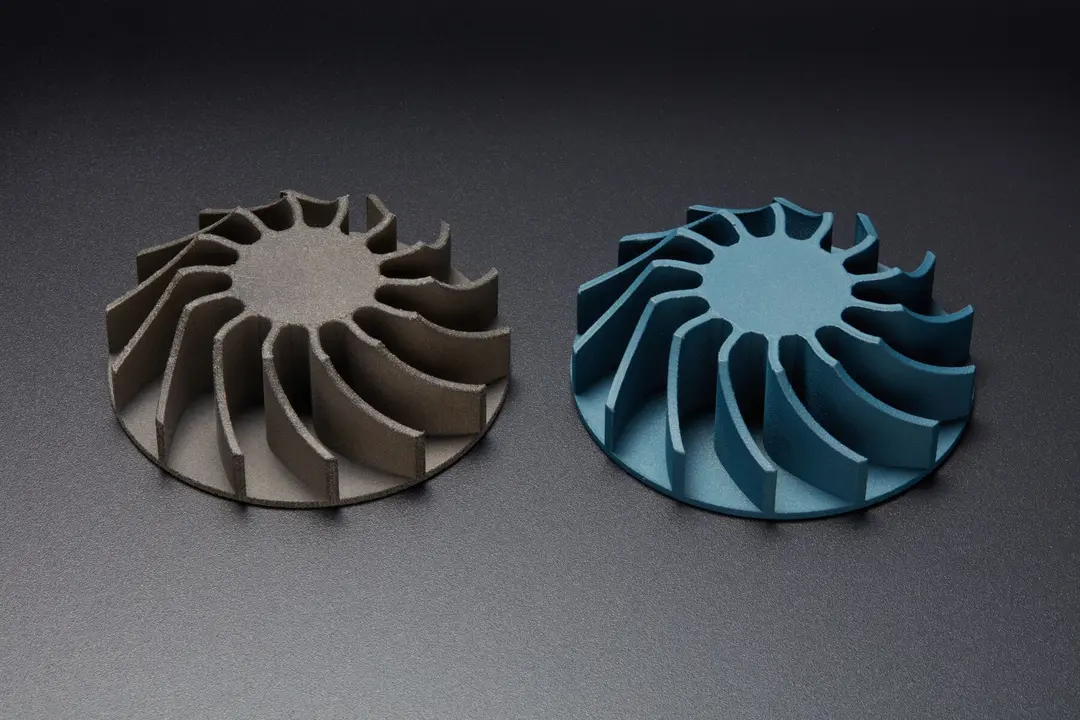

Vapor smoothing is a common post-processing step performed on selective laser sintering (SLS) 3D printed parts to improve porosity, reduce roughness, and improve the look and feel. Through vapor smoothing, SLS parts can achieve surface quality and durability comparable to injection molded parts, making them suitable for end-use applications.

Formlabs worked with Additive Manufacturing Technologies (AMT) to test the results of vapor smoothing on parts printed on the Formlabs Fuse 1+ 30W SLS 3D printer in our popular SLS powders: Nylon 12 Powder, Nylon 11 Powder, TPU 90A Powder, Nylon 11 CF Powder, and Nylon 12 GF Powder.

To learn more and see the full results of our collaborative testing, download our white paper.

Enhancing the Surface Quality of SLS 3D Printed Parts With Vapor Smoothing: A Collaborative Study by Formlabs and AMT

In this white paper, we will review the considerations and benefits of vapor smoothing, report results from testing Formlabs SLS powders with AMT Vapor Smoothing System.

What is Vapor Smoothing?

Vapor smoothing is a chemical process that involves exposing the surface of an SLS 3D printed part to a solvent vapor. During the process, a combination of heat and solvent vapor selectively melts the surface, creating a smoother, sealed surface.

The process predominantly alters the surface layers, leaving the inner core intact. The accuracy of the smoothing is controlled using tailored conditions within the process chamber to achieve the required surface finish, often with custom settings profiles developed by the vapor smoothing machine manufacturer.

Vapor smoothing is an ideal way to both create smooth surfaces and to draw attention to interesting surface design features for use in consumer goods or customized medical devices.

What Are the Benefits of Vapor Smoothing SLS 3D Printed Parts?

Vapor smoothing provides multiple benefits for SLS 3D printed parts, including:

-

Surface roughness and color uniformity:

-

Formlabs and AMT have found around 72-81% reduction in average surface roughness (Ra) after smoothing parts printed in Formlabs SLS Powders.

-

-

Preventing bacteria growth and moisture absorption:

-

Formlabs and AMT found a 60% reduction in MRSA bacteria growth on Nylon 12 Powder parts.

-

-

Non-line-of-sight application:

-

Vapor smoothing can uniformly interact with all surfaces of the part, including those concealed from direct view, making it a significant improvement over other types of coating processes.

-

-

Preservation of mechanical properties:

-

Formlabs with AMT revealed only a minor variance in mechanical properties, signifying that the benefits of vapor smoothing — improved aesthetics and surface finish — can be accomplished without impinging upon parts’ functional performance or structural integrity.

-

Vapor smoothing is an ideal way to improve the surface quality and aesthetics of consumer goods, like this customized perfume bottle.

Vapor smoothing is appropriate for parts with thin walls because it has almost no impact on structural integrity.

How to Vapor Smooth Your SLS 3D Printed Parts

Businesses producing higher volumes of SLS parts, especially in end-use applications, may purchase their own vapor smoothing equipment. There are currently two main companies that provide vapor smoothing equipment: AMT and Dyemansion. Both companies sell vapor smoothing hardware and consumables. The price of these machines varies depending on size, throughput, and material type, but typically starts around $100,000 with options for financing available.

However, there are also many reliable service bureaus and external contractors that can provide vapor smoothing for SLS 3D printed parts as a service. Download our white paper for recommendations.

Considerations Before Vapor Smoothing

When vapor smoothing yourself, it’s important to consider the design features and process parameters.

Vapor Smoothing Profiles

Each vapor smoothing company and machine has its own set of parameters and solvents used to smooth parts. The parameters most often adjusted are temperature and pressure. Additionally, each SLS material will have its own profile developed by the vapor smoothing manufacturer to ensure the best quality results. In a collaborative effort, Formlabs and AMT have developed specialized machine profiles tailored specifically for all Formlabs SLS materials. For access to these specially developed profiles, please reach out to AMT directly.

Part Geometry

Part geometry, such as wall thickness and total part size, can affect the smoothing process and should be accounted for in the vapor smoothing profile settings. For example, AMT has machine profiles for thin Nylon 12 Powder parts (less than 2 mm wall thickness) and a separate profile for thick Nylon 12 Powder parts (more than 3 mm wall thickness).

Racking or Witness Marks

During the vapor smoothing process, parts need to be suspended from a metal wire rack, which requires some geometry on which to attach a wire or clip. Though these marks are minimal, to avoid them completely consider adding a connection point to the 3D design or for production runs, connecting all of the parts together in the design stage.

Solvent Pooling

To avoid the vapor solvent pooling in cupped features, it is recommended to hang parts with cup-shaped features facing downwards, which encourages solvent runoff. Alternatively, consider eliminating such features from the part's design whenever feasible.

Safety and Facility Considerations

AMT provides a comprehensive site preparation guide for all PostPro SF machines to ensure the installation and operation of the vapor smoothing systems align with safety standards. This guide includes vital safety and handling training for operators, a critical step in mitigating potential risks. To learn more about Formlabs and AMT’s recommendations, or to see the full results of our collaborative testing for surface porosity, anti-microbial properties, and moisture absorption, download our white paper.

Costs of Vapor Smoothing

The cost of vapor smoothing depends on several factors, including the size of the part, the material used, the complexity of the part surface, and the quantity of parts. Typically, the cost of vapor smoothing is roughly proportional to the size and quantity of parts. Consider the following example cost scenarios in which the 3D printed part is printed by the customer and sent to Avid Product Development, a service bureau in Colorado, for vapor smoothing:

| Part | Rigid Orthotic Insole | Eyewear Frames | Watch Straps |

|---|---|---|---|

| Material | Nylon 11 Powder | Nylon 12 Powder | TPU 90A Powder |

| Model Dimensions (mm) | 157 x 23 x 80 | 144 x 36 x 47 | 262 x 13 x 37 |

| Quantity | 50 | 80 | 50 |

| Cost of Sintered Powder (per part) | $3.98 | $0.62 | $2.98 |

| Cost of Vapor Smoothing (per part) | $0.98 | $0.49 | $0.78 |

| Total Cost Per Part | $4.96 | $1.11 | $3.66 |

Applications for Vapor Smoothed SLS Parts

Many engineers, manufacturers, and product designers, rely on vapor smoothing to elevate the look and end-use capabilities of their SLS 3D printed parts. As SLS 3D printing becomes more widely used in a range of industries and applications, vapor smoothing will become an even more integral part of the SLS workflow.

Vapor smoothing can benefit automotive components like this flexible SLS 3D printed boot.

Eyewear frames can be more comfortable for the wearer when vapor smoothed.

SLS 3D printed orthotic insoles can be vapor smoothed for added comfort and aesthetic benefits.

Automotive Components

Vapor smoothing can be used to improve the surface finish and durability of automotive components, such as air intake manifolds, engine covers, and dashboard components. Moisture and solvent absorption reduction can also be useful for automotive applications in which solvents such as gasoline and diesel fuel are present, as vapor smoothing creates a sealed surface, reducing liquid and gas intake.

Medical Devices

SLS 3D printing is widely used in the production of medical devices today, and vapor smoothing can be used to improve the surface finish of parts such as prosthetics, orthotics, and medical device assemblies while maintaining the biocompatibility of the base material. Vapor smoothing also greatly reduces the surface friction that patients wearing orthotic devices may feel, as well as reducing the potential for bacteria growth.

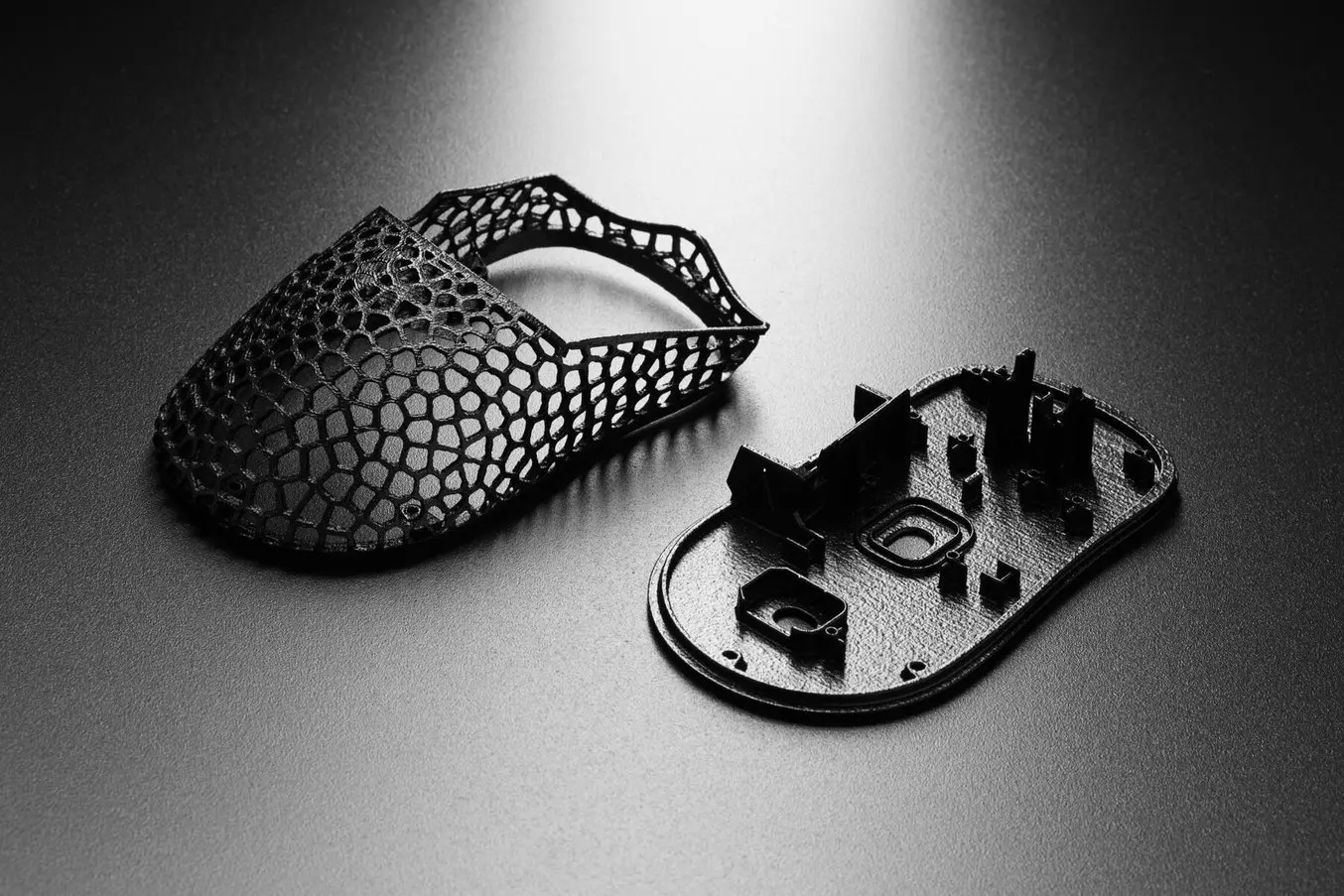

Consumer Products

Vapor smoothing can be used to enhance the appearance of consumer products, such as phone cases, eyewear, gaming components, and other electronic accessories, to that of a Class A or B surface. The surface glossiness can also be moderately controlled through this process, offering glossy to semi-matte finishes. Lastly, to achieve the best possible aesthetic, consider adding a coating on top of the vapor smoothed part, such as Cerakote on rigid SLS materials, or the BASF Ultracur3D Coat F on TPU 90A Powder.

Getting Started With Vapor Smoothing

As the collaborative test results in our white paper show, vapor smoothing can improve surface porosity, anti-microbial properties, moisture absorption, and aesthetics.

To learn more about the SLS 3D printing workflow and discuss if SLS with vapor smoothing is right for you, contact our team. To contact AMT about purchasing a vapor smoothing machine, visit their website.