SLS(粉末焼結積層造形)方式の3Dプリント品は、その優れた機械特性とコスト効率の高い生産性から、航空宇宙や眼鏡デザインなど多岐にわたる業界で活用が拡大しています。SLS プリント品の外観や機械的特性をさらに向上させるため、3Dプリンタユーザーの多くは染色、コーティング、めっき、塗装などの後処理を行っています。

Fuse 1シリーズSLS 3Dプリンタを使ってNylon 12 Whiteパウダーで造形した部品を染色することで、魅力的なプロトタイプや幅広いカラー展開の本番生産用部品を容易に実現できます。

このガイドでは、SLS 3Dプリント品の染色プロセスを概説するとともに、その多彩なメリットについてご紹介します。染色工程の全体的なワークフローについては、技術資料をダウンロードしてご覧ください。

SLS 3Dプリント品に染色が必要な理由

SLS 3Dプリント部品は、デザインから製造まであらゆる工程での普及が進んでいます。表面がわずかにざらついた独特の質感になることから、スムージングやコーティング、染色などの後処理技術もますます注目を集めています。

染色は低コストでSLSプリント品に色をつけられる手軽な方法で、機械的特性を損なわずに外観を向上させることが可能です。カラーパーツを少量だけ作りたい場合でも、パントンカラーコードにマッチした製品を大量に製作したい場合でも、あらゆるワークフローに対応する染色方法があります。

当社チームでは代表的な4種類の染色手法をテストし、その結果をレポートにまとめました。本ガイドで紹介するのは概要のみですが、テスト結果の詳細全文もぜひ技術資料をダウンロードしてご確認ください。

染色は、ブランドの美観に合わせたカスタムカラーが必要な機能試作や実製品用部品に最適。

無料サンプルパーツのお申込

Formlabsの品質を直接手に取ってご確認ください。Fuse 1+ 30WにてNylon 12 Whiteパウダーで造形したサンプルパーツを無償でお届けいたします。

Dyeing Equipment

We tested dyeing equipment to assemble the optimal setup for dyeing Nylon 12 White Powder. Below, we outline the hardware, dye mixture, and dye bath parameters that achieved the best results in our testing.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

| 方法 | サイズ | 数量 | 色 | 耐UV性 | コスト |

|---|---|---|---|---|---|

| ポット式染色 | ★★ | ★★ | ★★ | なし | $50以下 |

| 超音波染色 | ★★★ | ★★★ | ★★★ | なし | $100〜$1000 |

| 高圧染色 | ★★ | ★★ | ★★★★ | なし | $100〜$500 |

| DyeMansion DM60 | ★★★★★ | ★★★★★ | ★★★★★ | あり | $50,000 |

The hardware that we recommend for dyeing is the ESVC-28 - Spectrum Thermal Circulator from Winco. This machine is affordable, available from multiple sources, and is easy to set up and use.

US Source: $699.99

EMEA Source: €659.99

APAC Source: $299

The Winco ESVC-28 Spectrum Thermal Circulator is an ideal solution for ultrasonic dyeing.

Any system that is able to reach the necessary temperatures of 80 °C to 90 °C as well as circulate the solution should be adequate for dyeing. We also recommend having stainless steel tongs nearby to assist in removing parts from the dye bath.

There are also industrial solutions available on the market for dyeing SLS parts, like the Dyemansion DM60, that are cost-effective for high volumes of parts and when extremely consistent results are necessary. This product is capable of holding up to 60 L of components per dyeing batch and will automatically inject the dye as well as rinse the parts post-dye.

The DM60 confers a much higher degree of consistency when compared to pot dyeing as well as improved UV stability of the dyes. An additional service offered by Dyemansion is tailored color development. For users with a strict color requirement or who are looking to dye a very high volume of parts (end-use parts, production runs of 1000+ units), using an industrial machine such as the DM60 may be a good choice.

These larger format solutions take much of the manual labor out of the dyeing process and include programmed settings for different types of parts and colors. However, higher upfront costs mean the return on investment will be faster for those printing very high volumes of parts.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

SLS 3Dプリント品の染色方法

Formlabs has conducted extensive testing to determine what colors can be achieved with SLS printed parts using accessible, low-cost dyeing techniques. The dye used was RIT ProLine dye, a low-cost, easily accessible powder that contains a mixture of direct, acid, and disperse dyes, and is effective on nylon fibers. Further variables tested include temperature, acidity, saturation of dye, duration of dye time, and detergent additive in the dye solution. Both Nylon 12 Powder and Nylon 12 White Powder parts were tested and the effect of each variable is covered below.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

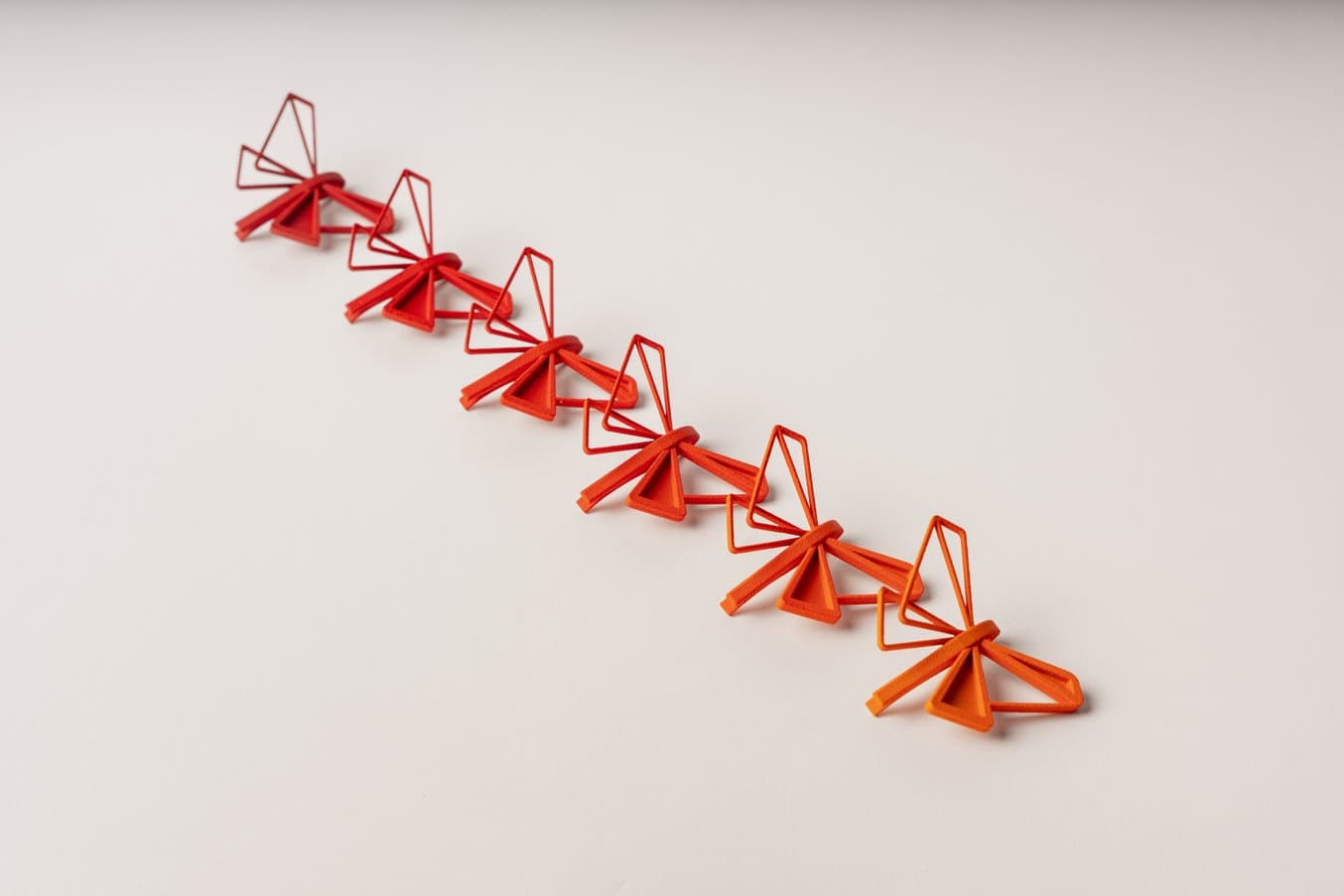

Temperature and time have a huge impact on the final part color. Based on our tests, higher temperatures lead to a more saturated color in a shorter amount of time.

The parts in this image were dyed in the same dye bath, at 90 °C, with parts removed at 3-minute intervals from right to left.

If a lighter shade is desired, consider reducing the dye solution temperature to 70 °C or lower. At higher temperatures, saturation can occur extremely quickly, leaving very little margin for deviation and potentially resulting in variance of finished parts. There is an increase in part uptake of dye over time but this trend plateaus at 20-25 minutes as the part reaches a saturation point where no more dye can penetrate the surface.

Changing Dye Bath Colors

When changing the colors of a dye bath, first drain the entirety of the current solution and dispose of it according to local regulations and the dye’s safety data sheet (SDS). Alternatively, the dye bath can also be stored in liquid form to be used at a later date, according to local safety regulations.

As a dye solution is heated and cycled, some settling can occur. Due to this, the walls and base of the tank should be wiped down after draining to ensure no cross-contamination of colors occurs. Once these two steps are completed, a rinse with clean water is recommended to make sure any remaining dye in the circulation system is removed.

Only after the machine is cleaned should a new dye solution be prepared. If multiple colors are going to be used frequently, getting multiple circulators to prevent frequent swapping is an option.

Ken Pillonel designed an easy workaround for this step, using large flasks filled with dye solution within the tank, and a rotating magnet on the bottom of them to agitate the liquid. This way, he can use different flasks for each dye color, without waiting for cooling and cleaning. To learn more about his method and this workaround, watch his video, shared at the end of the article.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

色と材料の組み合わせ

ホワイトパーツの染色

最も幅広いカラーバリエーションを実現するには、Nylon 12 Whiteパウダーで作った造形品を染色するというのが最良のオプションです。パステルや鮮やかな色など、明るい色で染色を行う場合はNylon 12 Whiteパウダーの使用が推奨されます。

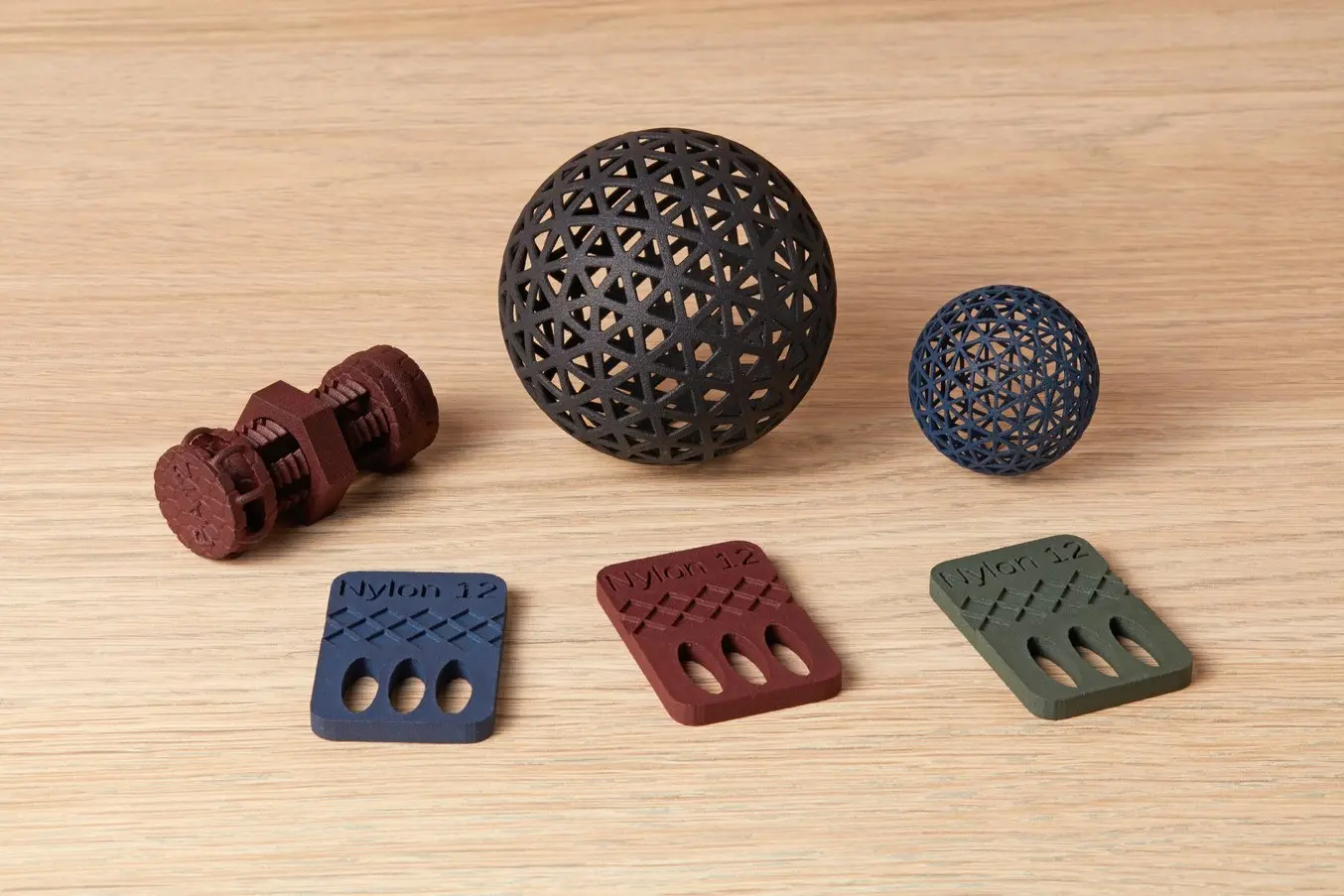

超音波染色を施したNylon 12 Whiteパウダー製3Dプリント部品。

グレーパーツを染色する

技術資料で解説したプロセスは、Nylon 12パウダーを使った造形品の染色にも成功しています。ただし、Nylon 12パウダーの造形品は色合いがダークグレーのため、染色可能なのは染料がパウダーより濃い色である場合のみに限られ、鮮やかさはやや抑えられます。

Nylon 12パウダーの造形品(ダークグレー)をより濃い色に染色。

造形品を黒色で染色

最終色を黒にしたい場合は、FormlabsのNylon 12パウダーとRit ProLine Blackの組み合わせを推奨します。この材料は下地が濃色なため、より一貫性のある黒色へ染色できます。

一方、Nylon 12 Whiteパウダーの造形品を黒色で染めることは可能ですが、推奨はしていません。下地が明るいと、最初から暗い色合いのNylon 12パウダーに比べて濃色の表現が難しくなります。

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

コスト

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

人件費

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

部品の形状

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

コスト

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

人件費

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

部品の形状

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

部品の形状

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Dyeing is ideal for both functional prototyping and end-use production of parts with custom colors to match brand aesthetics.

SLSナイロン部品の染色:Ken Pillonel氏の実験

エンジニアでもあり、人気YouTubeチャンネルExploring the Simulationの創設者でもあるKen Pillonel氏は、FuseシリーズSLS製品を使って「ワンマン運営のプラスチックファクトリー」を立ち上げました。生産能力を拡張し、2台目のFuse 1+ 30Wプリンタ、Fuse Sift、Fuse Blastを導入後、Pillonel氏はNylon 12 Whiteパウダーによる造形品を染色することで、実製品として使えるAirpods充電ケースを生産できるようになりました。実製品用パーツとしてのSLS 3Dプリントについて詳しく解説されているこちらの動画では、窒素を使用して造形する際のワークフロー、正確で再現性のある高品質な染色方法などが紹介されています。

SLS 3Dプリント品の染色を始める

超音波染色などの手頃な方法があることから、SLSプリント品の外観を高めるうえで染色は容易で取り入れやすいアプローチ。

入手しやすいハードウェアと染料を用いてNylon 12 WhiteパウダーおよびNylon 12パウダーの造形品を染色することで、どんな色合いでも、コストパフォーマンスや効率性に優れた方法で最終的な部品に色をつけることができます。このプロセスは、従来のコーティングに代わる有力な選択肢であり、複雑な形状でも最小限の手間で効果的に着色できます。

カラーのSLSナイロン部品の活用をご検討中の場合は、Formlabsまでお気軽にお問い合わせください。Fuse製品やナイロン部品の染色について詳細をお知らせいたします。

SLS 3DプリントやSLS部品の染色についてさらに詳しくお知りになりたい方は、当社チームまでお問い合わせください。また、テスト結果の詳細やステップバイステップの手順については、技術資料をダウンロードしてご確認いただけます。