Rebound Resin: A Production-Ready Elastic 3D Printing Material

With five times the tear strength, three times the tensile strength, and two times the elongation of other production-grade elastomeric materials on the market, Rebound Resin is perfect for 3D printing springy, resilient parts.

Reap the benefits of two years of custom materials development and rigorous testing with this cutting-edge material, developed as part of an exclusive footwear collaboration with New Balance.

Rebound Resin is subject to a minimum order quantity and has different printing and post-processing requirements than other SLA resins. Partner with Formlabs to evaluate and implement this material for production.

Resilient, springy structures.

Rebound Resin’s high elongation makes it perfect for tactile, stretchy parts such as handles and grips.

300%

Performs under pressure.

Rebound Resin is strong enough to handle constant compression or tension, great for manufacturing complex gaskets and seals that last.

110 kN/m

22 MPa

Miles of Real World Testing

New Balance shoes incorporating Rebound Resin are already on the market and worn around the world.

Rebound Resin withstands the elements, enduring daily use in all-weather conditions to outperform and outlast traditional materials.

57%

Working With Rebound Resin

Rebound Resin is more complex to work with than other Formlabs products and requires extra steps for successful production.

This material is available exclusively through partnership with Formlabs

and requires a minimum quantity commitment to get started.

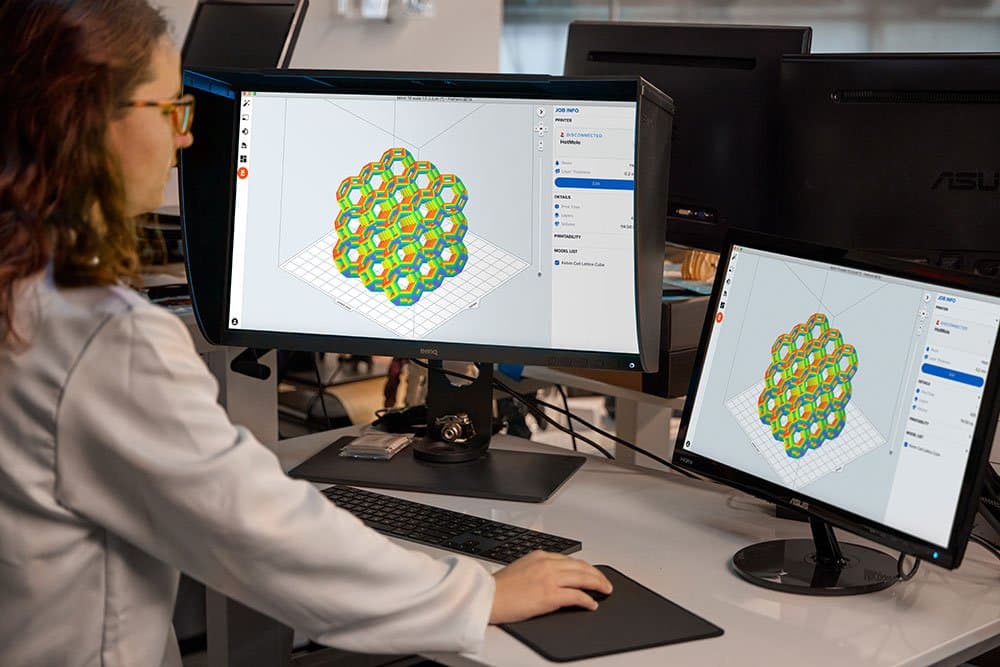

1. Design

Rebound Resin requires designing within specific constraints for successful printing. Start small, follow the usage guidelines, and experiment.

2. Prep Resin

Work with Formlabs to ensure an appropriate printing environment for this material. Select the resin delivery method that supports your production volumes.

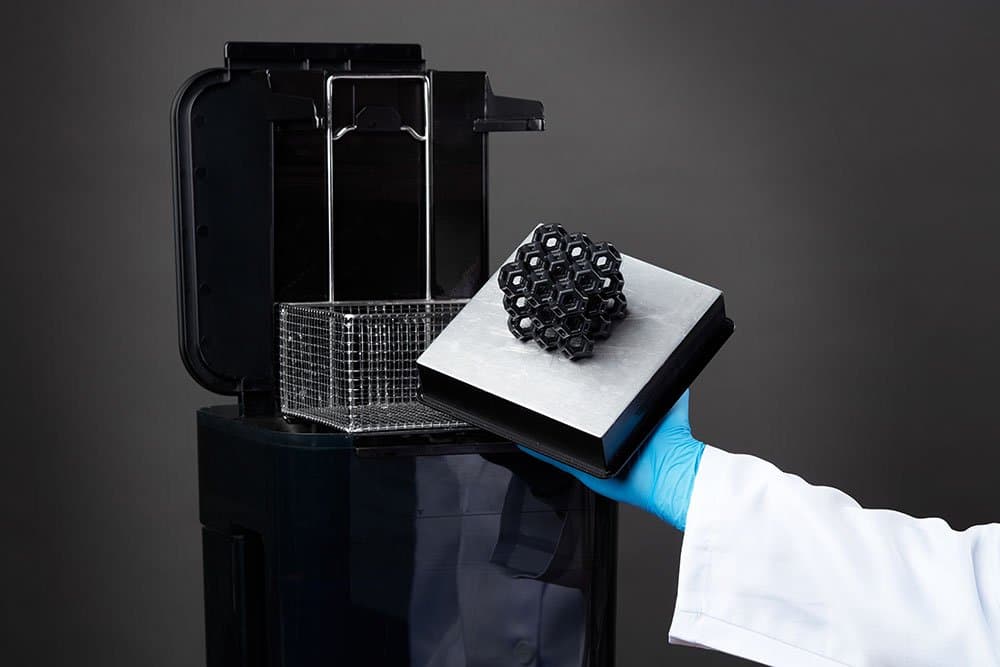

3. Print and Post-Process

Rinse and post-cure the part using specific recommendations for Rebound Resin. Contact Formlabs to learn how to set up your own Rebound printing station.

Make 3D Printing Your Secret Ingredient

Formlabs can help your team explore and implement new ways to use additive manufacturing to strengthen existing business, launch new initiatives, and explore new custom materials for your unique project demands.