Formlabs is dedicated to making the tools you need to bring your ideas to life. User feedback drives this mission, and the latest round of updates were guided by user requests.

In our latest PreForm 3.38 release, updates to Job Setup Cards and Print Summary Cards provide the information you need to power efficiency, while the addition of Open Material Mode (OMM) on the Form 4 masked stereolithography (MSLA) 3D printer creates opportunities for groundbreaking research and experimentation.

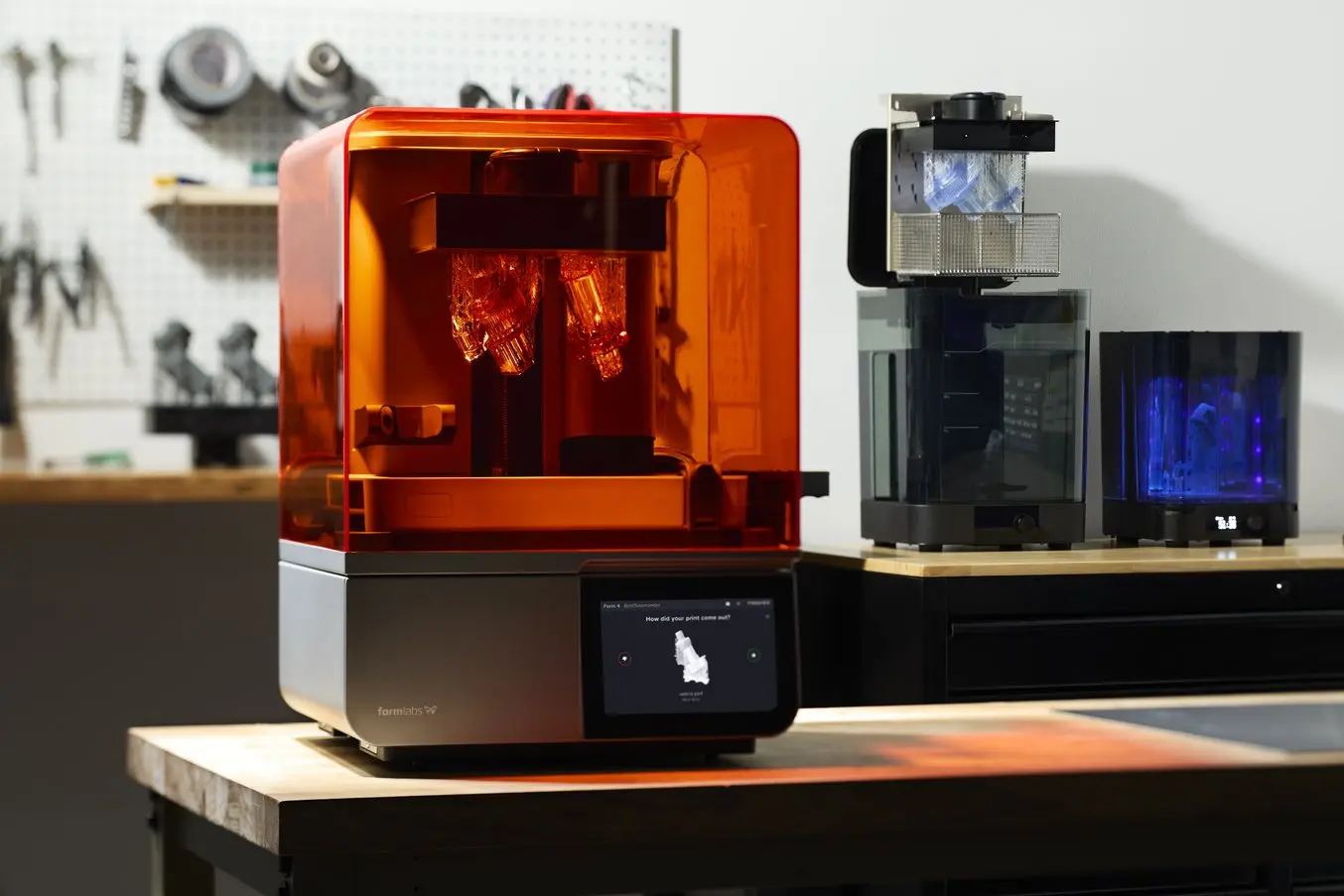

Open Material Mode for Form 4

Open Material Mode (OMM) empowers expert users and researchers to push the boundaries of 3D printing with custom resins. Previously announced for Form 3 Series 3D printers, OMM is now available on Form 4 Series printers. OMM allows users to experiment with any 405 nm photopolymer resin, unlocking unprecedented possibilities for material innovation and advanced applications.

To print with OMM, create a custom print setting with the PreForm Print Settings Editor. Learn more about using Open Material Mode here.

PreForm Updates

Updates to PreForm, Formlabs’ free print preparation software, make it easier to prepare parts, and give you more information on prints and materials, so you can maximize your efficiency. Ensure PreForm is updated to access these new features.

Job Setup Card

The Job Setup card at the top of the right sidebar in PreForm has been expanded to include printer information in addition to Job Settings. New information includes the printer name, type, status, connection, material, and consumables (build chamber or resin tank). If there’s a discrepancy between consumables and job setting material, you’ll be alerted to this issue so you can make changes for a streamlined job setup.

Print Summary Card

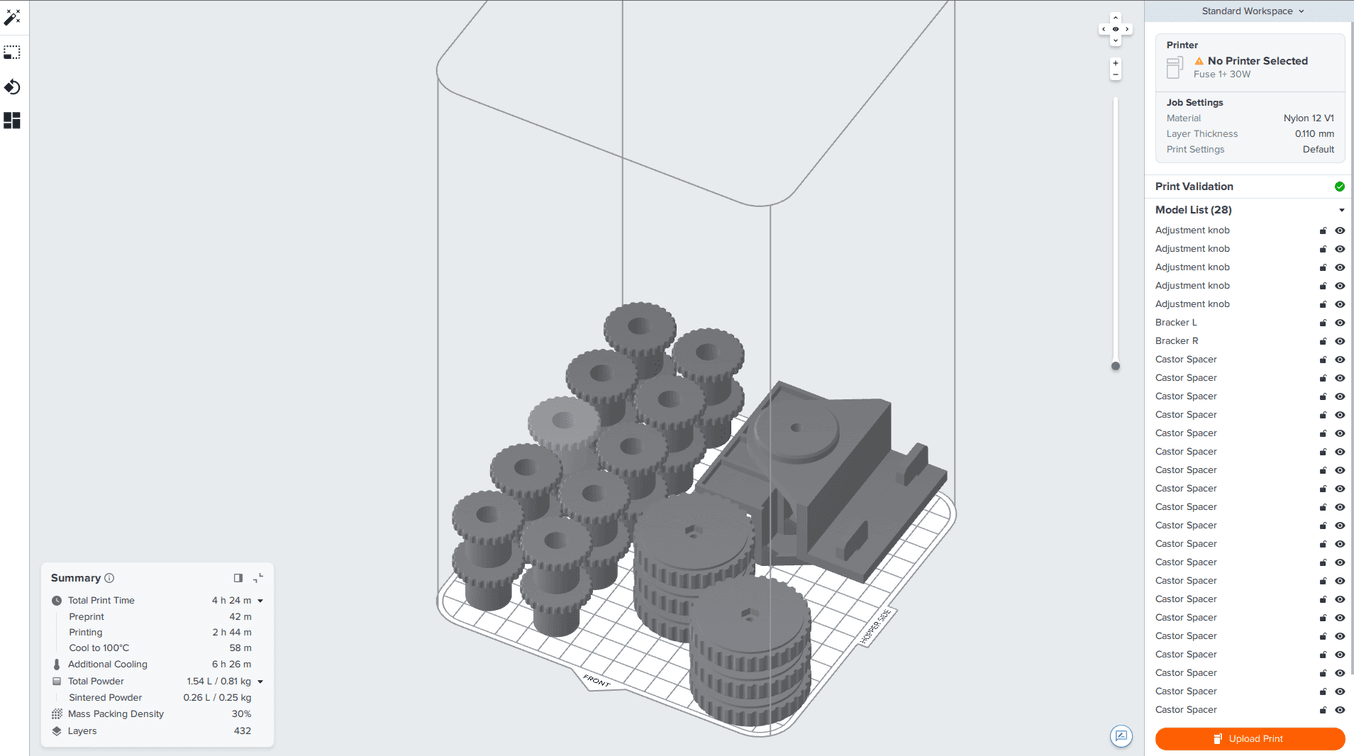

Declutter your right sidebar by unlocking the Print Summary window. By unlocking, you can dock the Summary Card in either the lower left corner of PreForm, or in the right sidebar. This opens up room for models in your model list so you can effectively manage your print job.

The PreForm Summary card can now be docked by clicking the upper righthand corner. This example, for SLS printing, also breaks down print time and cooling, and shows sintered powder.

When setting up prints for Fuse Series selective laser sintering (SLS) 3D printers, parameters have been expanded to include a breakdown of print time showing pre-print time, print time, cooling time to 100 ℃, and additional cooling time. For materials, the summary now displays total powder as well as the quantity of sintered powder. These breakdowns enable you to maximize your efficiency and make informed decisions on material usage.

Angle Snapping and Rotating

Requested by users, angle snapping enables the rotation of a part by 15° increments. This tool makes it faster and simpler to rotate a part. Simply press and hold the shift key to move at 15° increments, and release the Shift key to return to rotation at a tenth of a degree.

The Latest Updates Enabling Innovation

We’re continually developing our hardware, software, and materials to push the boundaries of what’s possible, creating the tools you need to bring your ideas to life. PreForm 3.38 represents our commitment to improving the tools you use, empowering users to expand the scope of what it’s possible to print.

At the bottom right corner of PreForm, you’ll find a Feedback button where you can submit your comments and requests. We take your suggestions seriously, and they continue to be a key factor in feature development here at Formlabs.

Leverage our latest software updates with the revolutionary hardware of Form 4 or Fuse 1+ 30W and fuel your innovation.