From fine furniture in Atlanta to customized Mercedes-Benz Sprinter vans in Southern California, Jenny and Alex Baumann know how to make a quality product. Post-pandemic, when the custom build-out market for Sprinter vans in the ‘van-life’ community became a bit too crowded, the Baumanns were able to pivot, and from that pivot came their wildly successful aftermarket automotive manufacturing business, Terra X.

Terra X’s 15 products are designed, prototyped, and produced on three Formlabs Fuse 1+ 30W selective laser sintering (SLS) printers, and their scalable approach to in-house manufacturing has helped keep their operation lean, consistent, and ahead of the competition.

“This changed our business. With in-house design and production, we are controlling 100% of the process. Every small-business, every bike shop should have one of these printers.”

Alex Baumann, co-founder and owner, Terra X

Building More Than Van Build-Outs

Doing high-quality van build-outs started the Baumanns on a path towards automotive aftermarket customization, eventually leading to Terra X and high volume production with the Fuse Series.

After years in the custom furniture business, Jenny and Alex Baumann emptied their Atlanta loft and gave away most of their possessions. They did one last (or so they thought) custom job — buying and overhauling a Dodge Promaster van to drive cross-country. Then, when they hit San Diego County, the community, the weather, and the business possibilities drew them in. “We were at a van meet-up, with probably 300 other vans, and people kept asking about our build-out,” says Jenny Baumann. The couple drew on their years of experience with high quality custom jobs, and started building vans for the growing wave of van-lifers getting out of cities and on the road.

Then in 2022, though the COVID-19 pandemic led to a booming van build-out industry, the market became oversaturated. “In San Diego County alone, there were 27 van builders. It was such a huge trend during COVID,” says Alex Baumann. Their initial business venture was facing an inflection point, and the Baumanns knew they could pivot to another great idea.

“We had always been asked about places to mount navigation equipment, phones, and iPads. People and businesses were spending so much time worrying about fitting homes into the back of the vans and focusing on exterior products, that they weren’t thinking about the driving experience, and being able to actually get places,” says Alex Baumann.

Trying It Out and Learning from Seals

Baumann initially thought these parts would all be sent to the machinist. After working with a local machinist who had used SLS 3D printing during his time as a Navy Seal, the plan changed.

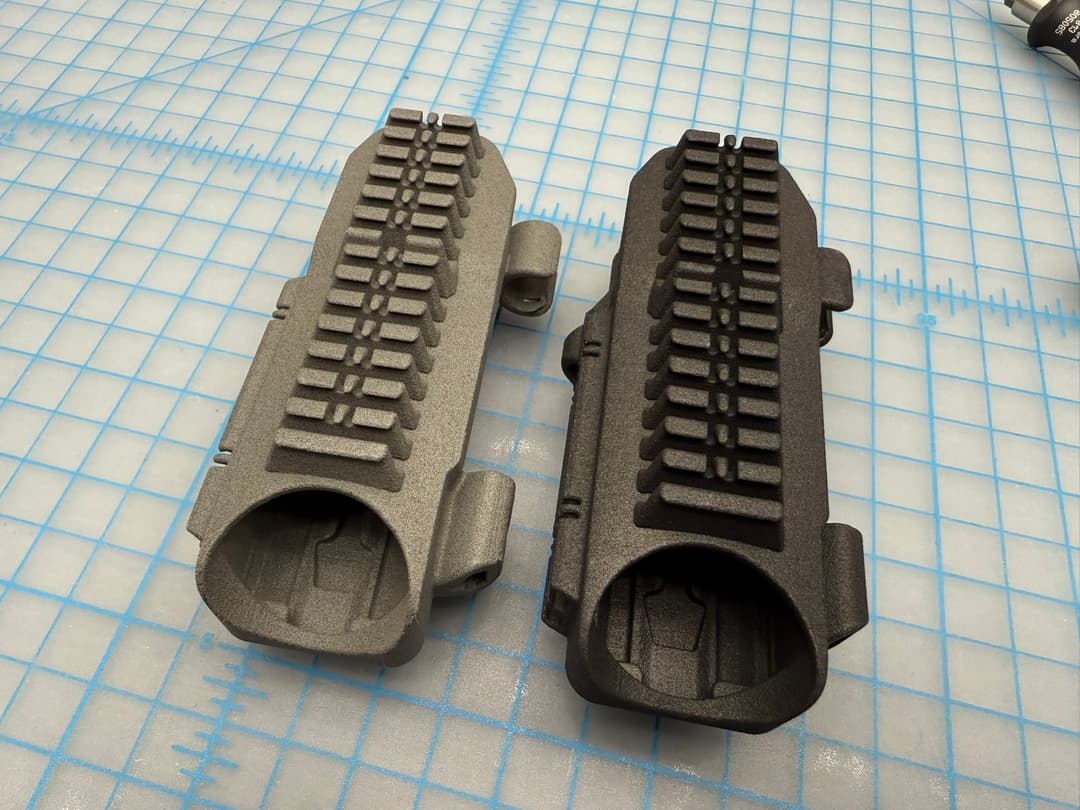

Printing quick prototypes on an inexpensive FDM 3D printer was helfpul for locking down his final design.

Putting his design skills to use, Alex drew up a prototype and bought a small fused deposition modeling (FDM) 3D printer to start trying things out. When the first couple of prototypes worked well, he and Jenny started to explore other ways of fabricating them, ways that could hold up to tough off-roading conditions and the rugged lifestyle of a lot of van owners.

The first step was to see a machinist to see if he could make molds that worked. “At the time, I had it in my mind that I wanted to make these with a machinist and do extrusions,” says Baumann. But the machinist had some other ideas. As a retired Navy SEAL, the machinist had spent a lot of time figuring out how to make durable tools that made navigation as easy as possible, and had used SLS 3D printing to make iPad mounts for SEAL teams.

“I came back from meeting with him saying, we need to use SLS 3D printing,” says Alex. The Baumanns started off using outsourcing, ordering parts printed with powder bed fusion technologies from service bureaus. They started with two parts, a mount and a bracket for phones and iPads to affix to Sprinter van dashboards.

Terra X started by using tracks manufactured by Ram integrated into their designs. After their products started to take off, Ram offered them a partnership, making Terra X an official dealer.

The brackets were expensive to assemble; they used OEM-manufactured tracks to attach to the dashboard. Then, as sales started to take off, Ram, the OEM in question, took notice. They made the Baumanns official dealers and “suddenly we were making a way better margin. We started to make money and then we could think about bringing everything in-house,” says Jenny Baumann.

In-House Considerations

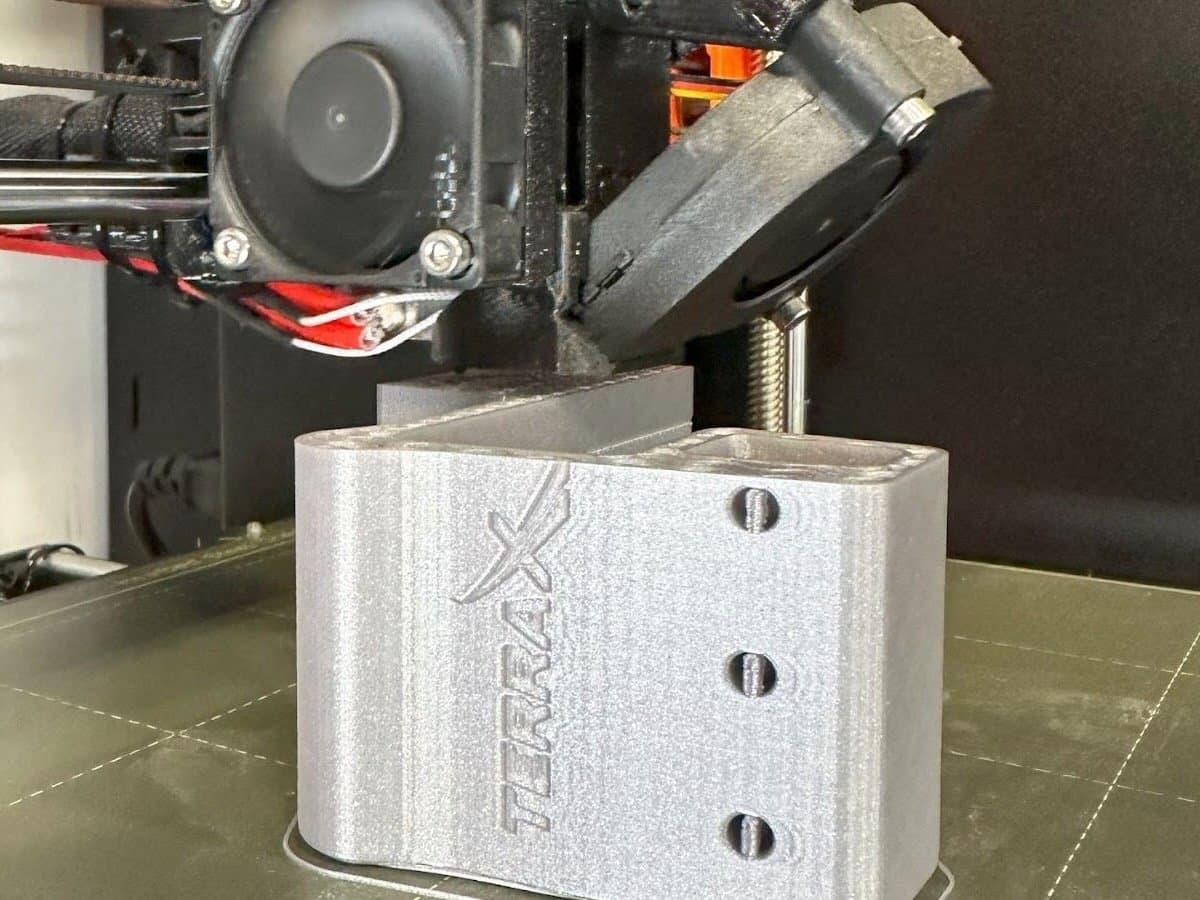

In-house production enabled Terra X to expand their product catalogue. This product, the Navidock, is printed on the Fuse 1+ 30W and enables drivers of Mercedes-Benz Sprinter vans to easily mount their navigation systems.

Bringing SLS in-house wasn’t just about getting a better margin, it would allow them to diversify and grow their business, to scale on their own timeline. “When we decided to do it, we already had five other products in mind. We’re already three designs ahead of our competition,” says Alex Baumann.

The print farms they were ordering parts from required higher quantities to set affordable prices, but with the number of products Alex was planning, that model just wouldn’t work out. He needed to start in lower quantities, but still with functional, high-quality parts, to test the market and get the integration with metal components right.

“We had this awesome product, but we couldn’t get them made because the required quantities were too high to get a halfway decent price. And the quality of the prototypes was bad. If I don’t do it myself, it’s not being done right," says Alex.

The parts they were receiving weren’t being printed for optimal orientation and structural integrity, they were being packed for efficiency. The Baumanns had received several parts with lines through the front face of the brackets, and Alex knew it was due to a nesting decision made for profit, not product integrity. “Once they did that on two orders, we said, okay, time to bring it in-house,” says Alex.

The Fuse 1+ 30W at Terra X

The small footprint and affordability of the Fuse Series allows scalable growth, so that you can add print capacity as demand grows without a big investment up-front.

Once the decision was made, Jenny left the printer research up to Alex. “I know he does his research on machines, and we’ve both worked with really expensive manufacturing equipment in the past, so we have experience with what it takes to get a consistent, reliable machine in-house,” says Jenny.

The research turned up that the Fuse 1+ 30W was the right price for a small business to bring in-house, and in the high-priced cityscape of San Diego County, the right size and voltage, too.

“We’re in Southern California, we needed something less than 110 volts. The team at Formlabs did test prints for us, and they were the right size, surface finish, tolerances, and price point,” says Alex. Getting into a reliable production workflow didn’t take very long. The Baumanns received the shipment, and were up in running the same day.

“It immediately went the way we wanted it to go. From the beginning on, we were rocking and rolling. The first print we did was 100% and we started selling.”

Alex Baumann, co-founder and owner, Terra X

Redundancy in Production and a Scalable System

The Baumanns added the Fuse Blast as soon as it came out, immediately cutting their hands-on labor time by nearly half. Their parts are unpacked in the Fuse Sift, media blasted and polished in the Fuse Blast, and then dyed using a manual dyeing process with a culinary slow-cooker and RIT dye in Black.

“With the Polishing System, we get a really nice shiny black finish. We’ve been asked if it’s vapor smoothed, and the dye penetrates great. We’ve even been doing UV weathering tests for an exterior camera mount, and after a year, there’s no fading in the sun.”

Alex Baumann, co-founder and owner, Terra X

As their products became more successful, Terra X hit a bottleneck. Even with an overnight print, they needed more capacity. They bought a second Fuse 1+ 30W to handle the overflow, and then, within six more months, bought a third. Alex Baumann believes in redundancy, to stave off the stress and the ‘what-ifs’ of manufacturing. “If you need one printer, you should have two, and if you have two, you need three. Now we’re printing on all three, every day,” says Baumann.

Customer service and on-time delivery are paramount to the Terra X, and they print six days a week, with all three printers, so that they never go out of stock or deliver a late shipment. In a crowded aftermarket automotive industry, their customer service helps keep their high-quality products selling out.

Enterprise for Reduced Downtime and Fast Fixes

The Baumanns have high standards for their own customer service as well as vendors’. After starting with the basic service plan, at three printers and a nearly 24/7 printing schedule, the Baumanns needed someone who was a bit more hands-on with their business and who knew that they could go through basic troubleshooting on their own.

“We’re familiar with these printers, we know what’s going on, and we needed a service plan that didn’t take us through the most basic steps first, but could get right to the fix,” says Jenny. They added the Enterprise Service Plan, Formlabs’ solution for production customers who need to avoid downtime and get fixes quickly, and got up and running quickly.

Now, their Enterprise Service rep knows their needs, understands their workflow, and can cut to the heart of the matter quickly. “With Enterprise Service Plan, we know how to talk to each other, and he knows we can work on these machines pretty well. We really do feel like Formlabs is trying to be a part of the manufacturing process,” says Alex.

Looking Forward, Beyond the Dashboard

With 15 products already flying off the shelves, Terra X is ready to continue expansion. Having a single workflow for prototyping to production in-house makes getting new products to market extremely fast.

The quality of parts that have been printed on the Fuse Series and finished with the Fuse Blast polishing system means that Terra X's parts can blend seamlessly into cars interiors while delivering high functionality.

When Ram recognized their product and brought the Baumanns in as dealers, that was a huge step for the business. Now, with 15 products and more ideas brewing, Terra X is ready to take another step forward. New OEMs, new models and products, and new printers: the business is set to scale fast, without having to add any massive overhead costs or huge infrastructure changes. With Fuse Series printers, they can double capacity without doubling costs, and the demand for these products isn’t going away any time soon.

“So many small businesses feel like they have to go through all these up-front processes, and have high quantities, and are afraid of their design getting stolen. But with solutions like these printers, this is a screaming good idea. People are empowered to make things based off the equipment they have, and this changed our business.”

Alex Baumann, co-founder and owner, Terra X

To see the Fuse Series in action, explore our page. To test a Fuse 1+ 30W printed part for yourself, request a free SLS 3D printed sample.