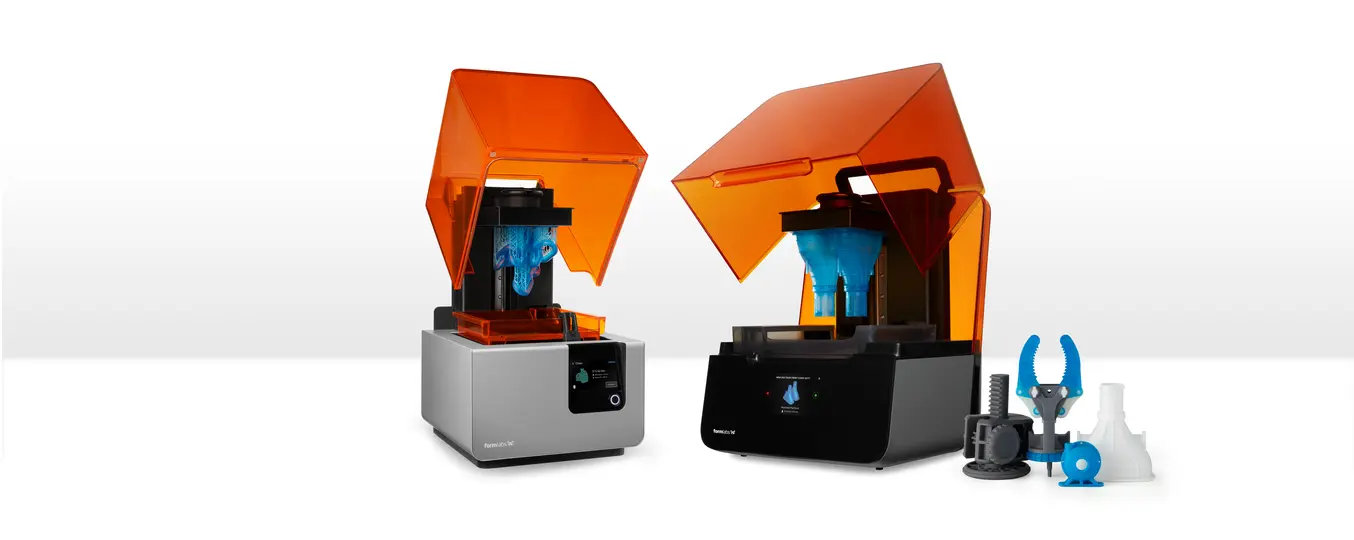

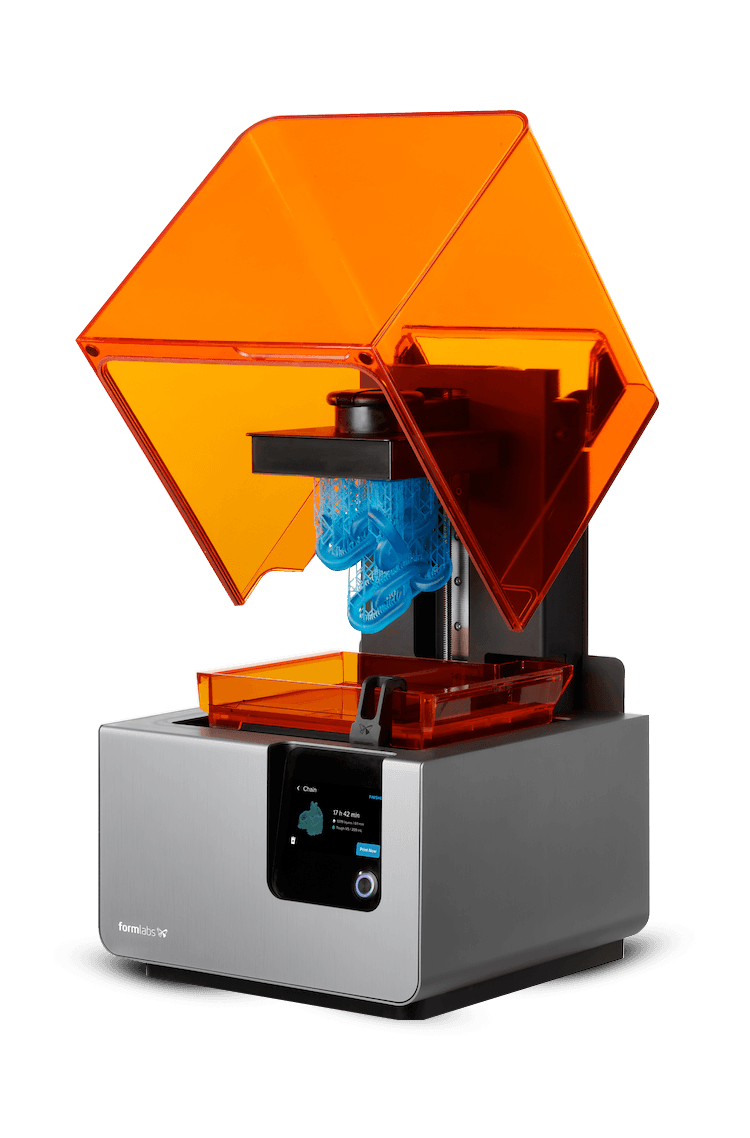

Form 2

The Desktop 3D Printer That Set the Standard

We have now stocked out of new Form 2 units, but our next-generation desktop SLA 3D printer, Form 4, improves upon its foundation in every possible way.

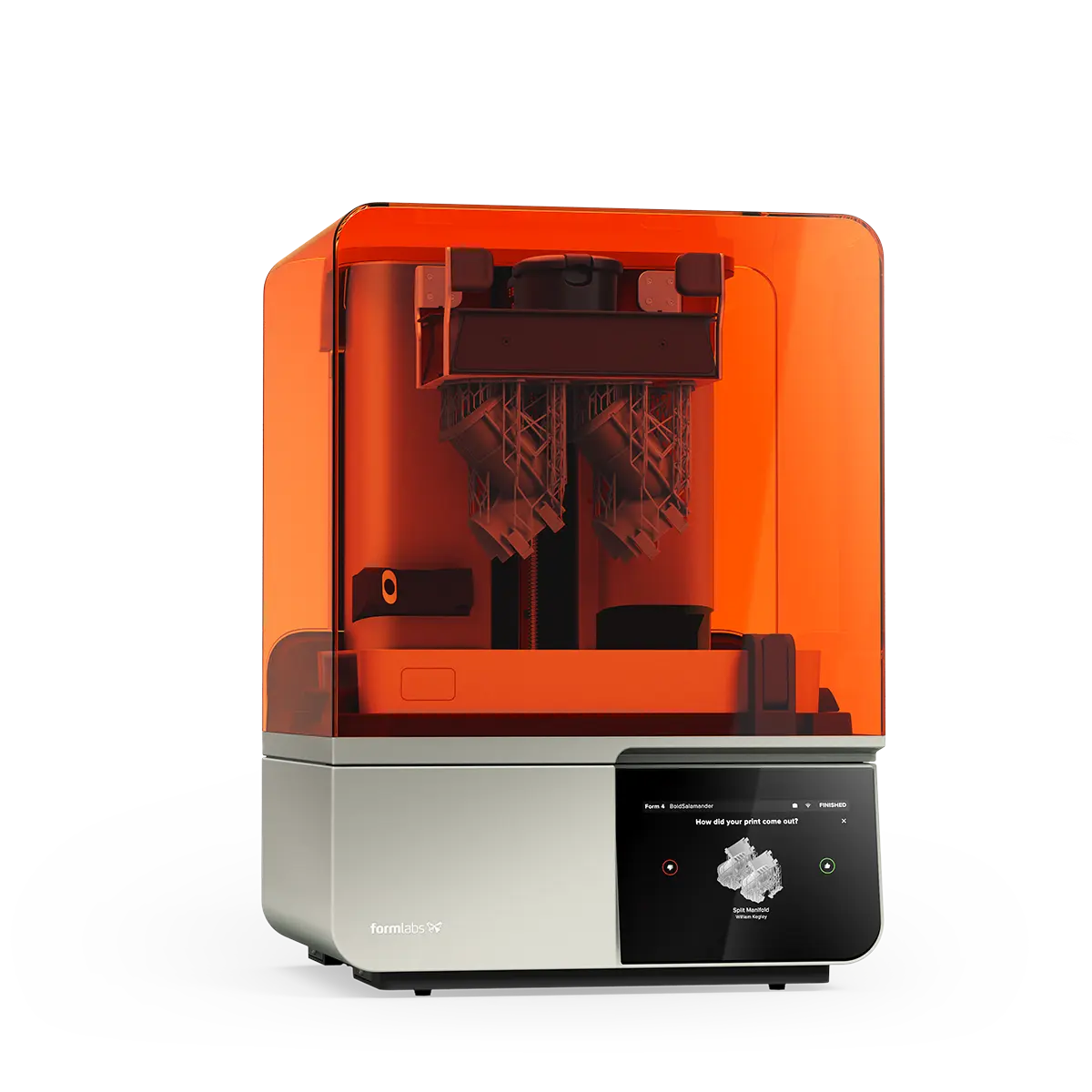

The Next Generation of Industrial 3D Printing

Form 4 is powered by our Low Force Display™ Print Engine, setting the new industry standard for blazing-fast speed, leading reliability and accuracy, and the widest range of performance 3D printing materials.

70,000,000 Successful Parts and Counting

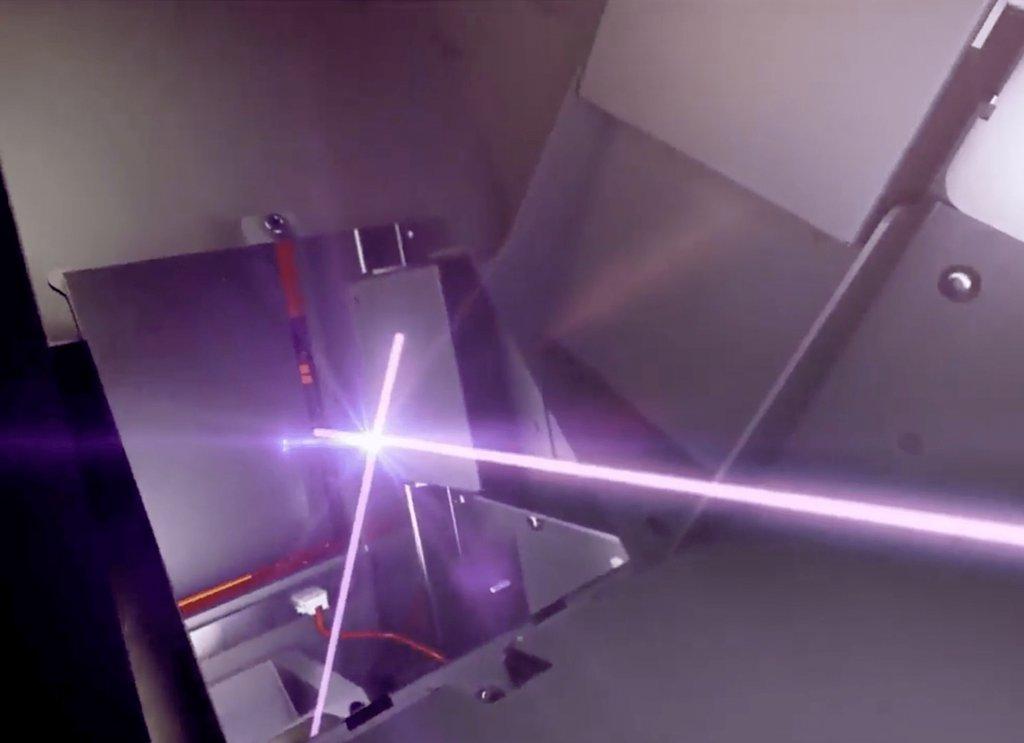

Professional 3D Printing, Powered By Lasers

Stereolithography (SLA) 3D printing uses a laser to cure solid isotropic parts from a liquid photopolymer resin.

Engineered For Precision. Designed for Reliability.

The Form 2 works as hard as you do so you can focus on developing innovative products and bringing your most creative ideas to life. 3D print strong, detailed models with stunning surface finish.

Request a Free Sample 3D Print

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

20+ Materials, Zero Hassle

Our integrated resin system makes material management easy and allows for clean operation. Switch between materials in seconds by replacing the cartridge. The Form 2, Form 3+, and Form 3L automatically recognize the resin type, configure settings, and allow you to keep track of resin supplies from your Dashboard.

A Proven, Intuitive Workflow

From print preparation to post-processing, you can rely on a dependable, scalable fabrication workflow and focus on creating.

Step 1: Design

Design

Design your model in your regular CAD software and import an STL or OBJ file into our PreForm print preparation software. One-Click Print offers an option for automatically orienting, supporting, and laying out your 3D models.

Step 2: Print

Send prints over WiFi, reprint previous jobs, and manage your print queue directly from our touchscreen interface. During printing, the peel mechanism, wiper, and heated resin tank create a consistent, reliable print process.

Step 3: Finish

Finish

For the best results and mechanical properties, all SLA parts require IPA rinsing and post-curing. Form Wash and Form Cure streamline and automate post-processing of Form 2 and Form 3+ prints. Consistently produce high-quality results with less time and effort.

Prepare and Manage Prints With Smarter Software

Get your 3D model ready in minutes with PreForm's automatic and manual print preparation tools. Manage printers and monitor supply levels remotely using your online Dashboard.

World Class Support When You Need It

Learn how to print on your own or alongside our Formlabs Services team. When you contact us, you're immediately working with a 3D printing expert. Helpful, human support is included with every printer, with options to purchase premier support services, designed to provide tailored learning experiences and even quicker responses.

Read our Ongoing Support Statement for information on our commitment to continuing to provide industry-leading support and consumables for the Form 2.

Add Desktop Stereolithography to Your Toolkit

Find everything you need to go from digital to physical part in the Formlabs store.