How to Create an Efficient 3D Printing Workflow

When creating an in-house 3D printing workflow it’s important to evaluate part design, scalability, post-processing, and storage and maintenance for maximum efficiency.

Scroll to Explore

Step 1: Design for Additive Manufacturing

Step 2: Manage Multiple 3D Printers

Reduce Disruptions With Multiple 3D Printers

By utilizing multiple printers, rather than relying on a single unit, a modular style of production is used to reduce disruptions in your workflow.

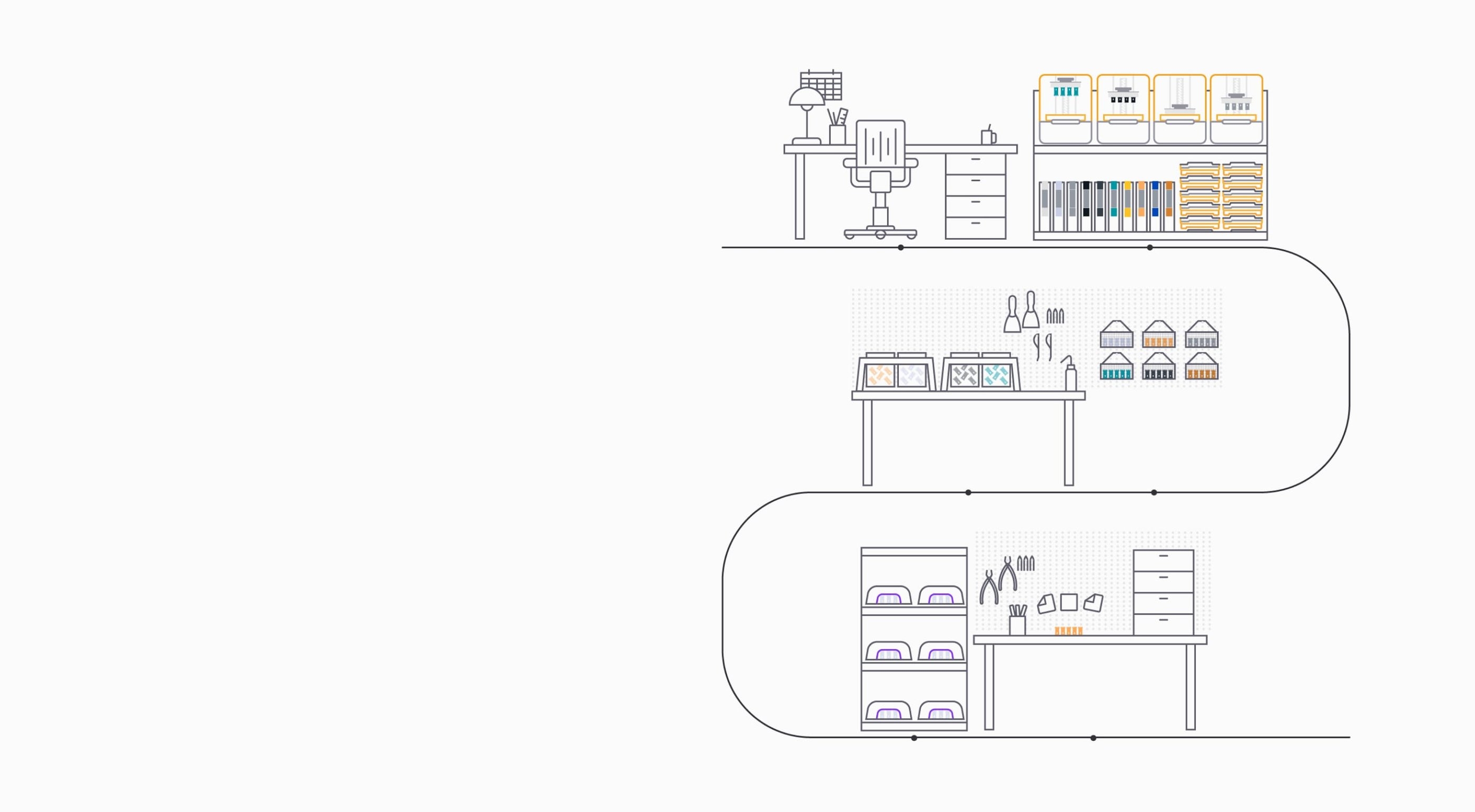

In this video, learn to:

- Seamlessly facilitate rapid iteration of prototypes and simultaneous prints in different materials to support multiple projects and teams.

- Operate your workflow end-to-end from design to completed part, like an assembly line.

- Organize your space and monitor print production.

Continue reading the Managing Multiple 3D Printers White Paper to learn more about developing this workflow.

Step 3: Post-Process Efficiently

IPA vs TPM

Tripropylene glycol monomethyl ether, or TPM, is a solvent which may be used instead of isopropyl alcohol, or IPA, in finishing workflows.

TPM is clear, low odor, and non-flammable, so it may suit your workflow better than IPA. Decide which solvent works best for your environment and how to transition from TPM to IPA if you choose to do so.

Step 4: Choose the Solvent for Your Workflow

Step 5: Maximize Your Consumables Lifetime

Grow Your Fleet of 3D Printers

Scale prototyping and production as your business grows with the Form 3, an affordable, industrial-quality 3D printer that consistently delivers. With advanced Low Force Stereolithography (LFS)™ technology, Formlabs has completely re-engineered resin-based 3D printing to drastically reduce the forces of the print process.