Why Choose Black Resin?

Black Resin V5 is a versatile 3D printing resin formulated to leverage the new Form 4 ecosystem, offering an optimal balance of fast print speed, high accuracy, presentation-ready appearance, strong mechanical properties, and an easy, reliable workflow.

High Dimensional Accuracy

Achieve precise tolerances and fine features.

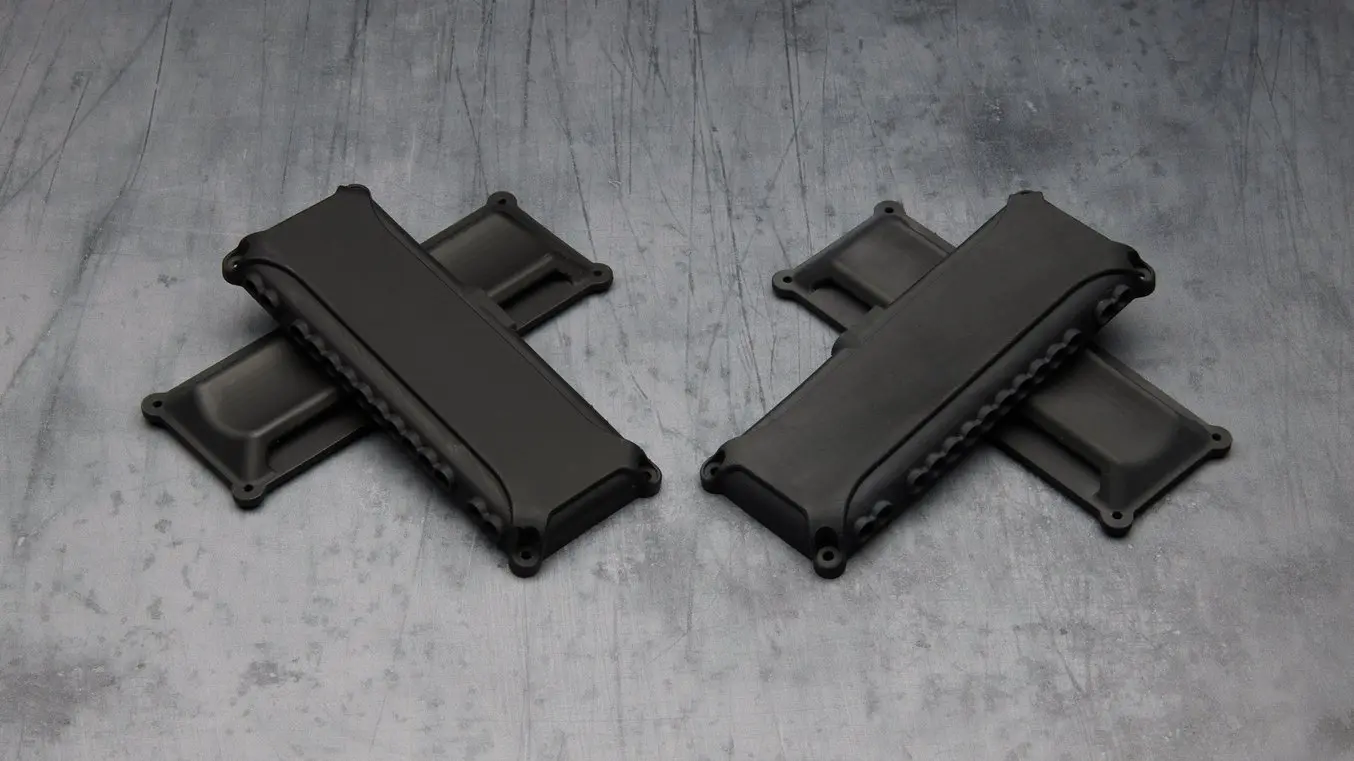

Superior Aesthetics

Rival the appearance of injection-molded parts with rich, matte color and crisp fine feature performance.

Versatile Mechanical Properties

Create parts with the optimal balance of strength, toughness, and stiffness for a wide range of applications.

Extremely Low-Odor Printing

Print with ultra-low volatile organic compounds (VOCs) for a pleasant and comfortable user experience.

Applications for Black Resin

Create dimensionally accurate parts that are stiff and strong with unmatched print reliability.

Consider Black Resin for:

What’s New With Black Resin V5?

Compared to Black Resin V4, Black Resin V5 is:

Mechanical Properties

Post-cured at room temperature for 5 minutes

Ultimate Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Notched Izod

Heat Deflection Temperature at 0.45 MPa

Post-cured at 60 °C for 15 minutes

Ultimate Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Notched Izod

Heat Deflection Temperature at 0.45 MPa

Post-Processing

Wash Settings

5 minutes

Start with a 5-minute wash and modify the wash time based on your part geometry and solvent purity.

Cure Settings

5 minutes at room temperature

15 minutes at 60 °C

Post-curing is optional for parts printed in Black Resin V5. However, we recommend either a 5-minute room temperature cure to reduce surface tack and improve mechanical properties, or a 15-minute cure at 60 °C for the highest strength, stiffness, and heat deflection temperature.