Leading the Future of Performance Products With Customized Manufacturing

Learn how Formlabs’ Factory Solutions team armed New Balance with the completely new 3D printing material and production system they needed to launch TripleCell, a new platform that’s poised to deliver the true on-demand performance customization that today’s consumers crave.

FuelCell Echo Triple

The FuelCell Echo Triple, the second TripleCell product from New Balance. Rebound Resin in the forefoot boosts performance during athletic activity.

990 Sport Triple Cell

The 990 Sport Triple Cell, the first TripleCell product to emerge of the Formlabs-New Balance partnership. The first shoe to contain custom built Rebound Resin.

Consumers Have Changed, Manufacturing Hasn’t

The modern consumer demands custom products that can be ordered from anywhere, from a variety of devices, and quickly delivered. On digital platforms, customization is everywhere. Physical products, constrained by the rigidity of traditional manufacturing, haven’t caught up.

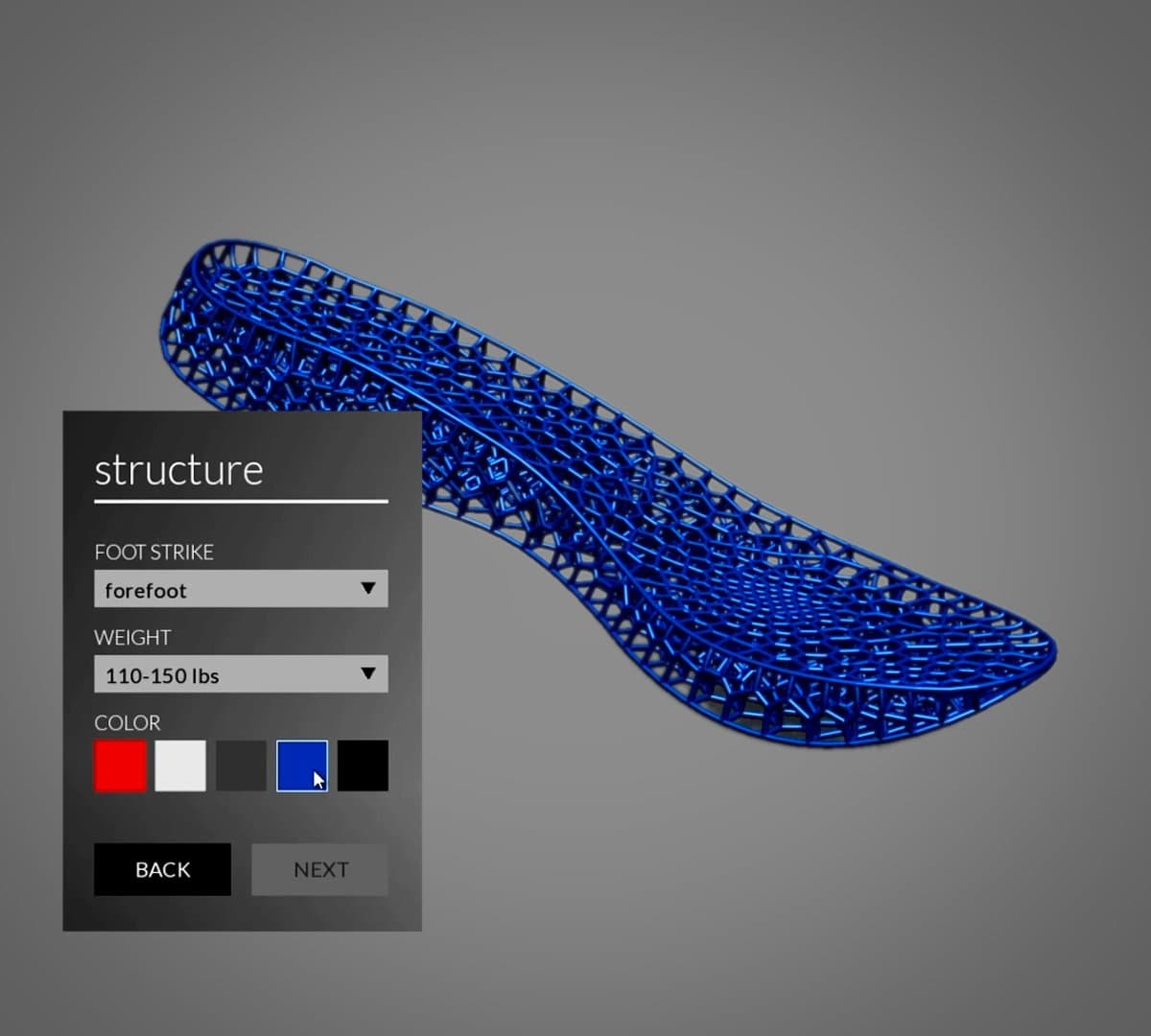

The Freedom to Design and Manufacture High-Performance Custom Products

3D printing offers the freedom to affordably produce complex, customized structures. New Balance understood this potential, but needed a way to move the technology from prototyping into production at scale—and find a material suitable for end-use in footwear. Formlabs’ Factory Solutions Team collaborated with New Balance every step along the way to make this a reality.

A Material Made for the Future

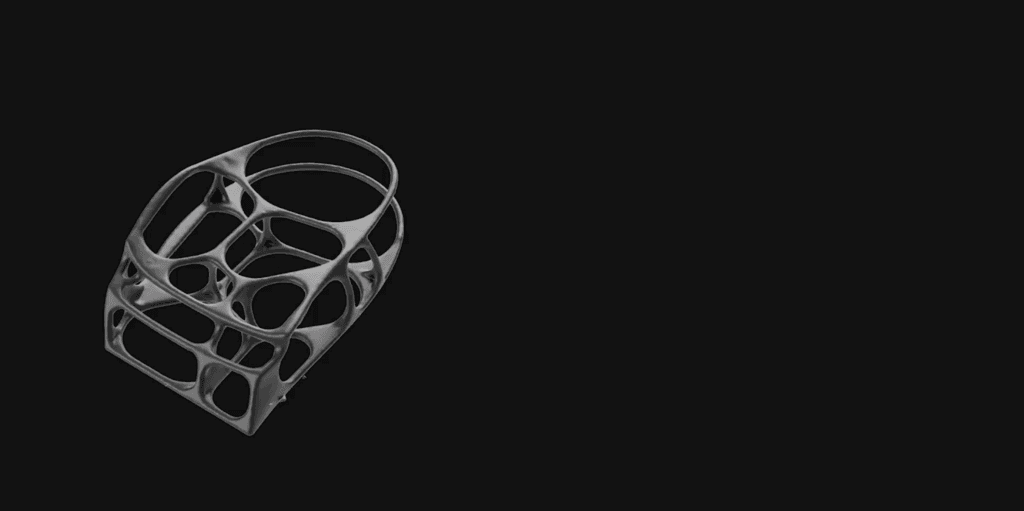

New Balance needed a 3D printing material that would withstand the necessary manufacturing and end-use applications, plus offer performance beyond what’s possible with foam—but it didn’t exist.

The Formlabs materials team collaborated with the company to develop a completely new material from the ground up. The result is Rebound Resin. Designed to create springy, resilient lattice structures, Rebound Resin has a much higher energy return, tear strength, and elongation than any other Formlabs stereolithography (SLA) resin.

“The world is changing. People want custom things made just for them that have higher performance and that can ship overnight.”

Dávid Lakatos, Chief Product Officer, Formlabs

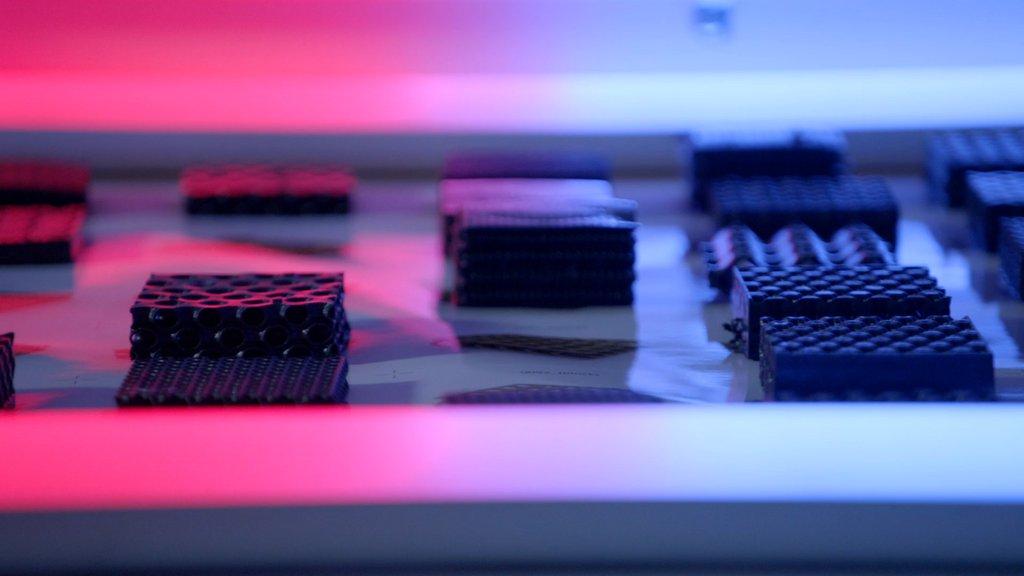

A New Production System for a New Kind of Product

Following a robust R&D program iterating through hundreds of exploratory material formulations to create Rebound Resin, Formlabs worked closely with New Balance to develop a production system to bring TripleCell to life and fully realize the benefits of the new 3D printing material.

The Formlabs Factory Solutions team collaborated closely with New Balance from beginning to end to create a seamless production workflow, from custom software features to on-site support, dedicated supply chain, and more:

- Material development

- Production workflow

- Logistics

- Software

- On-site support

A Foundation for the Future of Limitless, On-Demand Customization

TripleCell technology is now scaling exclusively within New Balance factories in the US. Next year, New Balance plans to scale up production to over 10,000 pairs per year of TripleCell products. Moving forward, TripleCell provides the foundation for leveraging unique athlete data and performance insights to create custom footwear in limitless combinations and produce it on demand, reducing development timelines and condensing delivery from concept to consumer.

“TripleCell is really on the leading edge of bringing New Balance domestic manufacturing into the digital age.”

Katy O’Brien, Engineering Manager, New Balance Manufacturing Innovation

Make Manufacturing Your Secret Ingredient

Collaborate with Formlabs on exploring and implementing new applications for 3D printing. Contact our Factory Solutions Team to learn more.

Get Started With 3D Printing

Get to know the SLA 3D printers that power New Balance’s TripleCell platform. Order the Form 3 or Form 3L and start exploring your own 3D printing applications today.