“Nap when the baby naps,” goes the popular saying. Here’s a product that helps new parents do just that. Rest Devices is a company developing a line of products they call a “Smart Nursery.” Their first product, the Mimo Smart Baby Monitor, gives parents a new level of insight into their baby’s sleep quality and activity. The Mimo features a small plastic “turtle” that snaps onto the baby’s clothing to monitor heart rate and sleeping position.

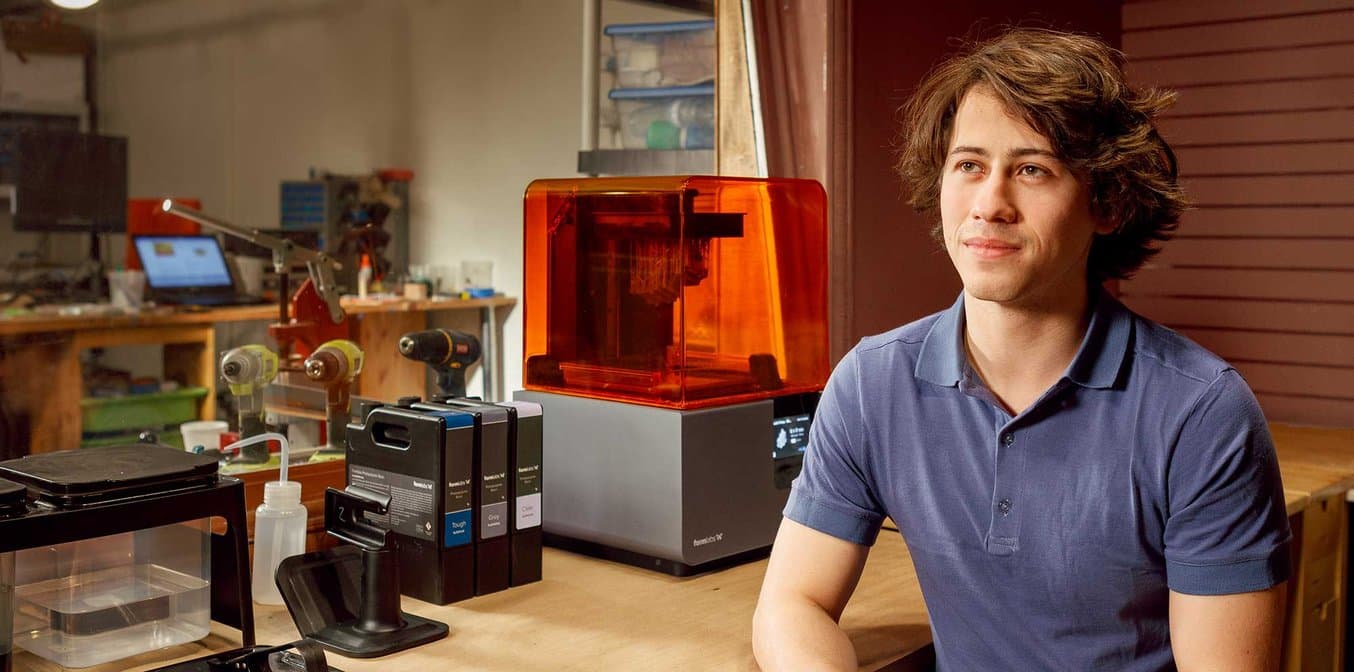

Silas Hughes, an engineer at Rest Devices, uses the Form 2 SLA 3D printer to prototype new products and make their manufacturing process more efficient. “3D printing [is] an integral part to how the products developed, how we think about developing, how we manufacture.”

From Prototype to Assembly Line

As a small company, Rest Devices has direct control over every part of the product. With 3D printing, they are even able to take on some of the assembly in-house.

“In our manufacturing process, if we weren’t using 3D printing, simply put, it would take longer and it would cost more money. ”

Previously assembling each Mimo device by hand, Rest Devices is now 3D printing tools to create a production assembly line. These tools, often referred to as jigs, help streamline tasks like pressing magnets into the bottom of the plastic turtles. To program the circuit boards, they’ve designed a rig that uses a camera to recognize the ID on device. By designing custom “rigs and jigs” for their production process, they reduced assembly time and improved the quality of their products.

“We prototype using a variety of 3D printed parts to make sure the idea and design is sound, and we build our final version of a product still using 3D printed parts.”

Rest Devices uses the optical qualities of Formlabs White Resin to make another 3D printed rig that holds and programs the circuit board. The tools to help manufacturing the Rest Devices are made in-house, tested, and then shared with their contract manufacturer. The company is using their Form 2 everyday to bring their customers the highest quality parts possible and make their lives, as well as parents’ lives, easier.

Bring 3D Printing In House

Learn when to outsource to a 3D printing service bureau or prototype in-house in our white paper.