Which 3D Printing Technology Is the Right One for You?

Compare Formlabs SLA and SLS 3D Printers

SLA

SLA

Stereolithography (SLA)

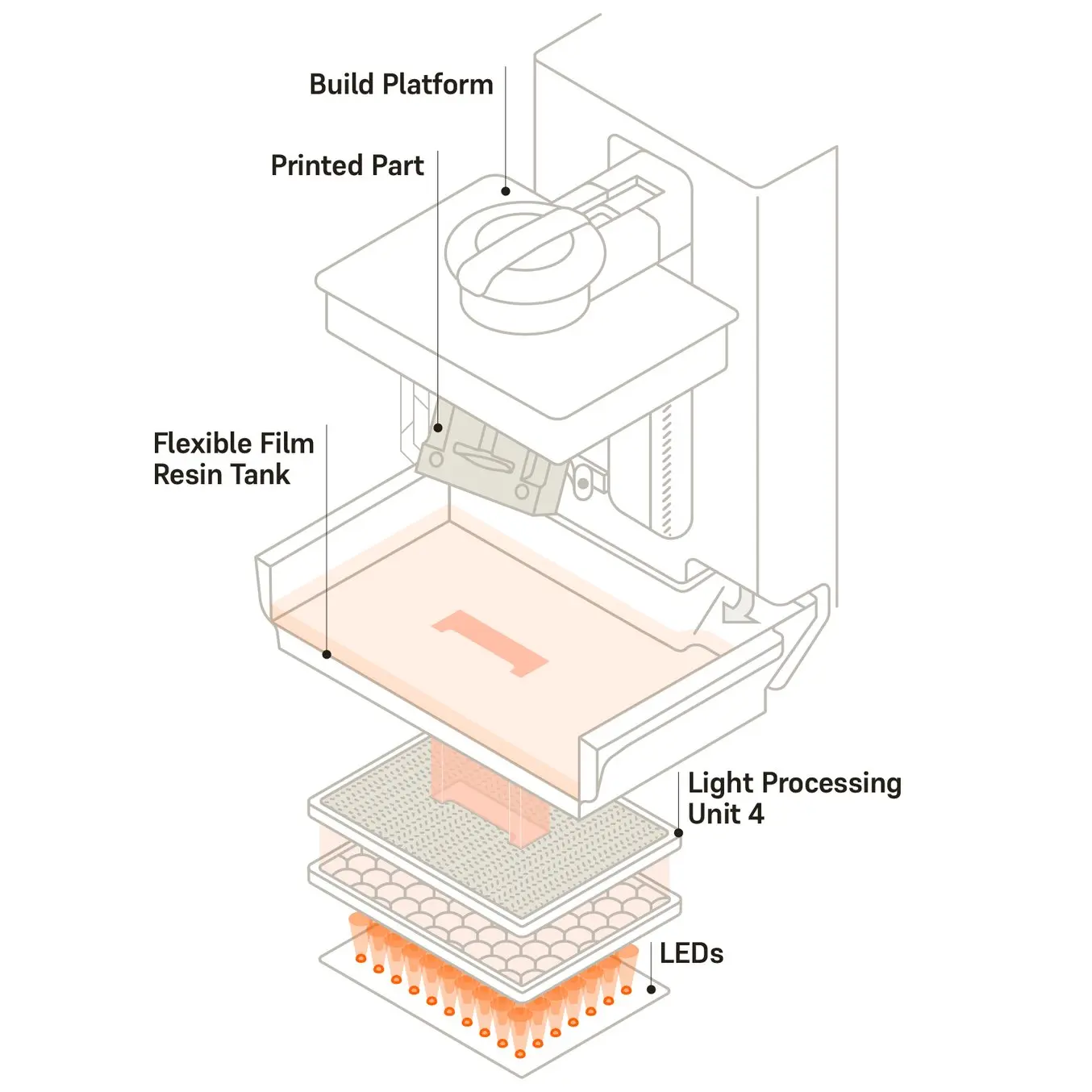

SLA 3D printers use a light source to cure liquid resin into hardened plastic in a process called photopolymerization.

Overview

TECHNOLOGY

Stereolithography (SLA)

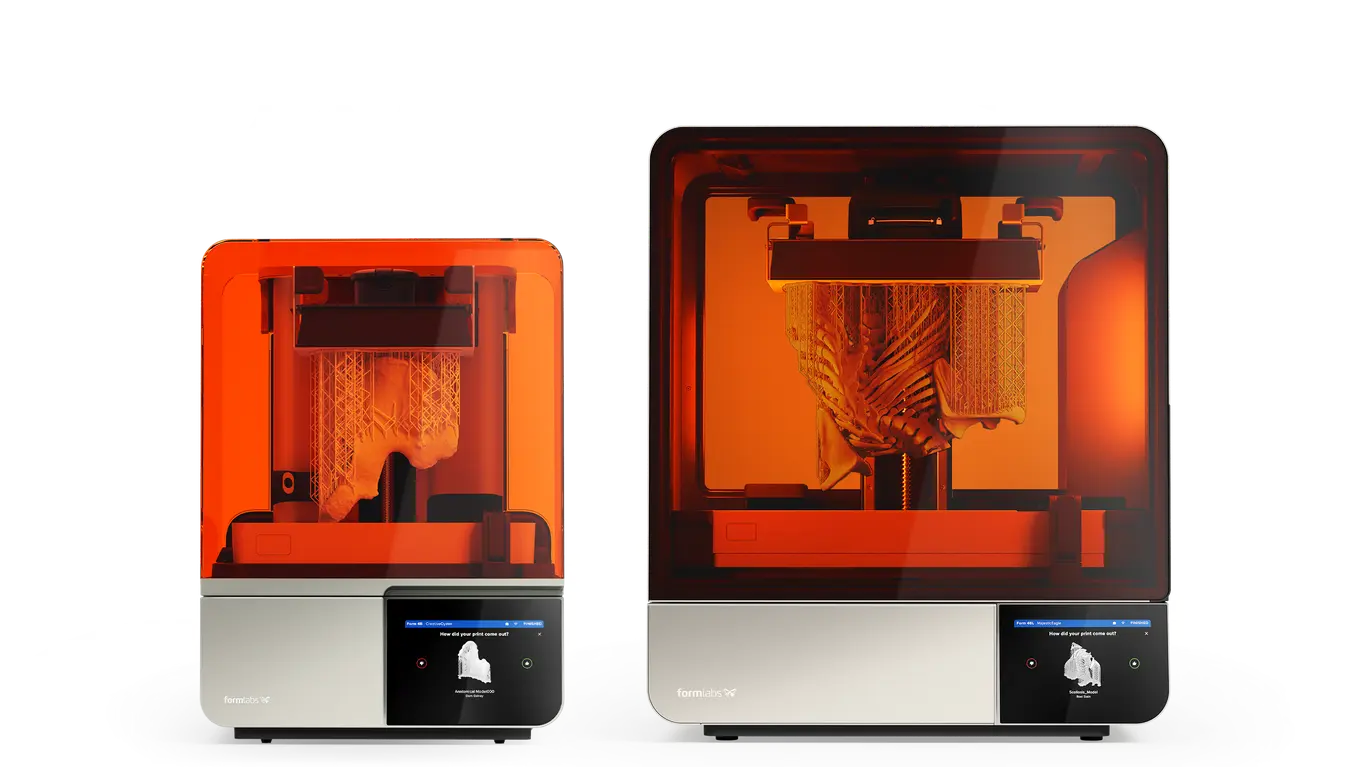

Formlabs SLA 3D printers use next-generation Low Force Display™ (LFD) technology to quickly deliver incredible surface quality and print accuracy, meeting the demands of today’s market for scalable, reliable, industrial-quality 3D printing.

BENEFITS

- Blazing-fast print speed

- High resolution and fine details

- Great accuracy and print quality

- Wide range of materials

- Easy to use

APPLICATIONS

- Rapid prototyping

- Functional prototyping

- Concept modeling

- Rapid tooling

- Manufacturing aids

- Low volume manufacturing

- Dental models and appliances

- Medical models and medical devices

- Jewelry prototyping and casting

- Models and props

Material

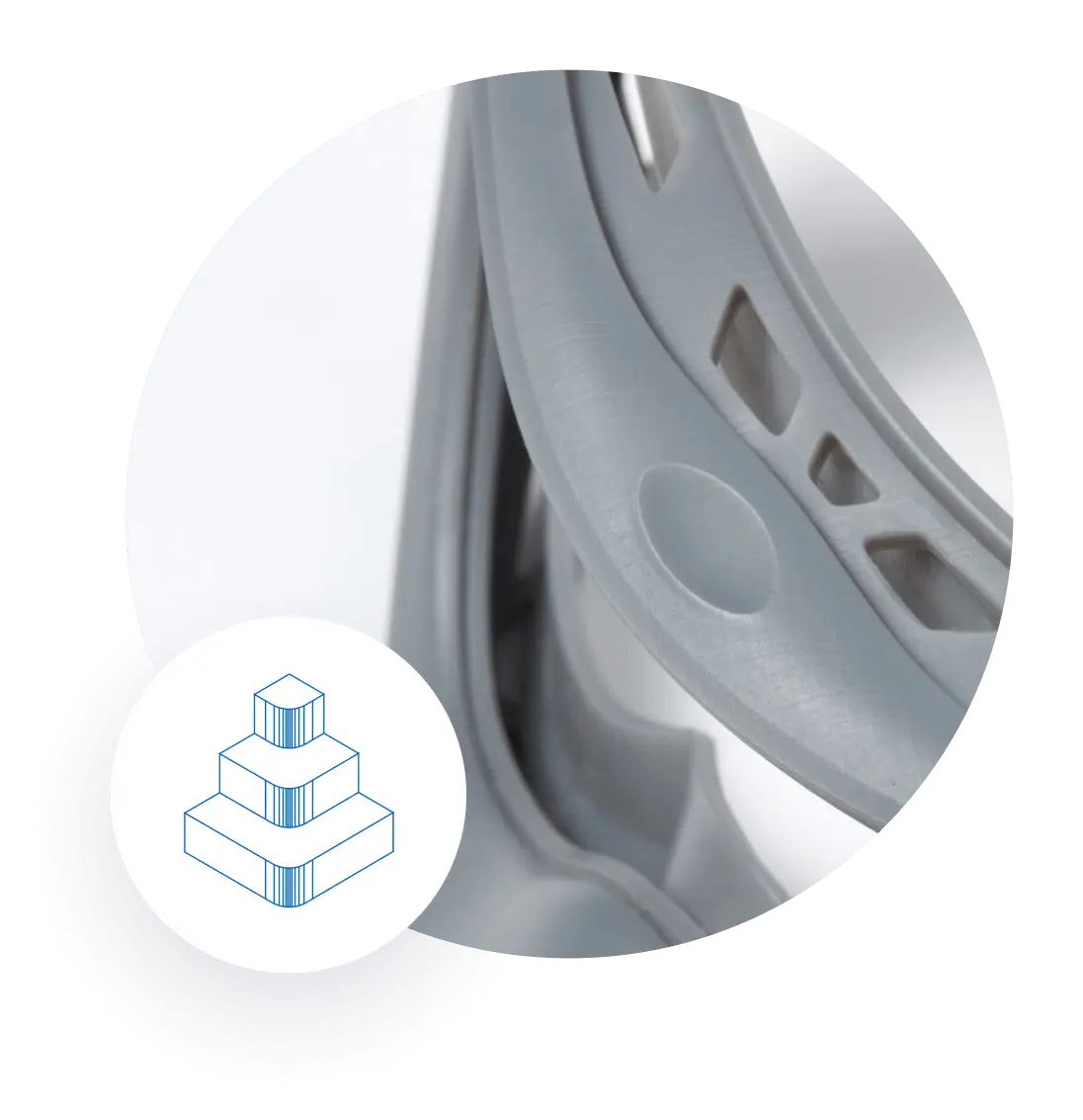

SURFACE FINISH

Smooth, minimal layer lines

MATERIAL LIBRARY

40+ functional resins for a wide range of applications

A wide range of materials for prototyping and production from true silicone to flexible, tough, durable, and rigid varieties. Specialty materials for high-temperature applications, castable patterns, and ESD-safe, flame-retardant, or pure ceramic parts. A wide variety of resins for dental and medical applications, including materials for biocompatible parts.

CHANGING MATERIALS

Easy with a cartridge system

Switch between a wide range of functional materials in seconds with our swappable resin cartridge system.

Build Volume

FORM 4L AND FORM 4BL

35.3 x 19.6 x 35.0 cm

13.9 x 7.7 x 14.0 in

FORM 4 AND FORM 4B

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

THROUGHPUT

High

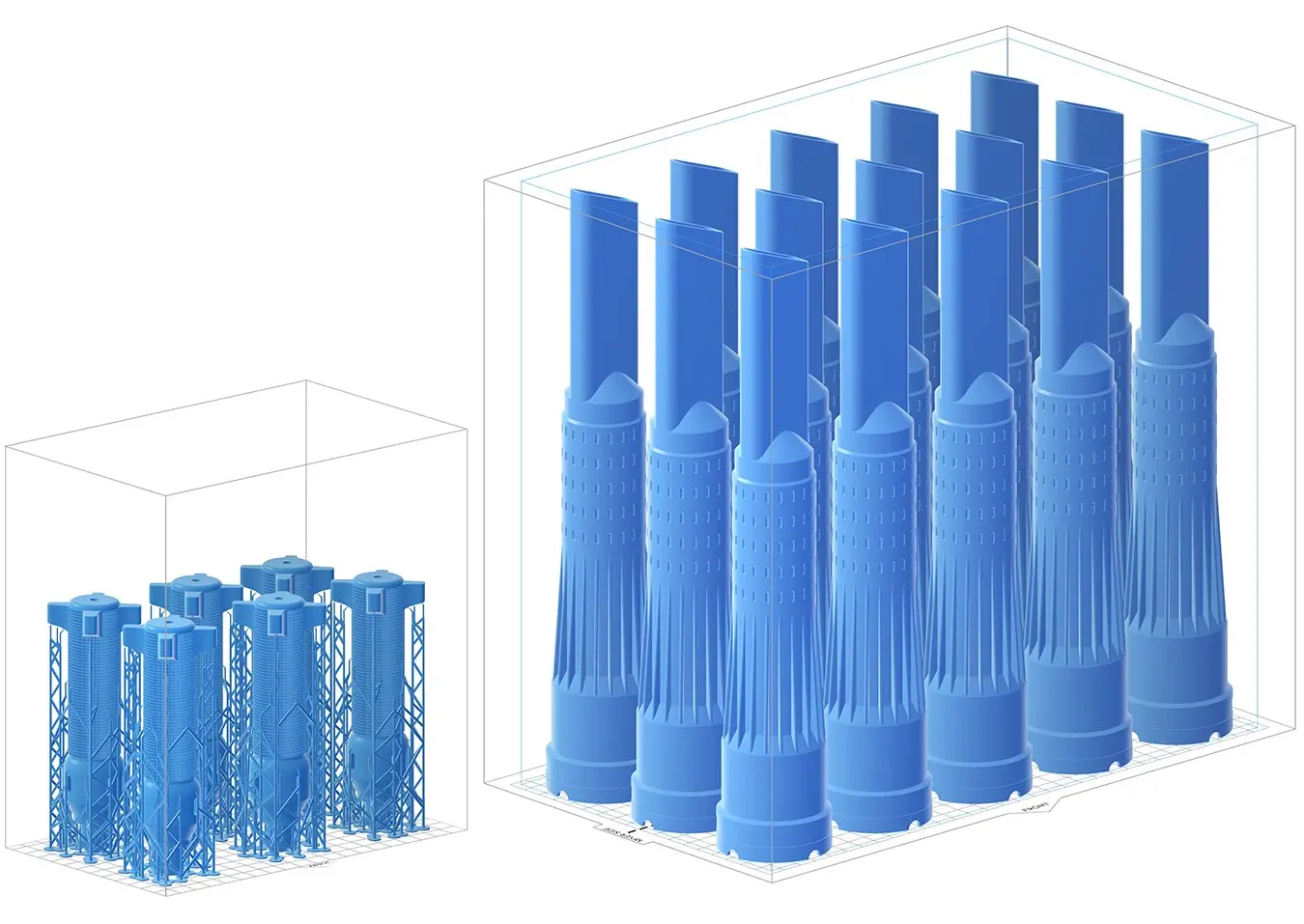

Formlabs SLA 3D printers offer a streamlined and blazing-fast means of producing functional, high-quality prototypes and end-use parts. Choose the large-format Form 4L and Form 4BL for producing large-scale parts as well as batches of small parts with minimal printer interaction.

Form 4L and Form 4BL offer 4.6x larger build volumes than Form 4 and Form 4B.

Setup & Ease of Use

Plug and print

Easy workflow empowers anyone at your company to use the system independently after minimal training. Formlabs offers contact-free delivery and online or in-person advanced training for the entire team to make onboarding even easier.

Maintenance

Minimal

Formlabs SLA 3D printers require minimal maintenance. In the rare case when something does go wrong, the optical systems are replaceable in-house to prevent the need for replacement printer shipments and maximize your uptime. Improved failure detection and handling means you can experiment with confidence.

Post-Processing

Form Wash and Form Cure, Form Wash L and Form Cure L

Our automated washing and curing solutions streamline the SLA post-processing workflow to consistently deliver high-quality results with less time and effort.

SUPPORTS

Light-touch supports

Our light-touch supports break off with ease, leaving behind minimal support marks that can be easily removed with light sanding.

CLEANING

Wash parts in a solvent

Cleaning printed parts in a wash solvent removes any uncured resin from the part, leaving you with a smooth surface finish. Automate washing with the Form Wash and Form Wash L.

FINISHING

Post-curing (optional)

When an SLA part finishes printing, it remains on the build platform in a “green state.” Through exposure to a combination of light and heat, post-curing unlocks this last mile of material properties. Post-curing is required for certain materials and for biocompatible parts. Automate curing with the Form Cure and Form Cure L.

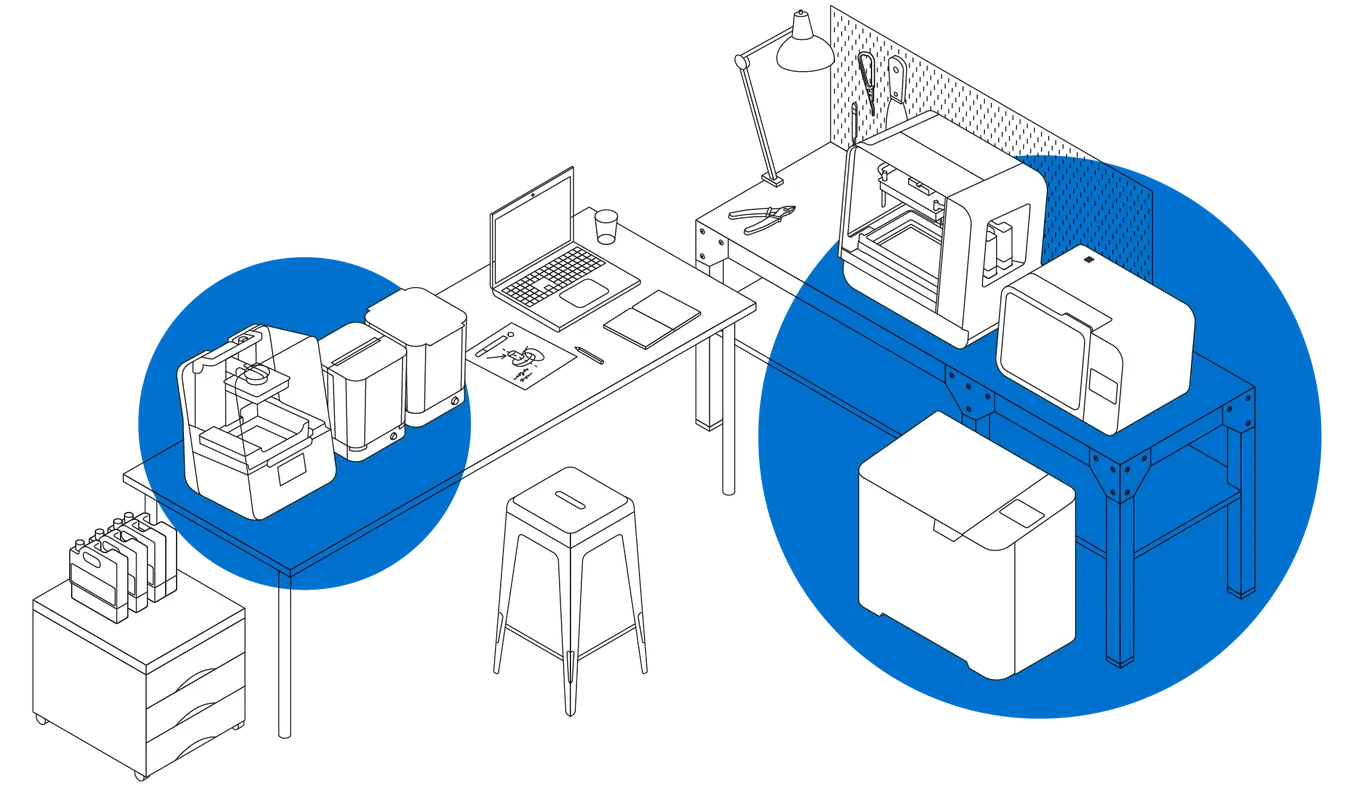

Space

ENVIRONMENT

Office and workshop

Formlabs SLA 3D printers are suitable for various environments, including the office, lab, workshop and the manufacturing floor. Our most compact SLA printers, the Form 4 and Form 4B, can fit on a desktop.

SLS

SLS

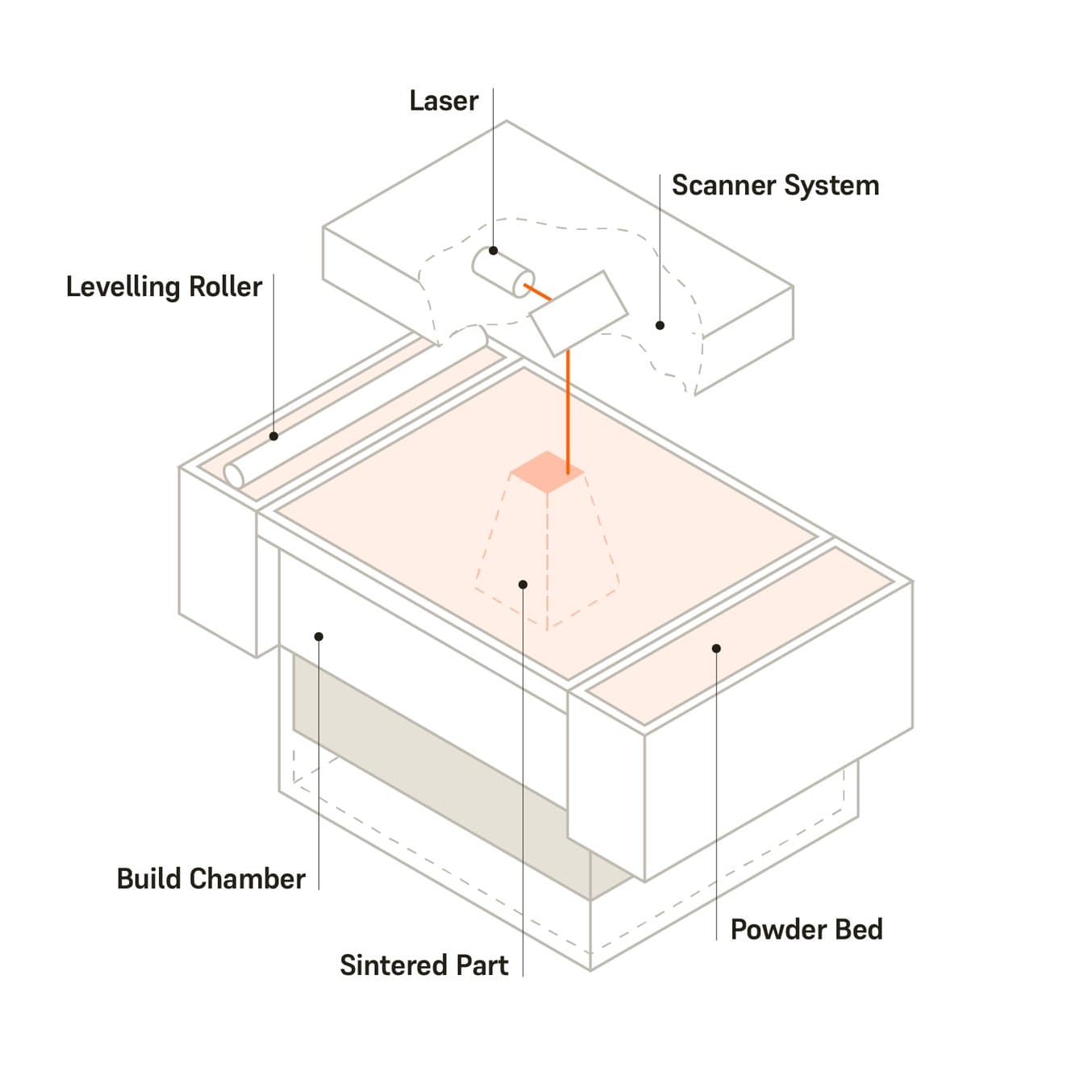

Selective Laser Sintering (SLS)

SLS 3D printers use a high-power laser to sinter small particles of polymer powder into a solid structure.

Learn More

Overview

TECHNOLOGY

Selective Laser Sintering (SLS)

Fuse Series is the first benchtop industrial SLS 3D printer ecosystem that offers high quality end-use parts in a compact footprint. The complete, simplified workflow delivers high throughput at a fraction of the cost of traditional industrial SLS systems.

BENEFITS

- End-use parts in under 24 hours

- Excellent mechanical properties

- Great accuracy and print quality

- No need for support structures

- Cost-efficient for series production

APPLICATIONS

- End-use parts

- Low volume, bridge, or custom manufacturing

- Functional prototyping

- Long-lasting, durable manufacturing aids

- Medical devices, prosthetics, and orthotics

Material

SURFACE FINISH

Slightly grainy finish

MATERIAL LIBRARY

8 high-performance industrial-grade materials

The Fuse 1+ 30W currently prints with nylon 12, nylon 11, TPU (elastomer), as well as glass and carbon-filled nylon composites. All SLS Powders are ideal for 3D printing long-lasting, durable, end-use parts and functional prototypes.

CHANGING MATERIALS

Manageable

Requires thorough cleaning of the 3D printer and related accessories, but it's possible, and substantially faster and less involved than with traditonal SLS systems.

Maximum Part Size

FUSE 1+ 30W and FUSE 1

16.5 x 16.5 x 30 cm

6.3 x 6.3 x 11.6 in

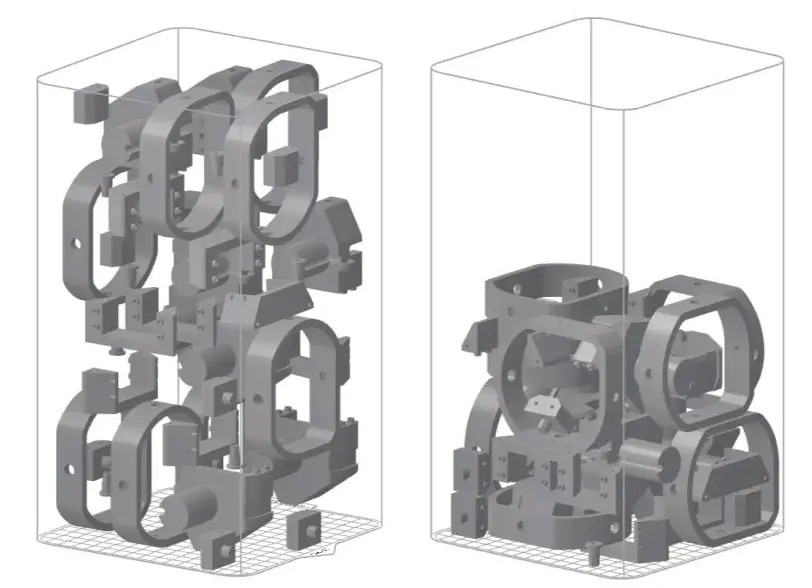

THROUGHPUT

High

Fuse Series SLS 3D printers are designed for nonstop throughput. They come with a removable build chamber, allowing you to start new prints right after the previous print has finished to minimize downtime. Cooldown time takes only about half the print time for large builds, an industry-leading value that allows you to get to finished parts quickly.

Fuse Series SLS 3D printers allow you to pack parts tightly to optimize each build for the highest productivity.

Setup & Ease of Use

SLS made manageable

From print setup to powder management to finishing, our hardware and software are designed to maximize your efficiency, with an intuitive interface to walk you through all steps of printing and maintenance. Anyone at your company can use the system independently after a quick online or in-person training.

Maintenance

Efficient

The Fuse Series ecosystem is designed for minimal upkeep, offering proactive maintenance alerts and a full-color touchscreen interface that guides you through every step of printing and maintenance.

Post-processing

Fuse Sift and Fuse Blast

Our advanced SLS post-processing solutions enable you to go from printed to finished parts in as little as 15 minutes with an efficient, hands-off workflow.

SUPPORTS

No supports needed

SLS parts are supported by powder as they print, so no supports are needed, reducing post-processing labor.

CLEANING

Clean excess powder

Extract and clean your parts from the build chamber and recover unused powder to be recycled in future prints. Use Fuse Sift as an all-in-one station.

FINISHING

Media blasting

Formlabs recommends using media blasting to fully depowder and improve surface finish of SLS parts. Use Fuse Blast for an easy-to-use, fully automated cleaning and polishing solution that consistently delivers professional parts that are clean to the touch.

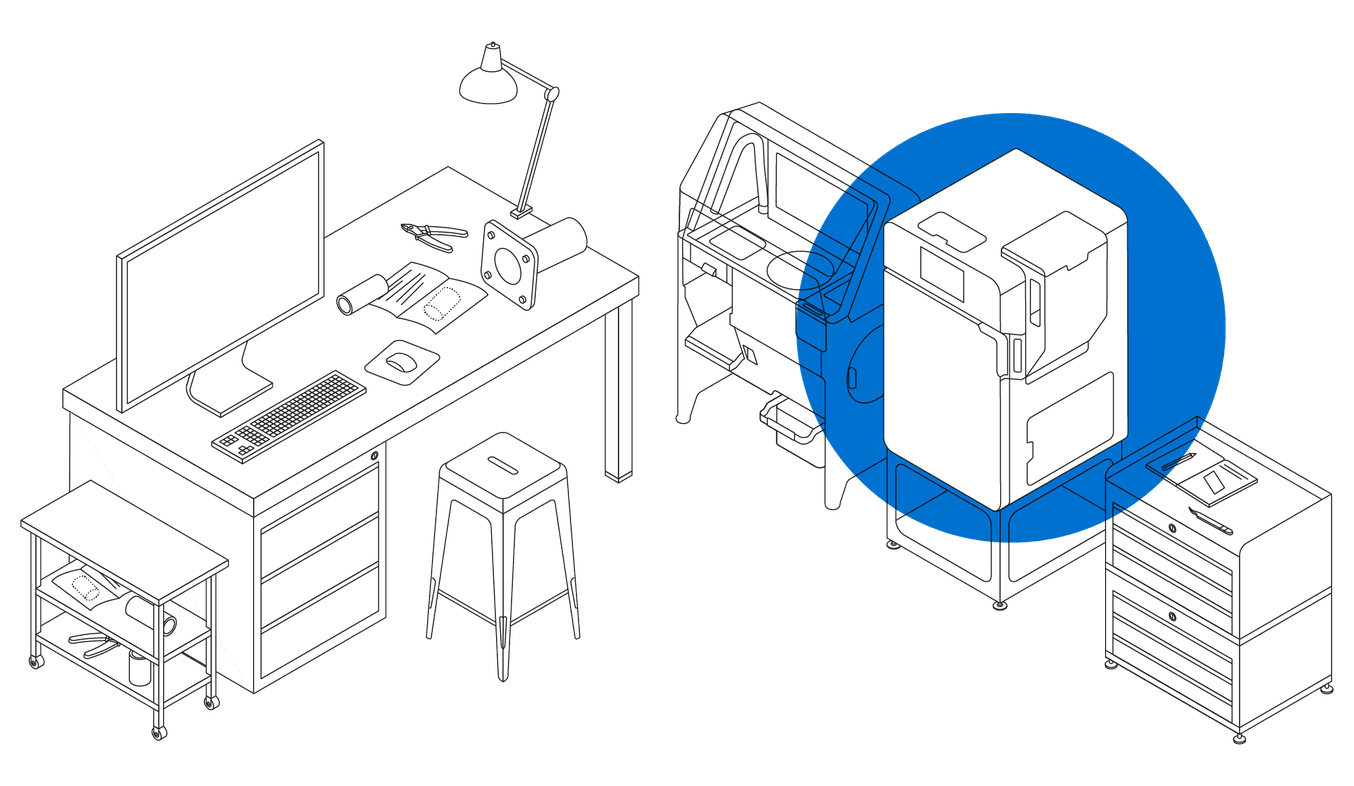

Space

ENVIRONMENT

Workshop

Fuse Series SLS 3D printers are best suited for a workshop or machine shop setting, though it can be used in an office environment if you have a large open space with consistent housekeeping practices.

Compare Formlabs 3D Printer Tech Specs

Technology

Masked Stereolithography (MSLA)

Material Type

Resin

Biocompatible Materials

No (available on Form 4B)

Maximum Part Size

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Layer Thickness

25 – 200 microns

.001 – .008 in

Light Source

Backlight Unit (60 LEDs)

Supports

Auto-generated

Light-touch removal

Materials

23 industry-leading Formlabs materials or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Printing Environment

Ambient conditions. Only PU Resins require a dry cabinet for humidity control.

Printer Dimensions (W × D × H)

39.8 × 36.7 × 55.4 cm

15.7 × 14.5 × 21.9 in

Technology

Masked Stereolithography (MSLA)

Material Type

Resin

Biocompatible Materials

No (available on Form 4BL)

Maximum Part Size

35.3 x 19.6 x 35.0 cm

13.9 x 7.7 x 14.0 in

Layer Thickness

25 – 200 microns

.001 – .008 in

Light Source

Backlight Unit (145 LEDs)

Supports

Auto-generated

Light-touch removal

Materials

19 industry-leading Formlabs materials or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Printing Environment

Ambient conditions. Only PU Resins require a dry cabinet for humidity control.

Printer Dimensions (W × D × H)

66.4 x 52.8 x 79.4 cm

26.1 x 20.8 x 31.3 in

Technology

Selective Laser Sintering (SLS)

Material Type

Powder

Biocompatible Materials

Yes

Maximum Part Size

15.9 × 15.9 × 29.5 cm (Nylon 12 Powder)

6.3 × 6.3 × 11.6 in (Nylon 12 Powder)

Layer Thickness

110 microns

0.004 in

Laser Power

One 30W Ytterbium fiber laser

Supports

No supports required

Materials

8 high-performance industrial-grade materials, including nylon 11, nylon 12, TPU, and glass and carbon-filled nylon composites, or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Printing Environment

Air environment, with the option to print in a nitrogen atmosphere for enhanced material properties and lower refresh rates.

Printer Dimensions (W × D × H)

64.5 × 68.5 × 107 cm (165.5 cm with stand)

25.4 × 27 × 42 in (65.0 in with stand)