Eight years ago Tariq Riaz was working on an engineering consultancy in Abu Dhabi, UAE. His wife, pregnant with their first child, found that her wedding ring had started to become constrictive as her fingers swelled during her pregnancy. She implored Tariq to figure out a solution, some design hack that would allow her ring to expand as necessary as her body changed. The idea of an expandable, beautiful, high quality ring stayed in the back of Riaz’s mind. He started taking the ring to work every day, sketching ideas in his free time, and doing research on introductory courses in jewelry manufacturing.

Fast forward seven years: Riaz has won 16 international awards for his jewelry designs, and has established himself as one of the jewelry industry’s top creators. His innovative designs sit at the convergence of art and mechanics, with multi-piece assemblies that use mechanical engineering principles to create one-of-a-kind pieces of luxury art.

Riaz credits Formlabs stereolithography printers for his success, saying, “I’m a very technical person. After a lot of research, I went with the Form 2. That completely changed everything. The Form 2, and now Form 3, are integral to what I do; my success would not have been possible without them.”

An Engineer’s Approach to Art

Raiz’s formal schooling at the University of Arizona was in computer engineering. After graduating he worked for years as an engineer for technology companies. Though his education and career helped him hone his CAD programming skills, it didn’t prepare him with the necessary tools for jewelry design and creation. One thing his education did provide however, was the ability to methodically research, extensively iterate, and build up a knowledge base through thousands of hours of practice.

These skills became important as the idea of this expandable ring became Riaz’s main focus, and he remembers, “I stared at it, thinking, if I had to take a stab at this, how would I do it?”

Making the Ring

Through online research, he started seeing various Kickstarter campaigns and small jewelry businesses that were using 3D printing for jewelry prototyping and production. Since his engineering background made him comfortable with 3D printing, he bought an inexpensive fused deposition modeling (FDM) 3D printer, and started printing out rough prototypes of his expandable ring to get a tangible proof of concept.

With that initial prototype in hand, Riaz traveled to manufacturers in Bangkok, Bali, and Japan, totally focused on the side project that had become his passion. Though at first these established jewelry manufacturers didn’t see his case as worth it, he eventually found a casting house that would take his CAD designs and rough prototype of his ring.

“That was the first time I saw what an integral part a 3D printer can play, especially when you’re starting from scratch.”

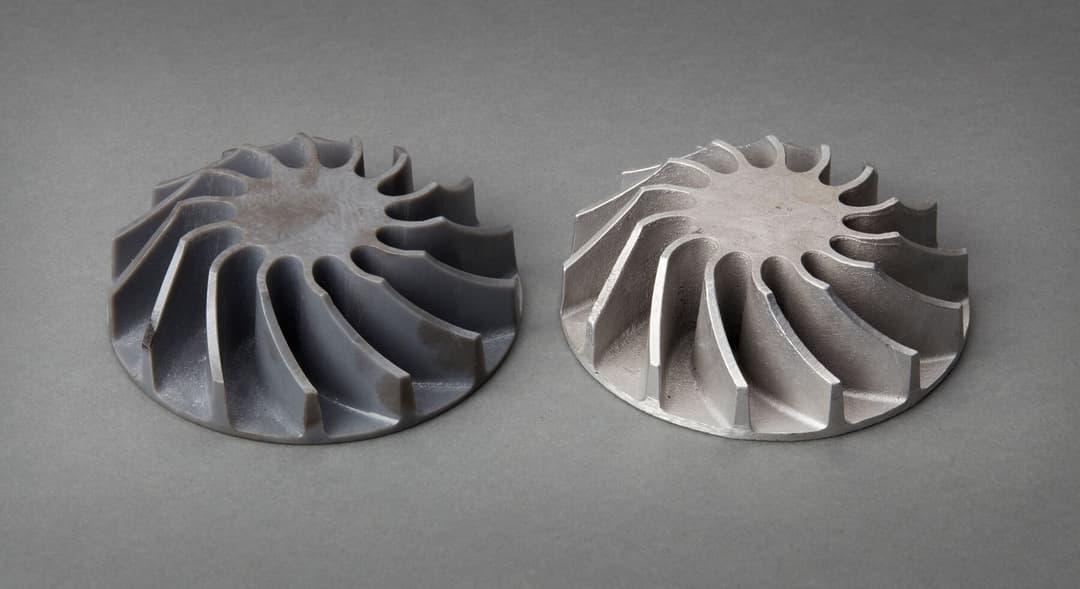

3D printed rings in Castable Wax 40 Resin, Castable Wax V2 Resin, Draft Resin, and Clear Resin.

A New Career: Determination and Challenges

After this first success, creating a ring that would grow and evolve along with he and his wife’s partnership, Riaz faced a dilemma. “I realized I had a problem—I couldn’t go back to what I was doing before. Jewelry creation is what I was born to do. My wife said, ‘I’ve never seen you this passionate and goal focused,’ and I thought, what’s the worst that can happen if I try.”

That drive and passion would be necessary as Riaz faced challenges entering the industry. One factor was his lack of industry knowledge; he needed to learn gemology, casting techniques, stone pricing, metallurgy, and so much more to compete with other jewelers, who often grow up learning the trade from parents and grandparents.

To close the knowledge gap, Riaz started soaking up all the knowledge he could, taking classes at the Gemological Institute of America’s satellite institutes across the world on subjects like gem identification, how to create micro pave and prong settings, designing for optimal reflection and refraction of light off a gem’s surface, metallurgy, and casting processes. He approached them all with an engineer’s mindset, knowing that through research and dedicated practice he could master this new art form.

Getting The Right Equipment

During the first three years working on jewelry full time, Riaz was taking classes, sketching, and scouring the internet for the best equipment. He uses dental equipment, like drills for filing, citing their heightened accuracy and detail ability. One piece of equipment that he spent the most time searching for was a 3D printer.

"I was going for the best of the best. I wanted a printer with ten micron ability, but the only thing people would refer to me was way out of my price range. So when I stumbled upon the Formlabs, there was nothing else at the price of point, consistency, and ease of use for a new business."

Riaz needed a 3D printer that could print intricate assemblies with tight tolerances. His first collection was a set of 25 pieces that could expand and change shape to fit the wearer even through pregnancy, weather changes, arthritis or any of life’s changes. This unique approach to jewelry became the basis for his trademark, the AbrazoFit™ technology, that ensures each piece acts as an embrace, an abrazo, for the wearer.

“Just like the proper position for partners in the tango, the abrazo, one does not look as elegant without the other. Just like partners that need that abrazo, my pieces are made to be worn on the body and interact with the wearer’s movement.”

Prototyping with Form 2 and Form 3

To create those AbrazoFit™ pieces requires extensive prototyping, and a machine that can handle small dimensions, as well as have high throughput capability for the sometimes hundreds of iterations Riaz goes through. One ring took him through over 250 prototypes; its complexity due to the fact that it has several internal gears that lock into each other via hundred of sub millimeter teeth.

“I don’t print a ring in one piece like most people. Some rings have 70 individual parts assembled together to make one ring. That way I can make so many different versions with the same base, changing the other pieces up like legos. The components are multi-purpose, multi-functionality.”

To achieve this level of complicated design, Riaz spends almost all of his time in research and development, painstakingly working through the sketching and prototyping phases until he’s 110% satisfied with it. When he was first starting out, he was prototyping constantly on his Form 2 printer, printing in Grey Resin and Clear Resin and polishing the pieces. Only when he was satisfied with the quality did he look into getting wax injectors or casting machines.

“Because of my tech background I relied completely on technology. It all started with 3D printing. From day one to today, I am all set up in-house, nothing gets outsourced. From the first line in a sketch to the final ring, everything is in-house, and done by myself.”

The Convergence of Art and Mechanics

Because Riaz didn’t know how things had always been done, he could engineer something that hadn’t been attempted before. For instance, the spring mechanism used in his first expandable ring band is the same piece of machinery used in pacemaker devices for cardiac health.

“I decided to dive headfirst. I wanted to learn old techniques, and merge them with something new. I had a really weird, gut feeling about this. People laughed at me, they said, ‘you don’t know the industry, you’re going about it the wrong way.'”

Riaz was able to take his scientific background and apply it to an art form that has been practiced for centuries. In this synergy of craft and mechanics, he created something entirely different, and the jewelry world started to take notice.

“Technology, in a very balanced way, can be used in perfect harmony for creating something organic. This is just as handmade as a handmade can ever be, with more repeatability, consistency, reliability and control over dimensions. Especially when we’re talking about micro level.”

Attention to Detail

To take full advantage of the technology, Riaz learned how to dial in the parameters on his printers to achieve maximum consistency and repeatability on his prints. For months he would tweak certain features, learning how to control every part of the process, from the temperature of the room to tremors in the floor.

“If it’s an extremely intricate part, I can make sure it’s on the ten micron level I’m going for. People don’t know how far you can go if you pay attention to tiny details. I’ve perfected it, from how long the part is in the Form Cure, how long in the Form Wash for the first dip and the second one, to leaving it in a vacuum overnight. People think the machine is just buttons and supports, but there are so many more parameters to get the type of precision you need.”

Riaz's designs are engineered for maximum impact when interacting with the wearer's movement and natural light.

That attention to detail has yielded spectacular results. Though Riaz entered the industry without any goals for external validation, his pieces have garnered global recognition for their unique designs and high level of intricacy.

How 3D Printing Reduces Costs

Using 3D printing to prototype has saved Riaz enormous amounts of time. And for a new business owner, time is money, especially in the jewelry industry, where a single gem can cost five times more than the 3D printer itself. The barriers to entry are extremely high, in both cost and technical know-how.

“3D printing is the bread and the butter of the business. It helped me with research and development, being able to see a finished product without having to cast it in 18 carat gold. It saved me those costs in the early days, when my budget was tight.”

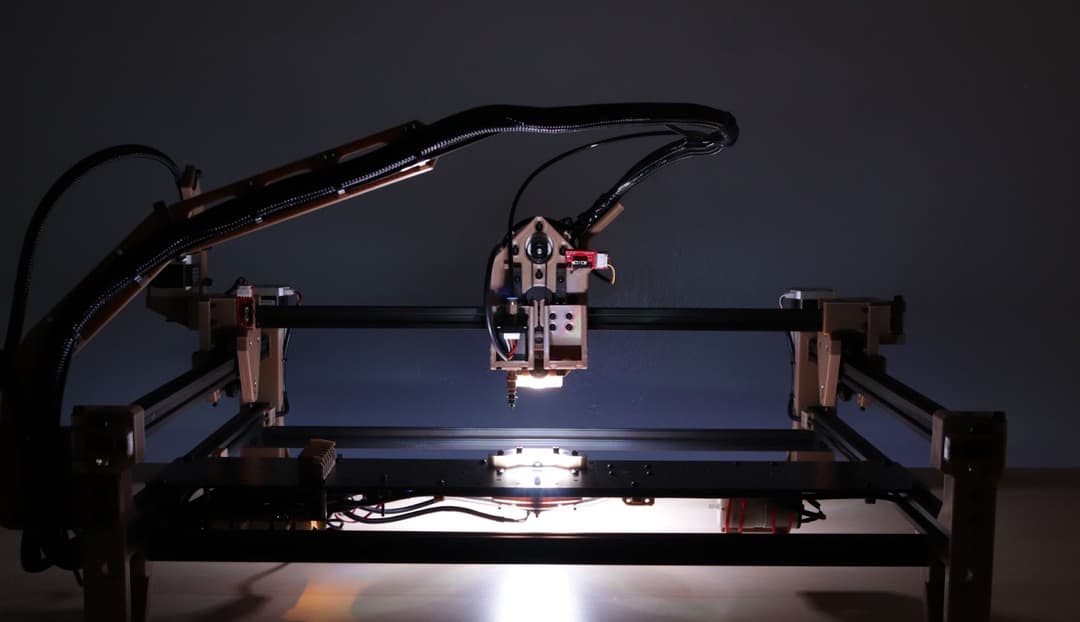

Riaz's workshop features his Form 3 printers and varied resins for prototyping and mold creature.

The Form 3 enables people like me, who are not deep pocketed, to get started. I’ve been able to experiment with new resins, use a new tray, then move on to the next phase.

Producing at High Speeds

When Riaz was working on the first ring, his wife’s wedding band, he was frustrated with the pace of production for the traditional jewelers he was visiting. He would visit a designer, have them start filing a wax model, and take hours to produce a rough prototype. Then days would pass before a full part would be ready to cast. Now with his Form 3, Riaz is able to iterate quickly, which is integral to his iterative-intensive process. He told us that, "It’s day and night. Now I print multiple rings in three hours, by the time I’m done assembling and processing them, the next four are done. It changes the game. I’ll print from home and when I get to the studio, they’re waiting for me."

Global Recognition

Riaz has won 16 awards for his designs, including the American Top Jewelers Award for pieces under $5000, the top price in 2021 in the International Pearl Design Competition, the 2021 Cindy Edelstein Memorial Emerging Designer of the Year, the 2021 JCK Best Statement Piece, and two American Gem Traders Association Spectrum awards. He was featured on the top luxury jewelry podcast, Couture, and will be highlighted in the 2022 JCK magazine.

In an industry where most jewelers learn their craft over decades by studying traditional techniques, often at the hands of parents, grandparents or mentors, Riaz has blazed an unconventional path. His engineering and research mindset creates a fundamentally different process than most artistry-minded designers. He turned that mindset into an advantage, creating designs only achievable through an exhaustive, methodical approach to testing, iteration, and assembly.

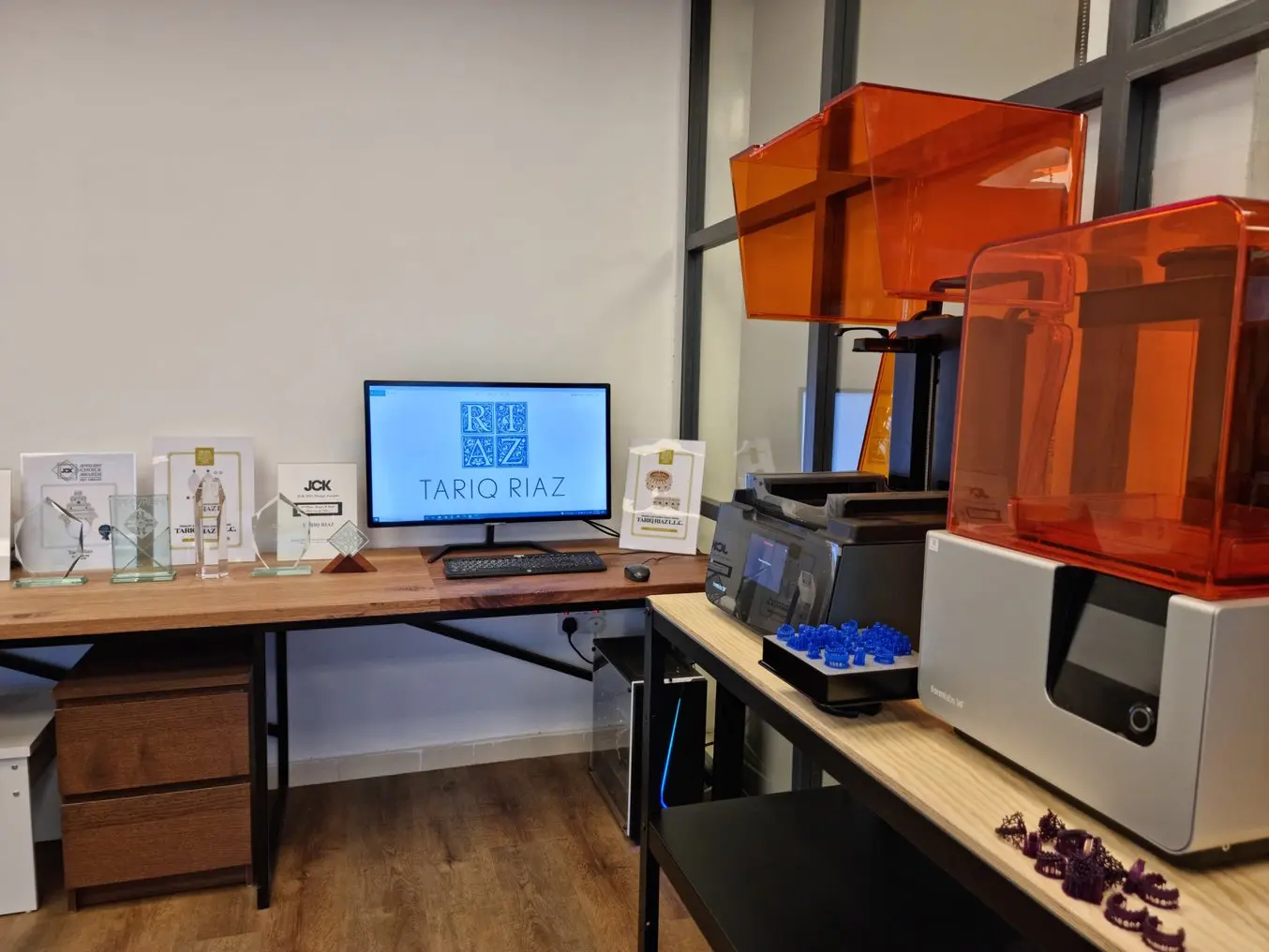

Riaz has won 16 international jewelry design awards for his innovative, interlocking mechanical designs.

Combining technical expertise with a passion for creativity has led to global success, and Riaz will continue to rely on his Form 3 printers as his production scales, telling us that, “For prototyping I don’t think there’s a better tool than this. It saves so much time, for when I go to direct casting and production I might get three more printers.”

Introduction to Casting for 3D Printed Jewelry Patterns

In this white paper, learn how to cast fine jewelry pieces from 3D printed patterns and how direct investment casting, or lost wax casting, works as a moldmaking technique.