Strength and toughness are often confused. Glass (soda lime) is a strong material; it has almost the same bending strength as aluminum when tempered, while also being lighter and just as stiff. Despite this, we do not make airplanes out of glass, and instead we have idioms like “glass castle” and “glass cannon” that both connote fragility. The reason is toughness: glass, like most ceramic materials, is not tough. Glass is ~40 times less tough than aluminum, and that lack of toughness makes it impractical in many engineering applications, because it cannot redistribute internal stresses and withstand impacts and dynamic loads.

In 3D printing, a similar phenomenon occurs with two of the most popular filaments. You may hear someone say “ABS is stronger than PLA,” but this is not true. PLA is significantly stronger and stiffer than ABS (about one and a half times depending on the exact filament). ABS is tougher, and it’s this toughness that makes it a desirable engineering material.

But what is the strongest 3D printing material? What’s the toughest material? When it comes to 3D printing, determining how strong or tough 3D printed parts are is highly dependent on the printing technology and material chosen, as each offers a different balance of tensile strength and impact resistance.

This guide compares the mechanical properties of the most popular materials, including PLA, ABS, nylon, carbon fiber composites, stereolithography (SLA) engineering resins, and selective laser sintering (SLS) powders, as well as the most common 3D printing technologies (fused deposition modeling (FDM), SLA, and SLS), and other factors that influence material strength.

Understanding Material Properties: Defining Strength in 3D Printing

Strength matters when you print functional parts including tools, jigs, fixtures, or anything that needs to withstand real loads. Strength, however, can mean different things to different people. When a part is described as “strong” it could mean in terms of holding a large load, resisting impacts and fractures, or resisting heat or environmental conditions.

In materials science, “strength” has a more narrow definition: it is the maximum amount of stress a part can withstand without breaking. “Stress” is the force applied divided by the cross-sectional area of the part to account for differences in geometry. Another important property related to the stress response of a material is stiffness. Stiffness is the amount of elongation or deflection caused by a given unit of stress. Strength and stiffness can be measured by pulling (tensile strength) or by bending (flexural strength). Strength and stiffness would be the most relevant properties for a load case where a part that needs to hold a heavy static load, like a bracket. Not all loads are static, and there are other properties that characterize material performance under more dynamic load cases, like impacts.

When we talk about “toughness” for materials, we are describing the ability of a material to absorb energy and plastically deform without fracturing. There are a variety of ways to measure toughness. One way is to measure the energy absorbed from a hammer swung from a pendulum, or a falling weight, which is called “impact strength.” These measurements have units of energy (often J, J/m, or J/m2) unlike strength which is measured in force per area (usually in Pascals or PSI). Izod, Charpy, and Gardner are three popular styles of impact testing. Toughness can also be characterized in other ways like measuring the energy required to propagate a crack. Toughness is important when you want a part that needs to withstand extreme dynamic loads, like protective housing.

Before comparing 3D printing materials, it is important to establish what the mechanical properties used to measure strength mean. In 3D printing, "strength" is often a shorthand for a combination of the following mechanical properties: tensile strength, impact strength, flexural strength, heat deflection temperature (HDT), and stiffness.

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

Tensile Strength (Ultimate Tensile Strength)

Tensile strength measures the resistance of a material to failing under tension. It is the maximum stress a material can withstand while being stretched or pulled before failing. Imagine pulling a rope from both ends until it permanently deforms or snaps. The maximum force withstood divided by the cross sectional area is the ultimate tensile strength.

-

Why it matters: High tensile strength is critical for parts that hang, carry static loads, or are pulled apart, such as lifting hooks or brackets.

-

Measurement: Stress (Force per Area), usually in Megapascals (MPa)

Flexural Strength

Flexural strength is the material's resistance to failure under a bending load. This is usually tested with a three point bending test where a sample is supported by two posts and loaded in the middle. In bending, one surface is experiencing tensile forces as it tries to stretch apart, and the opposite surface is experiencing compressive forces as it is pushed together. Plastics typically have very good properties in compression and the flexural strength is usually higher than when loaded in pure tension.

-

Why it matters: High flexural strength is critical for parts that must withstand bending forces like, beams, levers, cantilevered brackets, and frames.

-

Measurement: Stress (Force per Area), usually in Megapascals (MPa)

Elastic Modulus

Elastic modulus can be measured in tension or flex.

-

Why it matters: A stiff part (high modulus) will hold its shape under load, while a flexible part (low modulus) will deflect or stretch. For a drill locating jig, you would want a high modulus to ensure the hole location doesn’t shift under load. For a snap-fit enclosure, you want balance, with enough flex to snap, but enough stiffness to hold.

-

Measurement: Stress per unit of elongation – Usually GPa or MPa since elongation is treated as a ratio of initial length. Even though it shares units with strength, it is measuring stress per percentage of elongation – a material that has a modulus of 1000 MPa takes 10 MPa of stress to elongate 1% of its original length.

Impact Strength (Izod, Charpy, or Gardner Impact Resistance)

Impact strength measures a material's ability to absorb shock and sudden energy without breaking. A material with high tensile strength but low impact strength (like glass or standard PLA) is considered "brittle." If you need a part that can withstand drops or hits, look for high impact resistance. For Izod and Charpy impact resistance the samples may be either “unnotched” or “notched” where a small v-shaped notch is cut into the part. This notch acts as a starting point for crack propagation and makes the test much more challenging.

-

Why it matters: Crucial for protective casings, drone parts, jigs, fixtures, tools, or items that might be dropped.

-

Measurement: Energy absorbed divided by the thickness or area of the test specimen (J/m) or kJ/m². For Gardner Impact Resistance, only energy is reported.

Heat Deflection Temperature (HDT)

HDT is the temperature at which a polymer deforms under a specified load. HDT is the preferred way to compare the temperature at which load capacity diminishes. The glass transition temperature (Tg) is sometimes used as a proxy for HDT, and while this works well for amorphous thermoplastics like ABS, Tg and HDT can be very different from HDT for semicrystalline materials (Nylon, PP) and Thermosets like SLA Resins.

-

Why it matters: "Strong" parts are useless if they warp in a hot car or inside an enclosure with electronics. This matters for parts in mechanical assemblies, machines, or parts used in hot environments.

-

Measurement: Failure temperature in degrees Celsius (°C) at 0.45 MPa or 1.8 MPa of load.

FDM vs. SLA vs. SLS: Which 3D Printing Technology Is Stronger?

Print strength doesn’t depend only on the material. Whether it’s FDM, SLA, or SLS, the printing technology dictates the structural integrity of the final part. The fundamental differences lie in print quality, costs, and material variety.

FDM

FDM can produce strong parts, but they are anisotropic, and generally significantly weaker along the Z-axis.

FDM printers build parts by extruding melted plastic layer by layer. While the bond within a single layer (X and Y axes) is strong, the bond between layers (Z-axis) is significantly weaker, often by 30% to 50%.

| Pros | Cons |

|---|---|

| Material choices Post-processing not mandatory Good for tough, functional prototypes Affordable entry-level pricing | Layer lines weaken vertical strength (anisotropy) Low accuracy and detail Warping is possible, especially with ABS or Nylon Supports significantly hurt surface finish and are difficult to remove |

SLA

SLA printers use a laser to cure liquid resin. This chemical process creates covalent bonds between each layer as it is formed. As a result, SLA parts are isotropic: they exhibit uniform strength in the X, Y, and Z axes.

Engineers have more design freedom with SLA than FDM. You can orient a part for optimal surface finish or print speed without worrying that a load applied from the "wrong" angle will cause delamination failure. With advanced engineering resins, SLA can outperform several FDM filaments in tensile strength and stiffness.

| Pros | Cons |

|---|---|

| Very strong in all directions (isotropic) Smooth surface finish Excellent for tough, functional prototypes and engineering applications High detail for precise and accurate prototyping of fit and finish Supports are smaller and easier to remove than FDM | Requires post-processing for maximum strength Most parts require supports Some resins can be brittle |

Product Demo: Form 4

See how Form 4 can enable new levels of productivity and innovation through its unmatched speed, accuracy, and reliability.

SLS

SLS printers use a high-power laser to sinter a thermoplastic powder. Like SLA, the sintering process creates nearly isotropic parts. The greatest advantage of SLS 3D printers is that they don’t require support structures for printing.

SLS 3D printing offers some of the strongest 3D printing materials, including a range of nylon powders.

| Pros | Cons |

|---|---|

| Very strong in all directions (nearly isotropic) No supports required Excellent for load-bearing parts Durable, long lasting materials like Nylon and TPU. | Surface finish is rougher than SLA, but much better than FDM Parts need to be unpacked from the powder cake and media-blasted clean as a part of post-processing Higher startup costs, but the cost per part can be significantly optimized with volume Lower variety of materials, swapping materials is an involved process |

Fuse Series: Technology and Workflow Overview

Fuse Series SLS 3D printers are not just printers, they are an entire ecosystem for turning CAD files into fully-functional end-use parts with industrial thermoplastics.

FDM vs. SLA vs. SLS: Technology Strength Comparison

| FDM | SLA | SLS | |

|---|---|---|---|

| Pros | Low-cost consumer machines and materials available | Great value High accuracy Smooth surface finish Range of functional materials | Strong functional parts Design freedom No need for support structures |

| Cons | Low accuracy Low details Limited design compatibility High cost industrial machines if accuracy and high performance materials are needed | Sensitive to long exposure to UV light | More expensive hardware Limited material options |

| Applications | Low-cost rapid prototyping Basic proof-of-concept models Select end-use parts with high-end industrial machines and materials | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Models and props | Functional prototyping Short-run, bridge, or custom manufacturing |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends on consumer level machines. High performance composites on high cost industrial machines | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). Pure silicone and ceramic. | Engineering thermoplastics. Nylon 11, nylon 12, glass or carbon-filled nylon composites, polypropylene, TPU (elastomer). |

| Watertightness | Poor | Excellent | Good |

| Isotropy | Low (anisotropic) | High (isotropic) | Medium/High (nearly isotropic) |

Material Deep Dive

Compare material options to determine the strongest 3D printing material for a given application. Additional recommendations are given for the toughest and most heat-resistant materials for FDM, SLA, and SLS 3D printing.

Strongest, Toughest, and Most Heat-Resistant FDM Materials

While the materials are broken out into strongest, toughest, and heat resistant materials, Polycarbonate (PC) hits all these.

Polycarbonate (PC) is the strongest consumer-grade material available before stepping up to expensive industrial polymers like PEEK and PEKK. It is the same material used in bulletproof glass and riot shields. In FDM printing, it offers a great step up in both heat resistance and impact strength compared to ABS and Nylon. It is a challenging material to print, and is often blended with other materials to make it easier to print which will also reduce strength performance.

-

Pros: Extreme toughness (impact resistance), very high heat resistance, optical clarity (in specific translucent blends), and high tensile strength.

-

Cons: Difficult to print (requires very high nozzle temps of ~270-310 °C), hygroscopic (absorbs moisture), and prone to severe warping and delamination without a heated enclosure.

-

Tensile strength: High (60-70 MPa). It is stronger than Nylon and ABS, capable of bearing significant loads.

-

Stiffness: Moderate (2-2.5 GPa) Similar to ABS, but not as stiff as PLA.

-

Impact strength: Very high. PC is arguably the toughest non-flexible filament. It can take repeated heavy hammer blows without shattering.

-

Heat resistance: Excellent. With an HDT of ~110-130 °C, it remains rigid in environments where PLA and ABS would soften.

-

Best for: High-temp functional parts, automotive components (under the hood), electrical cases, and transparent durable covers.

Overall, if your 3D printer can handle the heat required for printing, Polycarbonate is the best choice for parts that need to be strong and heat-resistant.

Strongest FDM Materials

Carbon Fiber Reinforced Filaments (CF-Nylon/CF-PETG)

Carbon fiber filaments are usually a base plastic (like nylon, PETG, or ABS) filled with chopped or milled carbon fibers. These fillers increase the stiffness of the material, but usually do not significantly improve the tensile strength unless using longer chopped fibers which can cause nozzle clogs. The addition of carbon fiber filler tends to reduce warping in materials like PC and Nylon. When fillers are added to amorphous materials like ABS, PC and PETG, the HDT leads to minimal improvements, while adding fillers to Nylon can lead to an HDT just below the processing temperature of the material.

-

Pros: Extreme stiffness (high modulus), high dimensional stability (resists warping better than the base material), lightweight, good surface finish.

-

Cons: Abrasive (requires a hardened steel nozzle to print), expensive, and can be more brittle and harder to print than the unreinforced base material.

-

Tensile strength: High (50-100+ MPa, depending on the base). Strength can be higher than the base with long fibers at a higher loading, but with small fibers the strength can decrease.

-

Stiffness: Extreme (3 - 6 GPa) the fibers prevent the plastic from stretching, significantly reducing deflection under load.

-

Impact strength: Moderate to good. While strong, the added rigidity means it absorbs less energy than pure nylon before failing.

-

Heat resistance: Excellent. The fibers help the part hold its shape under heat, often pushing the heat deflection temperature higher than the base plastic alone, and achieving 150–160 °C.

-

Best for: Structural parts, drone frames, automotive components, jigs, and fixtures where stiffness is critical.

Carbon fiber filaments are overall the strongest 3D printer filament available for FDM, in terms of stiffness and structural rigidity.

PEEK (Polyetheretherketone)

PEEK belongs to the PAEK family of high-performance thermoplastics and is widely considered one of the strongest polymer materials. Often used in aerospace and medical implants, it serves as a legitimate lightweight replacement for metal.

-

Pros: Extreme chemical resistance, biocompatible (safe for implants), superior strength-to-weight ratio, and fire-resistant

-

Cons: Extremely expensive (often hundreds of dollars per kg), requires specialized industrial printers (nozzle temps ~400 °C or more, chamber temps ~100 °C or more), and difficult to process.

-

Tensile strength: Extreme (90-100 MPa). PEEK approaches the strength of some aluminum alloys while being significantly lighter.

-

Stiffness: Very high (3.5-4.5 GPa) PEEK is one of the stiffest unfilled polymers.

-

Impact strength: High. It is incredibly tough and resists fatigue and stress-cracking well.

-

Heat resistance: Superior. It can withstand continuous use at temperatures up to 260 °C (if annealed), making it suitable for engine parts and aerospace valves.

-

Best for: Metal replacement, aerospace components, medical implants, and chemical processing equipment

All in all, PEEK is a high-performance industrial engineering material.

PEKK (Polyetherketoneketone)

PEKK is a close relative of PEEK but is often preferred in 3D printing because it is slightly easier to process. Its molecular structure allows for a slower crystallization rate, which reduces the internal stresses that cause warping during the printing process.

-

Pros: Lower printing warping than PEEK, excellent layer adhesion, extreme chemical and heat resistance, low outgassing (crucial for space applications).

-

Cons: Extremely expensive, requires high-temperature industrial hardware, requires annealing (baking) to unlock full thermal properties.

-

Tensile strength: Very high (80-93 MPa). While sometimes slightly lower than PEEK in raw tension, it often exhibits better compression strength.

-

Stiffness: High (2.5-4 GPa) slightly less stiff than PEEK, but still stiffer than most unfilled polymers.

-

Impact strength: High. Like PEEK, it is durable and tough, suitable for harsh environments.

-

Heat resistance: Superior. Similar to PEEK, it handles temperatures well over 150 °C, and up to ~250 °C or more after annealing.

-

Best for: Aerospace parts (due to low outgassing), oil and gas components, and structural parts where PEEK warps too much.

PEKK is often the strongest and most reliable alternative to PEEK when producing parts that might warp.

PLA (Polylactic Acid)

PLA is the default material for most FDM printers. It prints easily and produces stiff parts with good detail, but low overall durability.

It has a medium-to-high tensile strength (50–60 MPa), often higher than ABS or PETG. However, this strength is deceptive, since PLA is extremely brittle.

-

Pros: High stiffness, easy to print, affordable.

-

Cons: Very low impact resistance, low heat resistance (deforms around 50 °C), biodegradable (can degrade in UV/moisture).

-

Strength: Ultimate Tensile Strength is High (53 MPa).

-

Stiffness: High (2.5-3.5 GPa) PLA is very stiff and deflects less under load than ABS or PETG.

-

Toughness: Impact strength is very low, with a Notched Izod of 16 J/m. PLA is brittle; it shatters rather than bends when hit.

-

Heat resistance: Low. PLA softens around ~55–60 °C, making it unusable for high-temp applications. PLA can often be annealed much like PEKK and PEEK to improve thermal properties by allowing for additional polymer crystallization to occur. PLA that has been heat treated this way will have a temperature resistance around 110 °C - 130 °C.

-

Best for: Aesthetic models, non-load bearing prototypes, quick "looks-like" models.

Overall, PLA is good for rigid, static objects (like a pen holder), but too brittle for strong, functional mechanical parts.

Toughest FDM Materials

PETG (Polyethylene Terephthalate, Glycol-modified)

PETG is a modified version of the common PET material that is used to make water bottles and food packaging and has the number “1” as its recycling code. PETG has the polymer backbone modified to improve processability, which makes it suitable for applications like injection molding and 3D printing.

PETG is one of the most widely used 3D printing filaments.

-

Pros: Tougher than PLA while being much easier to print than ABS or Nylon.

-

Cons: Can have “stringing” artifacts on prints.

-

Tensile strength: High – (45-55 MPa) Close to that of PLA.

-

Stiffness: Moderate - High (2.0 - 3.0 GPa) Stiffer than ABS and close to as stiff as PLA.

-

Impact strength: Low to moderate; typically higher than PLA, but lower than ABS.

-

Heat resistance: Low. Typically ~70 °C

PETG offers a general-purpose option that sits between PLA and ABS in terms of impact and temperature performance.

ABS (Acrylonitrile Butadiene Styrene)

ABS is the industry standard for injection-molded consumer goods (like LEGO® bricks). In 3D printing, it offers a balanced strength profile. It has a lower tensile strength than PLA (~34-36 MPa) but significantly higher impact resistance and ductility.

-

Pros: Yields before breaking (ductile), withstands temperatures up to ~85 °C, can be smoothed with acetone.

-

Cons: Prone to warping during printing, emits carcinogenic fumes, lower raw tensile strength.

-

Tensile strength: Lower than PLA, but sufficient for many plastic parts.

-

Stiffness: Moderate.

-

Impact strength: Moderate. ABS can resist impact better than PLA, but tends to have poor layer adhesion, causing easier fractures in the Z-direction.

-

Heat resistance: Moderate. It withstands temperatures up to ~85–95 °C.

-

Best for: Durable consumer goods, enclosures, parts requiring heat resistance.

ABS is a common answer when asking what the strongest 3D printer filament for general-purpose use is, as it is a reliable choice for functional parts that need to survive a drop or a hot environment. But it emits fumes and can be difficult to print reliably on budget machines.

Nylon (Polyamide)

Nylon (Polyamide) is widely regarded as one of the toughest thermoplastics. Unlike PLA (which is stiff) or ABS (which is ductile), Nylon offers a unique combination of strength, flexibility, and resistance to wear.

Nylon is the material of choice for functional parts that need to withstand repetitive mechanical stress, friction, or fatigue without snapping. It is self-lubricating, making it ideal for gears and moving parts. Nylon properties vary significantly based on grade and many filaments are blends of different Nylons like PA6, PA12, and PA11.

-

Pros: High impact resistance, low friction coefficient, excellent chemical resistance, and high fatigue resistance.

-

Cons: Highly hygroscopic (absorbs moisture from the air rapidly, ruining prints), prone to warping, requires high printing temperatures. Nylon filaments are frequently filled with Carbon Fiber to reduce shrinkage and make the material easier to print.

-

Tensile strength: High (40-80 MPa). This varies heavily based on both grade and moisture conditioning. Dry Nylon is stronger and stiffer, but moisture content will “plasticize” or soften the material.

-

Stiffness: Moderate to low (1.5-2.0 GPa). Typically less stiff than ABS

-

Impact strength: Good. Nylon can be tougher than ABS, depending on the grade and moisture content of the final part.

-

Heat resistance: Very good. Depending on the specific blend (PA6, PA12), it generally handles temperatures up to 120 °C or higher.

-

Best for: Gears, bearings, living hinges, snap-fits, and tooling handles.

Nylon is a great choice for durable, impact-resistant parts that need some flexibility. When asking what the strongest 3D printer filament for functional gears and hinges is, the answer is usually nylon.

Heat Resistant FDM Materials

Chopped or milled glass and carbon fiber are added to filament to increase temperature resistance, as well as stiffness. Polyetherimide (PEI) is one such material that falls into this category. Commonly known as Ultem® (a brand name), PEI filament is known for heat resistance, strength, and chemical stability.

Strongest, Toughest, and Most Heat Resistant SLA Resins

Strongest SLA Resins

Rigid 10K Resin

Rigid 10K Resin is the stiffest material in the Formlabs portfolio. This material is also one of the most heat resistant. It is glass-filled and designed to simulate the properties of glass-fiber-reinforced thermoplastics. The "10K" refers to its Tensile Modulus of 10,000+ MPa. It feels like ceramic or stone in the hand.

-

Pros: Extreme stiffness, smooth matte finish, high dimensional accuracy, heat resistant.

-

Cons: Very brittle. Like ceramic, it will break if dropped or bent.

-

Tensile strength: Very high (88 MPa). One of the strongest Formlabs materials.

-

Stiffness: Extreme (10 GPa). It resists deformation under load better than almost any other resin. Stiffer than most filaments and powders — even those with carbon fiber fillers.

-

Impact strength: Very low. It has almost no ductility.

-

Heat resistance: Extreme. It withstands heavy loads at high temperatures (HDT ~238 °C).

-

Best for: Injection molds, aerodynamic test models, and heat-resistant industrial parts, and welding fixtures.

Overall, Rigid 10K Resin is the best choice for parts that must not deflect or bend, like molds, jigs, and dies.

Rigid 4000 Resin

Rigid 4000 Resin is a glass-filled resin with a modulus of 4000 MPa, lower than Rigid 10K Resin. It is similar to PEEK (Polyetheretherketone) in strength and stiffness. It provides high stiffness while retaining more durability and toughness than the ceramic-like Rigid 10K Resin.

-

Pros: Stiff and strong, polished finish, higher impact resistance than Rigid 10K Resin.

-

Cons: Still brittle compared to the Tough Resin Family, abrasive to print tanks over time.

-

Tensile strength: High (69 MPa). It is a strong, structural plastic.

-

Impact strength: Low. It is brittle, but less likely to shatter than Rigid 10K Resin.

-

Heat resistance: Moderate. HDT is roughly 77 °C @ 0.45 MPa.

-

Best for: Thin walls, brackets, mountings, jigs, and fixtures that need rigidity but might face minor vibrations.

Overall, Rigid 4000 Resin is a general-purpose rigid material, offering a compromise between the extreme stiffness of Rigid 10K Resin and the durability of General Purpose resins.

General Purpose Resins

General Purpose Resins are versatile materials with a wide range of user applications including form and fit prototyping, models and props, 3D printed masters or molds, and more.

General Purpose Resins (including but not limited to Color Resin, Black Resin, Grey Resin, Clear Resin, and White Resin) are versatile resins that are stiff and strong, with a modulus around 2600 MPa depending on the color and post-curing protocol.

-

Pros: Available in a variety of colors, fast printing, good fine features, less brittle than PLA filaments and comparable to PETG in terms of toughness, but fully anisotropic with better Z-direction properties.

-

Cons: Not as strong or stiff as the filled resins, but not as tough as the Tough Resin Family or tough thermoplastics like ABS. More expensive than general purpose filaments.

-

Tensile strength: High (~62 MPa)

-

Stiffness: Moderate - High (2600 MPa)

-

Impact strength: Moderate. The Notched Izod of 32 J/m is higher than Rigid 4000 Resin.

-

Heat resistance: Low. HDT is roughly 71 °C @ 0.45 MPa.

-

Best for: Form and fit prototyping, presentation-ready models, jig and fixtures.

Toughest SLA Resins

Tough 1000 Resin

Tough 1000 Resin is the most pliable and impact-resistant of the Tough Resin Family. It is formulated to have comparable toughness to High-Density Polyethylene (HDPE) or Delrin (POM). It offers a low modulus (stiffness) of ~1000 MPa, making it incredibly tough and wear-resistant. Like the other resins in the Tough Resin Family, Tough 1000 Resin is named after its modulus.

-

Pros: Extreme impact resistance (highest in the Tough Resin Family), high elongation (180%), excellent wear resistance, and a smooth, low-friction surface.

-

Cons: Very flexible (not suitable for rigid structural parts), lower heat resistance.

-

Tensile strength: Low (26.3 MPa). It yields and stretches rather than holding a heavy static load.

-

Stiffness: Low. One of the most pliable non-elastomeric materials in the Formlabs portfolio.

-

Impact strength: Extreme. With a notched Izod of 72 J/m, it rivals industrial thermoplastics and, with a high work of fracture, it is arguably the hardest resin to shatter.

-

Heat resistance: Low. HDT is roughly 55 °C @ 0.45 MPa.

-

Best for: Impact-resistant jigs, squeezable prototypes, low-friction assemblies (like gears and ball joints).

Overall, Tough 1000 Resin is the best resin for durable parts that can resist high drops.

Tough 1500 Resin

Tough 1500 Resin is a resilient material with strength, stiffness, and toughness comparable to polypropylene (PP), offering exceptional resistance to fractures, impacts, and shattering. It has great balance between stiffness and ductility.

-

Pros: Sitting in between Tough 1000 Resin and Tough 2000 Resin, it blends high toughness, strength, and stiffness, and is also safe for short-term skin contact.

-

Cons: Lower tensile strength than Tough 2000 Resin, while not as tough and impact resistant as Tough 1000 Resin.

-

Tensile strength: Moderate (34 MPa). It is less resistant to pulling forces than Tough 2000 Resin but more ductile.

-

Stiffness: Low to moderate (1.5 GPa). While stiffer than Tough 1000 Resin it is on the more compliant end of the spectrum and comparable to some Nylon materials.

-

Impact strength: Very high. With high Gardner impact strength and work of fracture, it absorbs energy exceptionally well without shattering.

-

Heat resistance: Low to moderate. HDT is around 66 °C @ 0.45 MPa.

-

Best for: Latches, flexures, dampers, clasps and buckles, self-tapping screw bosses, and hinges.

Overall, Tough 1500 Resin is best for parts that need a combination of stiffness and ductility.

Tough 2000 Resin

Tough 2000 Resin is the strongest and stiffest material in the Formlabs Tough Resin Family. Formulated to rival the properties of injection molded ABS plastic, it is the go-to resin for functional prototyping when you need a part that is sturdy and holds its shape but will not shatter under stress, and is strong enough for functional jigs and fixtures.

-

Pros: Excellent stiffness-to-flexibility balance, resists cyclic loading (fatigue), properties similar to injection molded ABS.

-

Cons: Less tough than Tough 1000 Resin and Tough 1500 Resin.

-

Tensile strength: Moderate (40.4 MPa). It is strong enough for functional jigs, fixtures, and mechanical connectors and parts typically injection molded out of ABS.

-

Impact strength: High. It offers high fracture toughness, making it capable of withstanding drops and sudden shocks significantly better than standard resins.

-

Heat resistance: Moderate. It has an HDT of 70 °C @ 0.45 MPa.

-

Best for: Enclosures, jigs and fixtures, and functional prototypes that perform like ABS.

Overall, Tough 2000 Resin is ideal for parts that need to be stiff but not brittle.

Most Temperature-Resistant Resins

High Temp Resin

Choose High Temp Resin to print detailed, precise prototypes and end use parts that require high thermal stability, such as molds and inserts, parts exposed to hot air, gas, and fluid flow, as well as heat-resistant mounts, housings, and fixtures.

High Temp Resin has the highest HDT of any Formlabs resin. It is designed specifically for thermal stability, allowing it to withstand the heat of molding processes or hot air/fluid flow.

-

Pros: Extreme heat resistance (highest in class), precise detail.

-

Cons: Very brittle (similar to glass), absorbs moisture over time, and is difficult to post-cure.

-

Tensile strength: Moderate (~49 MPa). Good for holding shapes, but not for mechanical loading.

-

Stiffness: Moderate to high (2.8GPa)

-

Impact strength: Very low. Parts will shatter if dropped.

-

Heat resistance: Superior. It has an HDT of 238 °C @ 0.45 MPa, making it among the most temperature-resistant 3D printing materials.

-

Best for: Molds and inserts, parts exposed to hot air, gas, and fluid flow, as well as heat-resistant mounts, housings, and fixtures.

Overall, High Temp Resin is a specialty material used almost exclusively for applications where standard plastics would melt or deform.

Strongest SLS Powders

Nylon 12 Powder

A 3D printed drone frame in Nylon 12 Powder is strong and lightweight.

Nylon 12 Powder is the industry's gold standard for SLS. It offers a versatile balance of strength, stiffness, and detail, with very low moisture absorption. It is the easiest powder to print with, reliably producing parts with tight tolerances and complex geometries.

-

Pros: Excellent dimensional accuracy, easy to print, balanced mechanical properties, and has a good refresh rate.

-

Cons: Less ductile than Nylon 11 Powder. It is stiffer and will snap sooner if bent aggressively.

-

Tensile strength: High (50 MPa). It offers excellent general-purpose structural strength suitable for most engineering tasks.

-

Stiffness: Moderate (1.9 GPa)

-

Impact strength: Moderate (32 J/m Notched Izod). While tough, it is significantly less impact-resistant than Nylon 11 Powder or Nylon 12 Tough Powder.

-

Heat resistance: Excellent. It withstands temperatures up to 171 °C @ 0.45 MPa.

-

Best for: High-detail prototypes, permanent jigs and fixtures, housings, and general end-use parts.

Overall, Nylon 12 Powder offers the best balance of printability and performance for general prototyping and production where extreme ductility isn't required.

Nylon 12 Tough Powder

Drone parts can be SLS 3D printed in Nylon 12 Tough Powder.

Nylon 12 Tough Powder is a specialized formulation designed to offer improved ductility and toughness while providing the same versatility and easy workflow as standard Nylon 12. It is less brittle than standard Nylon 12 Powder and offers the best refresh rate in the industry (reusing up to 80% of old powder).

-

Pros: High ductility (flexes without breaking), excellent dimensional accuracy (reduced warping), and very cost-effective due to low refresh rate.

-

Cons: Lower tensile strength than standard Nylon 12 Powder. Lower heat resistance under heavy mechanical loads.

-

Tensile strength: Moderate (42 MPa). While slightly weaker than standard Nylon 12 Powder (50 MPa), it makes up for this with flexibility.

-

Stiffness: Low to Moderate (1.5 GPa)

-

Impact strength: Good (60 J/m Notched Izod). It absorbs shock well and is ideal for parts that need to snap or bend.

-

Heat resistance: Excellent. It withstands temperatures up to 161 °C @ 0.45 MPa, though it softens at lower temperatures under high loads (HDT @ 1.8 MPa is 46°C).

-

Best for: Snap-fit enclosures, ratchets, hinges, functional prototypes, and long parts susceptible to warping.

Overall, Nylon 12 Tough Powder is the go-to powder for difficult geometries that tend to warp, or for parts that need more flexion than standard Nylon 12 Powder.

Nylon 12 GF Powder

Nylon 12 GF Powder can print high tolerance threads, sockets, and moving elements within the part.

Nylon 12 GF Powder is a glass-filled composite material designed for applications where stiffness and thermal stability are critical. By incorporating glass beads into the standard Nylon 12 base, this powder produces parts that are significantly stiffer and flatter than unreinforced nylon, making it ideal for maintaining structural rigidity under load or heat.

-

Pros: High stiffness (high tensile modulus), excellent thermal stability (high HDT), and produces very flat parts with minimal warping.

-

Cons: More brittle than unfilled Nylon 12; abrasive to post-processing equipment over time.

-

Tensile strength: Moderate (38 MPa). While the raw tensile breaking point is slightly lower than pure Nylon 12, it resists stretching (deformation) much better.

-

Stiffness: Moderate to high (2.8 GPa).

-

Impact strength: Low to Moderate (23 J/m Notched Izod). The glass reinforcement adds rigidity at the cost of ductility, meaning it is more likely to snap than bend under sudden impact.

-

Heat resistance: Excellent. It offers improved heat deflection compared to standard Nylon 12 (175 °C @ 0.45 MPa), maintaining its shape better in hot environments.

-

Best for: Stiff housings, fixtures, tooling, threads, and parts requiring high sustained load-bearing capacity without creeping.

Overall, Nylon 12 GF Powder is the choice for stiff and stable parts. It is the go-to material when you need the printability of Nylon 12 but require increased rigidity.

Nylon 11 Powder

Nylon 11 Powder is a high-performance, bio-based material tailored for parts that need to bend and flex without snapping. While standard nylons are tough, Nylon 11 Powder offers superior ductility and impact resistance, making it the ideal choice for applications where the part might be dropped, twisted, or subjected to sudden shocks.

-

Pros: Exceptional ductility (40% elongation at break), high impact strength, and excellent long-term stability. It is bio-based (derived from castor oil) and ideal for thin features.

-

Cons: Can be more prone to warping than Nylon 12 Powder parts if not oriented correctly; printing in an inert nitrogen atmosphere is recommended for the best material properties and refresh rate.

-

Tensile strength: High (49 MPa). It holds heavy loads well but is defined by its ability to stretch before failing.

-

Stiffness: Low to moderate (1.6 GPa)

-

Impact strength: Very high (71 J/m Notched Izod). It absorbs energy efficiently, making it one of the most shatter-resistant powders available.

-

Heat resistance: Excellent. It has an HDT of 182 °C @ 0.45 MPa.

-

Best for: Snap-fits, living hinges, orthotics, prosthetics, and thin-walled ducts that need to withstand abuse.

Overall, Nylon 11 Powder is the specialist choice for durability and performance. If your part needs to survive real-world impacts or constant flexing, this is the material to use.

Nylon 11 CF Powder

Nylon 11 CF Powder is the strongest and most heat-resistant material in the Formlabs SLS material library. By reinforcing Nylon 11 Powder with carbon fiber, this material bridges the gap between plastic and metal. It offers the high impact resistance of Nylon 11 Powder combined with the extreme stiffness of carbon fiber, resulting in parts that are rigid, lightweight, and capable of handling repeated structural loading.

-

Pros: Excellent strength-to-weight ratio, extreme stiffness (high modulus), and superior thermal stability.

-

Cons: Requires printing with an inert nitrogen atmosphere; parts are rigid and will not yield much before breaking compared to unfilled nylon.

-

Tensile strength: Very high (69 MPa). It is significantly stronger than standard nylons and resists deformation under heavy loads.

-

Stiffness: Up to 5.3 GPa, but depends on part orientation since the fiber aligns with the X-axis.

-

Impact strength: High (74 J/m Notched Izod). Unlike many carbon-fiber filaments that become brittle, this powder retains the underlying toughness of Nylon 11 Powder, resisting shattering well.

-

Heat resistance: Excellent. It has an HDT of ~188 °C @ 0.45 MPa, making it suitable for under-hood automotive applications and high-temp tooling.

-

Best for: Metal replacement, high-impact equipment, aerodynamic components, and rigid jigs and fixtures.

Overall, Nylon 11 CF Powder is the top-tier choice for structural parts that need to be stiff, light, and heat-resistant all at once.

The Ultimate 3D Printer Material Strength Chart

| Material | Technology | Tensile Strength (MPa) | Tensile Modulus (Stiffness) (GPa) | Elongation at Break | Flexural Modulus (GPa) | Impact Strength (Notched Izod) (J/m) | Heat Deflection Temp (HDT @ 0.45 MPa) | Best For / Applications |

|---|---|---|---|---|---|---|---|---|

| PLA | FDM | 50–60 | 3.5 | 5–6% | 3.0–4.0 | 16–25 | 55 °C | Aesthetic models, static prototypes |

| ABS | FDM | 35–40 | 2.2 | 10–30% | 2.3 | 200–250 | 95 °C | Durable consumer goods, enclosures |

| Nylon (PA6/12) | FDM | 60–80 | 1.5 | >100% | 1.2 | 200–400 | 90–140 °C | High-wear gears, bearings, friction parts |

| CF-Nylon | FDM | 80–100+ | 6.0–10.0 | 2–4% | 8 | 40–60 | 150–160 °C | Structural parts, extreme stiffness |

| Polycarbonate (PC) | FDM | 60–70 | 2.3 | 5–10% | 2.2 | 50–80 | 135–145 °C | High-stress parts, heat resistance |

| PEEK | FDM | 90–100 | 3.8 | 30–40% | 3.9 | 50–80 | 150–260 °C* | Metal replacement, extreme environments |

| PEKK | FDM | 80–93 | 3 | 2–6% | 3 | 30–40 | 150–160 °C | Aerospace, chemical resistance, low outgassing |

| Tough 2000 Resin | SLA | 40 | 1.8 | 79% | 1.7 | 25 | 70 °C | Sturdy jigs, ABS-like functional parts |

| Tough 1500 Resin | SLA | 34 | 1.5 | 155% | 1.4 | 42 | 66 °C | Springy parts, snap-fits, living hinges |

| Tough 1000 Resin | SLA | 26 | 0.9 | 180% | 0.8 | 72 | 55 °C | Squeezable parts, high-impact tooling |

| Rigid 10K Resin | SLA | 88 | 11 | 2% | 9.9 | 20 | 238 °C | Injection molds, glass-filled simulation |

| Rigid 4000 Resin | SLA | 69 | 4.1 | 5% | 3.4 | 23 | 77 °C | Thin walls, stiff brackets, housings |

| High Temp Resin | SLA | 49 | 2.8 | 2% | 2.8 | 17 | 238 °C | Casting molds, fluid/airflow components |

| Nylon 12 Powder | SLS | 50 | 1.9 | 11% | 1.6 | 32 | 171 °C | General purpose, high detail, housings |

| Nylon 12 Tough Powder | SLS | 42 | 1.5 | 25% | 1.1 | 60 | 161 °C | Functional prototypes, snap-fit enclosures |

| Nylon 12 GF Powder | SLS | 38 | 2.8 | 3–4% | 2.4 | 36 | 170 °C | Robust jigs, fixtures, enclosures, and replacement parts |

| Nylon 11 Powder | SLS | 49 | 1.6 | 40% | 1.4 | 71 | 182 °C | Ductile parts, thin walls, impact resistance |

| Nylon 11 CF Powder | SLS | 69 | 5.3 | 4.2 | 74 | 188 °C | Lightweight structural parts, high heat |

Verdict: Which Material Should You Choose for Strength?

Depending on what strength means to your use case:

-

Impact resistance (parts that will be dropped or hammered): Choose Tough 1000 Resin (SLA) for prototyping impact-resistant parts, and Nylon 11 Powder (SLS) for end-use impact-resistant parts. Tough 1000 Resin is chemically designed to absorb high-energy impacts. Nylon 11 Powder is the superior choice for ductility if you need parts like living hinges or orthotics that must bend repeatedly and stretch significantly without ever snapping.

-

Highest strength (load bearing): Choose CF-Nylon (FDM), Rigid 10K Resin (SLA), or Nylon 11 CF Powder (SLS). These offer the highest tensile strengths, making them strong enough to replace metal components in structural applications.

-

Stiffness (parts that must not bend): Choose Rigid 10K Resin (SLA), CF-Nylon (FDM), or Nylon 12 GF Powder (SLS). Rigid 10K Resin provides glass-like stiffness (10 GPa modulus) for precision tooling, while Carbon Fiber reinforced Nylons (both FDM and SLS) offer extreme structural rigidity for lightweight functional parts.

-

Heat resistance: Choose High Temp Resin (SLA), Rigid 10K Resin (SLA), or PEEK (FDM). For pure heat deflection (resisting deformation at ~238 °C), the SLA resins are superior. For continuous use in harsh chemical/hot environments, PEEK is the industrial standard. In SLS, Nylon 11 Powder and Nylon 12 GF Powder are excellent "mid-range" heat performers, handling ~170–180 °C, which is significantly higher than standard ABS or tough resins.

-

Overall, balanced strength profile: Choose ABS/ASA (FDM), Tough 2000 Resin (SLA), or Nylon 12 Powder (SLS). These offer the best balance of performance and price.

-

FDM: ABS is the reliable, affordable standard for basic functional FDM prints.

-

SLA: Tough 2000 Resin is best for simulating ABS properties with a smooth surface finish.

-

SLS: Nylon 12 Powder is the gold standard for functional, end-use production parts that need to last.

-

Find the Right Material for Your Application

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Factors Influencing 3D Print Strength

Choosing the optimal material and technology to produce a strong part is only half of the equation. Factors such as printing infills, layer height, orientation, and post-processing will also dictate the final mechanical performance.

In addition to material choice, the following factors greatly impact part performance.

Infill Density

A hollow part is obviously weaker than a solid one. Generally, higher infill density increases strength, but requires more material and, especially in FDM 3D printing, more time to print.

General recommendation for stronger parts when printing with FDM 3D printers:

-

50% infill for moderate loads

-

80–100% infill for structural parts

Infill Pattern

The infill pattern for FDM 3D printing also plays a big role in strength. Cubic or gyroid patterns offer high strength, while rectilinear or grid patterns are generally weaker. Therefore, to make strong parts, the general recommendation is cubic or gyroid patterns.

Walls/Perimeters

The shell (wall) thickness often contributes more to part strength than infills. Increasing your wall count from two to four usually adds more strength than jumping from 50% to 80% infill.

General recommendation for stronger parts:

-

FDM: three to five perimeters for functional parts

-

SLS: 0.6 mm (vertical) and 0.3 mm (horizontal) minimum wall thickness

Print Orientation

As discussed, FDM parts are anisotropic, so print orientation is one of the biggest factors for FDM 3D printing strength. SLA and SLS parts are isotropic, so print orientation doesn’t compromise structural integrity.

General recommendations for stronger parts:

-

FDM: Weakest between layers (Z-axis), therefore orient parts so the mechanical load runs along the layer lines, not across them. For example, if printing a hook, print it lying flat on its side, not standing up.

-

Because SLA and SLS prints are isotropic, parts can be oriented to reduce print time or to minimize support marks for SLA, without compromising structural integrity.

Post-Processing

Post-processing 3D printed parts can have a high impact on performance.

In FDM, materials like PLA and Nylon can be annealed (baked) in an oven. This re-crystallizes the polymer chains, potentially increasing strength and heat resistance, though it can cause dimensional shrinkage.

In SLA, UV curing is required for resin prints to achieve full strength. An uncured or green part has significantly lower tensile properties.

In SLS, post-processing techniques such as vibratory tumbling and vapor smoothing can improve surface hardness.

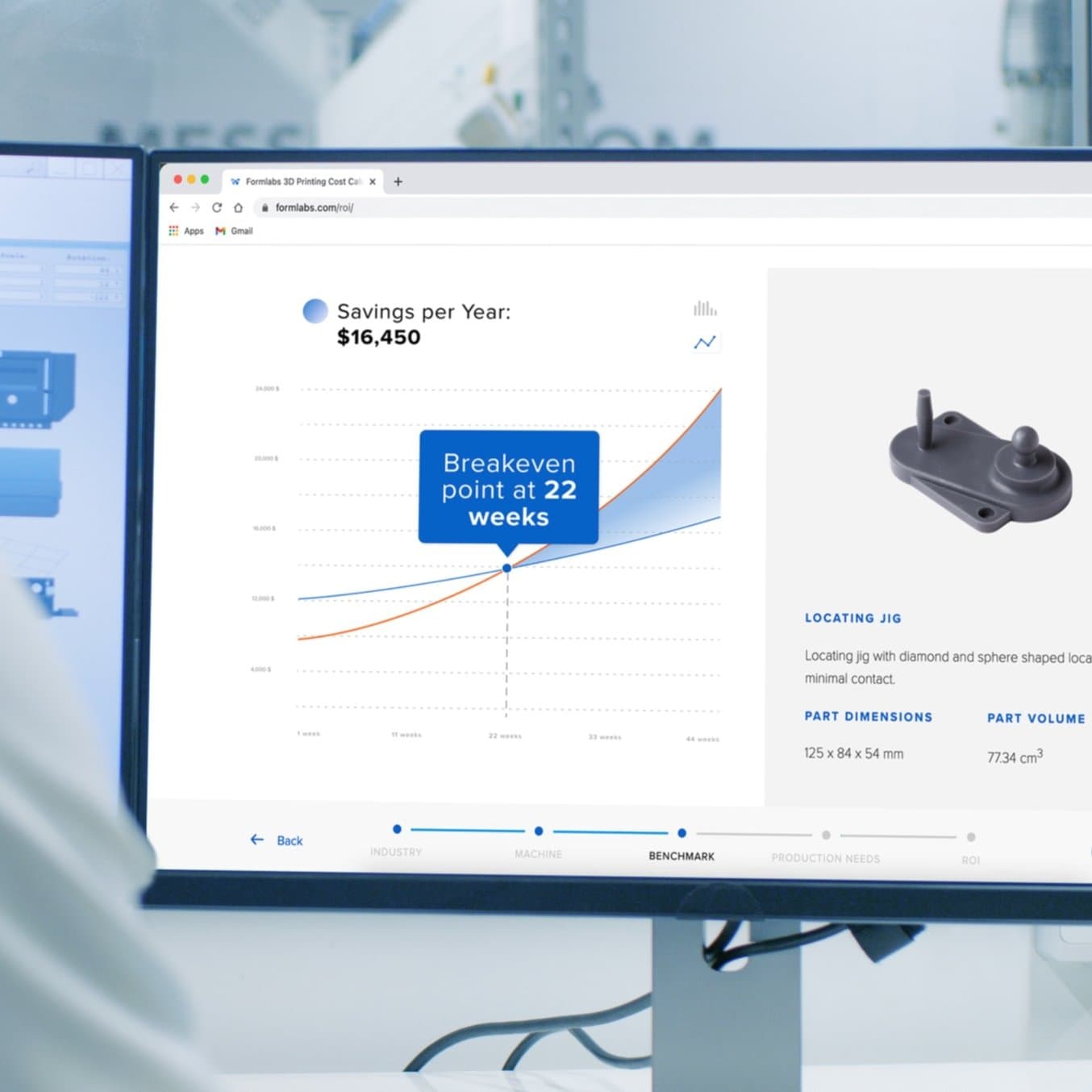

Calculate Your Time and Cost Savings

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

FAQ

What is the strongest 3D printing material?

There is no single strongest material. For pure tensile strength and stiffness, carbon fiber reinforced nylon (FDM) or Rigid 10K Resin (SLA) are top contenders. For impact strength and durability, Nylon 12 Tough Powder (SLS) or Tough 2000 Resin (SLA) are superior.

What is the strongest 3D printer filament?

Carbon fiber reinforced nylon and polycarbonate (PC) are widely considered the strongest filaments available for prosumer FDM printers. PEEK and PEKK are stronger but require expensive industrial high-temperature printers.

What’s the strongest resin for 3D printing?

Formlabs’ wide range of engineering resins delivers high tensile strength and stiffness. Some suggestions include:

-

Tough 2000 Resin provides strength and stiffness comparable to ABS.

-

Tough 1500 Resin provides strength, stiffness, and toughness comparable to polypropylene (PP).

-

Tough 1000 Resin provides strength, stiffness, and toughness comparable to HDPE.

-

Rigid 10K Resin provides comparable stiffness to glass and fiber-filled thermoplastics.

-

Rigid 4000 Resin provides comparable stiffness to PEEK and PEKK thermoplastics.

-

High Temp Resin provides thermal stability up to 238 °C @ 0.45 MPa.

Overall, for stiff, load-bearing parts, Rigid 10K Resin (glass-filled) is the strongest. For parts that need to survive drops and impacts, Formlabs Tough 1000 Resin is the strongest option.

What’s the strongest powder for SLS 3D printing?

Nylon 11 CF Powder is the best-performing SLS powder when it comes to strength. It is a carbon fiber-filled material, perfect for applications that require both superior stiffness and strength. It produces lightweight, strong parts that remain structurally stable even at elevated temperatures.

Is resin stronger than filament?

Resins are generally more brittle than standard filaments like PLA or ABS. However, engineering resins can outperform filaments in metrics like stiffness and tensile strength, while offering the added benefit of isotropic (uniform) strength and smoother surface finish.

How strong are 3D printed parts?

They can be as strong as molded plastics when printed with the right technology, material, and orientation.

Which 3D printing material is best for functional parts?

FDM nylon and carbon fiber reinforced composites filaments, SLA Tough Resin Family, and SLS Nylon powders are top choices.

Does infill density affect strength in FDM?

Yes. More infill means stronger parts, especially with strong outer walls.

How strong are 3D printed parts compared to injection molding?

SLA and SLS parts printed in engineering resins can reach similar strength to injection-molded plastics.

How strong are 3D printed parts compared to metal?

Plastic 3D prints are generally weaker than machined aluminum or steel. However, for metal-like strength, you can use SLS printers to print Nylon 11 CF Powder, which is incredibly robust, or SLA 3D printers to print parts in Rigid 10K Resin to replace tools such as aluminum molds for injection molding, or SLA casting resins to produce casting molds for metalmaking.

What Is the Strongest 3D Printing Material?

There is no single strongest 3D printing material because no single material excels in every category. The strongest part is the one that survives the intended application and environment. By understanding the difference between tensile strength (pulling) and impact resistance (shattering), and by leveraging the isotropic advantages of SLA and SLS technologies for complex geometries, you can produce parts that rival traditional manufacturing.

Strongest 3D Printing Materials Based on Print Technology

FDM

-

PAEK (PEKK and PEEK)

-

PLA

-

Polycarbonate

3D Print Strong Parts

Explore the Formlabs Materials Library to find the optimal material for yourself, or request a free sample part to evaluate Formlabs materials for yourself.

Compare materials to determine the best material for your application or contact a 3D printing expert.