How Precision ADM Became the Largest Producer of 3D Printed Medical Devices

COVID-19 sent the world reeling starting in March 2020. Twenty-five million people worldwide contracted the disease as of this writing, industries ranging from hospitality to service shuttered, healthcare workers faced a shortage in PPE, and there weren’t enough nasal swabs for testing. Nasal swab shortages create serious hurdles to tracking and controlling the virus. Testing was delayed and labs could not operate at full testing capacity as machines designed for analyzing samples sat idle.

In times of crisis, individuals and organizations sought innovative ways to help. Precision ADM, an additive manufacturing company based in Canada, transformed their business to 3D print the CANSWAB™, their Health Canada-approved nasopharyngeal test swab. Precision ADM concepted CANSWABs in March and within five months, CANSWABs became the leading 3D printed medical device. Using more than 100 Form 3B printers, the company pivoted their business model and worked with Formlabs to create a custom 3D printing solution tailored to their new goal.

Read on to learn:

-

How Precision ADM changed their business model to respond to COVID-19.

-

How the company went from an idea for a swab to efficiently producing more than 100,000 swabs a week.

-

How they devised and implemented an expanded 3D printing setup on a tight timeline.

Making the Pivot From Metal 3D Printing to Producing Swabs

Precision ADM has great expertise in 3D printing, serving the medical, aerospace, industrial, and defense industries. They have plenty of experience in the healthcare sector, working with companies that produce implants and orthotics. Before COVID-19, Precision ADM worked primarily with metal 3D printing. The company worked mostly with EOS machines like M290 and M400. Metal 3D printing made a huge difference in orthotics. “You'd also find that with knee implants, you'd find it with hip implants that they're working with these lattice structures, microstructures in metal that you just can't traditionally manufacture,” said Precision ADM CEO Martin Petrak.

But that all changed when COVID-19 became a public health emergency in March 2020. Canada had a major shortage in nasopharyngeal swabs for COVID-19 testing and faced a contaminated swab supply. Precision ADM didn’t hesitate to jump in and try to help the situation. They quickly found success, becoming the first in Canada to produce 3D printed swabs.

“When this all happened, we said, okay, how can we bring in quickly a solution to help out those in our community? So ideally, we wanted to help those in our immediate community, in our province and in Canada, but also how can we help out even more so? It originally started with, some people are making 3D printed nasal test swabs, nasopharyngeal test swabs for COVID-19. There's a big shortage. And this is something that we could potentially be able to spool up and help out with,” Petrak said. “It was very, very shortly after everything sort of happened that we stepped in and said, ok, let's get some of these printers. Let's do some testing. Let's try to get Health Canada approval for something so that we can start getting this essential testing equipment out to at least our country and our province right away.”

Petrak said they found Formlabs, knowing that Formlabs was a trusted brand with FDA approval and our 3D printers were the driving force behind Northwell Health’s swabs that were created in partnership with USF Health. “We don't want to reinvent the wheel. Let's get some printers so we can start engineering a solution that works,” Petrak said.

Building the factory

Precision ADM was able to print swabs thanks to Formlabs Factory Solutions, a comprehensive and customized package for manufacturers that includes 3D printing hardware, software, and materials. Factory Solutions played an integral role from the start, working with Precision ADM to make their manufacturing process more efficient. Precision ADM was equipped with custom software and hardware solutions to streamline operations.

Factory Solutions worked with Precision ADM to deliver printers and resin to get started as quickly as possible. Because Formlabs has experience working on swabs—both internally and with pioneering customers Northwell Health and USF Health—Formlabs had a set of manufacturing best practices ready to implement in Precision ADM’s facility. Formlabs also provided design help, regulatory guidance, customized software, and workflow optimization.

According to Ryan Olson, Project Managing Engineer for the 3D printed nasal test swabs, the team worked closely with Formlabs to learn the baseline design and process flow. After getting the basics down, they made iterations and increased energy efficiency in the process. “We went through each step of the process and really tried to do everything we could to understand the implications of the parameters, the inputs and what we would get as an output...that was obviously aided a lot by Formlabs,” Olson said.

Formlabs guided Precision ADM in updating their manufacturing process to create a Health Canada-approved swab—it was a collaborative effort that involved process changes and redesigns. “It was a case of designing around the material properties that we had, making do with what we knew about the material...relying on our understanding of geometric stiffness to come up with a more flexible neck to better suit the patient's comfort. We're very happy with the bendability of our swab. It more than meets the flexibility standards that have been put out by Health Canada,” Olson said.

Additionally, Formlabs helped Precision ADM reduce their cost by becoming more efficient, resulting in the company becoming competitive against other nasopharyngeal swabs.

The company scaled in three stages, adding printers with each stage—they started with 20, added 20 more at the second stage, then bought 65 most recently. Because Formlabs printers create a modular production station made of many individual printers, PADM could add capacity when they needed it as opposed to having to invest speculatively. When Precision ADM received a large customer order, Formlabs delivered increased production capacity that was operating within 2-3 weeks.

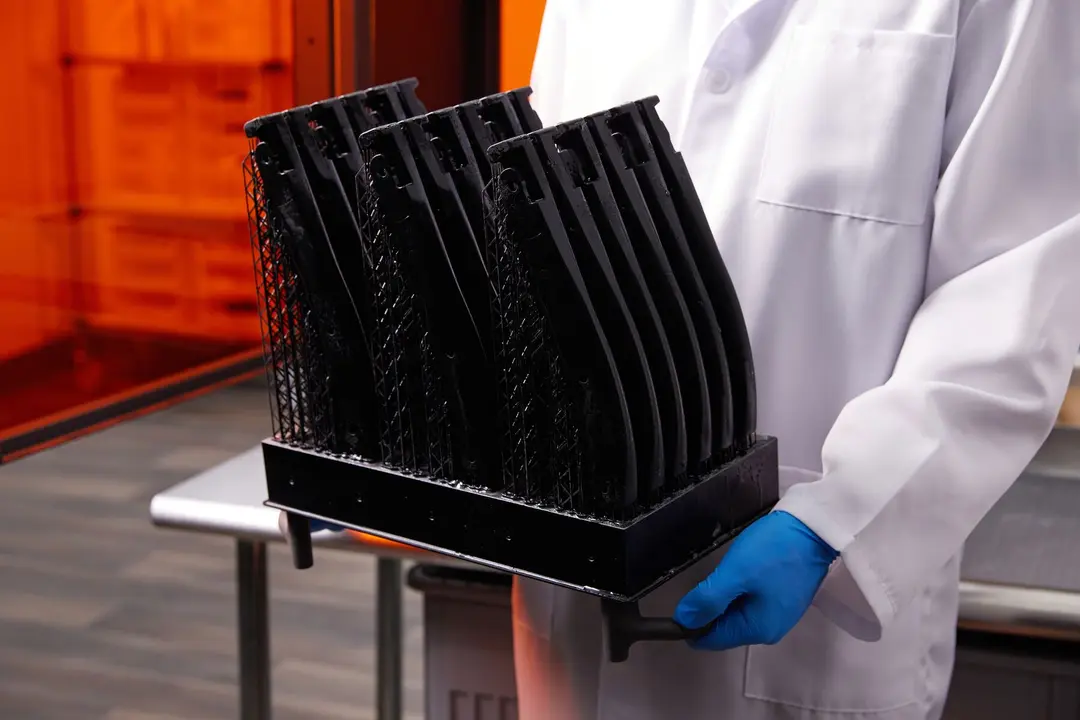

Producing such a high quantity of swabs means being as efficient as possible. The swab production workflow involves printing every day, post-processing, and quality inspection before the swabs are sent off for sterilization and packaging. “We validated the wash cycles to ensure that we can maintain a biocompatible product after multiple consecutive washes...without degrading the material and recycling the IPA as much as possible,” Olson said.

Formlabs Factory Solutions delivered the industry’s lowest total cost of ownership and lowest all-in cost per printed part to Precision ADM. With cost effective, reliable, and scalable printers and resins, the Factory Solutions team helped reduce costs at many points throughout Precision ADM’s workflow.

The swabs Precision ADM printed with the Form 3B on Surgical Guide Resin are unique—while they were inspired by the USF Health-patented swab, they are not an exact replica. “Initially, we found that the swabs were a little bit brittle so we had to do some in-house changes to some of the designs...So we reengineered a little bit. After numerous testing we were able to come up with a design that works for us and the treatment of it that works for the patients for comfort,” Petrak said. Trademarked as the CANSWAB™, Precision ADM went from wanting to help in mid-March to prototyping swabs to getting Health Canada approval for the swabs in early July.

Unprecedented Times

COVID-19 and swab production fundamentally changed Precision ADM’s business model. Once an aerospace and medical orthotics focused company, they are now a medical device company, though they are still committed to serving the industries they were previously well known for. The company has even expanded their operations by acquiring a neighboring facility. The space will be used for more Class 7 cleanrooms. Whatever COVID-19 throws in the way of a challenge, Precision ADM is prepared to respond—a second wave, a harsh fall and winter, a yearlong ordeal, or new strains. The company has hired more employees-quality inspectors, engineers, and more.

“We're hiring employees to do QA, to look after the manufacturing with all the Formlabs machines that are running constantly 24 hours a day in our cleanrooms that we've set up. It’s been incredibly busy since March,” Petrak said. “We've got orders from the federal government and our provincial government and we're looking at other provinces that are interested as well so that they can build up their supply of these swabs...we're trying our best to meet the demands that we have currently and expanding to meet those demands as best we can.”

For Precision ADM, adding resin-based polymer 3D printing to their metal printing capabilities wasn’t difficult. Metal 3D printing requires much more supervision and caution—the risk of setting something on fire is much higher when working with metal than it is with resin. According to Petrak, it was a treat for Precision ADM engineers to get the Form 3B printers up and running.

Precision ADM’s Workflow for Printing a High Volume of Swabs

Precision ADM was able to hit the ground running and produce 110,000 to 120,000 swabs per week, with a goal to print 400,000 to 500,000 per month. While they made many new hires for the purpose of working on swab production, it is still around 30 people dedicated to that role. How is Precision ADM able to be so efficient, producing such a high volume of swabs without an overwhelmingly large team? A large part is their streamlined workflow made hassle-free by the Formlabs package and the Form 3B printers that are able to run overnight.

Once the engineers figured out the prototype and how to optimize the workflow, it was just a matter of adding more machines. “The real tell of how streamlined it can be, is when we add new machines, it's not a big deal to get them up and running at this point. We know what it's going to be. We can add machines, add them to the network, add the print, and they're good to go,” Olson said.

3D Printing’s Future in the Medical Industry

Precision ADM is keeping busy with COVID-19 response efforts. But even if COVID-19 dissipates, being introduced to Formlabs’ 3D printers transformed their way of thinking about and approaching 3D printing. “If tomorrow the world suddenly cures COVID-19 and we don't need any more test swabs, I'm sure that we'll be able to put the printers to use. We’ve just got to figure out a different use case for them,” Petrak said. Biocompatible materials played a huge role in expanding 3D printing applications in the medical industry—they would enable Precision ADM to expand beyond metal 3D printing. Furthermore, 3D printing can aid in producing patient specific models, as healthcare becomes more personalized.

“Previously we thought we were only a metal 3D printing company and that that was what we wanted to specialize in...We wanted to stick with the really high value components which were titanium and cobalt chrome. But I think that this has really opened the door for us to look at things differently,” Petrak said.