Nylon 12 Powder Technical Data Sheet

Nylon 12 Powder is a general purpose, versatile, and biocompatible material with high detail and great dimensional accuracy. As the go-to material for SLS 3D printing, it is ideal for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

Nylon 12 Powder Technical Data Sheet

Download as PDF

Nylon 12 Powder is a general purpose, versatile, and biocompatible material with high detail and great dimensional accuracy. As the go-to material for SLS 3D printing, it is ideal for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

Mechanical Properties

Tensile Properties

| Nylon 122 | Method | |

|---|---|---|

| Ultimate Tensile Strength | 50 MPa (7252 psi) |

ASTM D638-14 Type 1 |

| Tensile Modulus | 1900 MPa (268 ksi) |

ASTM D638-14 Type 1 |

| Elongation at Break (X/Y) | 11% |

ASTM D638-14 Type 1 |

| Elongation at Break (Z) | 6% |

ASTM D638-14 Type 1 |

| Tensile Properties at Low Temperature | ||

| Ultimate Tensile Strength at -60 °C | 67 MPa (9720 psi) |

ASTM D638-14 Type 1 |

| Tensile Modulus at -60 °C | 2650 MPa (385 ksi) |

ASTM D638-14 Type 1 |

| Elongation at Break at -60 °C | 3.40% |

ASTM D638-14 Type 1 |

Flexural Properties

| Nylon 122 | Method | |

|---|---|---|

| Flexural Strength | 66 MPa (9.6 ksi) |

ASTM D790-15 |

| Flexural Modulus | 1600 MPa (232 ksi) |

ASTM D790-15 |

Impact Properties

| Nylon 122 | Method | |

|---|---|---|

| Notched Izod | 32 J/m (0.60 ft-lb/in) |

ASTM D256-10 |

| Gardner at 1.6 mm (1/16") thickness |

0.45 J (4 in*lb) |

ASTM D5420-21 |

General Properties

| Nylon 122 | Method | |

|---|---|---|

| Shore Hardness | 75 D | ASTM D2240-15 |

| Density (Printed) | 0.99 g/cc (0.0358 lb/in³) |

ASTM D792 |

| Moisture Content (Powder) | 0.25% |

ISO 15512 Method D |

| Water Absorption (Printed Part) | 0.66% | ASTM D570 |

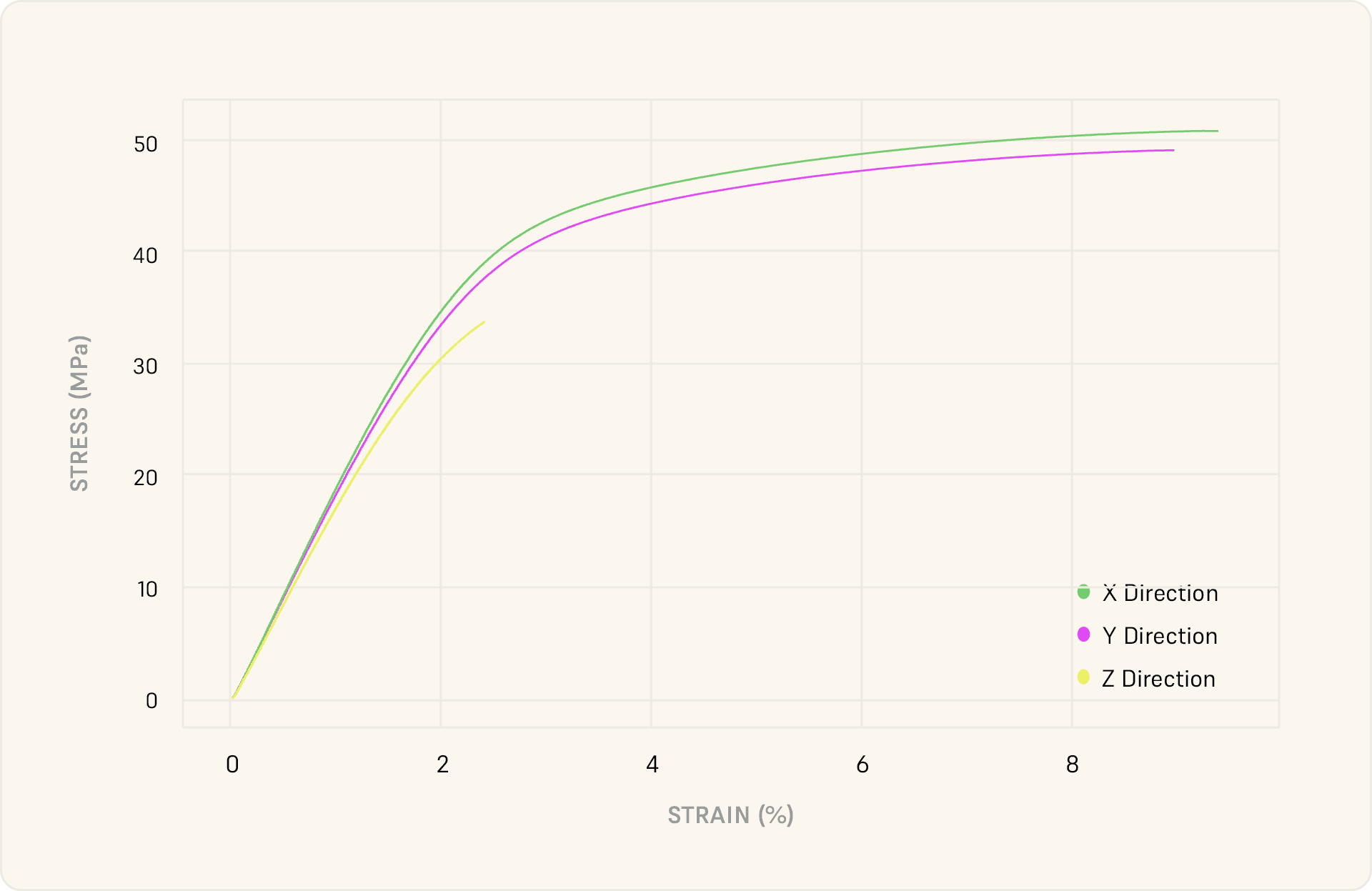

Representative Tensile Curves

Samples were tested following ASTM D638, Type I in all three axes along the Fuse 1+. Each curve is a single sample chosen as representative and may not be representative of the average values of stress and strain. Samples were conditioned in a laboratory environment at 23°C, 50% relative humidity for 48 hours prior to testing.

Single Sample ASTM D638 Type 1 Bar Conditioned 23°C 50% RH

Representative Tensile Curves: Samples were tested following ASTM D638, Type I. The curve is a single sample chosen as representative and may not be representative of the average values of stress and strain. Samples were conditioned in a laboratory environment at 23°C, 50% relative humidity for 48 hours prior to testing.

Thermal and Electrical Properties

Thermal Properties

| Nylon 122 | Method | |

|---|---|---|

| Heat Deflection Temp. @ 1.8 MPa | 87 °C (189 °F) |

ASTM D648-16 |

| Heat Deflection Temp. @ 0.45 MPa | 171 °C (340 °F) |

ASTM D648-16 |

| Vicat Softening Temperature | 175 °C (347 °F) |

ASTM D1525 |

| Thermal Conductivity | 0.428 W/m*K (2.97 BTU-in/hr-ft²-°F) |

ASTM D7984-16 |

| Thermal Effusivity | 787.4 W*s0.5 / K*m² (2.3 BTU /ft² · hr0.5 · °F) |

ASTM D7984-16 |

| Glass Transition Temperature (Tg) | 60 °C (140 °F) |

ASTM D4065-20 |

| Coefficient of Thermal Expansion (-30-140 °C) | 150.1 µm/m-°C (83.4 µin/in-°F) |

ASTM E831-19 |

| Flammabillity - 3.00mm (0.118 in) thick | HB | UL 94 Section 7 |

Electrical Propeties

| Nylon 122 | Method | |

|---|---|---|

| Surface Resistivity | 1 x 10^11 Ω/sq | ASTM D257 |

|

Dielectric Constant (k') |

2.86 @ 6.78 MHz | ASTM D150-22 |

| 2.80 @ 13.56 MHz | ASTM D150-22 | |

| 2.74 @ 27.12 MHz | ASTM D150-22 | |

|

Dielectric Dissipation (D) |

0.034 @ 6.78 MHz | ASTM D150-22 |

| 0.028 @ 13.56 MHz | ASTM D150-22 | |

| 0.008 @ 27.12 MHz | ASTM D150-22 | |

| Dielectric Stength | 8.82 kV/mm (224 V/mil) |

ASTM D149-20, Method A |

| Comparative Tracking Index | 600 V |

ASTM D3638 |

| CTI 600 Compliance | Pass | IEC 601 12:2020 |

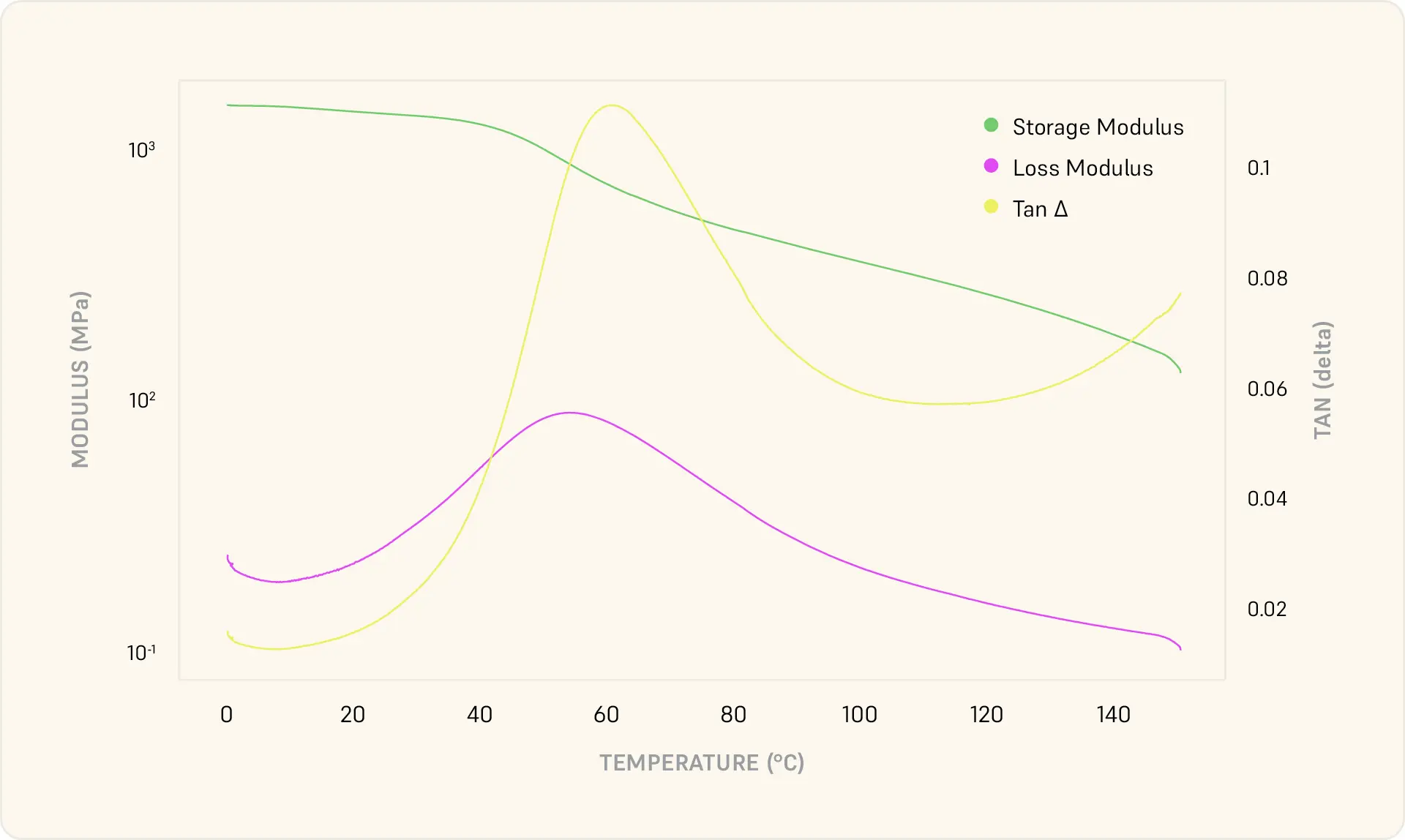

Dynamic Mechanical Analysis (DMA)

A DMA curve from 0 °C to 150 °C at 3 °C/min is shown.

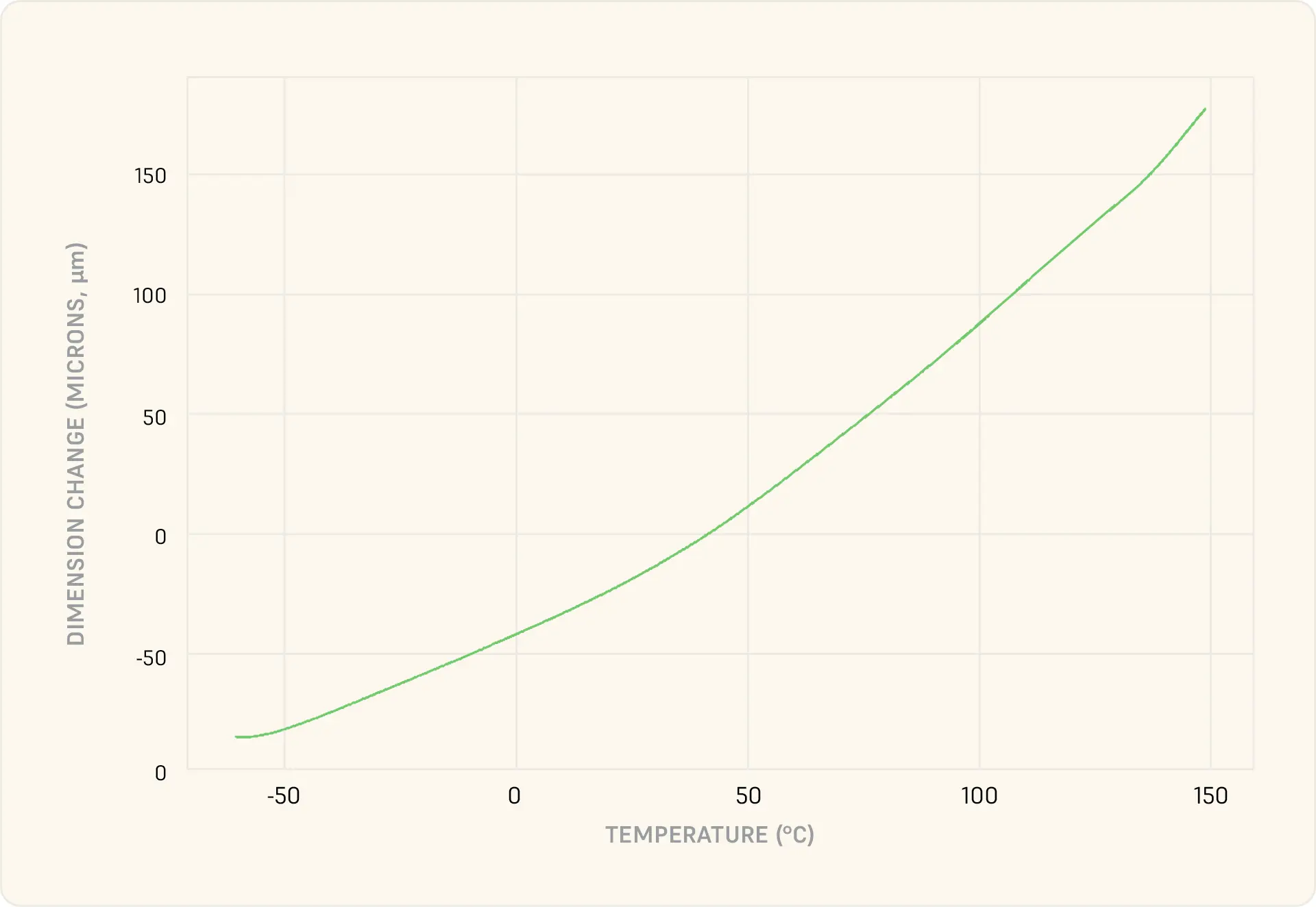

Thermal Expansion by TMA

Sample was tested by ASTM E831-19 in a TMA. Ramp rate was 5 °C/min with a Ultra-High Purity Nitrogen purge of 50 cc/min.

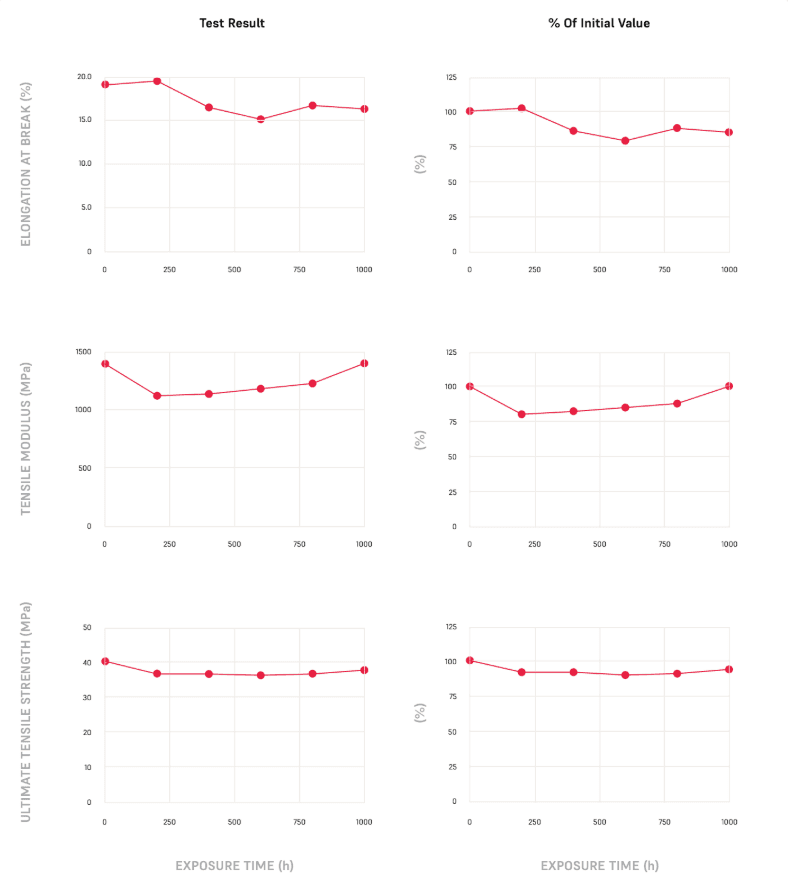

UV Aging

Outdoor Aging ASTM D4329

Tested in accelerated outdoor weathering conditions according to ASTM D4329 (Cycle A). Test samples were exposed to defined conditions of heat, water condensation and UV light. Exposed samples were conditioned for 24 hours at 22 °C before mechanical testing. Control samples were stored at a constant 22 °C. Mechanical testing was conducted according to ASTM D638 at standard lab conditions (22 °C). “0 hrs” represents non-aged samples stored at 22 °C and tested 24 hours after post-processing.

Please note, accelerated weathering testing cannot fully represent all aging conditions. Formlabs recommends conducting additional testing relevant for your specific application needs.

| Hours exposed | 0 Hours | 200 Hours | 400 Hours | 600 Hours | 800 Hours | 1000 Hours |

|---|---|---|---|---|---|---|

| Elongation at Break (%) | 9.8 | 9.5 | 10.3 | 8.9 | 9.7 | 8.1 |

| % of Initial EAB | 100% | 97% | 105% | 91% | 99% | 83% |

| Tensile Modulus (MPa) | 1832 | 1794 | 1633 | 1854 | 1863 | 1764 |

| % of Initial Tensile Modulus | 100% | 98% | 89% | 101% | 102% | 96% |

| Ultimate Tensile Strength (MPa) | 50.76 | 49.32 | 49.17 | 49.06 | 50.64 | 48.91 |

| % of Initial Tensile Strength | 100% | 97% | 97% | 97% | 100% | 96% |

Biocompatibillity

Samples printed with Nylon 12 has been evaluated in accordance with ISO 10993-1:2018, and has passed the requirements for the following biocompatibility risks:

| ISO Standard Description | Result3,4 |

|---|---|

| EN ISO 10993-5:2009 | Not Cytotoxic |

| ISO 10993-10:2010/(R)2014 | Non Irritant |

| ISO 10993-10:2010/(R)2014 | Not a sensitizer |

| ISO 10993-11:2017 | No Evidence of Systemic Toxicity |

| ISO 10993-11:2017 | Non-Pyrogenic |

Chemical Compatibillity

Solvent Weight Gain

| Solvent | 24 hr weight gain, % |

|---|---|

| Acetic Acid 5% | 0.1 |

| Acetone | 0.1 |

| Bleach ~5% NaOCl | 0.2 |

| Butyl Acetate | 0.2 |

| Diesel Fuel | 0.4 |

| Diethyl glycol monomethyl ether | 0.5 |

| Hydraulic Oil | 0.6 |

| Hydrogen peroxide (3%) | 0.2 |

| Isooctane | <0.1 |

| Isopropyl Alcohol | 0.2 |

| Mineral oil, heavy | 0.7 |

| Mineral oil, light | 0.5 |

| Salt Water (3.5% NaCl) | 0.2 |

| Skydrol 5 | 0.6 |

| Sodium hydroxide solution (0.025% pH = 10) | 0.2 |

| Strong Acid (HCl Conc) | 0.8 |

| TPM | 0.3 |

| Water | 0.1 |

| Xylene | 0.1 |

Chemical Compatibility ASTM D543

Tested for chemical compatibility according to ASTM D543. The influence of various chemicals was tested by measuring tensile modulus and strength after different exposure times. Exposed samples were stored in containers and fully immersed in the test chemicals for 1 day and 1 week. After removal, exposed samples were washed and conditioned for 24 hours at 22°C before mechanical testing. Mechanical testing was conducted according to ASTM D638 using Type 4 tensile samples at standard lab conditions (22°C). Results are reported as a % difference from the measured values of non-exposed samples.

1 Day Immersion

| Solvent | Relative Modulus | Relative Strength | Relative Elongation | Relative Mass |

|---|---|---|---|---|

| IPA | 100.44% | 101.19% | 117.35% | 100.29% |

| Acetone | 92.89% | 97.95% | 105.83% | 100.19% |

| NaOH | 102.99% | 102.77% | 120.19% | 100.36% |

| HCl | 96.53% | 99.59% | 100.52% | 100.44% |

| DI Water | 93.57% | 100.43% | 105.05% | 100.43% |

| H2O2 | 97.11% | 102.92% | 109.89% | 100.34% |

| Bleach | 92.25% | 100.45% | 104.39% | 100.31% |

| Diesel | 95.54% | 98.61% | 102.64% | 100.44% |

| Motor Oil | 101.92% | 101.32% | 108.10% | 100.88% |

| Skydrol 5 | 97.57% | 100.86% | 107.26% | 101.03% |

1 Week Immersion

| Solvent | Relative Modulus | Relative Strength | Relative Elongation | Relative Mass |

|---|---|---|---|---|

| IPA | 94.97% | 100.84% | 110.49% | 100.63% |

| Acetone | 93.71% | 99.13% | 132.37% | 100.43% |

| NaOH | 95.66% | 100.70% | 122.75% | 100.71% |

| HCl | 91.56% | 101.66% | 111.25% | 100.48% |

| DI Water | 85.37% | 97.86% | 112.44% | 100.49% |

| H2O2 | 86.70% | 98.58% | 119.42% | 100.76% |

| Bleach | 92.31% | 99.83% | 113.74% | 100.90% |

| Diesel | 100.12% | 101.68% | 119.33% | 100.51% |

| Motor Oil | 95.30% | 98.70% | 95.41% | 100.76% |

| Skydrol 5 | 102.48% | 104.60% | 113.59% | 100.68% |

Outgassing

The Outgas Test was performed in a vacuum environment of less than 5 X 10-5 torr according to ASTM E595, for a duration of 24 hours, at 125°C on three specimens per sample

| Outgassing | Nylon 12 | Method |

|---|---|---|

| TML | 0.38% | ASTM E595 |

| CVCM | <0.01% | ASTM E595 |

| WVR | 0.14%% | ASTM E595 |

Footnotes

- Material properties may vary with part geometry, print orientation and temperature.

- Parts were printed using Fuse 1, with Nylon 12 powder. Parts were conditioned at 50% relative humidity and 23 °C for 7 days before testing.

- Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

- Nylon 12 was tested at NAMSA World Headquarters, OH, USA.