3D Printing for Jewelry Retailers & Casting Houses

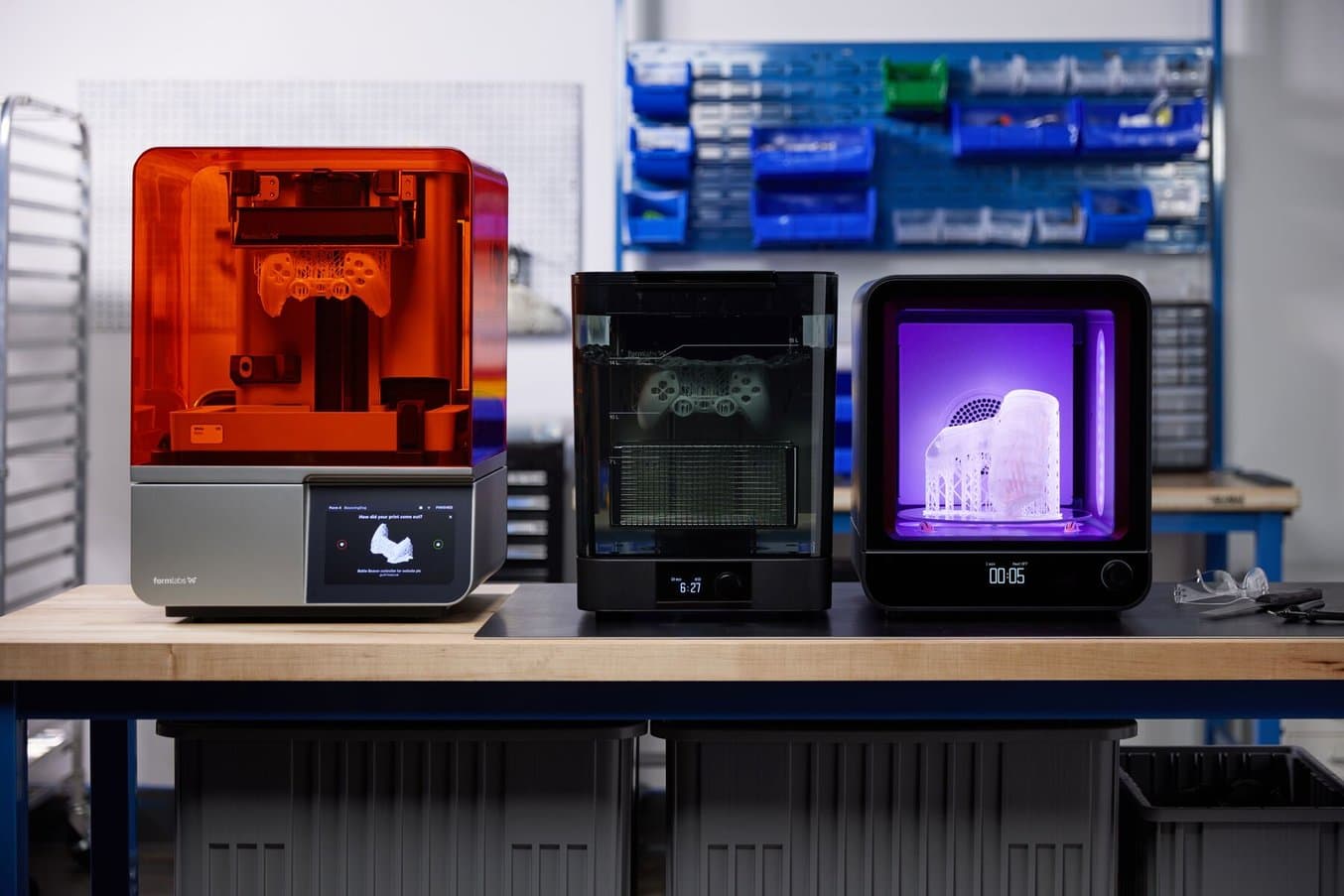

From retailers and designers producing custom jewelry to large casting houses manufacturing at scale, jewelers can scale their business with Formlabs’ reliable ecosystem of jewelry products.

A Complete 3D Printing Solution for Jewelry

Formlabs SLA 3D printers' seamless print process, high accuracy, and smooth surface finish allow you to move directly from design to production. Whether you are 3D printing try-on pieces for customers, ready to cast custom jewelry, or masters for reusable jewelry molds, Formlabs offers a material up to the task.

Compare Formlabs Castable Resins

Applications

Fine filigree

Lightweight jewelry

Dental

Compatibility

Form 2

Form 3/B/+

Form 3L/BL

Form 4/B

Form 4L/BL

Applications

Medium to heavy jewelry

Medallions

Figurines

Small engineering components up to 5 mm thick

Compatibility

Form 4/B

Applications

Medium to heavy jewelry

Small engineering components

Compatibility

Form 2

Form 3/B/+

Why Go Digital?

Lower Costs

Faster Turnaround Time

Design Freedom

Investment Casting with True Cast Resin

Create castable parts in hours, cutting down on manual labor. Formlabs SLA 3D printers' rapid print process, accuracy, and surface finish allow you to move directly from design to production.

1. Pattern Design

Design the part in CAD software. Find design guidelines and best practices in the True Cast Resin Application and Usage Guide.

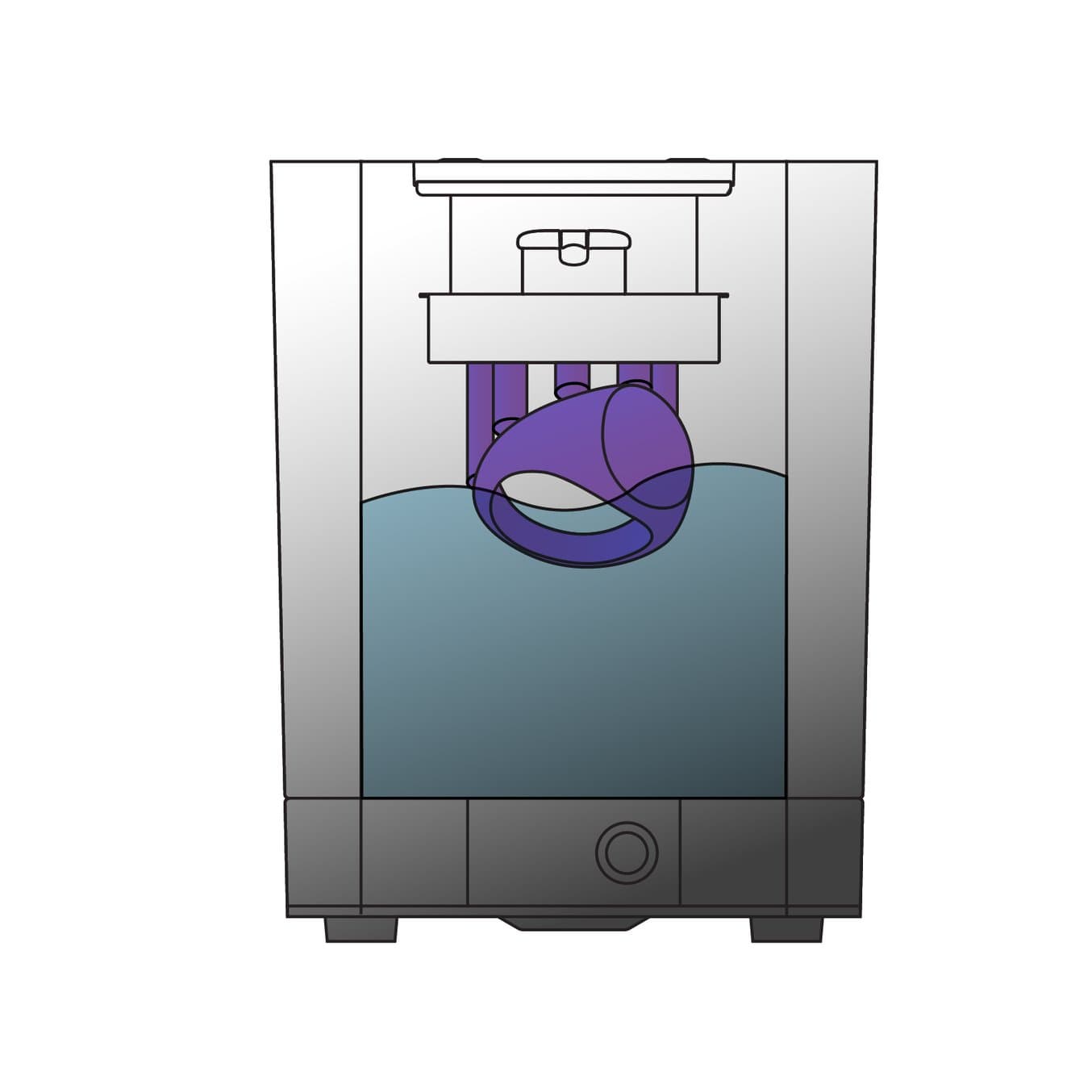

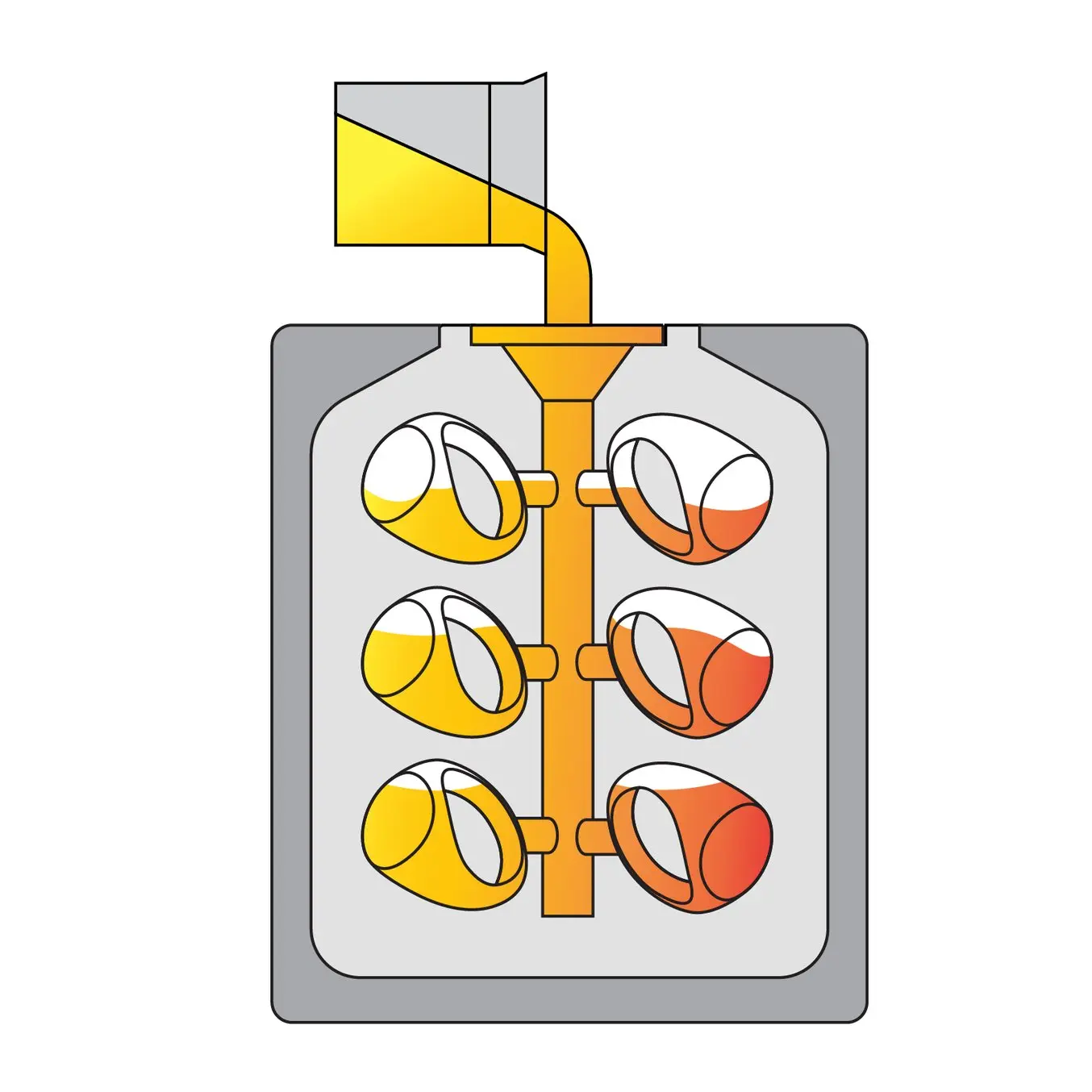

2. Pre-Heat and Mix Resin

Heat and then mix the resin prior to printing to ensure that the wax component is completely liquid and evenly dispersed.

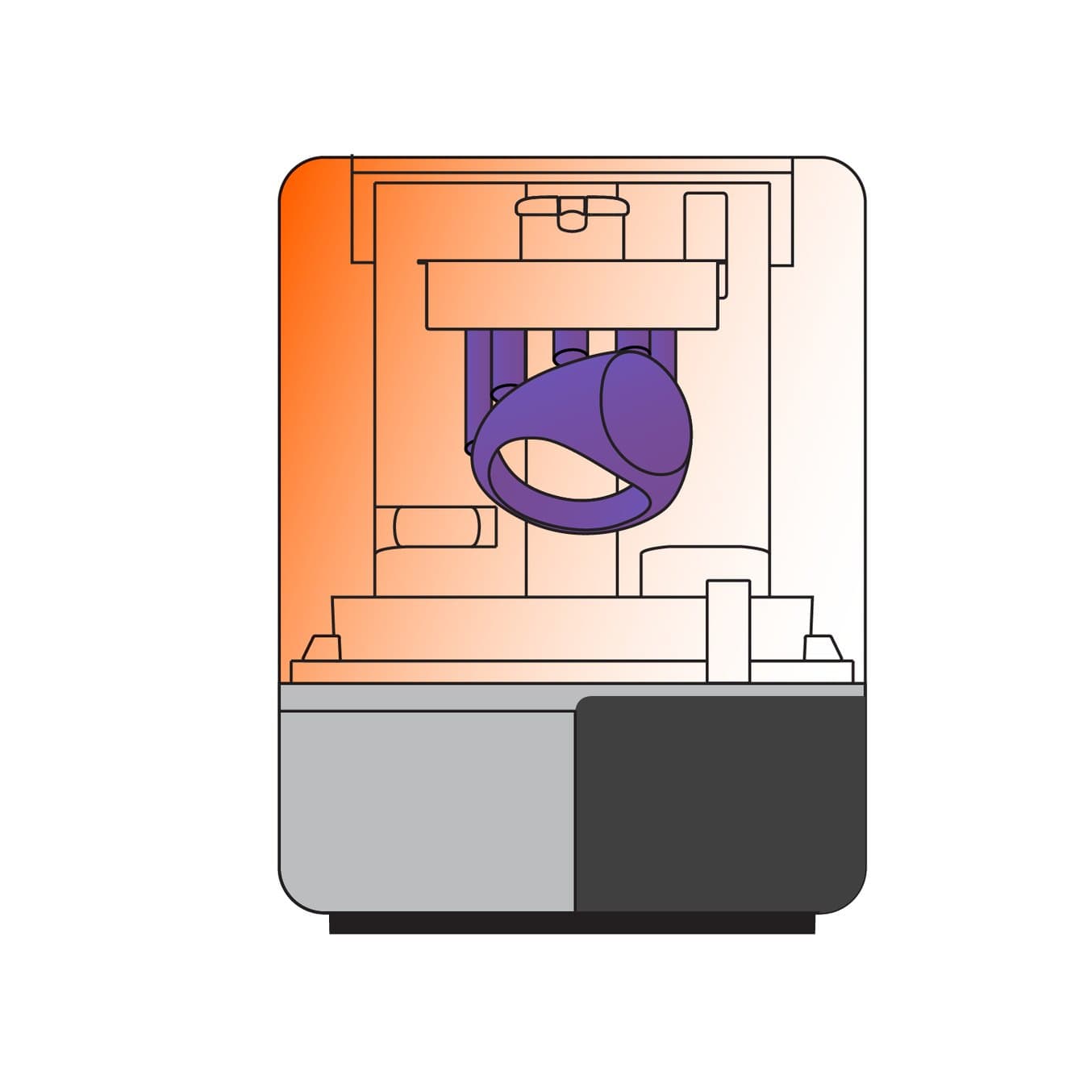

3. Pattern Printing

3D print with True Cast Resin following Formlabs’ instructions.

4. Wash Patterns

Thoroughly clean the printed patterns using a Form Wash with IPA for 5 minutes to remove any residual uncured resin. Rinse the parts for a second time in clean IPA to ensure that the patterns are completely clean. Uncured resin on parts may result in casting defects.

5. Dry With Compressed Air

Use compressed air to dry the printed parts completely. This will ensure the parts are free of any uncured resin and IPA prior to casting.

6. Post-Cure Patterns

For best casting results, post-cure the parts to complete the polymerization reaction started during printing. This will improve the strength and robustness of the patterns and reduce defects during the casting process.

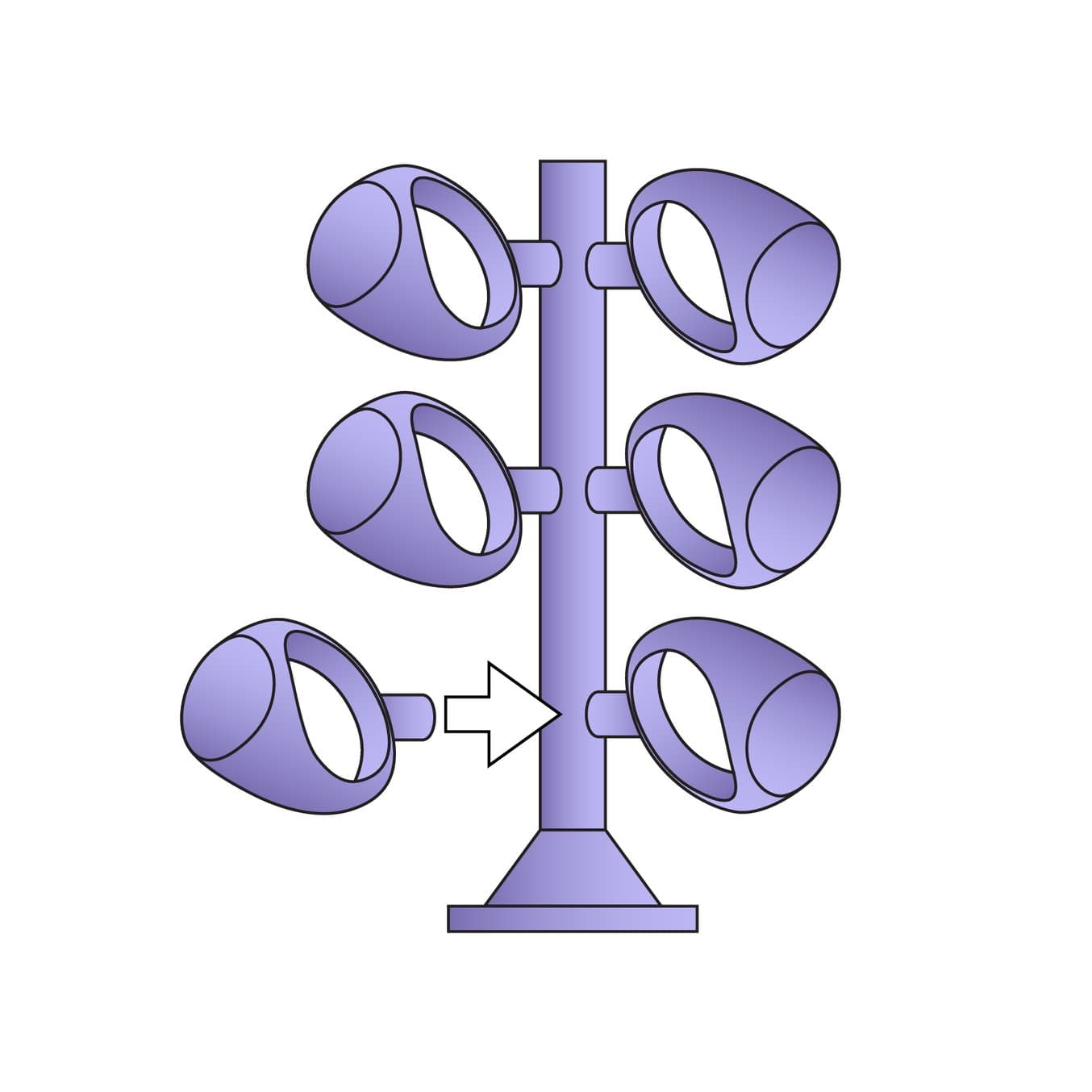

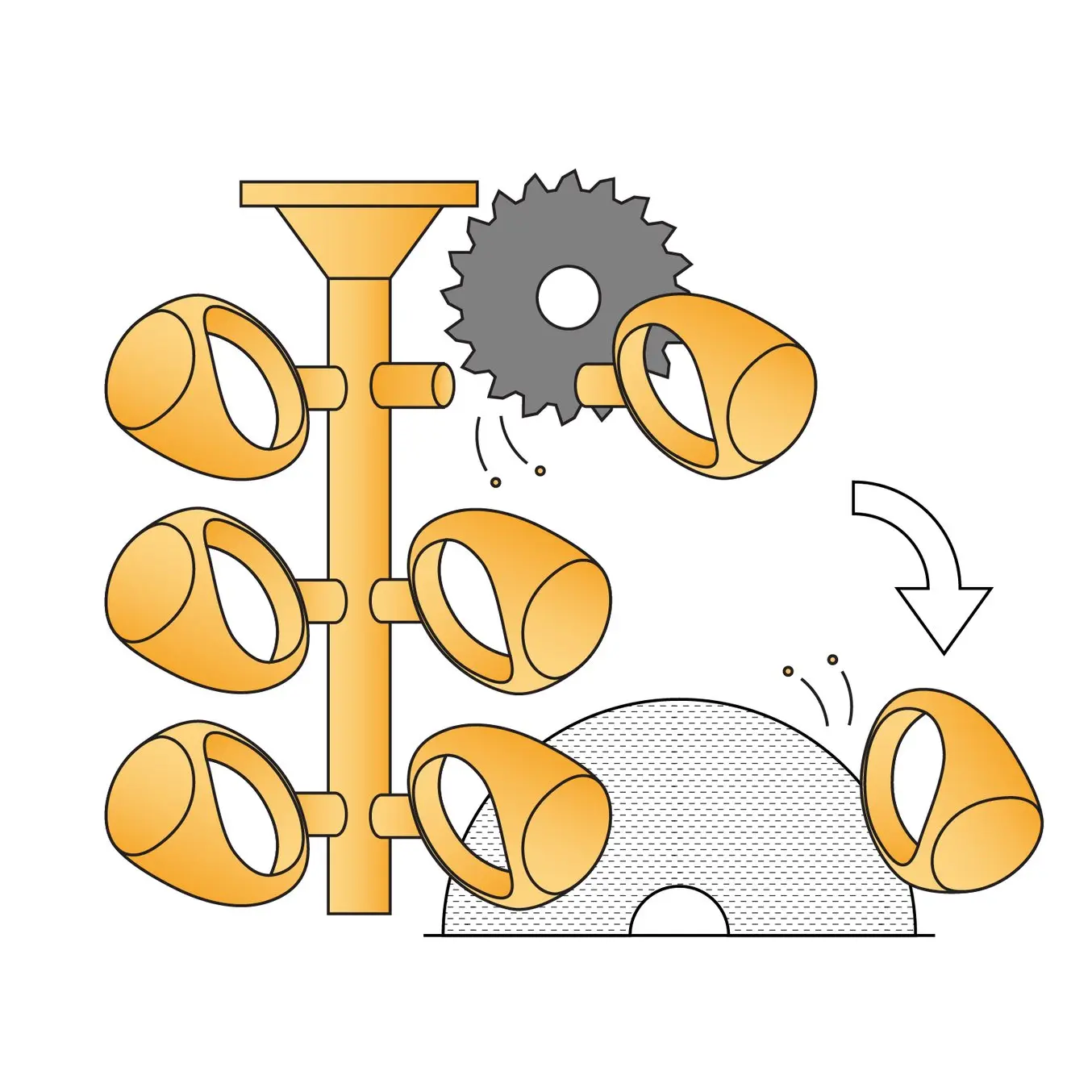

7. Build the Sprue Tree

To prepare for casting, attach the prints to a wax tree using spure wax. Attach the tree to a casting flask.

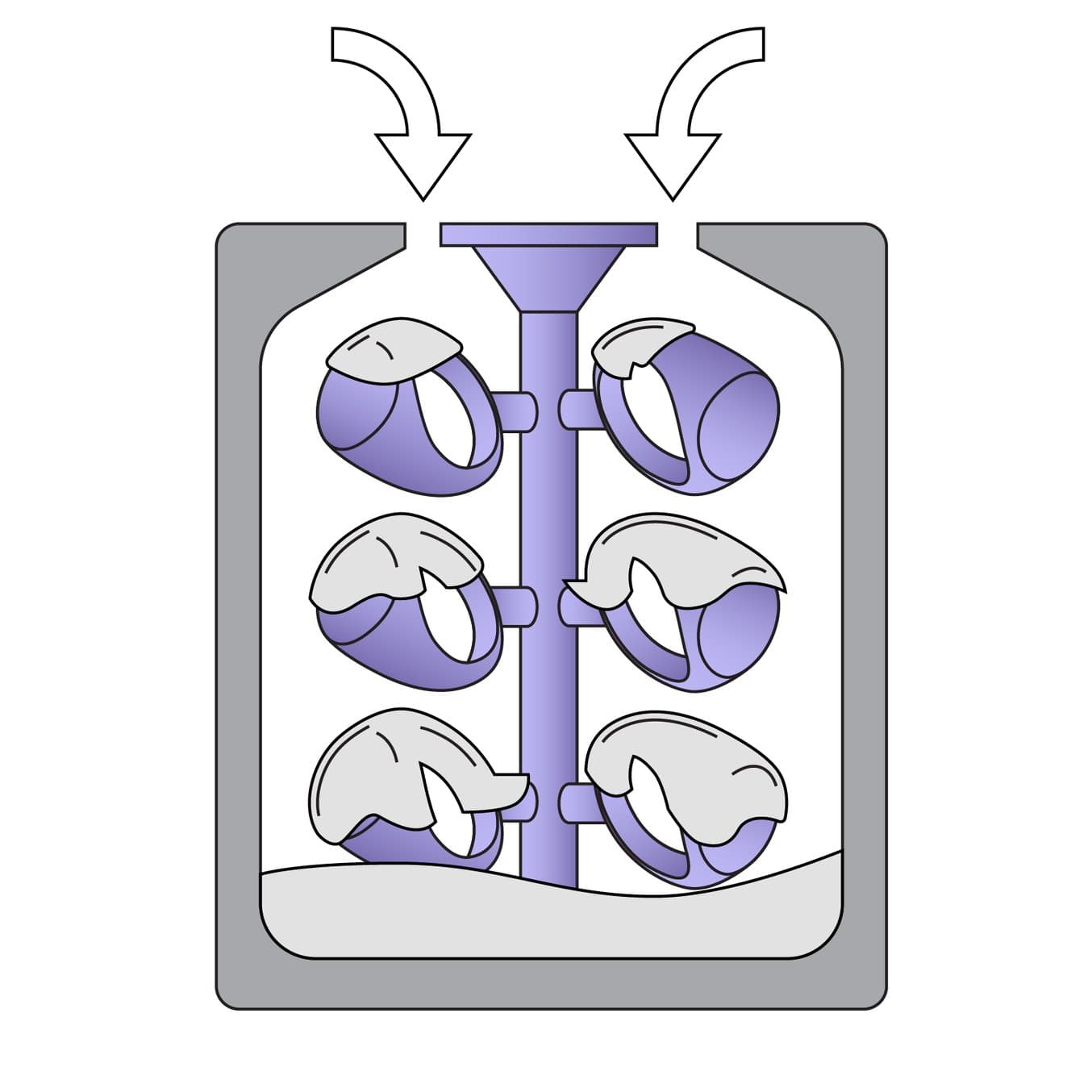

8. Prepare the Mold

Mix the investment and water following the investment manufacturer’s instructions. Slowly pour the investment into the flask.

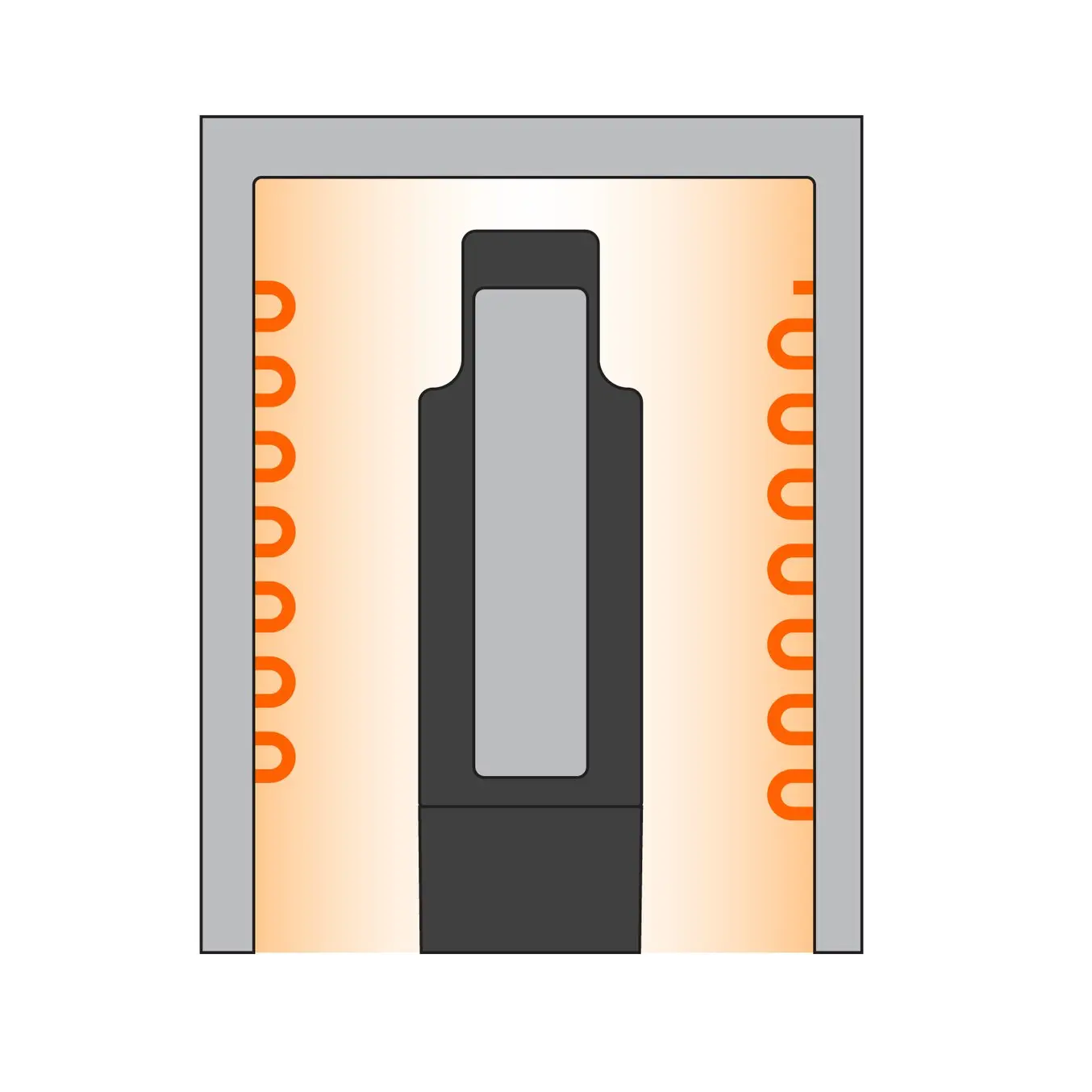

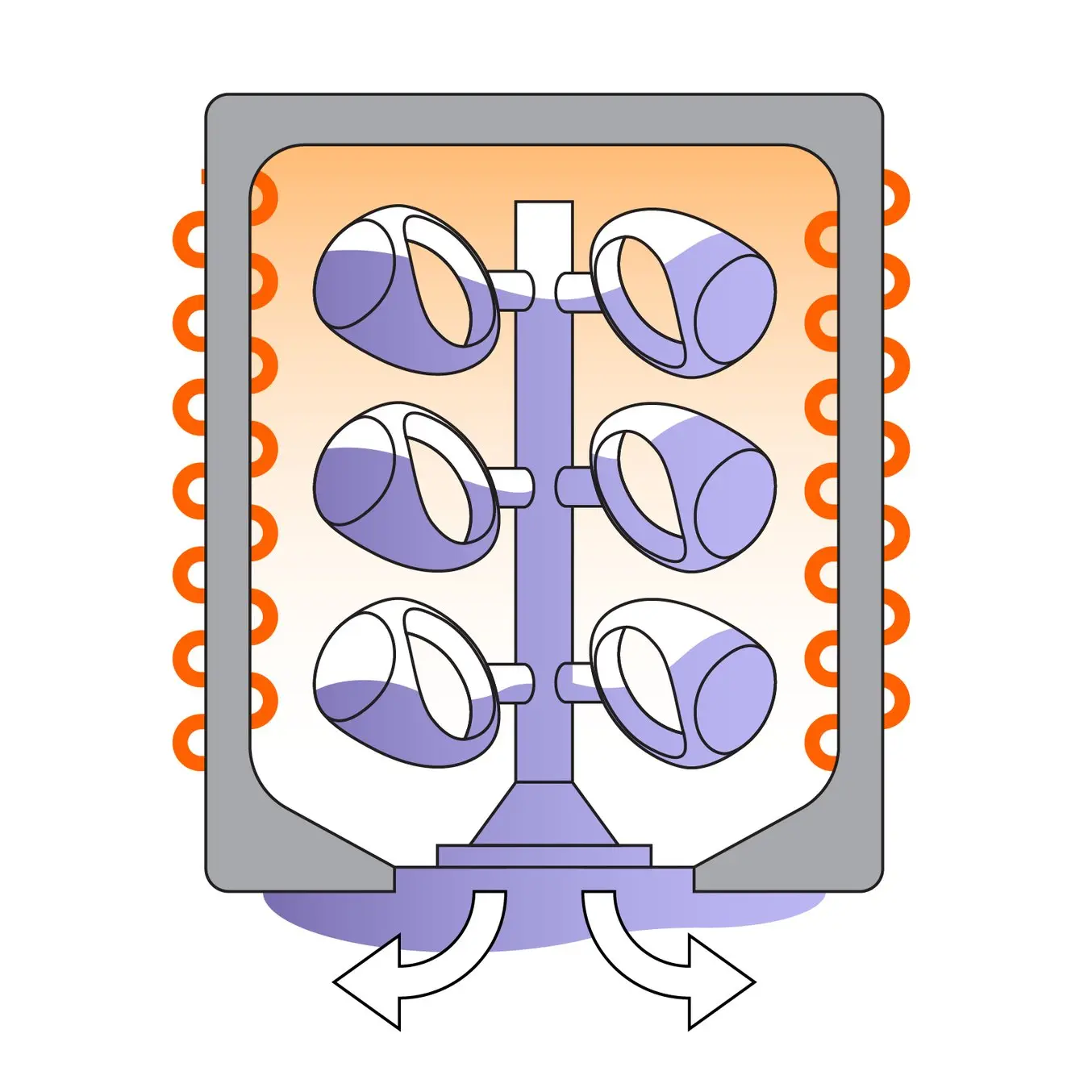

9. Burnout

Place the flasks in an oven and follow the burnout schedule recommended by your investment material.

10. Cast

Cast metal in flask.

11. Recover the Parts

Reclaim the cast parts, remove them from tree, and use sand blasting to clean off any residual investment if needed.

12. Finish

Post-process and finish parts as needed.

Fittings and Consultations

Take advantage of the Formlabs SLA 3D printers to create “fitting pieces” to provide a consultative experience which builds excitement and delights your clients. SLA 3D prints are sturdier and more cost-effective than wax originals and can be reproduced or adjusted with a few clicks.

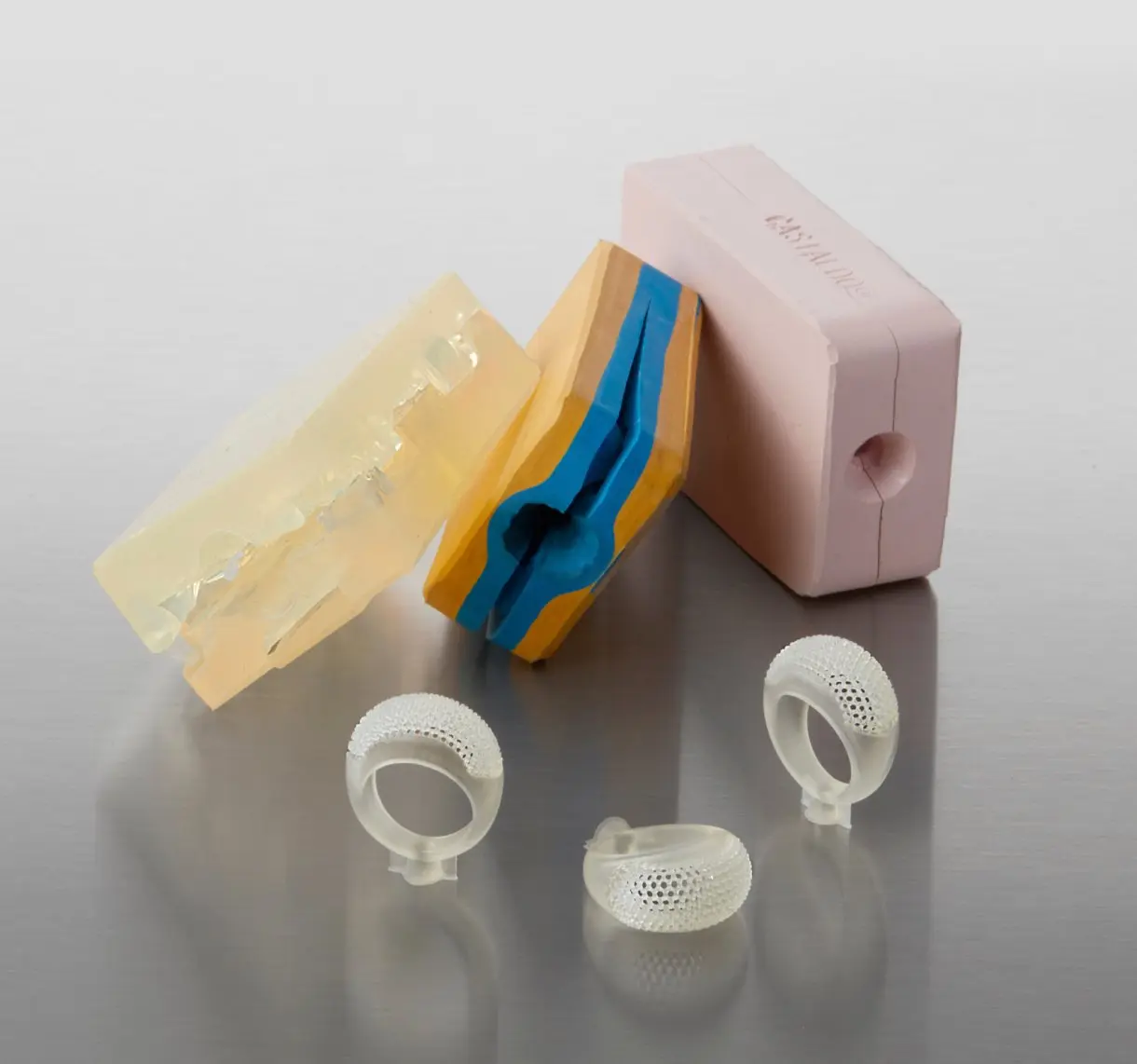

Rubber Molds For Production Casting

Make master patterns for rubber molding with 3D printing for faster iteration and lower costs. Use the masters to create molds that produce waxes in quantity for investment casting. Standard Resins are perfect for cold molding (RTV) and High Temp Resin withstands the heat of vulcanizing natural rubber.

Resources for Jewelers and Casting Houses

Learn how to integrate 3D printing into your workflow. Download

free white papers, watch webinars, and read our guides about 3D

printing workflows for jewelry.

“Casting thicker pieces in resin has always presented unique challenges, whether it was lettering on a class ring, models with thick cross-sections, or generally dealing with the casting defects. Castable Wax 40 Resin performed amazingly similar to regular injection wax, the high wax content allowed sprues to stick more securely, and the surface finish is top notch. It actually feels like wax in your hands. Casting larger items from resin has never been easier.”

Go Digital With Formlabs SLA 3D Printers

Formlabs has lowered the barrier for entering the jewelry 3D printing market by creating accessible, easy-to-use products that have put stereolithography in the hands of more businesses than ever before. Formlabs SLA 3D printers offer a diverse material portfolio and a large build volume, allowing you to efficiently produce multiple high-quality parts in a single print. With easy-to-cast materials like True Cast Resin, Formlabs is the ideal choice for any jeweler looking to go digital.