Formlabs BioMed Clear Resin for Audio

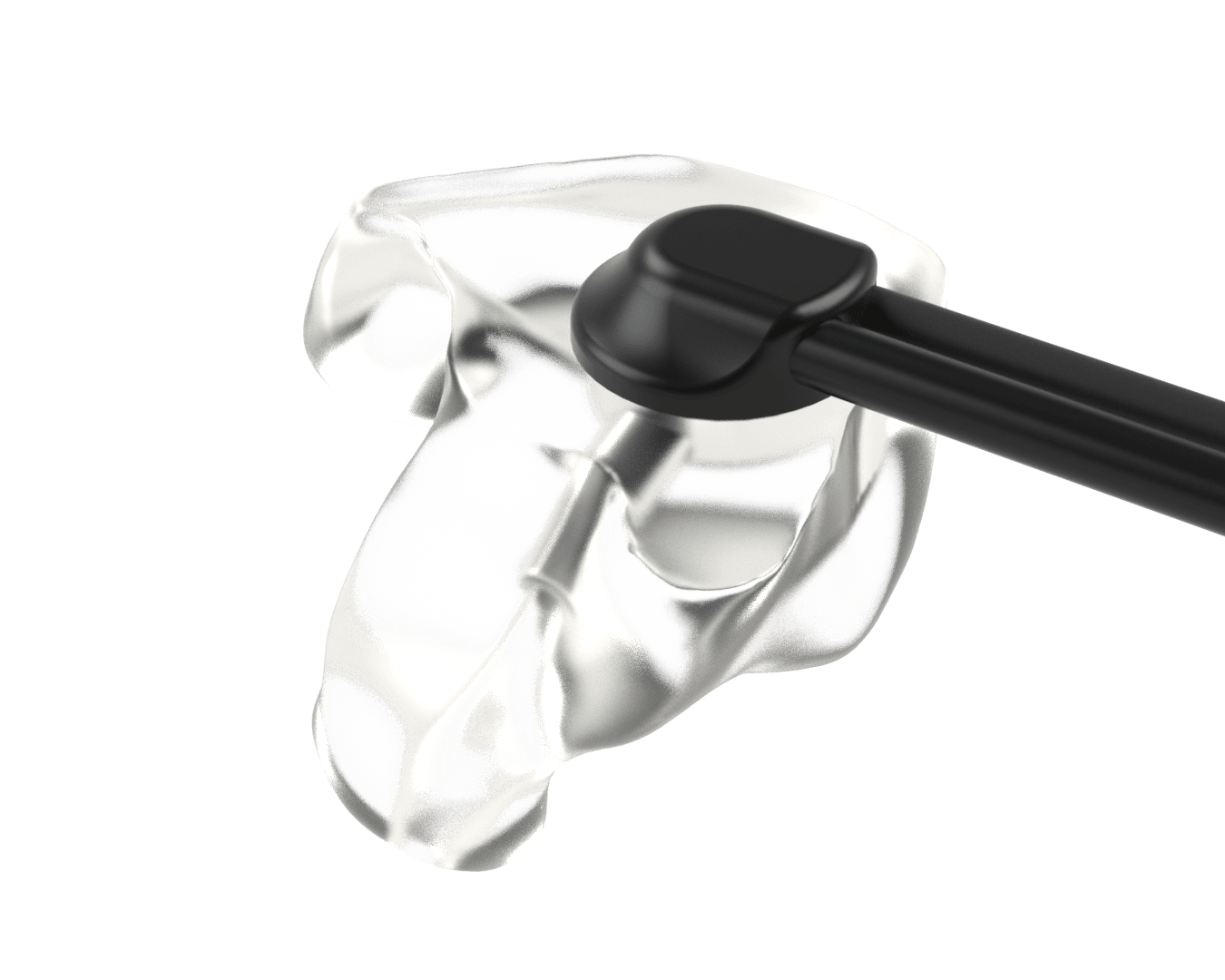

Formlabs continues to expand access to digital fabrication for the Audio industry with the launch of BioMed Clear Resin, a clear high-impact resistant biocompatible resin for hard earmolds, shells, and in-ear monitors. This important investment is part of Formlabs’ commitment to bring affordability to the digital production of hearing aids, ear protection, and consumer audio.

“With the launch of BioMed Clear, labs can now print in a high-impact resistant material that is ideal for audiology, noise protection, and custom fit earphones. The surface quality achieved with this resin on the Form 3B is truly exceptional, and we really look forward to bringing Formlabs affordability into our industry.”

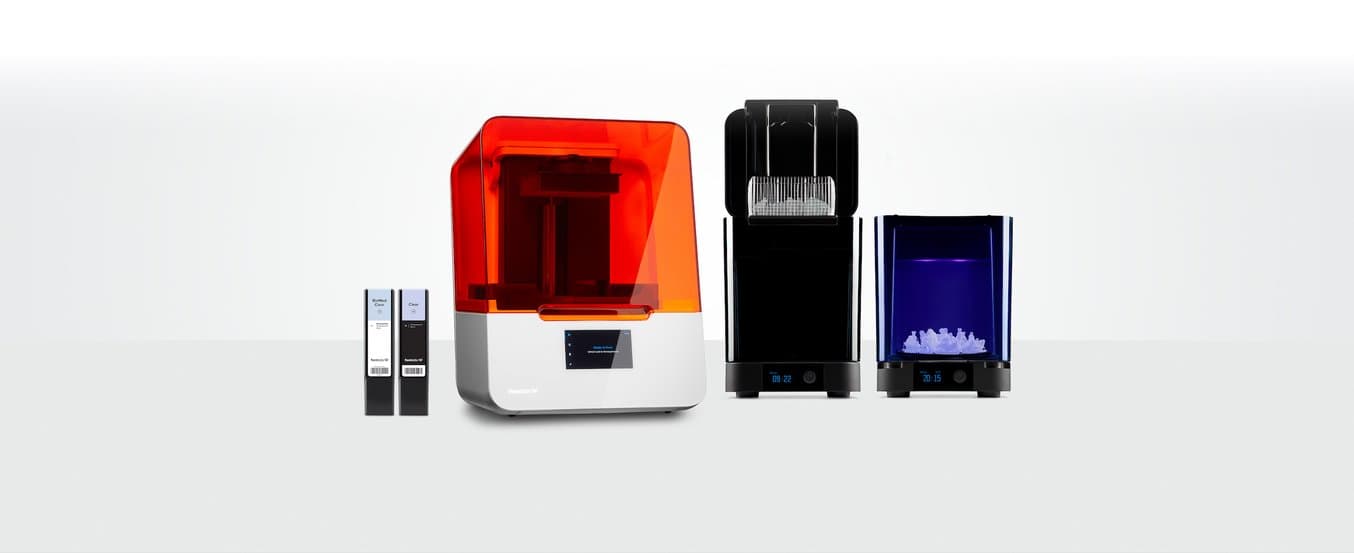

Customers using a Form 2, Form 3B, or Form 3BL can now greatly expand what is possible with 3D printing in their clinics and labs, bringing true long-lasting biocompatible materials in-house. Leveraging the benefits of the Form 3B Low-Force Technology, the low peel forces produce increased accuracy and amazing smooth surface finish right off the build platform and into the patient's ear. With a build platform more than three times the size of some competing 3D Printers (14.5 × 14.5 × 18.5 cm) and less than half the price, Formlabs delivers a truly unique triple value proposition: quality, throughput, and price.

“We have been a long user of the Form 2 which met all our expectations and more, but the Form3B has raised the bar with the awesome surface quality. The quality of BioMed Clear resin at 100um on the Form 3B is amazing! All the embossed names come out perfect, and overall surface quality is great. You guys nailed it”

Justin Stack, The Listening Stack

BioMed Clear Resin is compatible with common sterilization methods. It is manufactured in our ISO 13485 facility and is supported with an FDA Device Master File.

The Evolved Digital Audio Workflow

Provided by SensorCom

Digital workflows have disrupted dozens of industries, with every aspect of the Audio industry being upended. Covering audiology, noise protection, communication and consumer audio, the combination of scanners and 3D printing have led to the creation of custom-made, high performance ear devices delivering a perfect fit.

From hearing aids to let patients fully experience the world around them to high-end custom in-ear monitors for musicians who need to hear music in crystal clear clarity, performance and comfort are top of the priority list. Inaccuracies in the printing process will cause custom fit devices to either cause discomfort from being too large, lose acoustic performance or simply fall out if too small. With the Form 3B, the exact geometry of the ear is accurately recreated using the precision of SLA technology.

“Using Formlabs BioMed Clear Resin on our Form 3B printers allows us to produce biocompatible hard acrylic hearing aids that have a high detailed finish directly from the build platform. We have been able to quickly scale our digital production, benefiting from the affordability and performance of the Form 3B and BioMed Clear.”

Paul Thorpe, Lab Manager, Universal dB

With affordable in-house printing from Formlabs, bringing a custom fit audio experience to your patients and customers has never been more achievable. From clinics looking to offer one hour same day in-clinic services, or labs looking to scaling their business to allow production of up to 100 prints on a single machine per day, Formlabs evolves the digital audio workflow to the next generation.

Start Printing Today

BioMed Clear Resin is available globally from the Formlabs webstore, sales team, and our partners. Furthermore, other popular resins enable the Form 3B to do more, such as our Standard Clear Resin. Clear Resin remains one of the most affordable ways of creating molds for soft earpieces; learn more in our white paper on the cost effective workflow in creating soft silicone earmolds.