Fuse Series SLS Design Guide

Success with selective laser sintering (SLS) begins with parts optimized for the SLS 3D printing process. This guide covers the important dimensions and design considerations to keep in mind when designing parts for the Fuse Series printers.

Note: The following guidelines are intended as a general reference for printing with Formlabs materials on Fuse Series printers. While these recommendations apply to most situations, they may not reflect all circumstances and materials. Users should refer to the material-specific guidelines for additional information and considerations.

Fuse Series SLS Design Guide

Success with selective laser sintering (SLS) begins with parts optimized for the SLS 3D printing process. This guide covers the important dimensions and design considerations to keep in mind when designing parts for the Fuse Series printers.

Note: The following guidelines are intended as a general reference for printing with Formlabs materials on Fuse Series printers. While these recommendations apply to most situations, they may not reflect all circumstances and materials. Users should refer to the material-specific guidelines for additional information and considerations.

Reference Dimensions

These reference dimensions were developed for Nylon 12 Powder and serve as a baseline set of guidelines for printing with Fuse Series printers. Please see the Material Specific Characteristics section below for material-specific design considerations and how they are expected to deviate from results typically achieved with Nylon 12 Powder.

Minimum Unsupported Wall Thickness

Vertical walls: 0.6 mm/600 microns

Horizontal walls: 0.3 mm/300 microns

An unsupported wall is one that is connected to other walls on fewer than two sides. An unsupported vertical wall with a thickness of 0.6 mm or less or an unsupported horizontal wall with a thickness of 0.3 mm or less may warp or detach from the model during printing. Thinner walls have reduced strength.

Minimum Supported Wall Thickness

Vertical walls: 0.6 mm/600 microns

Horizontal walls: 0.3 mm/300 microns

A supported wall is one that is connected to other walls on two or more sides. A supported vertical wall with a thickness of 0.6 mm or less or a supported horizontal wall with a thickness of 0.3 mm or less may warp or detach from the model during printing. Thinner walls have reduced strength.

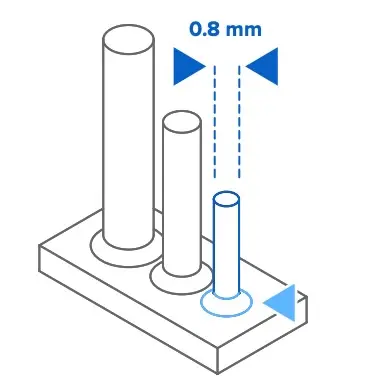

Minimum Pin/Wire Diameter

Recommended: 0.8 mm/800 micron diameter

A pin or wire is a feature whose length is at least two times greater than its width. Pins or wires with a diameter less than 0.8 mm may deform or break during the print.

NOTE: CLEANING SMALL WIRES

Take extra care when separating printed parts with thin wires from the powder cake, as they can easily be damaged. Filleting the edges where they meet the bulk of the part mitigates this risk.

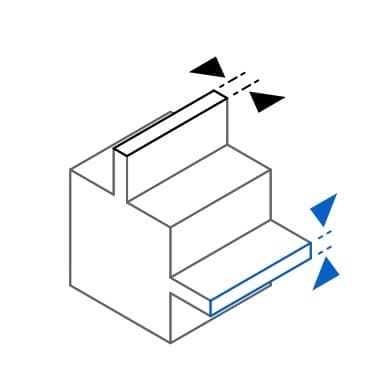

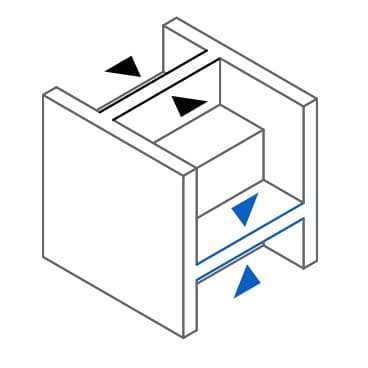

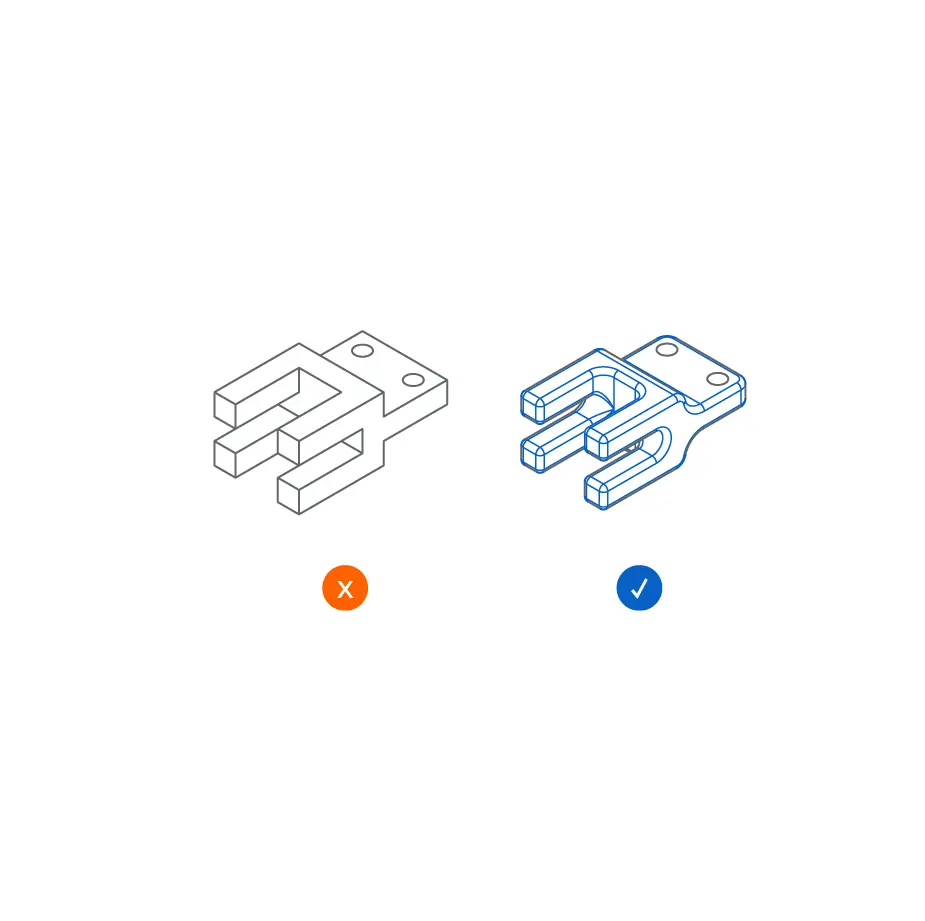

Minimum Assembly Tolerance

Features less than 20 mm2: 0.2 mm/200 microns

Features greater than 20 mm2: 0.4 mm/400 microns

Clearance is the distance between two parts of a model (e.g., the distance between a pair of gears). Leave a slight clearance between printed parts intended to mesh or interface after printing, like assembly joints or gears.

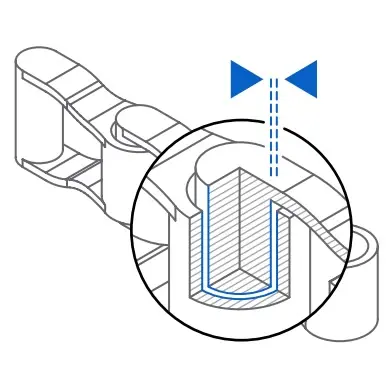

Minimum Integrated Assembly Clearance

Features less than 20 mm2: 0.3 mm/300 microns

Features greater than 20 mm2: 0.6 mm/600 microns

Clearance is the distance between two parts of a model (e.g., the distance between a pair of gears). For parts that are printed together in an integrated assembly, leave clearance to prevent the parts from fusing together during the print.

Separate Part Clearance

Minimum: 1.0 mm/1,000 microns

Recommended: 5.0 mm/5,000 microns

Clearance is the distance between two parts of a model. Parts that are intended to be separate and not interact with one another should be placed at least 5 mm apart to minimize thermal warping effects from the neighboring part.

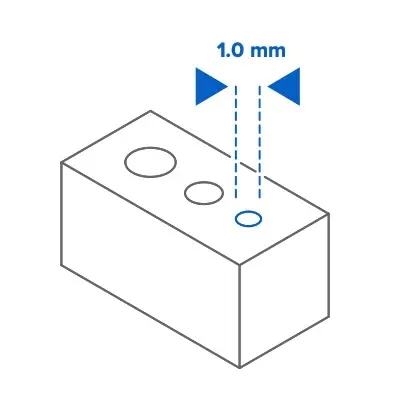

Minimum Hole Diameter

Recommended: 1.0 mm/1,000 microns

Holes with a diameter of less than 1.0 mm in the X-, Y-, and Z-axes may close during printing. The accuracy of a hole not only depends on the diameter of the hole, but also on the thickness of the wall through which the hole is printed. The thicker the wall section, the less accurate the hole becomes. Through holes must also allow for line-of-sight clearance to ensure all material is cleared during post-processing.

TIP: For precisely concentric holes, design an undersized pilot hole and use a reamer to open the hole to its intended diameter.

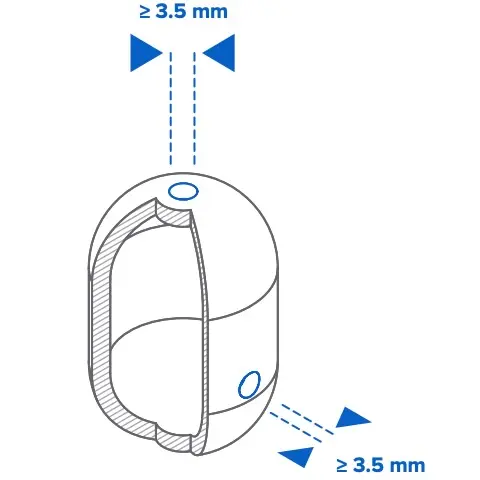

Minimum Drain Hole Diameter

Recommended: 3.5 mm/3500 micron diameter

Enclosed cavities remain filled with unsintered powder without proper drain holes. For best results, include at least two drain holes when designing a cavity, each greater than or equal to 3.5 mm in diameter.

TIP: More and larger drain holes make it easier to remove unsintered powder from internal cavities. To guarantee a clean internal surface, design the part so that the surface in question is easy to access with cleaning tools.

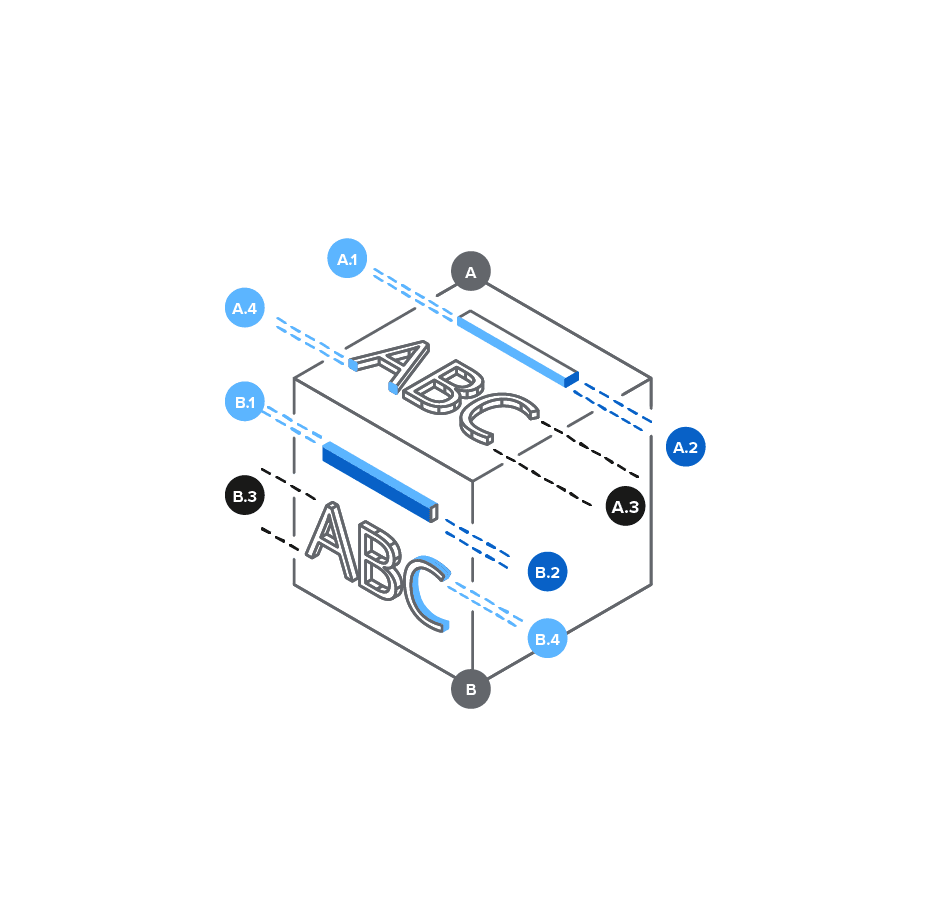

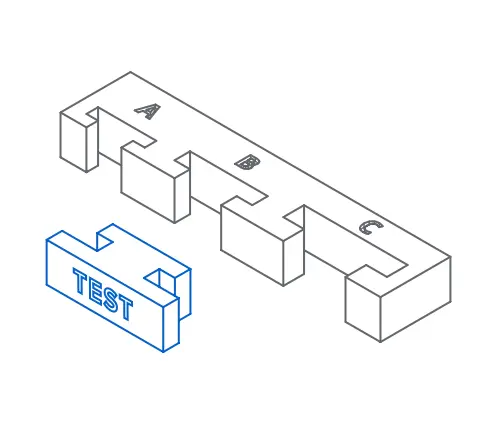

Minimum Embossed Detail

A. HORIZONTAL FACES:

A.1 Depth: 0.15 mm/150 microns

A.2 Width: 0.35 mm/350 microns

A.3 Text font height: 4.5 mm/4,500 microns

A.4 Text font depth: 0.3 mm/300 microns

B. VERTICAL FACES:

B.1 Depth: 0.35 mm/350 microns

B.2 Width: 0.4 mm/400 microns

B.3 Text font height: 4.5 mm/4,500 microns

B.4 Text font depth: 0.3 mm/300 microns

Embossed details are shallow raised features on the surface of a model like text. Small embossed features may not be visible on the finished part. Use a bold font where possible for best results with embossed text.

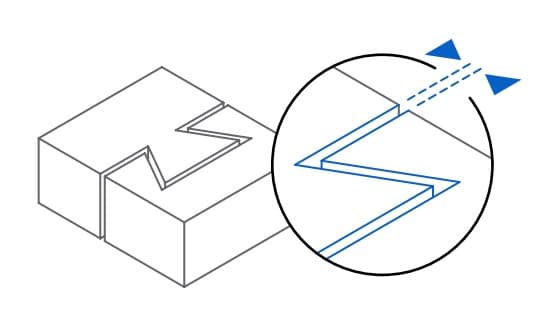

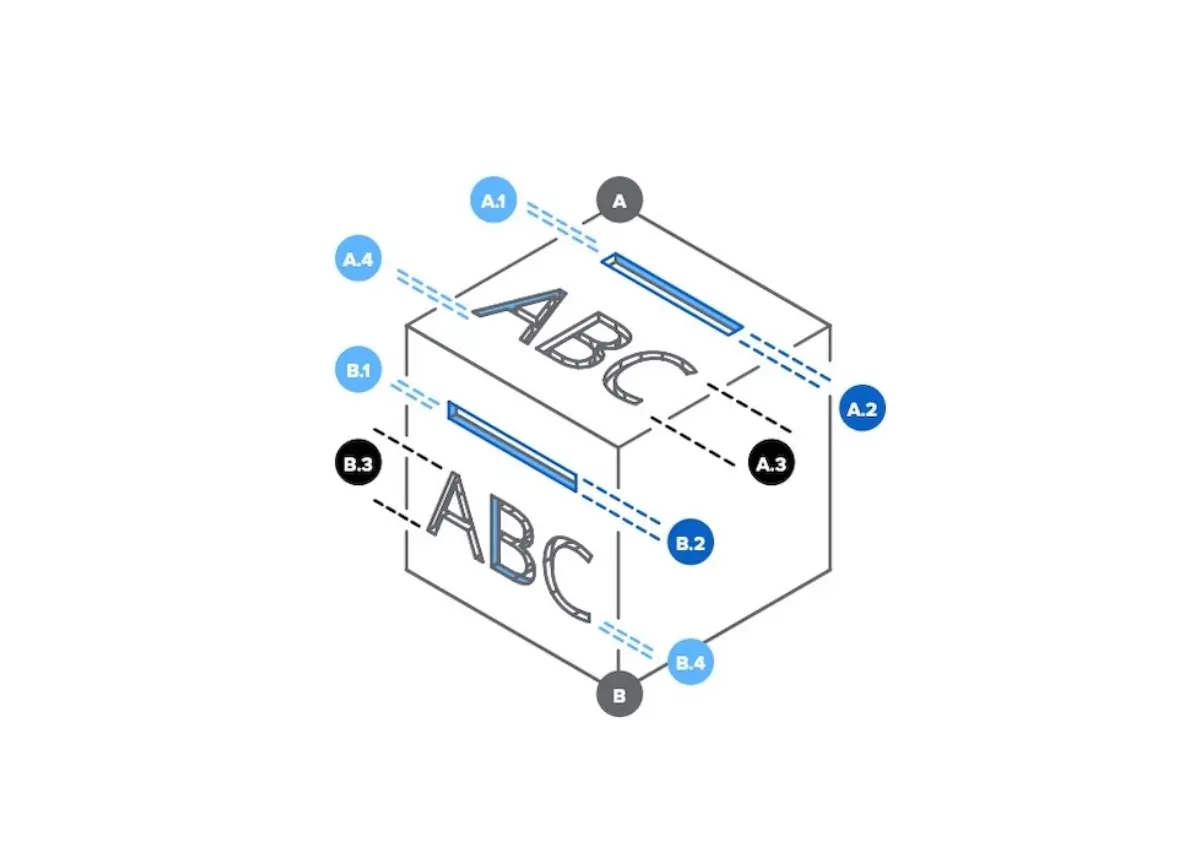

Minimum Engraved Detail

A. HORIZONTAL FACES:

A.1 Depth: 0.1 mm/100 microns

A.2 Width: 0.3 mm/300 microns

A.3 Text font height: 3.0 mm/3,000 microns

A.4 Text font depth: 0.3 mm/300 microns

B. VERTICAL FACES:

B.1 Depth: 0.15 mm/150 microns

B.2 Width: 0.35 mm/350 microns

B.3 Text font height: 3.0 mm/3,000 microns

B.4 Text font depth: 0.3 mm/300 microns

Engraved details are imprinted or recessed features on the surface of a model. Small engraved features may not be visible on the finished part. Use a bold font where possible for best results with engraved text.

Get Started with 3D Printing

Formlabs' complete, easy-to-use ecosystem makes it simple to get started with 3D printing. Explore our 3D printers and materials to find the right fit for your needs.

Achieving Design Success

The SLS 3D printing process differentiate itself by using loose powders, fused together to create your part, which enables printing without dedicated support structures. As with any process, there are ways to optimize your design to optimize print success and results. These recommendations can help you conserve material and print time while optimizing your part for successful printing and implementation.

Maintaining Uniform Thickness

Recommended: 3.5 mm/3500 micron diameter

Enclosed cavities remain filled with unsintered powder without proper drain holes. For best results, include at least two drain holes when designing a cavity, each greater than or equal to 3.5 mm in diameter.

TIP: More and larger drain holes make it easier to remove unsintered powder from internal cavities. To guarantee a clean internal surface, design the part so that the surface in question is easy to access with cleaning tools.

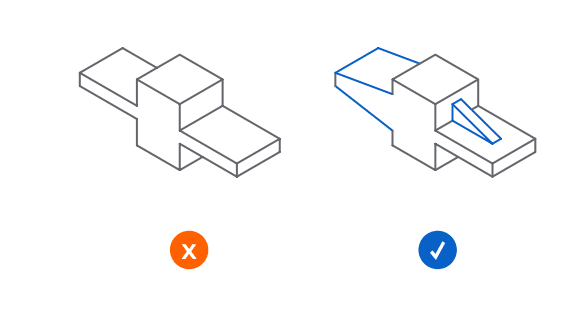

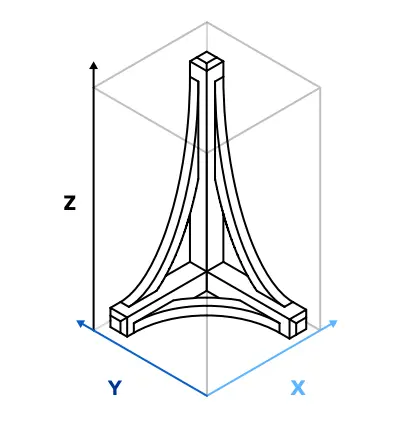

Reducing Stress Concentrations

Parts can experience stress buildup at sharp changes in cross-section, such as thin extrusions from thick bases. Design gradual edge transitions instead of abrupt ones to reduce these stress concentrations.

Managing Aspect Ratio

Parts with a high aspect ratio are susceptible to warping. Features such as ribs or drafts can mitigate risk of warping on thin, extruded sections like cantilevers and wires.

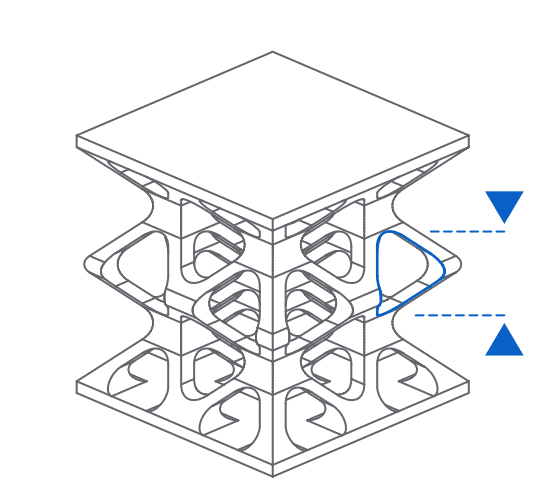

Designing Lattices

When designing a lattice structure, loose powders will need to be cleared from the lattice. To ensure easy powder removal in the Fuse Sift, design lattices with no smaller than 8 mm gaps, and leave open faces in your lattice so that you don’t trap powder inside.

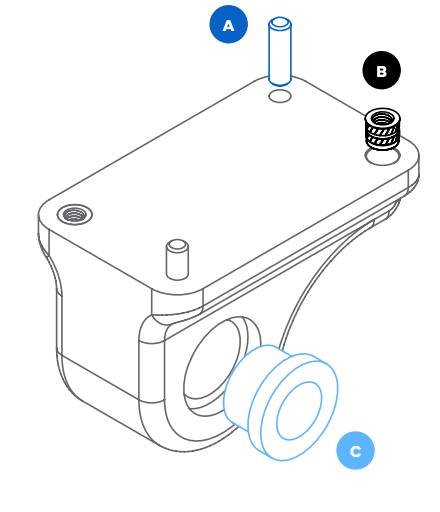

Integrating Hardware In Your Designs

Identify where it makes sense to integrate hardware into your printed designs. Here are some examples:

- Dowel pins as precise locating features

- Heat set inserts for durable threaded connections

- Bushings for concentric interfaces to shafts or rails

When In Doubt, Test!

If you are concerned about the success of a specific feature, create a small test print of the specific geometry in question. Isolate the feature and print the test part in the same intended orientation as the full part to get the best indication of design success.

Note: You might want to try printing multiple test pieces with different dimensions at once, starting from a tight tolerance and incrementing up by 0.1 mm to test various fits before committing to a larger print.

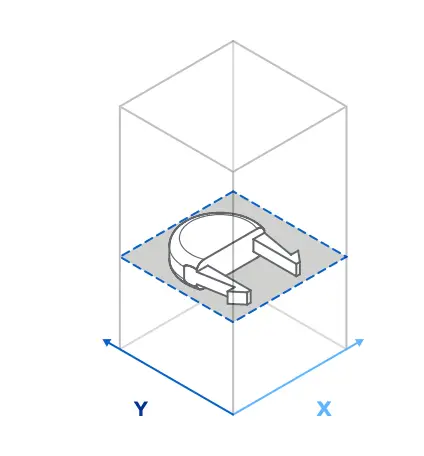

Part Orientation and Build Chamber Packing

Part layout in the Fuse Series build chamber can also affect print success. Below are a few helpful tips to keep in mind when laying out your parts.

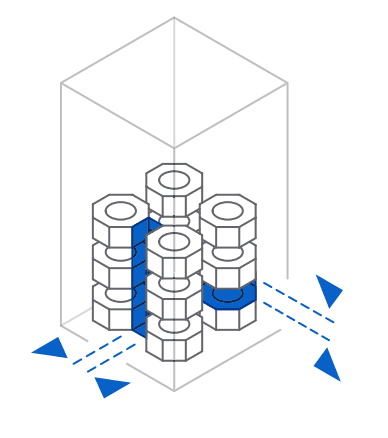

Part Spacing

When packing parts in the build chamber, space parts at least 5 mm apart for high-quality results. Distribute parts across the chamber to reduce the potential for thermal buildup.

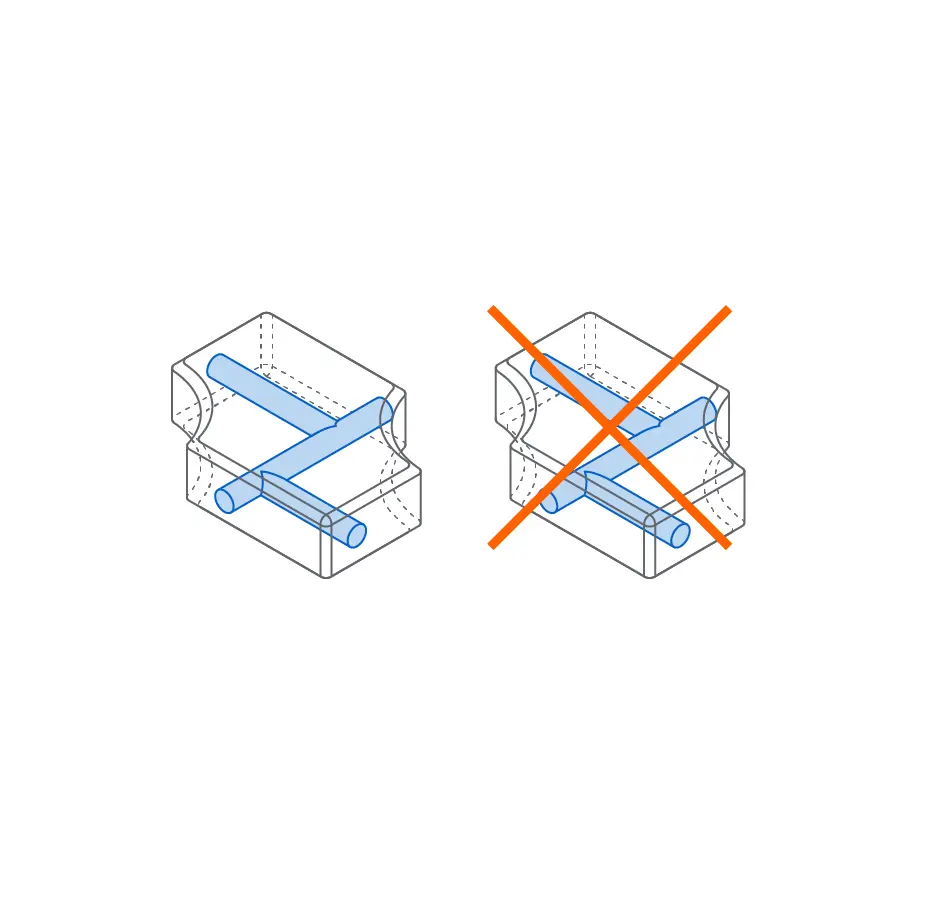

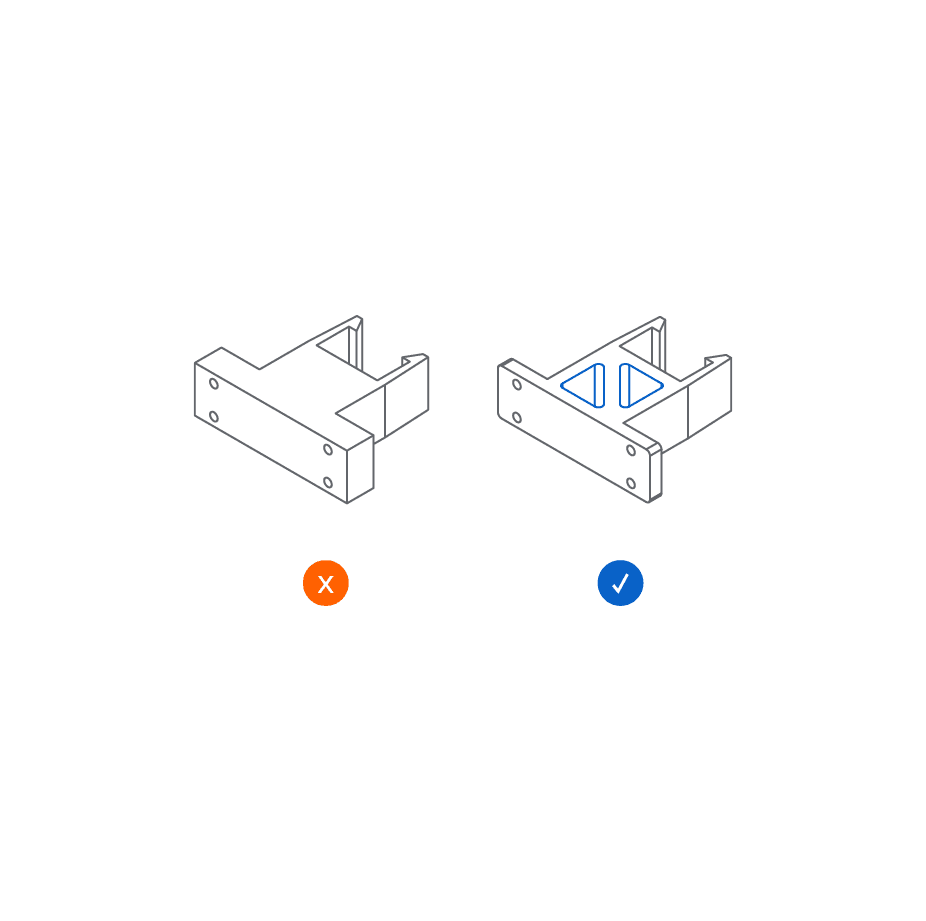

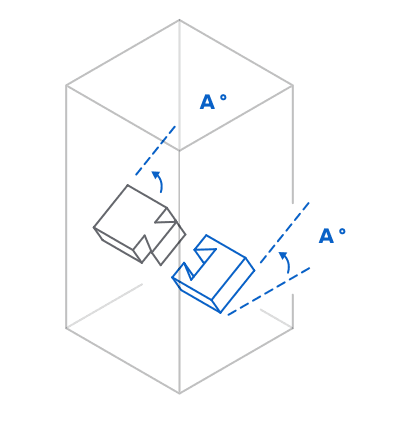

Interfacing Components

Parts that are designed to interface should have their mating features oriented in the same rotation to ensure they fit cleanly together.

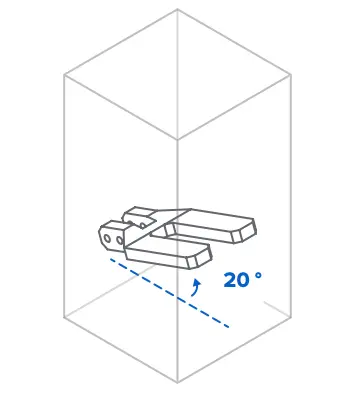

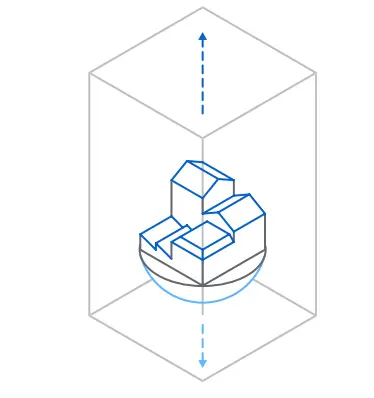

High-Aspect-Ratio Parts

High-aspect-ratio parts that are wide and relatively flat should be printed at a slight angle of about 20 degrees to minimize warping.

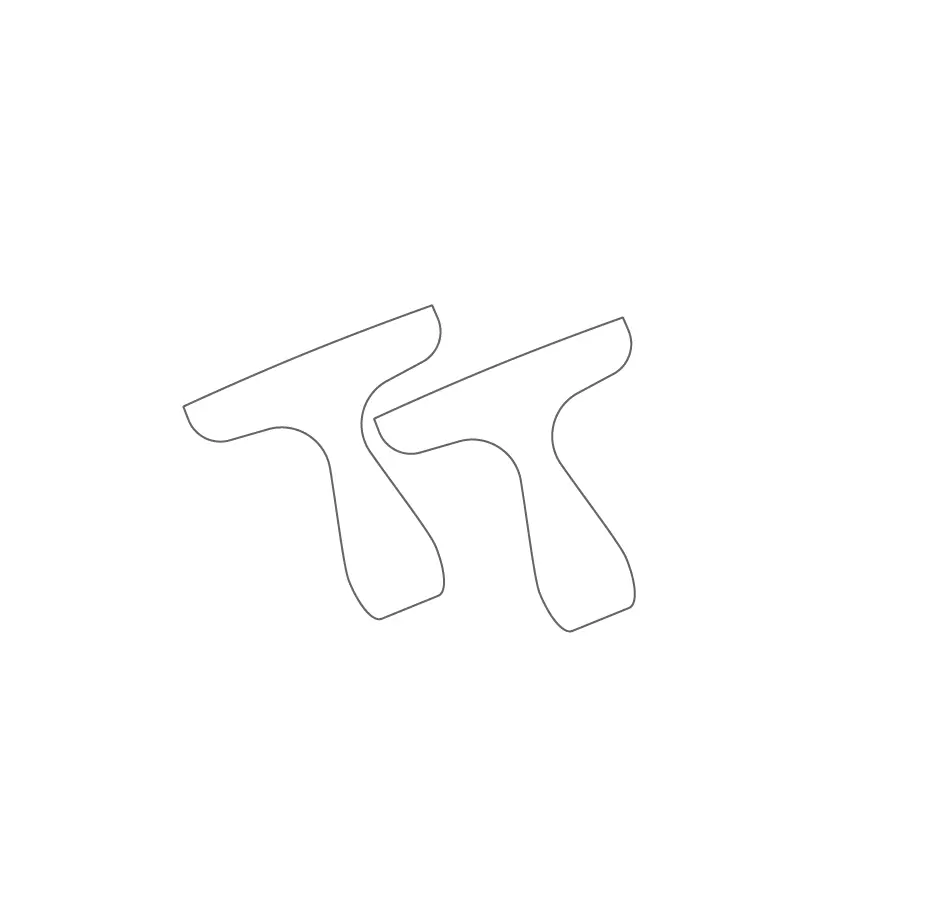

Flexural Features

Recommended: 3.5 mm/3500 micron diameter

Enclosed cavities remain filled with unsintered powder without proper drain holes. For best results, include at least two drain holes when designing a cavity, each greater than or equal to 3.5 mm in diameter.

TIP: More and larger drain holes make it easier to remove unsintered powder from internal cavities. To guarantee a clean internal surface, design the part so that the surface in question is easy to access with cleaning tools.

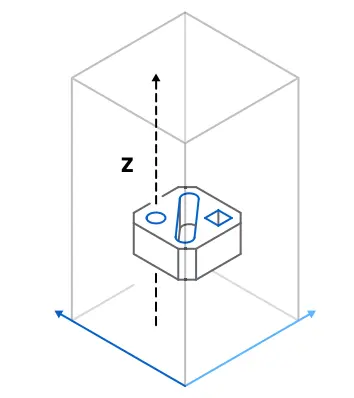

Dimensional Accuracy

Features like holes and pins are most accurate with their axes oriented in Z. When possible, align these features vertically in the chamber.

Surface Finish

For features where a smooth surface finish is desired, such as rounded faces or contours, orient the surface facing downward. For features that need a sharp, crisp finish, orient them facing upward.

Build Volume and Packing Density

The build volume refers to the largest possible part that can be printed on the Fuse 1 Series printers. There is no physical limit to the packing density within that build volume, which means that the entire build volume can be filled, to maximize part size, and minimize powder waste. The maximum part size may vary slightly from one material to the other, please refer to the section below for details.

Materials-Specific Characteristics

For the best results when printing with the Fuse Series printers, it is important to consider the unique properties of the specific material being used. The following guidelines will assist users in optimizing their designs for additive manufacturing with various powders on the Fuse Series printers.

Build Volume

Due to varying thermal expansion rates for different materials, the largest parts size printable in the Fuse Series printers varies. The largest part sizes achievable are given in the table below:

| Material | Largest Part Size |

| Nylon 12 Powder |

159.8 x 159.8 x 295.5 mm |

| Nylon 12 GF Powder |

160.1 x 160.1 x 297.3 mm |

| Nylon 12 Tough Powder |

158.8 × 158.8 × 293.5 mm |

| Nylon 12 White Powder |

159.8 × 159.8 × 293.8 mm |

| Nylon 11 Powder |

158.6 x 158.6 x 294.4 mm |

| Nylon 11 CF Powder |

162.0 x 162.0 x 287.6 mm |

| TPU 90A Powder |

152.1 x 152.1 x 294.9 mm |

Nylon 12 Powder Design Considerations

Nylon 12 Powder serves as an excellent general-purpose material due to its balanced material properties, ease of printing, and ease of post-processing as well as biocompatibility. The guidelines provided in the previous sections were compiled with Nylon 12 Powder in mind, so no additional design considerations are required.

Nylon 12 Tough Powder Design Considerations

Nylon 12 Tough Powder offers high ductility and high dimensional accuracy across the build chamber, allowing you to print more durable parts with less warpage, without sacrificing strength.

Design considerations specific to this material include:

- Model position: Orient parts towards the center of the build chamber and away from build chamber walls and floor, the back wall in particular, to reduce surface defects.

- Part spacing: Space all parts at least 5 mm from each other for best surface quality and easiest depowdering.

Nylon 12 GF Powder Design Considerations

Nylon 12 GF Powder excels at printing stiff, thermally resistant parts that are stable under load. It also has the benefit of biocompatibility for skin-contacting applications.

Design considerations specific to this material include:

-

Surface Roughness: The surface finish with this material is rougher than parts printed in Nylon 12 Powder. Designs that require a smooth finish should account for secondary post-processing steps needed to achieve a smooth finish whether that be machining, sanding, or another finishing process

-

Brittleness: The glass bead filler in Nylon 12 GF Powder provides enhanced stiffness, but also causes parts printed to be more brittle. Fine positive features may need to be thickened to prevent them from breaking in post-processing steps and in end-use. Brittleness is particularly notable across layers, so features requiring strength should generally be oriented to align with the XY plane whenever possible.

-

Escape Holes: The Surface Armor on parts printed with Nylon 12 GF Powder is tougher than when printed with Nylon 12 Powder. Escape holes should be larger, and ideally, all surfaces (internal and external) should have line of sight access so that the surface can be fully cleaned in the final cleaning steps using a media blaster.

Nylon 12 White Powder Design Considerations

Nylon 12 White Powder combines the great qualities of Nylon 12 Powder with the customizability of white parts. Create functional prototypes and end-use customer-facing parts that can be dyed to match branding as well as medical devices and models with high contrast and detail.

Design considerations specific to this material include:

- Model position: Orient parts towards the center of the build chamber and away from build chamber walls and floor, the back wall in particular, to reduce surface defects.

- Model orientation: Large flat surfaces print with the best quality perpendicular to the print plane. Avoid facing flat faces towards the front of the build chamber.

- Layer lines: Slightly curved surfaces oriented along the Z-axis will result in layer lines on parts.

- Part spacing: Space all parts at least 3 mm from each other for best surface quality and easiest depowdering.

Nylon 11 Powder Design Considerations

Parts printed with Nylon 11 Powder offer enhanced ductility compared to the ones printed with Nylon 12 Powder. They offer greater resistance to impact and vibration and are certified for biocompatible applications.

Design considerations specific to Nylon 11 Powder include:

-

Warping: Nylon 11 Powder has an increased tendency to warp when large cross sections are printed in the XY plane. Follow the guidance for high aspect ratio parts to minimize the effects of warping.

-

Clearances: Integrated assemblies require greater clearances. Leave at least 1 mm of clearance between the component pieces of integrated assemblies and iterate to optimize for the precise clearances that work best for the assembly’s requirements.

-

Fine Features: The minimum feature sizes for Nylon 11 Powder are slightly greater than those noted for Nylon 12 Powder and can vary depending upon the orientation of the feature on the part. This can have an effect on fine features such as small negative features, small positive features, thin walls, embossed text, and engraved text. To help ensure that fine features resolve correctly, try a small test print containing the desired features before printing the full part or a series of parts.

Nylon 11 CF Powder Design Considerations

Nylon 11 CF Powder is a high-performance material offering excellent stiffness, temperature resistance, impact strength, and tensile strength. It also has a lower tendency to warp than Nylon 11 Powder and therefore is more suitable to print parts with large cross sections.

-

Surface Roughness: Similar to Nylon 12 GF, the surface finish is rougher than the surface finish of parts printed in Nylon 12 Powder. Designs that require a smooth finish should account for secondary post-processing steps needed to achieve a smooth finish whether that be machining, sanding, or another finishing process

-

Anisotropic Properties in X, Y, and Z: Due to a tendency for the carbon fibers to align in the X-axis, or parallel to the front door of the printer, the mechanical properties of parts differ in the X direction compared to the Y direction. Similar to other 3D printed parts, the mechanical properties in the Z direction also differ and are generally lower than XY properties. For maximum stiffness and strength, orient features so that they are aligned with the X-axis.

TPU 90A Powder Design Considerations

TPU 90A Powder is an elastomer that offers high tear strength and high elongation at break. With a Shore Hardness of 90A, it is a material with firm, rubber-like characteristics. Softer parts can be achieved by substituting solid features with lattice structures to achieve targeted levels of stiffness. TPU 90A Powder is biocompatible and suitable for skin-contacting applications.

-

Thick Cross Sections: Fine features (including small pins, holes, and engraved or embossed text on the upper surfaces of geometries greater than 3 - 4 cm thick) may not resolve. This is caused by thermal buildup in the part and can be improved by re-orienting parts or hollowing out geometries.

-

Fine Features: The minimum feature sizes for TPU 90A Powder are slightly greater than those noted for Nylon 12 Powder and can vary depending upon the orientation of the feature on the part. This can have an effect on fine features such as small negative features, small positive features, thin walls, embossed text, and engraved text. To help ensure that fine features resolve correctly, try a small test print containing the desired features before printing the full part or a series of parts.

-

Warping: TPU 90A Powder has a tendency to warp. Warping is typically most prevalent on the bottom faces of parts. Follow the guidance for high aspect ratio parts to minimize the effects of warping.

-

Dimensional Accuracy: The layout of a build may affect the dimensional accuracy of parts. Pack parts tightly and towards the bottom of the build chamber to achieve the best dimensional accuracy.

-

Clearances: Integrated assemblies require greater clearances. Ensure a clearance of at least 1 mm to ensure that integrated assemblies function as intended. Clearances in close proximity to thick printed cross sections may require a greater gap, while clearances in close proximity to thin printed cross sections may achieve a smaller clearance.

-

Circular Feature Elongation: Circular geometries with an axis in the XY plane tend to elongate and become slightly egg shaped or elliptical rather than circular. Choose a part orientation that orients circular geometry axes in the Z direction to mitigate this effect.

Request a free sample part to see Formlabs 3D printed materials firsthand and contact our 3D printing specialist to find the right solution for your application.