3D printing test fixtures and manufacturing aids saved nearly a quarter of a million dollars last year for Bendix Commercial Vehicle Systems (Bendix). The Avon, Ohio-based company is a tier-one developer and supplier of leading active safety technologies, energy management solutions, and air brake charging and control systems for commercial vehicles and school buses throughout North America.

This year, on track to exceed that number, Bendix is relying on their fleet of 3D printers. However, even with 10 different advanced 3D printing systems in-house, over one-third of their output comes from the Formlabs Fuse Series selective laser sintering (SLS) printers. In the first ten months of 2025, their Fuse 1+ 30W printers have printed over 3,235 parts, far outpacing their Bambu and Stratasys printers.

“The Fuse ecosystem is great. We love the Sift, and the Fuse Blast is an award-winning piece of machinery. The Fuse price point is a win. I must like it, because I keep pushing it every time we talk about additive manufacturing at Bendix.”

Mark Matko, Bendix Advanced Engineering & Additive Team

Mark Matko keeps detailed accounts of the productivity of each of his 3D printing processes. So far in 2025 (through November), he’s printed over 3,235 parts on his Fuse Series SLS printer, more than his benchtop Stratasys FDM, desktop SLA, or desktop FDM, all while keeping costs low.

With nearly three million commercial semi-trucks registered in the United States, each traveling an average of 45,000 miles each year, Bendix needs their systems to be expertly manufactured, reliable, and highly traceable, down to the last steel pin. Though introducing 3D printing can be difficult with that level of oversight, Bendix is working to establish an AI tracking system for 3D printing across different departments that will serve as a model for any manufacturer looking to expand additive manufacturing. The AI model will draw from the meticulously detailed records Matko has kept of 3D printing for the Advanced Engineering and Additive Team.

By starting with high-impact test fixtures and manufacturing aids, Matko and the engineering team at Bendix have been able to improve processes, accelerate development timelines, and reduce costs across the company.

The Challenges of Additive in Commercial Vehicle Manufacturing

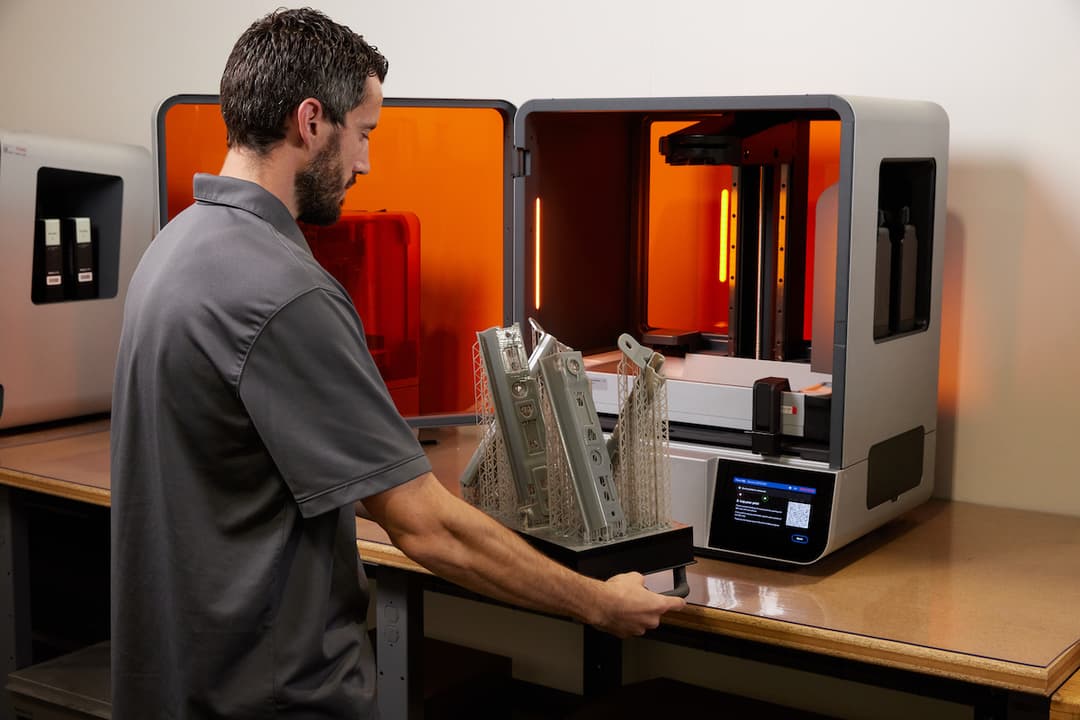

Bendix has printed more than 3,200 parts on their Fuse 1+ 30W printer in 2025 so far (through November), outpacing even their high-volume FDM printers.

Matko takes parts out of the Fuse Blast, which has dramatically reduced the hands-on post-processing time for SLS parts, making it easier to handle higher-volume requests.

3D printing for commercial vehicle manufacturing is not new, but it is nearly always relegated to the realm of the R&D departments and iterative prototyping teams. To make it a production-ready technology that’s putting 3D printed parts out on the road or on the factory floor requires each manufacturer to develop tracking systems so every 3D printed component can have the same traceability as every metal spring or molded duct.

“The challenges we still have are that if we manufacture additively, we have to ensure there’s traceability to the printer and the location within that printer,” says Matko.

For parts that help ensure the safety of 80,000 lb trucks driving down interstate highways, that traceability could help save lives. But building an automated system like that takes time. Though Matko has three years of data on cost per part, printer performance, savings, and efficiency improvements, there’s more that needs to be done. To get end-use components out on the roads will require proving the use case with manufacturing aids, prototypes, mock-ups, and more.

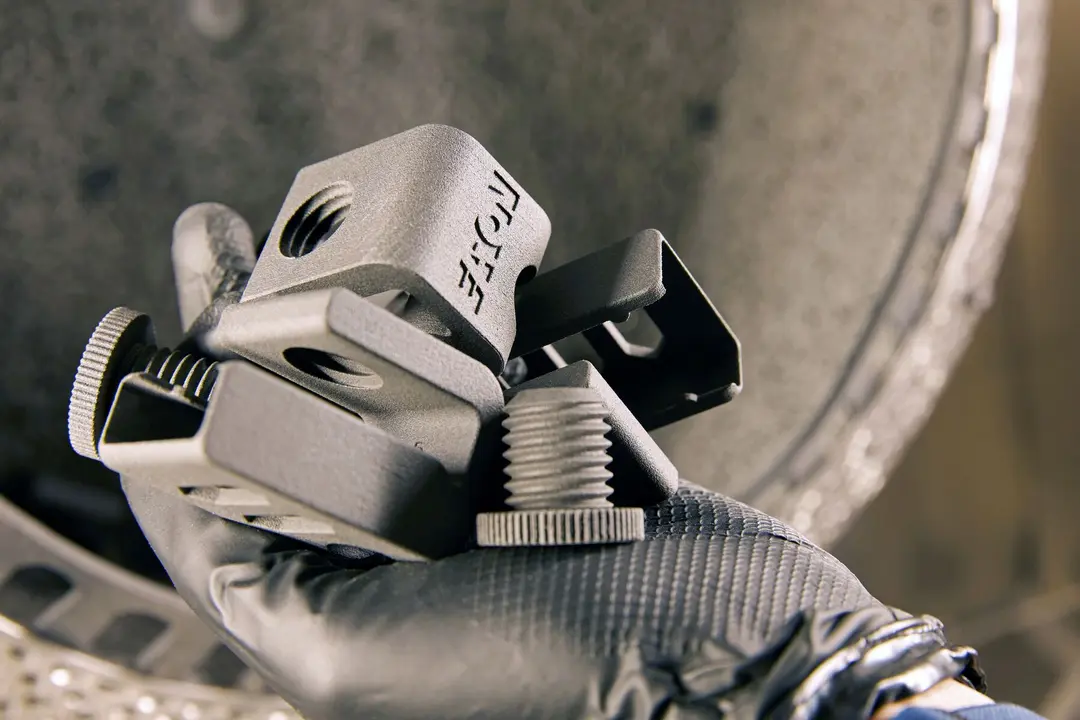

This camera mount was designed as part of a fully 3D printed robotic installation on the shop floor while aluminum tooling was being made. The camera visually measures parts going into an engine dampener assembly cell in order to tell the robotic arm which size gripper to use when moving the parts.

“Everything we want to print additively, we run through multiple months of testing for any part. We’re making safety-related products, so we can’t have anything fail; that’s additive’s biggest challenge,” says Matko.

But before end-use 3D printed products are approved, Matko is building the case with a range of impactful, cost-effective SLS 3D printed fixtures, jigs, end-of-arm-tooling, and other manufacturing aids that make production faster and more consistent.

3D Printed Manufacturing Aids at Bendix CVS

For a manufacturer that produces such complex assemblies, and for a range of end-use commercial vehicles, manufacturing aids and the tools that make them have to be versatile. Matko has a fleet of different 3D printers, all with different strengths. He turns to SLS almost half the time, however, because of its capabilities for functional parts that can withstand the demands of rigorous testing.

“We can apply air pressure to SLS, we can tap SLS parts to put threads or fittings in. We can do lots of small pieces or larger parts with unlimited geometries, and we can get them quickly, without messy post-processing.”

Mark Matko, Bendix Advanced Engineering & Additive Team

Matko prints nearly every day on the Fuse Series. These are some of the recent projects where SLS has saved Bendix significant cost or streamlined their manufacturing process by making life easier for operators, reducing stoppage time, or replacing a broken part.

Controller Top (build of 1000 pieces per year)

Background: Solving for OEM Obsolescence

Producing this part in SLS could reduce part price by as much as 40% as compared to traditional methods like injection molding.

The controller top covers the electronic system that manages the continuous air supply in commercial vehicles. It was previously molded into the valve as one piece, but was very expensive to produce in low volumes. As the commercial vehicle industry requires this component, 3D printing is a more cost-efficient solution.

Though low-volume, both OEM and aftermarket customers need this part, making it a very high-profit component. “This is actually one of our actions with obsolescence, which is a big reason for us to use 3D printing. We don’t want to retool these parts because they’re low-volume. We can print 1,000 of them a year, and then never incur tooling costs again, even when there are revisions to the part,” says Matko.

Camera Mount

This multi-part assembly holds the AI camera used in a robotic assembly station for engine dampeners. The dampeners were formerly built manually, but are now built by a fully automated robotic arm. The AI camera measures each component to tell the cell which gripper size to use.

During the programming and set-up of the cell, Matko printed every fixture, mount, bracket, and gripper on the Fuse Series. The camera mount was built with interference fitting on every joint, so it can be tapped together with a hammer and hold securely — it’s affixed to the camera with steel bolts.

“We were able to test and program the robotic cell without waiting for aluminum tooling — everything was printed on the Fuse and we could do multiple iterations of every piece without holding things up, while saving a lot of money on machining,” says Matko.

Enclosure and Cover (build of 1000 pieces)

This two-piece part allows the connector to be soldered to the PC board and then installed as a single unit. There is a seal between the two halves, and the top snaps into position.

Before 3D printing this, Bendix would overmold the PC board, shooting plastic around the part after it was assembled.

“Although the part is not exposed to the environment, it’s pretty much waterproof now. The SLS two-piece enclosure fits together smoothly, so you can take the components out if you need to, unlike the overmolded plastic,” says Matko.

Park Valve Tester: Bendix Mv -3 Dash Valve

This product is included in an overall lifetime testing fixture. In this parking valve tester, hardware cycles buttons in and out — as a driver would do over several years.

Before 3D printing, Bendix was using machined aluminum parts that would wear the buttons prematurely. The aluminum tester parts were more durable than the buttons, causing Bendix to replace the buttons before finding the actual lifetime limit.

“With SLS nylon parts, we can print 20 parts on the Fuse, and replace them when we need to, as we’re still in the lifecycle testing and the fixture can take the wear, not the part being tested,” says Matko.

Electrical Cover for Electric Truck Maintenance

When working on an electric semi-truck, operators need to disconnect the electrical power for safety reasons. Though the manufacturer of these electrical plugs sells covers, the contractor might forget to bring them, and no work can be done until the plug is covered. Instead of waiting six hours for a replacement, Matko printed a replacement on the Fuse in 90 minutes, enabling work to commence.

Electric Compressor Display Part

This display part (top) is a one-fifth reproduction of the electric compressor Bendix manufactures and sells. The display part, though only about five inches long, has a pull-tie that actually rotates.

“Being able to print something with this much detail that didn’t require a lot of post-processing has been huge for trade shows and customer visits. The 3D model allows us to show how we've designed the real component without having to get the entire compressor out,” says Matko.

*Material priced without including a bulk discount. Contact sales to learn more.

Next Steps at Bendix With Additive

This electrical cover used for performing maintenance on Bendix's Electrical Truck was quickly printed on the Fuse Series and enabled the MRO team to complete their work immediately, rather than having to drive hours to go find the OEM-provided part.

Manufacturing aids, prototypes, and road show displays are what Bendix has been printing for years. Before expanding to end-use production, the company has a goal of becoming experts in additive manufacturing. Bendix is a member of Munich, Germany-based Knorr-Bremse. Germany is a country that has led the world in 3D printing innovation — especially in the automotive industry — for years. “We're owned by a German company that champions the use of additive manufacturing. The end goal is to get to a place where we can start to pursue end-use 3D printed production. We are just now at a point where the technology and chemistry are matching the requirements that the automotive industry requires, and harnessing this will favorably position us in the industry," says Matko.

The going looks good — Matko’s meticulous record-keeping has helped make the case across the company. 3D printing is now being recognized as an alternative to traditional manufacturing for some parts and, with other parts, a way of improving processes.

“Our next step is additive manufacturing for production. We’re trying to identify which parts we can do with additive manufacturing. There are probably 10,000 parts that have potential, and maybe 10% of those will end up being end-use 3D printed. Our Advanced Manufacturing Engineering organization is leading a cross-functional team evaluating options to move from product development into production. This involves simulation, using established industry standards from the US and abroad, as well as AI to determine which components fit the desired criteria for production."

To learn more about SLS 3D printing for manufacturing aids or end-use production, visit our site. To test Nylon 12 Powder for yourself, request a free SLS 3D printed sample.