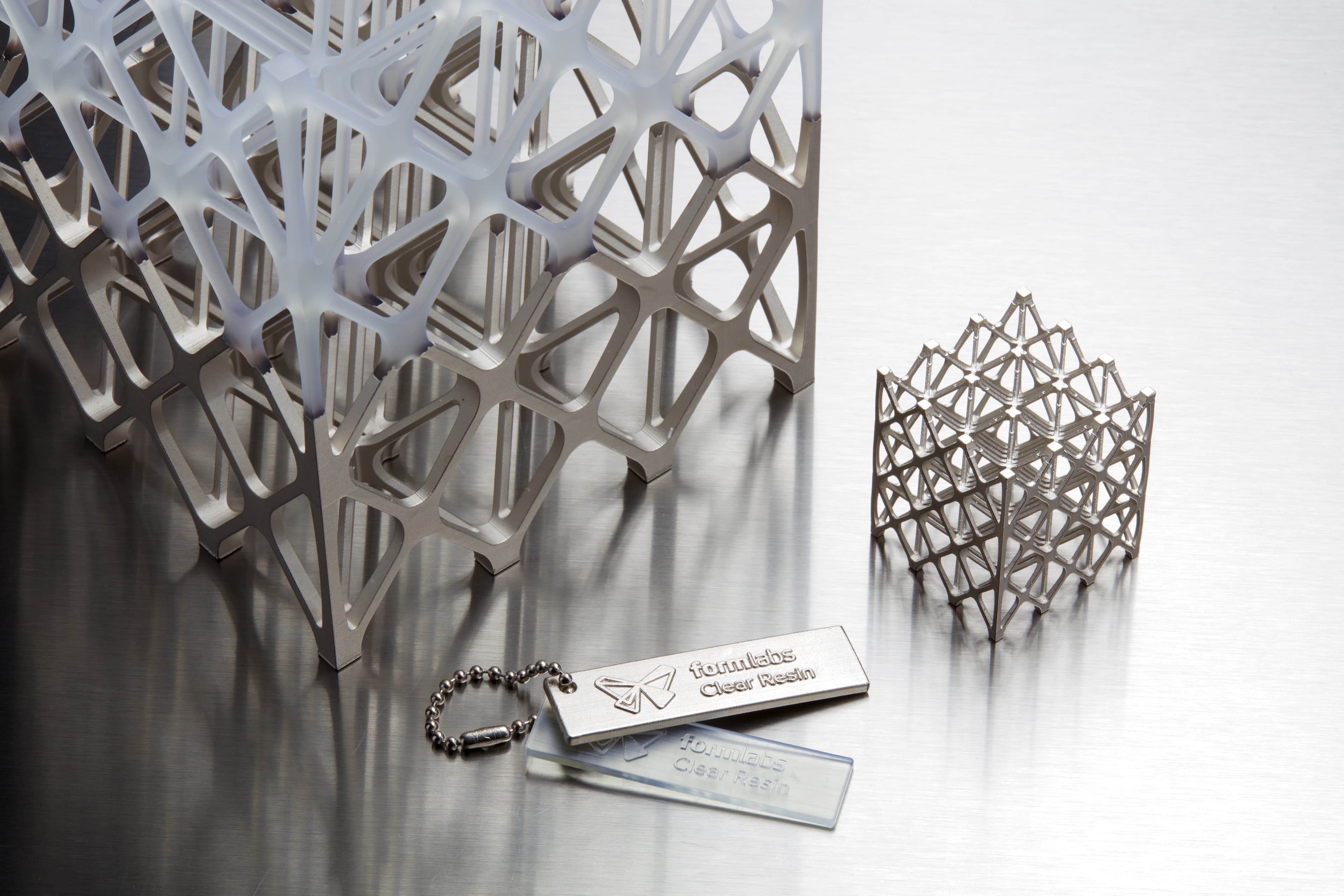

3D printing has the well known advantage of being capable of producing complex geometry with no added manufacturing cost. New techniques such as latticing and topology optimization, often seen in expensive direct-to-metal 3D printing, have emerged to take advantage of this feature.

Definitions: Topology optimization involves computationally reducing a part to the minimum material necessary to achieve specified design goals, while latticed parts replace solid mass with a light porous 3D mesh to reduce weight.

Both of these techniques have the side effect of increasing surface area and generating geometry with complex curvature, and together act synergistically to increase the stiffness of your design. When the surface-area to volume ratio is high, such as in a latticed structure, it is easier to achieve a higher metal volume fraction with a thinner plate - and that means your parts can be made both stiffer and more accurate.

Besides modifying the underlying shape of your parts, generative design tools such as nTopology Platform make it easy to add design features such as ribs, gussets, through-holes, and even surface texturing. These features improve the mechanical grip or “key” between the 3D printed resin substrate and the plate layer. As a general rule: the better the adhesion between substrate and coating, the stronger your part will be.

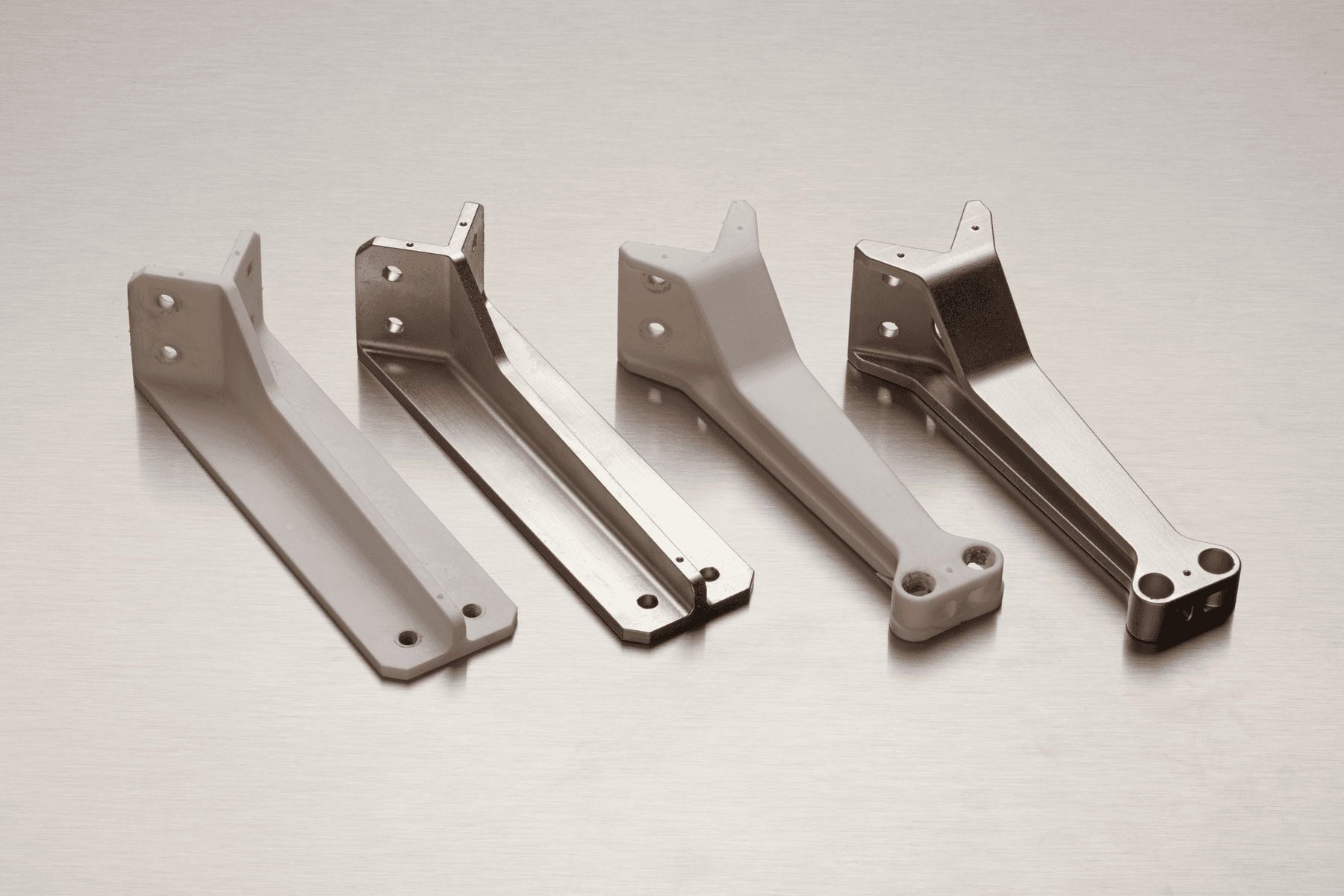

Case Study: Designing a Composite Bracket

How does an electroplated resin part solve a problem compared to other solutions? In order to study this question, Formlabs examined a 3D printed bracket used to mount a rack inset from the corner of a test enclosure. If a 3D printed bracket could stand in for the custom aluminum bracket, it could be produced with no shop time, for a fraction of the cost.

Applying the Rule of Mixtures

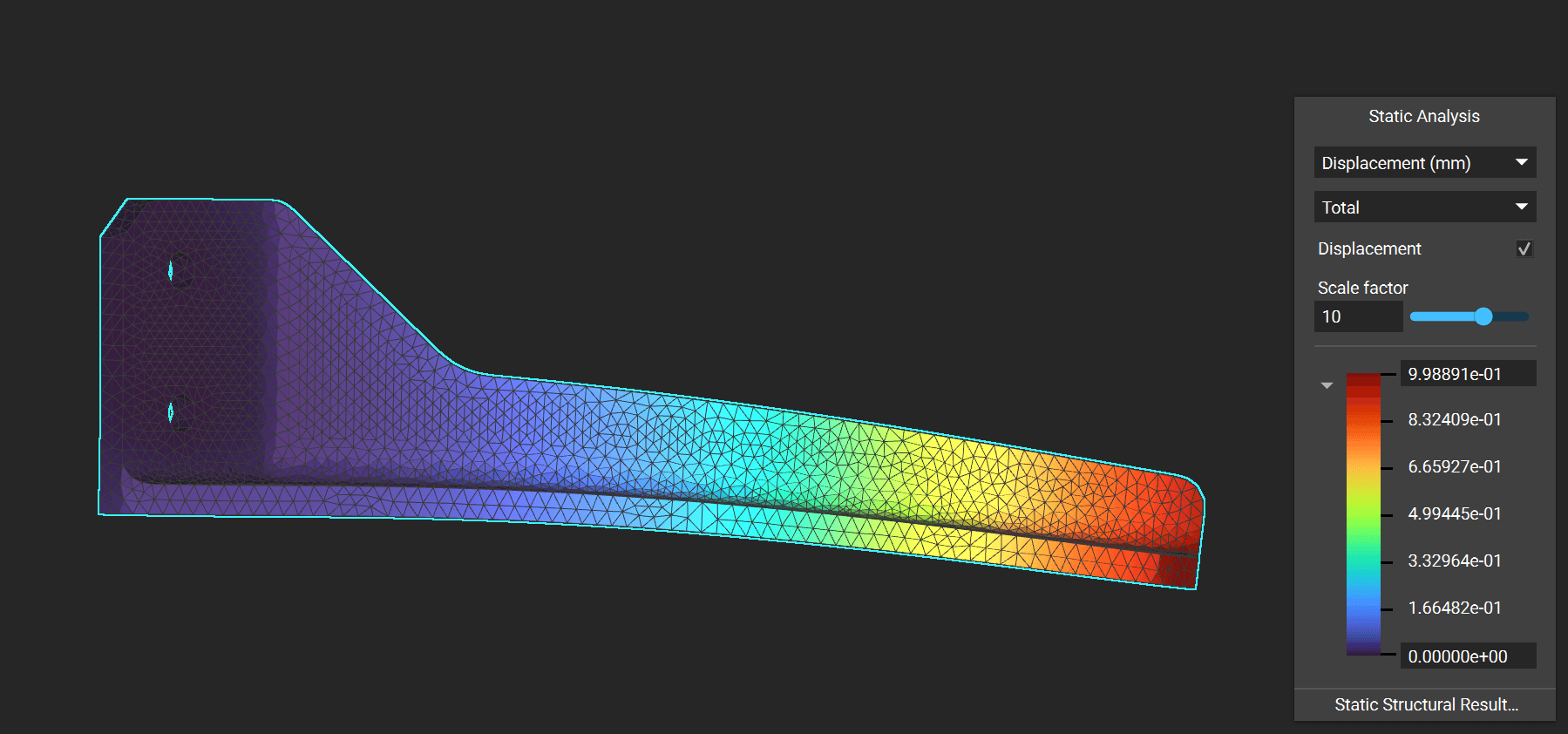

The first step in engineering a plated part is to decide what our objective for part stiffness is. The reference part is made from 6061 aluminum, and deflects about 0.15 mm under the 100N load - barely at all. When the same geometry is 3D printed in Rigid 10K Resin, it deflects 1.05 mm under load.

We know that even a small amount of plated metal will resist creep at room temperature. But what kind of stiffness improvement can be expected through plating alone, without fundamentally changing the design of the original part?

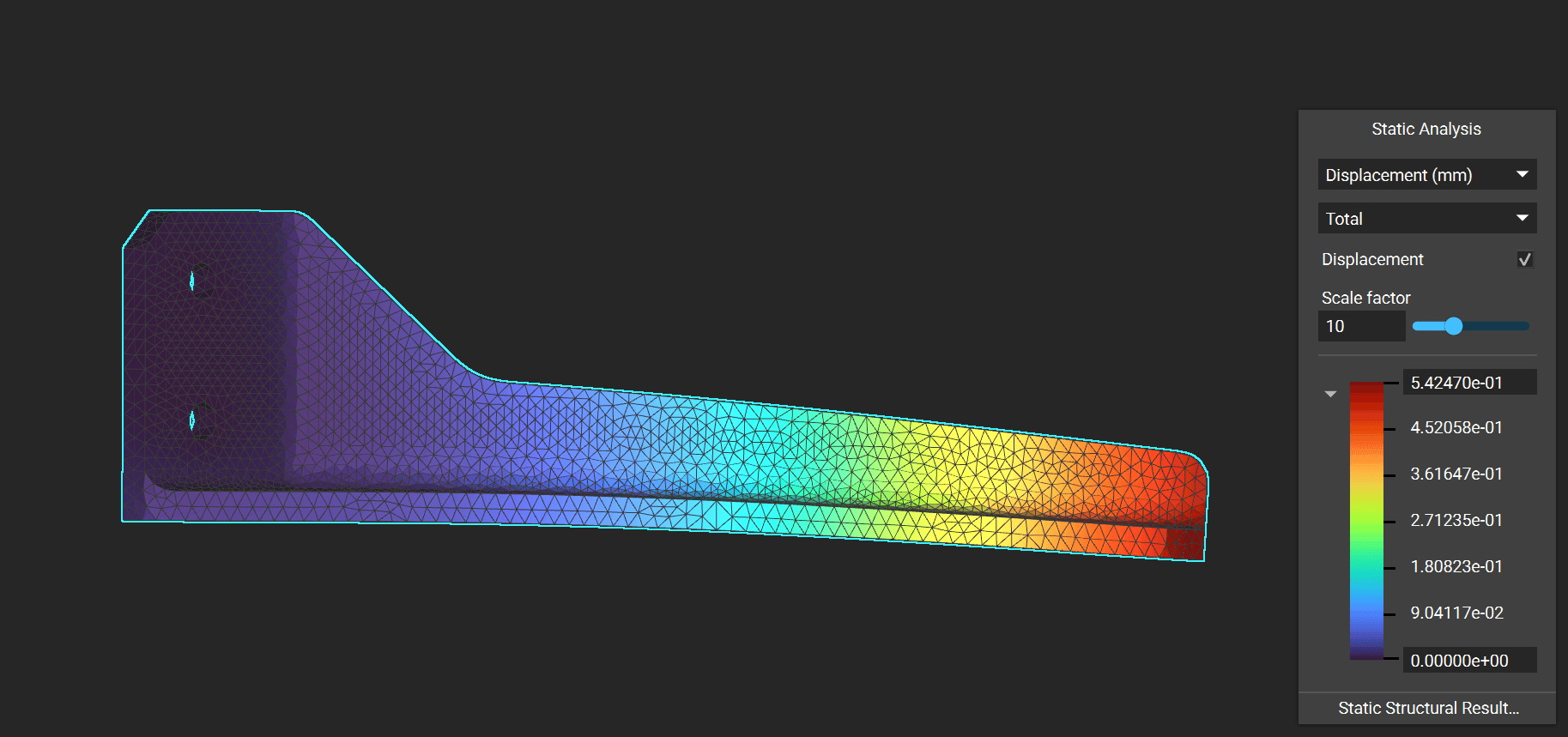

For a like-for-like comparison, we used the same plating composition as our tensile test. Three layers of metal of equal thickness were applied, totalling 150 microns. The rule of mixtures predicts that our part will have a tensile modulus of at least 18 GPa. A finite element analysis using this modulus predicts the loaded end will flex 0.54mm, roughly half the deflection of the unplated part.

See the Appendix for details on how to calculate the Rule of Mixtures for multiple plated layers.

FE analysis using ROM modulus. Left: Unplated, Right: 150μm Plated (note: displacement scaled by 10x)

Plated Performance

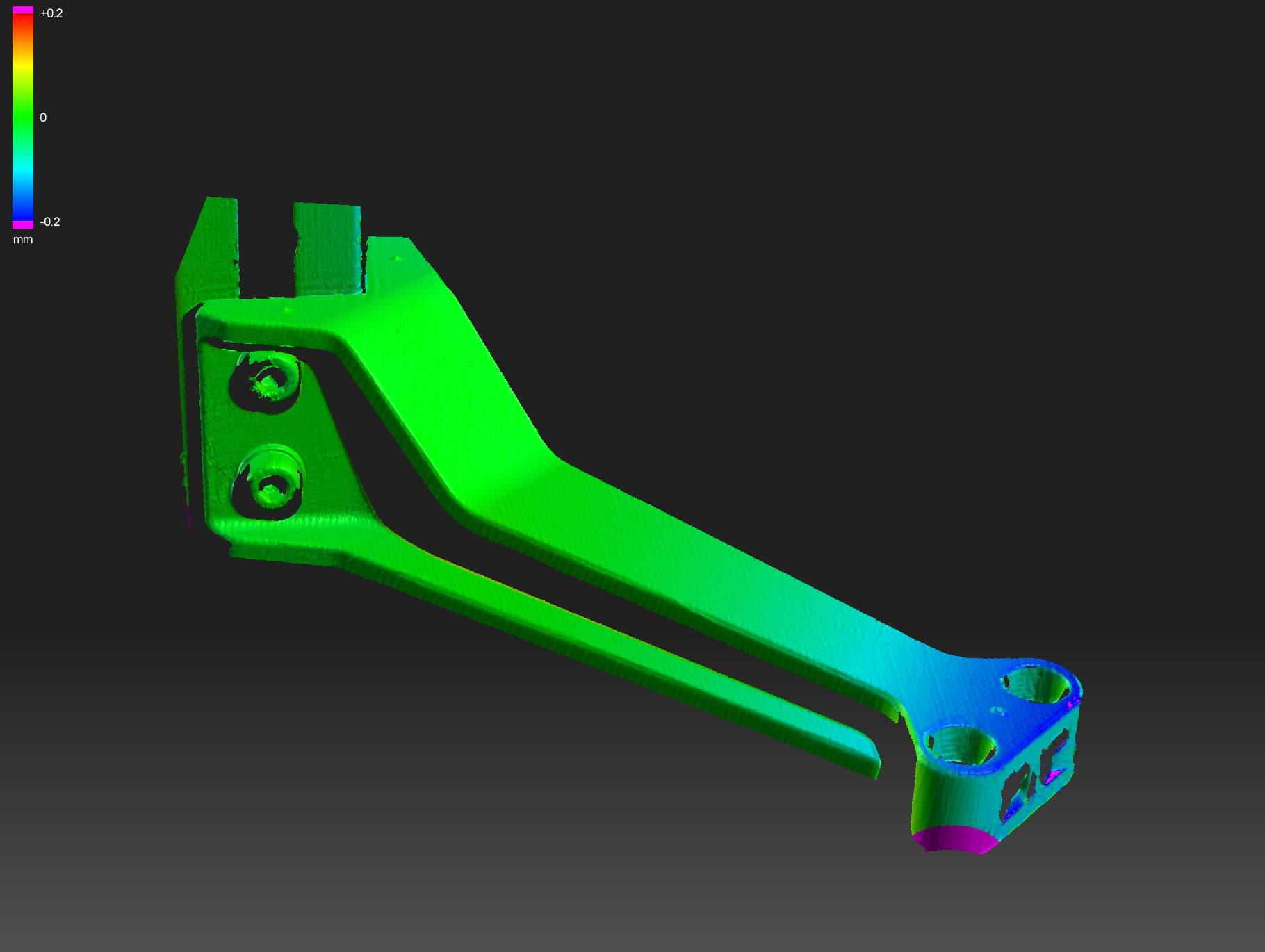

How close is the ROM value to the behavior of the real plated part? We loaded the end and compared the actual deflection with a 3D scanner accurate to within 50 microns.

We know that these parts are actually experiencing bending (flexure), so we expect the experimentally tested values for flexural modulus to be closer to representative. The rule of mixtures does not capture the difference between flexural and tensile stiffness for electroplated parts - that’s why we were not too surprised to see that the real plated parts were stiffer than the simulation predicted. However, we still see ROM as a useful tool for establishing a baseline for likely performance and deciding the necessary plating thickness for your application.

3D scanning the plated bracket shows that it deflects 0.44mm (±25 μm) under 100N load, less than half the deflection of the plain resin part. Furthermore, the plated bracket is at least 2.4 times stronger than the unplated bracket: the unplated Rigid 10K Resin part snapped at a maximum load of 405N, while the plated bracket reached 1000N (exceeding the maximum rating of our load cell) without failure.

Stacking Rigidity

Structural electroplating and topology optimization are complementary strategies. Working together, they produce a class of strong, stiff, and lightweight parts that break the mold of what is possible with polymer 3D printing alone.

The SIMP method of topology optimization maximizes stiffness for a given volume fraction constraint. We used TopOpt to find a stiffer geometry within the bounding box of the existing bracket with equal (or less) material, by setting the SIMP volume fraction equal to:

[VolOriginal Part ] / [VolBounding Box ], and by using the tensile modulus estimated by the Rule of Mixtures as the bulk modulus of the finite element material.

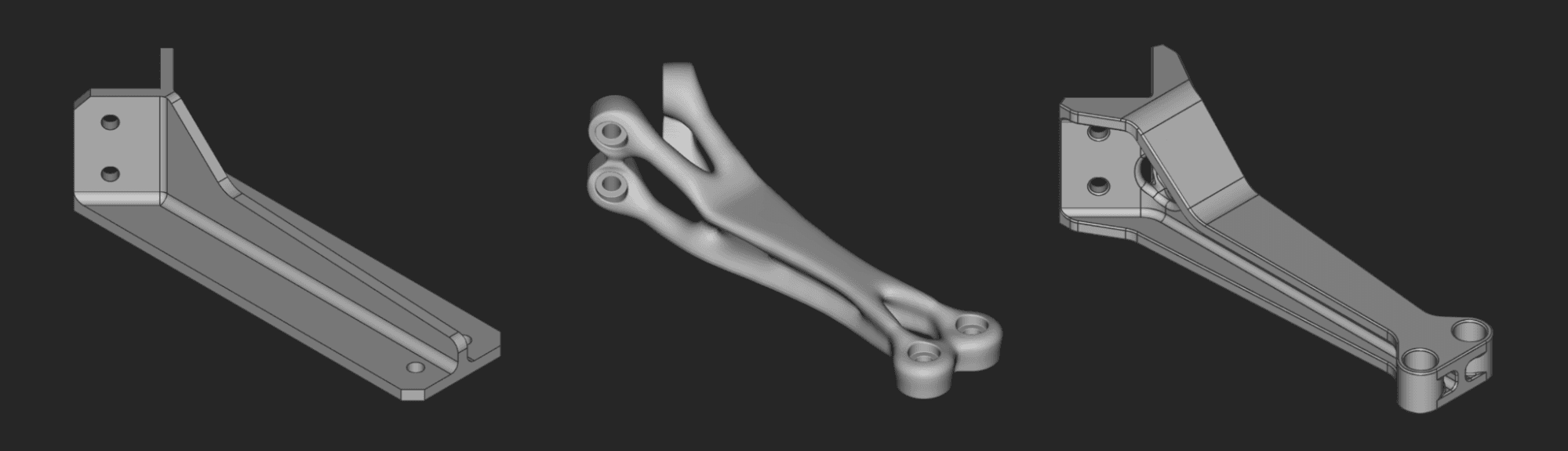

Left: Original bracket. Middle: TopOpt result merged with screw hole geometry to create a functional part via nTopology. Right: TopOpt result used as a guide to make modifications to the original bracket CAD.

Depending on the software you choose to generate a TopOpt solution, it may or may not be possible to directly use the output as a functional part. Comparing the three, the original bracket has a slightly higher volume and material cost (5%). The right two brackets are much more rigid due to their optimized geometry.

Formlabs tested the CAD-remodeled brackets with the same plating composition and 100N load case as before, and measured an average deflection of 0.2 mm (±25 μm). The new design puts the part remarkably close to the stiffness of the original aluminum bracket.

Deflection analysis of the plated TopOpt part. 3D Scanned from fixed view, unloaded, and loaded.

While perfect parity with aluminum isn’t the goal, it’s easy to dramatically transform the behavior of a part with a relatively small amount of metal applied to the outer surface of the bracket. Of course, topology optimization takes extra design effort and additional software tools. Simply plating your basic design will get you most of the way with strength, stiffness, and longevity improvements. But if you are looking for ways to produce small numbers of end-use parts using your existing 3D printing capacity, these strategies can extend your reach.

Left to right: Bending failure of the unoptimized part at 405N. Plated basic bracket after deflection testing to 1000N. Shear failure of TopOpt part at 774N at load mounting point. TopOpt bracket after deflection testing to 1000N.

| Part Sample | Observed Deflection (±25 µm) |

|---|---|

| Original Design (Unplated) | 1.05 mm |

| Topology Optimized (Unplated) | 0.67 mm |

| Original (Plated) | 0.44 mm |

| Topology Optimized (Plated) | 0.20 mm |

Planning for Thickness of Plate

Electroplating adds thickness to parts. The nominal amount of thickness, anywhere from 10 to 300 microns or more, is an important decision for the part designer, which should be based on their application requirements. The degree of control one has over coating thickness is determined by the specific geometry of the part, and the capability of the plater. Usually, once you have decided on a plate thickness for your application, you can simply use an Offset or Move Face tool as needed in CAD, to remove that thickness from your part before printing.

In general, electroplating adds more thickness on positive features than recesses, due to the line-of-sight nature of the plating process. The difference between plate thickness in high regions and recesses increases over the course of plating, which means that thinner layers tend to have more controllable accuracy. Some electroplating services can combine an initial ultra-thin electroplate with “electroless” plating, a related process which is capable of depositing (a more limited set of metals, most commonly hard and brittle nickel) uniformly.

Engineering-oriented plating services will aim to achieve a specified tolerance in a given region of your model. This allows you to adjust your parts in CAD to compensate for plate thickness despite some global variation. For most practical purposes, a tolerance of ±0.005 inches can be achieved, but we recommend asking your plating service provider about their expected tolerance for your specific part.

Tip: When compensating for plated thickness in CAD, think about which surfaces have critical dimensions. Not all surfaces can be plated with precisely the same thickness of metal.

For cosmetic finishes, plated coatings can be exceptionally thin if desired. As little as 10 microns will give a part a metallic appearance. Thicker plate layers will be more durable and forgiving if additional post-finishing steps are needed, such as polishing or buffing.

This Volkswagen hub concept was nickel-plated and polished to a mirror surface. Read the full story here.

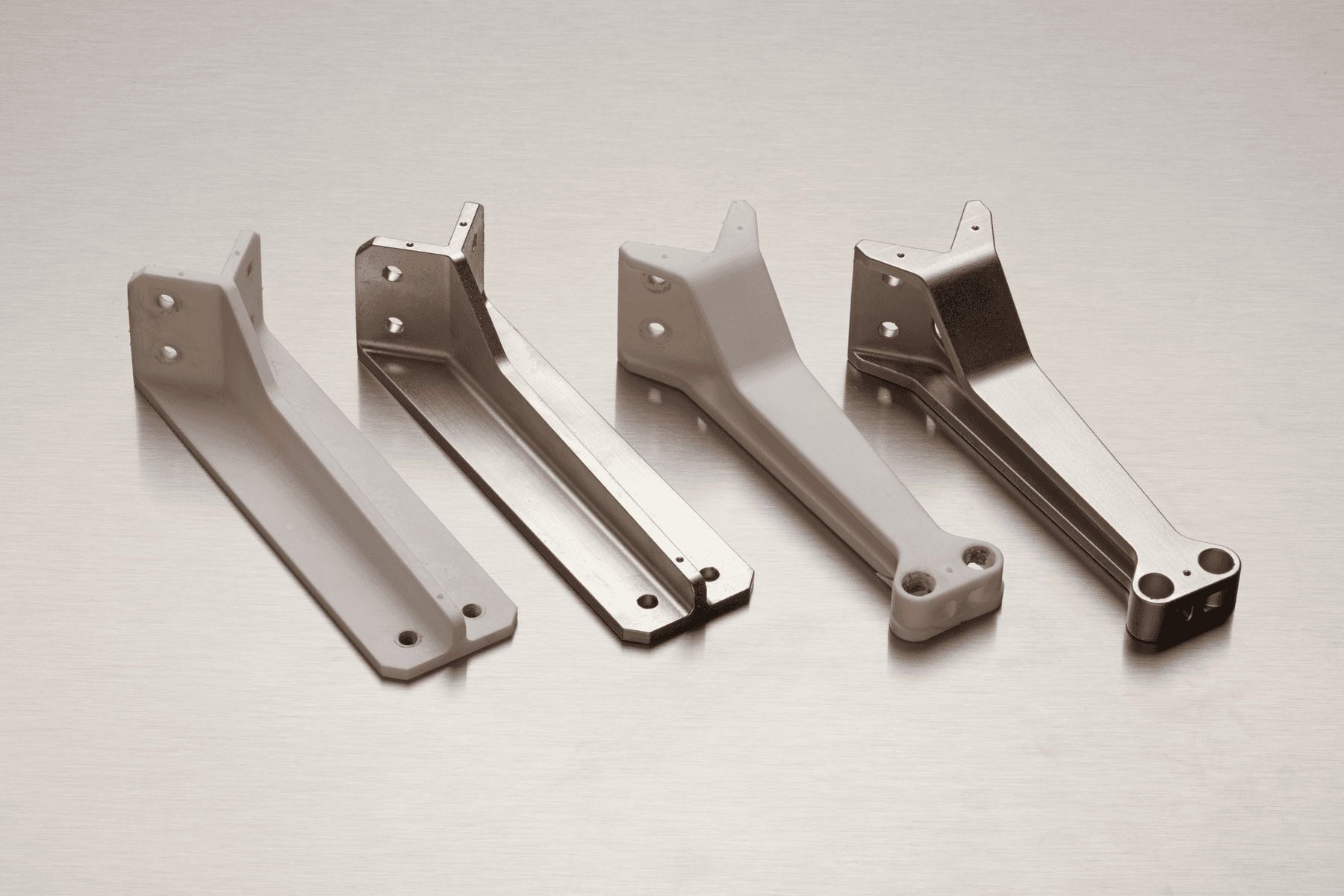

Case Study: Albatross Bikes Functional Prototyping and Badging

These aren’t your average wheels from your local bike shop. Albatross engineers performance bicycles to meet the demands of riders who want a completely unique riding experience. That means they don’t just build from off-the-shelf parts - they manufacture bikes from the ground up: frame to fender. And while Albatross has the in-house ability to CNC machine and mold, they are evaluating structural electroplating for a wide range of their on-bike prototype - and even production - components, due to the ease of design and manufacturing.

Albatross needed lightweight, high-stiffness parts with excellent weathering resistance. When designing new components, Albatross puts them to the test in the sun, rain, and gravel of Northern California. Although they’re equipped with a Form 3, resin only goes so far when dealing with prolonged UV exposure, not to mention the abrasion of a bicycle chain. To address these conditions, they see great potential in using electroplated 3D printed parts with a hard nickel finish. And since Albatross produces components unique to each bicycle, 3D printing provides a level of geometric freedom that helps them meet the ergonomic requirements of each customer, without compromising on a classic design style that looks better in metal.

A year ago, structural electroplating was new to Will Hilgenberg (Albatross CEO). Since then, he’s worked with large and small electroplated parts, including full-scale carbon-fiber layup mold tooling printed on his large-format Form Series printer. We asked him about the value he sees in this approach and what he’s learned about better incorporating electroplating into his manufacturing toolkit.

What were your first impressions of the parts?

Will: My first impression of the plated parts was that they didn't feel like printed parts at all. They had a certain heft, feel, and look to them that made them feel completely different from printed parts that I am used to handling. They also looked amazing!

How are you going to modify your designs in the future to take advantage of this manufacturing method?

Will: We’ve found that it’s useful to add a small radius to any angles/transitions sharper than 90 degrees, in order to improve the durability of the coating. We’re also working with varying print orientations to see if highlighting layer lines could be a desirable aesthetic feature in metal. Some of our plated parts have precision features, so we offset those surfaces to ensure that the plated part remains dimensionally accurate.

What value does electroplating bring to your workflow?

Will: Electroplating allows 3D printed parts to have much-improved surface properties, such as reduced friction, increased durability, and increased chemical resistance and conductivity. We are able to combine the geometry capabilities and no-tooling benefits of additive manufacturing with the mechanical properties of metals.

Does having your own 3D printer in-house make your production process more efficient?

Will: Having our own printer helps address supply chain issues in two ways: by reducing development time of new products, and replacing end-use products made using traditional methods. In-house printing speeds up the development process on long-lead-time components and reduces the number of pre-production samples required, allowing us to place orders sooner and be able to receive the parts quickly. We’ve also started to replace injection molded parts with printed components that we’re able to produce in-house. Unlike molding, we can now modify and customize those parts to suit the customers' needs.

What other tools or methods did you use before adopting electroplated composites?

Will: These parts would traditionally be made using a combination of forging, CNC, and EDM for some of the tight interior features. All of these methods require an extensive amount of tooling that would only be viable for large production runs. Plating allows us to produce small volumes of components that replace some of our traditionally made parts, and do so at reduced cost.

Economics of Electroplating: Cost and Lead Time

Since electroplating is most frequently done by external services, lead times of one to two weeks between shipping parts and receiving them plated are the norm. Since electroplated 3D printed parts can sometimes be used in place of machined metal parts for prototyping, in particular when geometries are complex enough to require 5-axis machining, this lead time is comparable to custom machined parts, but generally at a lower cost.

| Part Size/Type | Part Description | Resin Cost | Plating Cost + Flat 2-Day Shipping | Total Cost |

|---|---|---|---|---|

| Small and Simple | Chain Guide | $2 | $33+20 | $55 |

| Small w/ Complex Masking | Brake Lever | $2 | $60+20 | $82 |

| Small w/ Polishing | Tube Frame Logo Badge | $2 | $90+20 | $112 |

| Medium | Aero Fairing Bracket | $11 | $118+20 | $149 |

| Large | TopOpt Caliper Model | $53 | $550+20 | $623 |

| Large w/ Polishing | Auto Hub Plate | $29 | $637+20 | $686 |

Even if your business is equipped with machining capabilities, electroplating looks-like prototypes can be a valuable stop-gap measure when your machine shop bandwidth is limited. Additionally, compared to machining, an engineer can print, ship out, and receive plated parts with barely more effort than in-house plastic prototyping.

Note: Electroplating complex shapes with deep recessed areas can be difficult; however, auxiliary anodes can be incorporated in the electroplating rack design to improve coverage in recessed features. This will increase the cost of plating.

Elevated Temperature Applications

Some applications require structural-electroplated parts to survive thermal cycling. For example, structural electroplating can be used to produce parts with a high thermal conductivity, such as heat exchangers or compression mold tools, that might experience temperatures of 150 °C. As you might expect, thermal cycling stresses the adhesive bond between the resin substrate and plated metal, and the most common failure mode due to thermal cycling is delamination.

Formlabs and RePliForm have found that some resins perform better than others in thermal cycling. Filled resins perform the best, with Rigid 10K Resin showing the least delamination of all Formlabs resins. Rigid 4000 Resin and Tough 2000 Resin had similar performance, while High Temp Resin surprisingly showed the most thermal delamination.

RePliForm also found that high ratios between plate thickness and underlying resin thickness are less prone to thermal delamination. If your application involves heat exposure, Formlabs recommends using a thick plate ( > 80μm), and attempting to keep resin wall thickness low (1- 3mm) if possible.

Do It Yourself, Or Not?

Although it is possible to electroplate resin parts yourself, amateur users may run into difficulty. The main reason is quality and capability. Laminate adhesion strength using DIY methods is usually lower than what is achieved by a professional plating service. Structural plating, which requires long plate times, multiple baths, and compatibility between metals, is quite difficult to execute reliably. Successful applications of in-house plating are typically simple and small, such as jewelry prototyping and thin (single-layer) RF copper coatings.

Safety and Chemical Disposal

Most electroplating requires chemicals that are often corrosive and sometimes carcinogenic. If you do decide to bring electroplating in-house, please follow strict safety protocols to protect against exposure. In addition to health dangers, electroplating chemicals are often environmental hazards. Plating chemicals contaminate wash water and require eventual disposal. If you are considering the DIY path, be sure to factor in costs for chemical disposal services and local disposal regulations.

The Jentner “Comfort II” plating machine.

Plating Equipment and Supplies

If you do have plating experience, existing equipment can also be used to plate over resin. Silver spray paint, sold by Caswell Plating (North America) and Pino Technology (China) is a reasonably effective an electroplatable coating, if low adhesion strength is not a concern.

Low-Volume Plating

To make it easier for our customers to create and use electroplated composites, Formlabs has compiled a list of services in addition to RePliForm, which is searchable by region and job size.

Electroplating Companies and Their Contact Info

| Plating Service | Contact for Quote | Location | Services | Quantities? | Finishing Services? | Certification |

|---|---|---|---|---|---|---|

| RePliform, Inc. | Online Quote | Maryland | Structural and Decorative Coatings | One-offs to batches | ||

| Bel Air Finishing | Online Quote | Rhode Island | Structural and Decorative Coatings | |||

| 3d-Squared | Online Quote | UK | Structural and Decorative Coatings | |||

| Solution4Plastic | Online Quote | India | Structural and Decorative Coatings | |||

| Artcraft Plating | Online Quote | Southern California | Decorative Coatings | One-offs to batch | ||

| Cal-tron Plating | Online Quote | Southern California | Decorative Coatings | Polishing, Masking | ||

| Epner Technology | Online Quote | Precision and structural coatings | Polishing | ITAR/EAR certified | ||

| Sharretts plating | Online Quote | Pennsylvania | Structural coatings for commercial customers | |||

| SAT Plating | Online Quote | Michigan | Precision and structural coatings for industrial customers | |||

| Component Surfaces | Contact for a Quote | Precision and structural coatings | ||||

| Techmetals | Contact for a Quote | Precision and structural coatings | Medical ISO 13485:2016 | |||

| ENS Technology | Contact for a Quote | Southern California | Precision and RF coatings | ISO 9001:2015 | ||

| Tanuary Industries | Contact for a Quote | UK | Precision and precious metal coatings | Polishing | ||

| Precision Plating Company | Contact for a quote | Illinois | RF-spec precision coatings | Small pre-production batch to full production | ||

| Lacks Enterprises | Contact for a quote | Michigan | Automotive electroplating | |||

| Cybershield Inc | Contact for a quote | Texas | Selective Coating |

Conclusion

Electroplated composites are a means to a wide variety of ends. More and more, Formlabs customers are finding value in functional coatings; for greater strength than resin alone, for outgassing protection, or superior weathering and chemical resistance for outdoor or corrosive applications. In the world of product design, electroplating is a simple and straightforward way to produce prototypes and end-use parts that look and feel like metal, often at lower cost and with less waste. If you use a Formlabs SLA printer in your workflow, you may already be producing resin prototypes that, in a matter of days, can be converted into functional components that take on even more utility as you test, refine, and approach production.

If you’re unsure whether electroplating is right for your project, contact Formlabs sales to learn more about applicability for your project, as well as other potential options.