Silicone is a synthetic rubber that boasts several appealing characteristics for manufacturing. Its chemical structure is amazingly versatile, making it possible to adapt its chemical formula to fit diverse industrial applications from seals to joints, wearables, medical devices, robotic grippers, cooking utensils, thermal and electrical insulation, and more.

Most silicone products today are produced with injection molding, compression molding, or casting. With advancements in 3D printing, many people ask the question, “Can you 3D print silicone parts?” The answer is yes!

Silicone has a very high viscosity, making it difficult to 3D print with it precisely. It cannot be heated and extruded or cured with UV light like photopolymer materials. This means that 3D printing silicone has not typically been as widely available as other materials, but there’s finally an accessible solution available on the market today. There are also many 3D printing processes that offer 3D printing materials with silicone-like properties, and 3D printing can also be used to create molds for molding silicone parts, bringing many of the benefits of 3D printing to traditional silicone manufacturing methods.

In this comprehensive guide, learn about the different options for silicone 3D printing, its alternatives, and how additive manufacturing supports traditional silicone manufacturing processes.

Book a Free Consultation

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.

Silicone 3D Printing Processes and Alternatives

Silicone 3D printers and their alternative solutions can be divided into three categories:

-

Direct silicone 3D printing: Silicone 3D printers that can print with 100% pure silicone materials.

-

3D printing using materials with silicone-like properties: Common polymer 3D printing processes offer various materials with silicone-like material properties that can serve as alternatives for certain applications.

-

Casting or molding silicone using 3D printed molds: Rapid tooling with 3D printing can bridge the gap between prototyping and mass-producing silicone parts with traditional manufacturing methods.

Creating Silicone Medical Devices

This guide aims to help the user decide on the best method of silicone part production for their intended use, and provides step-by-step instructions for both printing with Silicone 40A, and molding silicone using SLA 3D printed tooling (including two-part injection molds, overmolds, and compression molds).

Direct Silicone 3D Printing

While most 3D printing technologies have been around for many years or even decades, silicone 3D printers have long remained a relatively experimental field due to the complexity of printing with silicone. Over the last few years, some companies have brought silicone 3D printers to the market, but these solutions all had certain limitations alongside excessively high costs (over $100,000), which means that they were not suitable for most businesses and applications.

In 2023, Formlabs introduced the Silicone 40A Resin, the first accessible 100% pure silicone 3D printing material, made possible by the patent-pending Pure Silicone Technology™, which combines the outstanding material properties of cast silicone and the benefits of 3D printing.

The solution relies on the accessible (starting at $3,499) and versatile (over 35+ additional advanced materials) Form 4 stereolithography (SLA) 3D printing ecosystem, to produce 100% silicone parts in-house, in a matter of hours.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free Silicone 40A Resin sample part to your office.

Silicone 40A Resin parts, with 40A Shore durometer, 230% elongation at break, and 12 kN/m tear strength, are ideal for applications requiring pliability and durability even through repeated stretching, flexing, or compression. Parts made with Silicone 40A Resin have a rebound resilience of 34%, excellent chemical and thermal resistance (-25°C to 125°C), and can have fine features as small as 0.3 mm and complex shapes that are challenging to achieve with traditional manufacturing methods.

Direct silicone 3D printing with Silicone 40A Resin is ideal for a wide range of applications, from rapid prototyping to manufacturing aids, tooling, and low volume or custom manufacturing.

Silicone 40A Resin parts are ideal for the following applications:

- Rapid prototyping, beta testing, and validation stages of the product development cycle for elastic consumer goods, automotive components, and industrial equipment such as connectors, grommets, actuators, keypads, and watch bands.

- Cost-efficient low-volume or custom manufacturing of indoor end-use parts, such as seals and gaskets.

- High-quality, long-lasting custom manufacturing aids and tools such as flexible casting molds, jigs, fixtures, and masking tooling.

- Medical device components, patient-matched prosthetics, and audiology applications.

- Complex geometry parts that are difficult to manufacture with traditional methods.

Introducing Silicone 40A Resin

In this webinar, our 3D printing experts walk you through the key benefits and applications of Silicone 40A Resin and present the material properties and the workflow for this resin.

Finis used 3D printed silicone gaskets and buttons to create functional prototypes of their new smart goggles.

The product development team at FINIS, Inc. 3D printed swimming goggle gaskets similar to production quality within a mere eight hours for just $10 a piece, significantly undercutting the usual expenditure of over $1,000 and a three-week timeline associated with outsourced urethane casting. The 3D printed silicone gaskets underwent rigorous water tightness assessments within a swimming pool environment, helping the team shorten their product development schedule.

Custom gaskets from Dorman Products 3D printed in Silicone 40A Resin.

Dorman Products, a century-old manufacturer of aftermarket automotive parts, has turned to silicone 3D printing to produce custom gaskets for pressure testing new products. Previously they’d cut the gaskets using the metal dies in an arbor press, but switching to 3D printing allowed the team to drastically reduce lead times and costs, especially considering that they had to test hundreds of new components.

Connectors seals from HGM Automotive Electronics 3D printed with Silicone 40A Resin.

HGM Automotive Electronics is a specialty transmission controller manufacturer that, through rigorous chemical and mechanical testing, demonstrated that the parts printed in Silicone 40A Resin have excellent mechanical properties and chemical resistance, similar to injection molded silicones that they have traditionally relied on. After six weeks of thermal cycling in an engine bay under normal operating conditions and additional chemical fluid exposure tests, they have qualified 3D printed Silicone 40A Resin parts for end-use automotive parts.

3D Printing Pure Silicone: Applications and User Cases

In this webinar, Formlabs’ Product team will discuss the applications of Silicone 40A Resin with experts from the automotive industry.

3D Printing Using Materials With Silicone-Like Properties

Some of the primary reasons why manufacturers choose silicones are the elasticity and flexibility of these materials that empower a wide range of applications.

Silicones generally fall between 10A and 80A Shore durometer hardness. Common polymer 3D printing processes like fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS) offer various materials in this hardness range, with various degrees of likeness in other important material properties of silicone such as durability, thermal stability, UV resistance, food safety, biocompatibility, as well as color and translucency options.

FDM Material Alternatives to Silicone

For FDM 3D printing, elastomers such as thermoplastic polyurethane (TPU) and thermoplastic elastomer (TPE) are the most flexible materials that can offer an alternative to silicone. These materials are commercially available at Shore 45A to Shore 90A hardness, which covers the harder end of the silicone hardness range.

The pros associated with these alternatives are the general affordability of FDM 3D printers and materials. Conversely, the cons include lower precision and dimensional accuracy, low resolution, quality, and part strength, and limited design freedom that all restrict real-world usability. Silicone-like FDM materials are generally less durable than standard silicone, not food-safe, have lower temperature resistance, and offer limited color and no real translucency options, but they can be biocompatible and skin-safe.

SLA Material Alternatives to Silicone

Stereolithography 3D printing is popular among professionals for its high precision and wide range of material options. SLA 3D printing offers multiple alternatives to silicone that empower manufacturers to prototype silicone-like parts or even manufacture end-use parts with the flexibility, elasticity, and durability of silicone. SLA parts offer the smoothest surface finish and greater design freedom than FDM.

Silicone-like flexible 3D printing resins are generally also less durable than standard silicone, not food-safe, not biocompatible (but can be skin-safe), and have lower temperature resistance. Silicone-like SLA materials can be translucent and can also be dyed to different colors.

SLA 3D printing offers multiple alternatives to silicone that can be used to prototype silicone-like parts or even manufacture end-use parts.

The specific material availability is dependent on the printer model, but generally falls within the 30A and 90A Shore durometer hardness range. Alternative materials to silicone among Formlabs’ SLA 3D printing materials include:

-

Elastic 50A Resin is a soft material that’s suitable for prototyping parts normally produced with silicone. This 50A Shore material is ideal for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing, and spring back quickly to their original shape. Choose Elastic 50A Resin for applications like wearables (straps), stretchable enclosures and casings, compressible buttons, or soft tissue anatomy models in healthcare.

-

Flexible 80A Resin is a stiff soft-touch material with an 80A Shore durometer to simulate the flexibility of hard silicones, as well as rubber or TPU. Balancing softness with strength, Flexible 80A Resin can withstand bending, flexing, and compression, even through repeated cycles. It is ideal for prototyping applications like handles, grips, overmolds, cushioning, damping, shock absorptions, seals, gaskets, and masks, or cartilage, tendon, and ligament anatomy models in healthcare.

- While slightly beyond the hardness range of silicone materials, Rebound Resin is an 86A Shore elastic 3D printing material that offers unique properties for end-use applications. With five times the tear strength, three times the tensile strength, and two times the elongation of other production-grade elastomeric materials on the market, Rebound Resin is perfect for 3D printing springy, resilient parts. Rebound Resin’s high elongation makes it perfect for tactile, stretchy parts such as handles and grips. It is strong enough to handle constant compression or tension, which is ideal for manufacturing complex gaskets and seals that last.

New Balance shoes incorporating Rebound Resin are already on the market and worn around the world. Rebound Resin withstands the elements, enduring daily use in all weather conditions to outperform and outlast traditional materials.

Request a Free Silicone-Like SLA 3D Printed Sample Part

See and feel Formlabs quality firsthand with an Elastic 50A Resin or Flexible 80A Resin SLA 3D print with silicone-like properties. We’ll ship a free sample part to your office.

SLS Material Alternatives to Silicone

Selective laser sintering (SLS) 3D printing is the most common additive manufacturing technology for industrial applications. It offers high accuracy, high throughput, and almost limitless design freedom as the unfused powder supports the part during printing and eliminates the need for dedicated support structures.

SLS materials with silicone-like properties include TPU, TPE, and TPA, offering hardness ranges between 45A and 90A Shore. The exact availability is dependent on the printer model.

For Formlabs Fuse Series SLS 3D printers, TPU 90A Powder is a tough elastomer for producing resilient products with unmatched design freedom and ease. Balancing high elongation at break and superior tear strength, TPU 90A Powder enables you to produce flexible, skin-safe prototypes and end-use parts that withstand the demands of everyday use – all at a low cost per part. TPU 90A Powder is ideal for prototyping as well as end use part production of wearables, soft-touch elements, padding, dampers, grippers, gaskets, seals, soles, splints, orthotics, prosthetics, and more.

Parts produced with silicone-like SLS materials are accurate, durable, abrasion and wear-resistant, and have the highest temperature resistance of the three plastic 3D printing processes. They can be biocompatible, skin-safe, and also food-safe after post-processing. On the downside, SLS printing offers limited color and no translucency options, and designs with thin walls may warp while cooling down.

Request a Free Silicone-Like SLS 3D Printed Sample Part

See and feel Formlabs quality firsthand with a TPU 90A SLS 3D print with silicone-like properties. We’ll ship a free sample part to your office.

Casting or Molding Silicone Using 3D Printed Molds

For those looking to produce pure silicone parts with unique properties (different hardnesses, colors, etc.), 3D printing can also help bridge the gap between prototyping and mass-producing silicone parts with traditional manufacturing methods.

Injection molding, thermoforming, compression molding, and silicone casting all make use of molds to create the finished silicone product. However, tooling comes with high upfront costs and weeks or months-long lead times from service providers, slowing down product development and extending the time it takes to get a product to market.

Incorporating in-house rapid tooling into the product development process empowers businesses to validate the design and material choice before transitioning to mass production and provides an affordable means to produce custom or limited series of end-use parts.

How to Produce Silicone Parts With 3D Printed Tools

In this webinar, you get to learn from a detailed example of a gravity-filled injection overmold printed with Formlabs Clear Resin. We also discuss how to select a mold type for your application, as well as silicone-resin compatibility and other silicone casting best practices.

Guide to Rapid Tooling

In this white paper, learn how to combine rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or casting.

Google’s Advanced Technology and Projects (ATAP) team used 3D printed stand-ins or surrogate parts instead of overmolded electronic sub-assemblies for the initial tool tuning at the factory. They were able to cut costs by more than $100,000 and shorten their testing cycle from three weeks to just three days using a combination of 3D printing and insert molding. Google ATAP’s team found that by 3D printing test parts, they could save time and money over using expensive electronic parts that had to be shipped in from a supplier.

Dame Products, a Brooklyn-based startup, designs products for the health and wellness industry. They employ silicone insert molding to encapsulate internal hardware for customer beta prototypes. The Dame Products product line incorporates complex ergonomic geometries fully encapsulated in a layer of skin-safe silicone in vibrant colors.

Dame Products employs silicone insert molding to encapsulate internal hardware for customer beta prototypes.

Silicone insert molding is also ideal for manufacturing low volumes of end-use parts. Advanced prosthetics manufacturer Psyonic uses the process to create fingers for prosthetic hands that have a hard 3D printed core overmolded with silicone, while Robotics manufacturer RightHand Robotics uses the same process to create grippers for robots.

Psyonic uses silicone insert molding to create fingers for prosthetic hands.

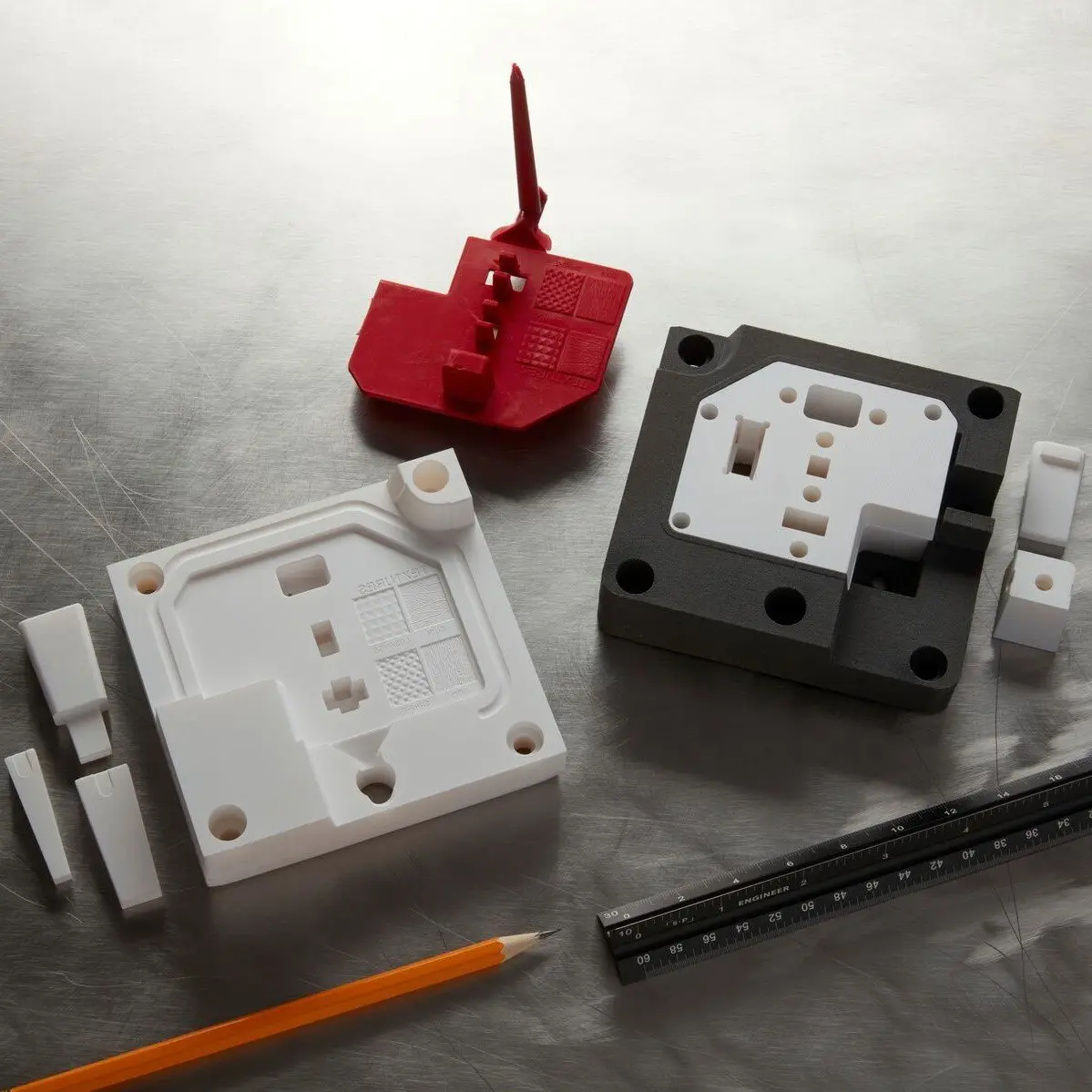

3D printed rapid tooling for compression molding can be leveraged for the production of thermoplastic, silicone, rubber, and composite parts. Product developers at kitchen appliance manufacturer OXO use 3D printing for prototyping rubbery components such as gaskets by compression molding two-part silicone using 3D printed molds.

3D printing is a fast and cheap method for creating molds for compression molding.

Silicone Part Production With 3D Printed Tools

Download this report for a step by step guide on 3D printed tooling for silicone part production, with mold design best practices and customer case studies.

Casting is also a popular method for producing silicone and plastic parts for medical devices, audiology, food-safe applications, and more.

Medical device company Cosm manufactures patient-specific pessaries for patients with pelvic floor disorders. They 3D print molds on an SLA 3D printer and inject biocompatible, medical-grade silicone into it to create the part. Rapid tooling with 3D printing allows them to create custom parts without the high costs of traditional tooling.

Patient-specific pessaries, produced by silicone casting.

Manufacturing custom ear molds with 3D printing has also revolutionized the audiology space, for applications like hearing aids, noise protection, and custom-fit earphones. Digital manufacturing provides greater control and accuracy compared to traditional mold production, significantly reducing the number of errors and remakes.

The step-by-step process of making custom-fit ear tips using silicone ear molds.

3D Print Custom Soft Ear Molds

Walk through a step-by-step guide of the process for affordably producing custom silicone ear molds using a Formlabs 3D printer and Formlabs’ Standard Clear Resin.

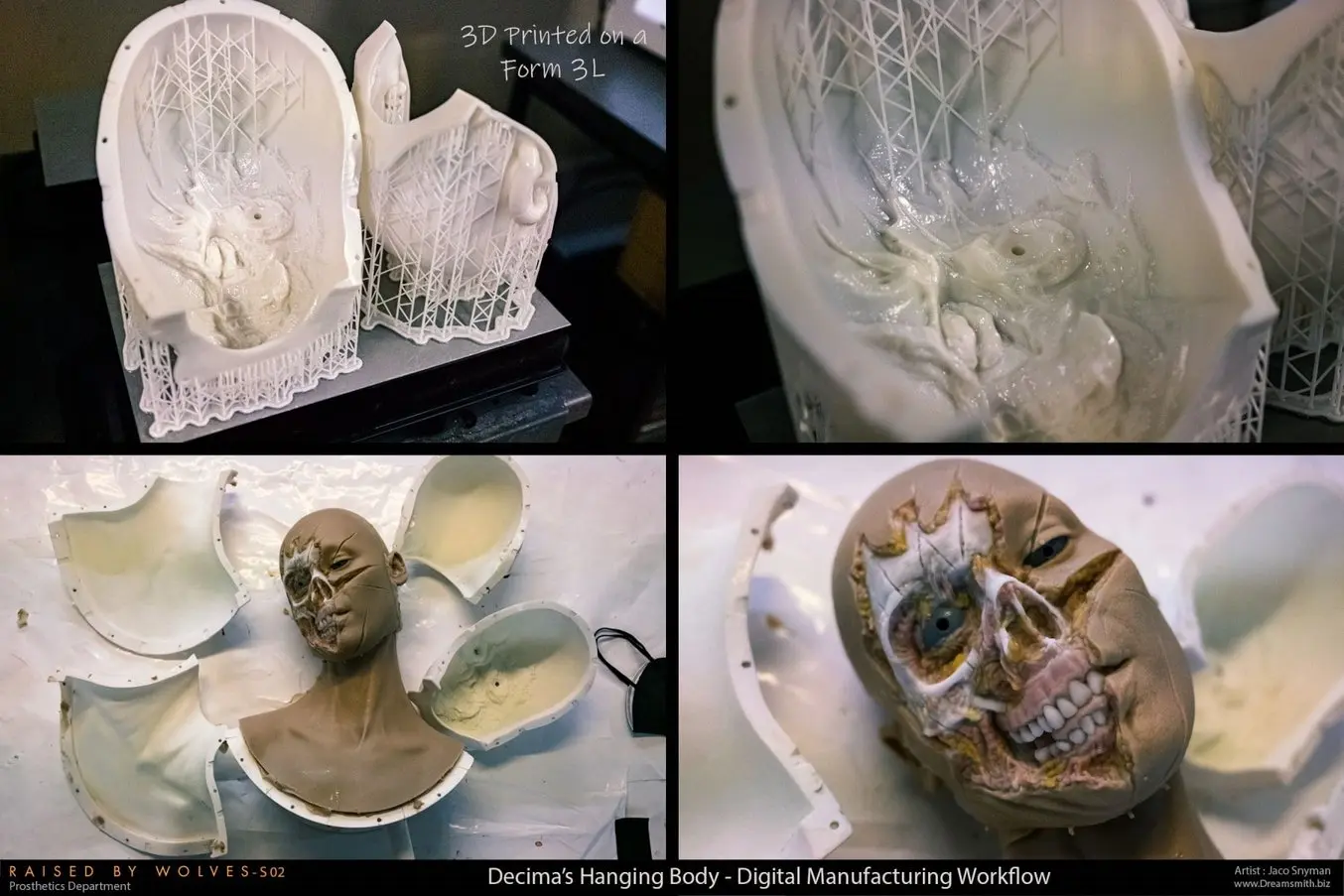

Silicone casting is also used in the entertainment industry. Jaco Snyman, founder of the award-winning practical prosthetic make-up effects and prop-making company Dreamsmith Studio, used a variety of these techniques for the sci-fi series “Raised by Wolves”. Leveraging the large build volume of the Form 3L large-format resin 3D printer, Snyman created a hyper-realistic silicone replica of an actress’s body, silicone masks for actors, human-size dummies, and more.

Making a hyper-realistic silicone replica of an actress’s face, with molds digitally designed and 3D printed on the Form 3L.

Conversely, silicone materials can also be used to create molds for molding various materials. Read our guide to learn how to make silicone molds.

Comparing Silicone 3D Printing Processes and Alternatives

| DIRECT SILICONE 3D PRINTING (SLA) | FDM 3D Printing | SLA 3D Printing | SLS 3D Printing | Casting or Molding Silicone Using 3D Printed Molds | |

|---|---|---|---|---|---|

| Accuracy | ★★★★★ | ★★★☆☆ | ★★★★★ | ★★★★★ | ★★★★★ |

| Surface Finish | ★★★★★ | ★★★☆☆ | ★★★★★ | ★★★★☆ | ★★★★★ |

| Design Freedom | ★★★★☆ | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| Ease of Use | ★★★★☆ | ★★★☆☆ | ★★★★★ | ★★★★☆ | ★★★★★ |

| Materials | Silicones | TPU, TPE | Proprietary resins | TPU, TPE, TPA | Silicones |

| Hardness | 40A Shore | 45A to 90A Shore | 30A to 90A Shore | 90A Shore | 10A to 80A Shore |

| Price | Professional SLA 3D printers cost around $2,500 to $10,000, and large-format resin 3D printers are in the $5,000 to $25,000 range. | Budget printers and 3D printer kits start at a few hundred dollars. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. | Professional SLA 3D printers cost around $2,500 to $10,000, and large-format resin 3D printers are in the $5,000 to $25,000 range. | Benchtop industrial SLS 3D printers start just under $30,000 for the printer and $60,000 for the entire ecosystem, including powder management and cleaning stations. Traditional industrial SLS printers start at around $200,000. | Same as SLA 3D printing for the printer. Other costs depend on the manufacturing process. |

| Pros | Uses real silicones Durable and wear-resistant Temperature and chemical resistant Affordable High accuracy Smooth surface finish Easy to use Can be biocompatible | Affordable Can be biocompatible | Affordable High accuracy Smooth surface finish Easy to use Can be translucent and colored Can be biocompatible | Durable and wear-resistant Design freedom No need for support structures Can be biocompatible | Uses real silicones Durable and wear-resistant Temperature and chemical resistant Affordable High accuracy Smooth surface finish Can be biocompatible and food safe |

| Cons | Limited material options | Low accuracy and resolution Limited design freedom Limited durability Limited material options | Limited material options Limited durability | Limited material options Rough surface finish | Labor-intensive workflow |

| Ideal for | Functional prototyping Manufacturing aids and tooling Moldmaking (soft molds) End use parts | Prototyping simple parts | Functional prototyping Moldmaking (patterns and hard molds) | Functional prototyping End use parts | Functional prototyping End use parts |

Choosing the Right Silicone 3D Printing Process or Alternative

Direct silicone 3D printing is now finally easily accessible and there are many other ways to leverage the benefits of 3D printing to produce silicone or silicone-like parts.

Request a free sample part printed in Silicone 40A Resin or Formlabs’ flexible and elastic SLA materials or speak with a 3D printing expert today to find the right solution for your application.

Not sure which 3D printing solution fits your business best? Book a 1:1 consultation to compare options, evaluate ROI, try out test prints, and more.