Begin Your Engineering Learning Pathway

Learn how to apply your design and product development skills to 3D printing. Review concepts such as design and tolerances for 3D printing, creating parts with threading and snap fits, and curing parts to optimize mechanical and physical properties.

Follow along step-by-step for thorough instruction, or pick and choose individual resources most relevant to your needs or learning style.

3D Printing Design Requirements

Learn guidelines for designing for 3D printing to ensure a higher level of print success.

Learn to account for:

- Overhangs and bridges

- Minimum wall thicknesses

- Minimum vertical wire diameters

- Embossed details, clearance distances, and more

Adding Threads to 3D Printed Parts

Create functional prototypes that can be fastened and unfastened by adding screw threads to 3D printed parts.

Learn to use:

- Screw-to-expand and glue-in heat-set inserts

- Nuts in 3D printed sockets

- Thread cutting plastic screws and more

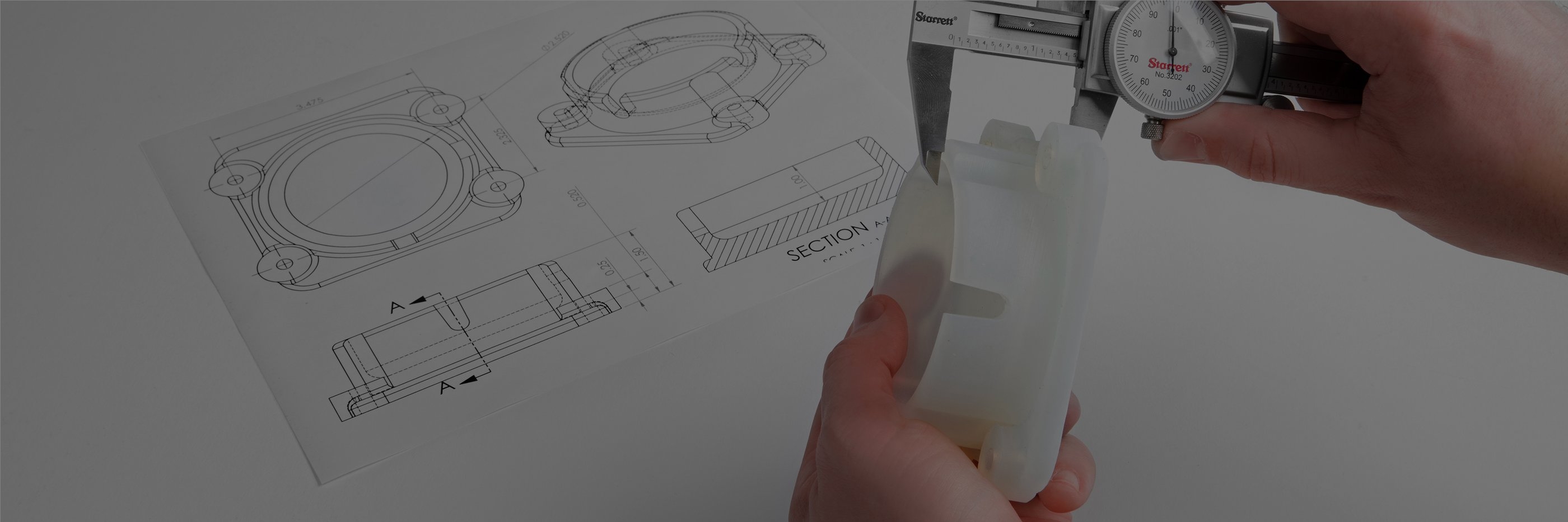

Engineering Fit and 3D Printing

Optimize the functionality of mechanical assemblies by mastering tolerance and fit with 3D printed parts.

Learn to:

- Choose the appropriate fit for different types of functional 3D printed assemblies

- Account for friction and lubrication

- Incorporate machining and boring

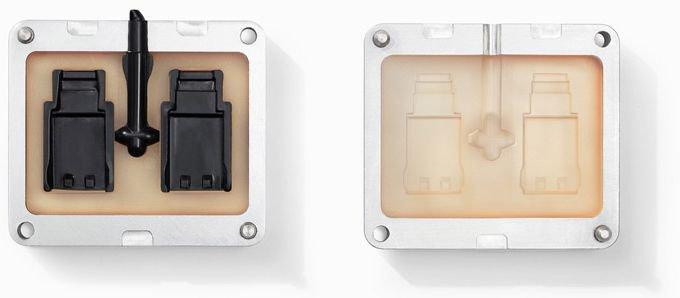

3D Printed Snap-Fit Enclosures

Design and print custom snap-fit enclosures using any parametric or solid modeling tool in five easy steps.

Learn to:

- Design snap features for use with Formlabs Tough Resin

- Understand 3D printing tolerances

Learn to Choose the Right Materials

Gain a deeper understanding of the properties and functions of each Formlabs resin and learn which are best for your applications.

Learn to:

- Identify the resins you will use most frequently

- Understand the material properties of individual resins

- Understand the printing and post-processing requirements of each resin you use

Material Guide: Tough Resin

Learn to print parts in Tough Resin for prototyping strong, functional parts and assemblies that will undergo brief periods of stress or strain.

Learn to:

- Choose suitable applications for Tough Resin

- Print successfully with Tough Resin

- Post-process and post-cure Tough Resin

Material Guide: Rigid Resin

Learn to use glass-reinforced Rigid Resin to produce parts requiring high stiffness, resistance to deformation, and a polished finish.

Learn to:

- Choose suitable applications for Rigid Resin

- Print successfully with Rigid Resin

- Post-process and post-cure Rigid Resin

Learn to use glass-reinforced Rigid Resin to produce parts requiring high stiffness, resistance to deformation, and a polished finish.

Learn to:

- Choose suitable applications for Rigid Resin

- Print successfully with Rigid Resin

- Post-process and post-cure Rigid Resin

Material Guide: Durable Resin

Learn to use Durable Resin to print parts with a smooth, glossy finish and high resistance to deformation.

Learn to:

- Choose suitable applications for Durable Resin

- Print successfully with Durable Resin

- Post-process and post-cure Durable Resin

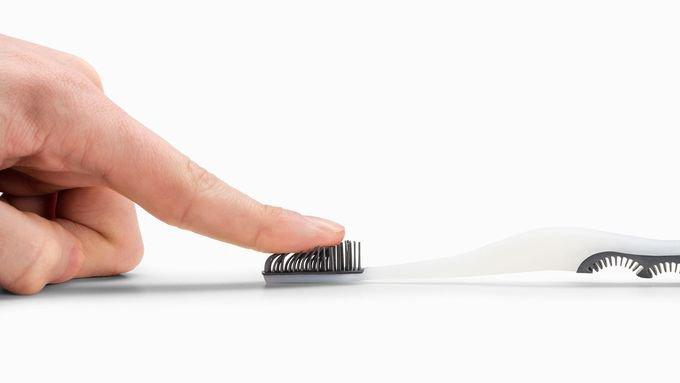

Material Guide: Flexible Resin

Learn to use Flexible Resin to print parts that bend and compress, simulate soft-touch materials, and more.

Learn to:

- Choose suitable applications for Flexible Resin

- Print successfully with Flexible Resin

- Post-process and post-cure Flexible Resin

Material Guide: High Temp Resin

Learn to use High Temp Resin to print models for environmental testing, or create molds and masters for production processes like casting and thermoforming.

Learn to:

- Choose suitable applications for High Temp Resin

- Print successfully with High Temp Resin

- Post-process and post-cure High Temp Resin

Material Guide: Grey Pro Resin

Learn to use Grey Pro Resin to print high precision concept models and functional prototypes, or for parts that will be handled repeatedly.

Learn to:

- Choose suitable applications for Grey Pro Resin

- Print successfully with Grey Pro Resin

- Post-process and post-cure Grey Pro Resin

Prototyping in Engineering Resins

Read an overview of the six essential mechanical properties to consider when choosing a Formlabs Engineering Resin for prototyping.

Learn to:

- Compare mechanical properties of Formlabs resins

- Make informed choices when choosing prototyping resins

Multi-Material Prototypes

Confidently design and print looks-like, works-like prototypes using multiple resin types.

Learn how:

- Multiple Formlabs Engineering Resins can be incorporate into a single design

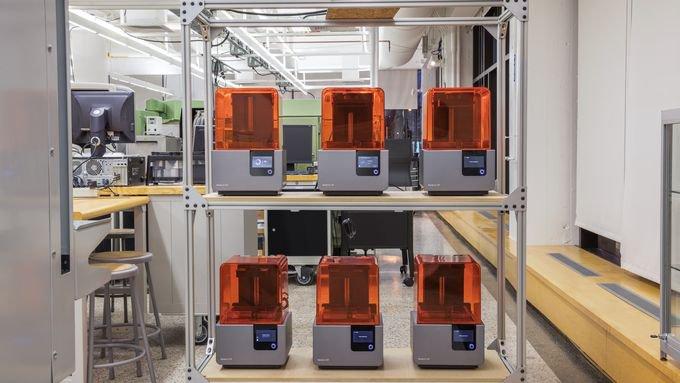

Manage Multiple 3D Printers

Learn the unique demands of managing multiple 3D printers to increase productivity while growing your 3D printing capacity.

Learn to:

- Configure a multi-printer lab or workspace

- Acquire and manage consumables and essential supplies

- Understand the 3D printing process at scale