In March 2020, when COVID-19 first started to overwhelm America’s healthcare systems, University of South Florida Morsani School of Medicine Dean Dr. Charles Lockwood, MD, MHCM immediately recognized that global supply chains for personal protective equipment, ventilators, and testing swabs would be overwhelmed. The two main producers of nasopharyngeal swabs, Puritan Medical Products in Maine, and Copan Diagnostics in Italy, weren’t able to keep up with demand, and federal stimulus arrived too late. The seven million dollar federal grant to Puritan Medical Products for a factory expansion would take months to bear fruit, and an air-shipment of swabs from Copan wasn’t enough to meet states’ demands.

Dr. Lockwood knew that new methods outside of traditional manufacturing processes would have to fill the gap, and he spotted 3D printing, also known as additive manufacturing, as the solution to address the shortage of personal protective equipment, ventilators, and perhaps most importantly, testing swabs — and distribute them to the frontlines. Knowing this, he enlisted Dr. Summer Decker, an expert in additive manufacturing and Director of 3D Clinical Applications within the USF Health Department of Radiology.

She called Gaurav Manchanda who, in his role as Director of Healthcare at Formlabs, had a history of working with healthcare organizations and regulatory bodies to develop new ways to use 3D printing for prototyping and producing custom medical devices and surgical aids. Just as COVID-19 was first starting to overwhelm American healthcare systems, Dr. Lockwood spotted the potential for 3D printing to fill an urgent shortage of personal protective equipment, ventilators, and perhaps most urgently, testing swabs — and distribute them to the frontlines.

The goal became clear: a 3D-printed COVID-19 testing swab.

With the background and expertise in 3D printing for medical applications, Dr. Lockwood, Dr. Decker, and Manchanda established a goal to develop a 3D-printed COVID-19 testing swab.

Using the Formlabs machines they had relied on for years, Dr. Decker and her colleague in the 3D Lab, Dr. Jonathan Ford, sought to fix the swab shortage by providing a turnkey solution that could utilize the many Formlabs printers already deployed in hospitals and medical device facilities across the country. The team at USF knew they could rapidly design a swab for mass production, but to clear the regulatory hurdles, establish manufacturing best practices, and reach a wider audience, they reached out to the Healthcare team at Formlabs. “Within hours of my initial conversation with Dr. Decker, it was all hands on deck here,” said Manchanda, as he recruited colleagues across the company to lend their expertise in print optimization, regulatory and quality processes, and decentralized manufacturing operations.

After a frenzied weekend of prototyping, the swabs were evaluated by clinicians, tested on volunteers for comfort, and bench lab tested by Tampa Bay General Hospital, Northwell Health, and USF Health.Dr. Decker’s team then reached out to their colleagues in the USF Health Department of Infectious Diseases to conduct validation testing (24-hour, 3-day, and leaching). They coordinated with the team at Formlabs, who were discussing regulatory requirements with the Food and Drug Administration and establishing manufacturing and quality protocols for other health systems who had already requested the printable file. In parallel, Dr. Todd Goldstein at Northwell Health, who also contributed to early designs and testing, quickly established rapid clinical testing with almost 300 patients as New York State was hard-hit in March before the virus spread to other parts of the country.

“This is a prime example of the incredible impact we can have on human lives when teams of experts across academia, health care delivery, and the tech industry come together,” said Dr. Lockwood. “During this current COVID-19 outbreak, there is little time for delay, and the swift, agile and adept action of everyone on this effort will greatly improve this nation’s ability to test patients.”

Just 12 days after Dr. Decker’s call to Manchanda, the final design was approved and the 3D file made available for other health systems through the Formlabs website and forums for COVID-19 response efforts. Along with the file, Formlabs put together a validated and detailed workflow with guidelines for qualified users in healthcare to print the swabs and ensure the health and safety of patients.

“We are grateful that we were able to work as a team to get this solution out so quickly in order to hopefully help many people. The response has been overwhelming,” said Dr. Decker.

As COVID-19 cases soared through April, the need for widespread testing continued. Hospitals, dental labs, and academic medical centers who had been using their 3D printers for patient-specific surgical models were able to repurpose their equipment and fill a gap in their own supply chain.

Hospitals across the country, from Thomas Jefferson Hospital in Philadelphia, to the University of Nevada Health Department, had faculty members reach out for guidance on transitioning their Formlabs printers from research and patient care to swab printing. The results were published in Clinical Infectious Diseases, and a commentary accompanying the paper cites the authors’ timely, collaborative response to supply chain disruptions affecting testing capacity early in the pandemic.

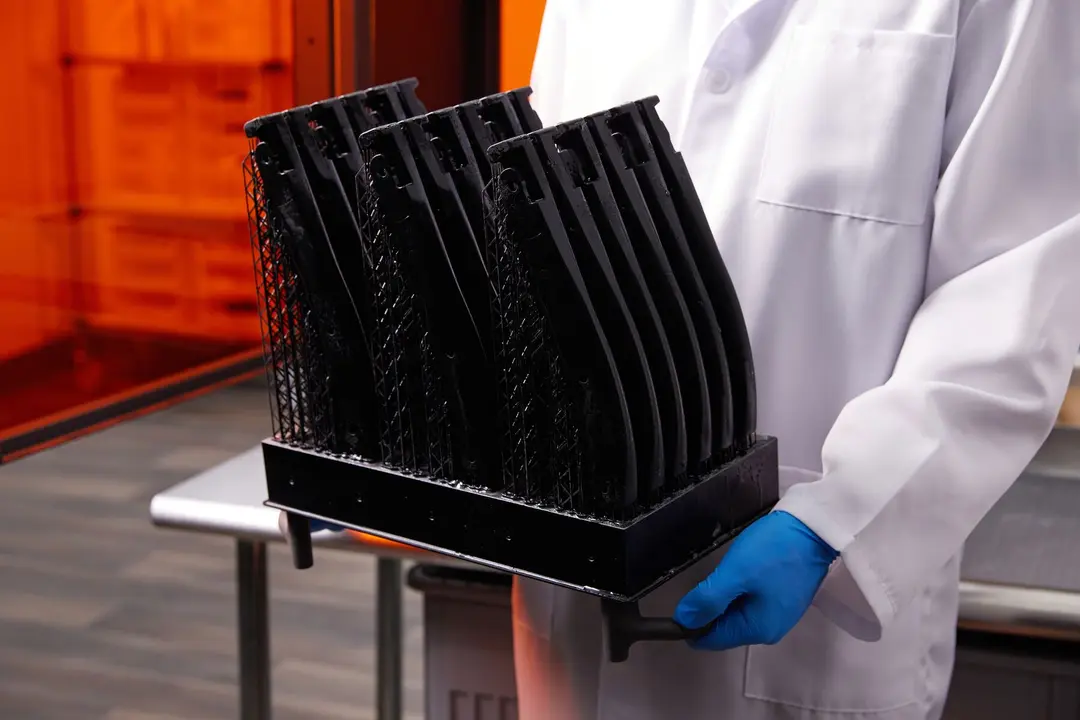

Formlabs also contributed to swab production, pivoting its FDA-registered, ISO 13485 certified manufacturing facility in Ohio from resin production to print hundreds of thousands of swabs for public use. With the necessary clearances to produce medical grade devices and materials, Formlabs was positioned to repurpose its facility for printing NP swabs, showing how 3D printing workflows and materials can easily adjust to demand.

The impact of the COVID-19 pandemic required a global, concerted response. Through collaborating with USF and Northwell, Formlabs enabled a solution that has been deployed worldwide. With the accessible design, affordable equipment, and validated processes, the swab design enabled over forty million COVID tests in twenty five countries. Over the last year, Formlabs 3D printers have continued being used by governments and healthcare providers to improve patient testing and care. This global solution is just one example of how the agility of 3D printing can benefit the public good.