Why Choose Tough 2000 Resin?

Tough 2000 Resin is a functional material that’s difficult to bend and will hold up with extended use.

Stiff and Sturdy

Produce strong parts with minimal deformation.

Resistant

Withstand intermittent or constant loads required of heavy-duty parts.

Aesthetic, Neutral Color

Create professional-looking parts that blend seamlessly into their environment.

Robust

Iterate with higher confidence and reduce brittle failures.

Applications

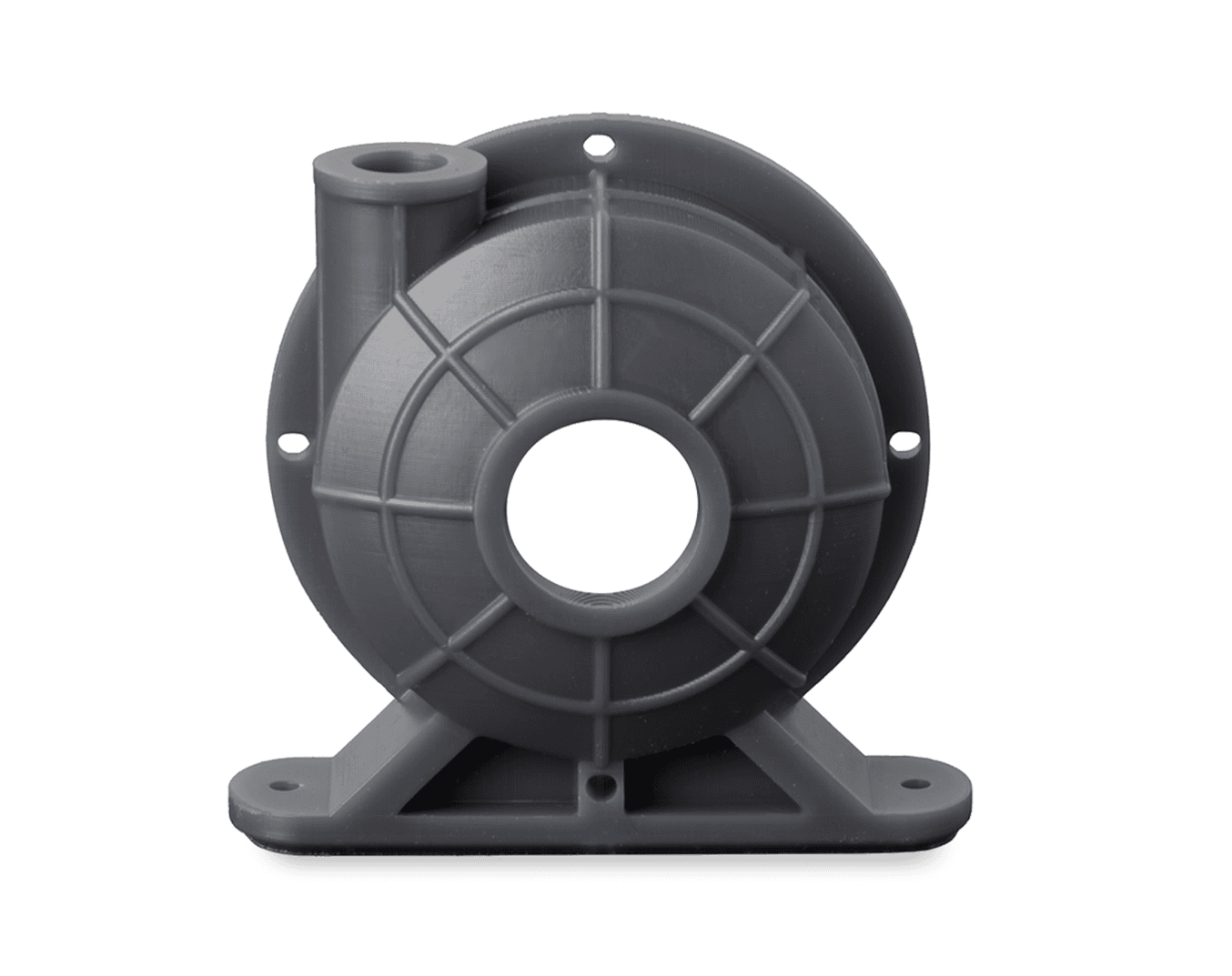

Tough 2000 Resin is ideal for rugged prototyping or simulating the strength and stiffness of ABS.

Consider Tough 2000 Resin for:

Material Properties*

Tough 2000 Resin

Ultimate Tensile Strength

Tensile Modulus

Elongation

Flexural Modulus

Notched Izod

Heat Deflection Temp @ 0.45 MPa

* Material properties may vary based on part geometry, print orientation, print settings, and temperature. Data was obtained from parts printed using Form 2, 100 μm, Tough 2000 settings and post-cured with a Form Cure for 120 minutes at 80 °C.

Post-Processing

Form Wash Settings

10 minutes + 10 minutes in IPA

Part surfaces may become tacky if washed in IPA with more than 5% resin concentration. Use fresh solvent if your parts remain tacky after washing. Parts with two wash times require two wash cycles. For the second wash cycle, use clean solvent. The first wash cycle removes the bulk of the resin, while the second cycle fully cleans the parts.

Form Cure Settings

60 min

70 °C

For parts printed in an engineering-focused resin (such as those in the Rigid, Tough & Durable, and Flexible & Elastic families), post-curing ensures that the parts reach their optimal mechanical properties and can function as designed. There is only one recommended post-curing time for Tough 2000 Resin.