Why Choose Clear Resin?

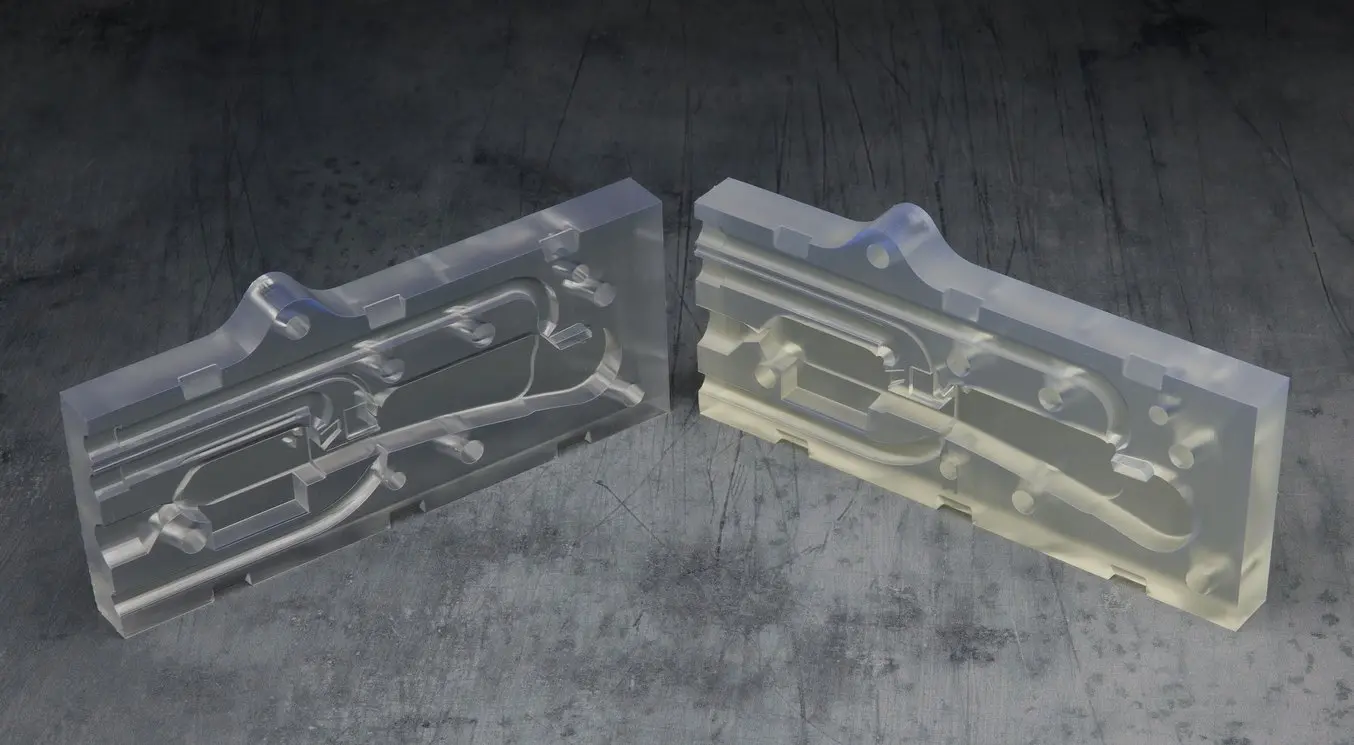

Clear Resin V5 is an exceptionally clear and color-neutral 3D printing resin formulated to leverage the new Form 4 ecosystem, offering an optimal balance of fast print speed, high accuracy, transparency, strong mechanical properties, and an easy, reliable workflow.

Highest Dimensional Accuracy

Achieve precise tolerances and fine features.

Superior Aesthetics

Produce high-clarity, colorless parts that rival the transparency of acrylic.

Versatile Mechanical Properties

Create parts with the optimal balance of strength, toughness, and stiffness for a wide range of applications.

Extremely Low-Odor Printing

Print with ultra-low volatile organic compounds (VOCs) for a pleasant and comfortable user experience.

Applications for Clear Resin

Create highly transparent, stiff, and strong 3D printed parts with a smooth, clear surface that can be polished to near transparency.

Consider Clear Resin for:

What’s New With Clear Resin V5?

Compared to Clear Resin V4, Clear Resin V5 is:

Mechanical Properties

Post-cured at room temperature for 5 minutes

Ultimate Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Notched Izod

Heat Deflection Temperature at 0.45 MPa

Post-cured at 60 °C for 15 minutes

Ultimate Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Notched Izod

Heat Deflection Temperature at 0.45 MPa

Post-Processing

Wash Settings

5 minutes

Start with a 5-minute wash and modify the wash time based on your part geometry and solvent purity.

Cure Settings

5 minutes at room temperature

15 minutes at 60 °C

Post-curing is optional for parts printed in Clear Resin V5. However, we recommend either a 5-minute room temperature cure to reduce surface tack and improve mechanical properties, or a 15-minute cure at 60 °C for the highest strength, stiffness, and heat deflection temperature.