Formlabs Ambassadors Inspire!

Meet our community of over 50 3D printing leaders from 13 countries, using Formlabs products to solve challenging problems.

The same tools, dozens of perspectives

From users who rely on a single printer for everyday prototyping, to those leveraging print farms to manufacture at scale, our ambassadors all have one thing in common: they are redefining the way things are made.

Formlabs Ambassadors share their experiences and expertise with the 3D printing community by leading webinars, writing blog posts, posting their work on social media, and advising on white papers.

The 2022 3D Printing Applications Report

Filled with key insights on what is driving current and future investment in additive manufacturing, our report is based on survey data from 400 global businesses, and includes testimonials from Ambassadors Kat Ermant, Christina Perla, and Will Hilgenberg.

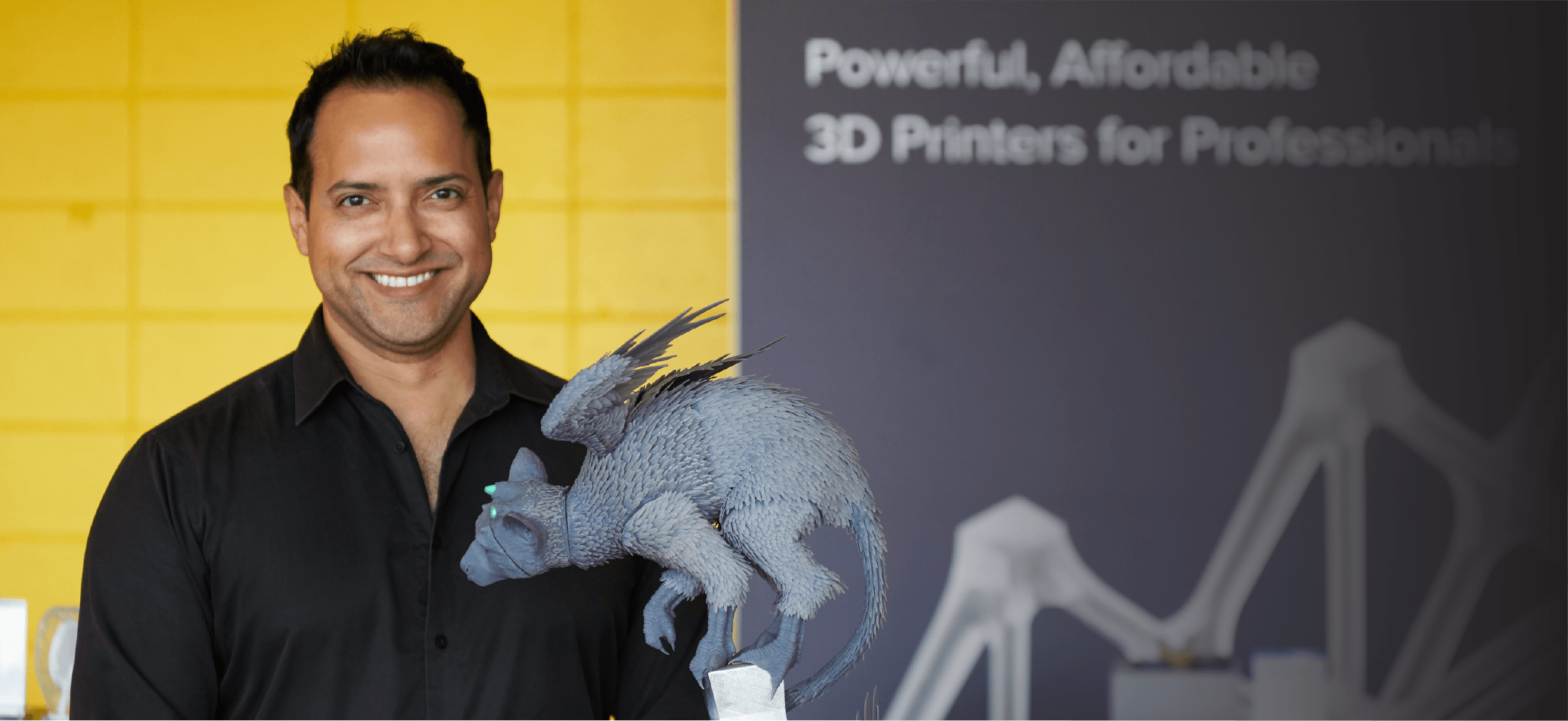

Daniel De Leon of Lion Arts showcased his intricate model of Trico from The Last Guardian at Formlabs User Summit 2019.

Jocelyn DeSisto at work in her NYC studio where she runs environmentally sustainable jewelry brand Lot28 Design.

Follow #formlabsambassador on Instagram

Why Become a Formlabs Ambassador?

As a Formlabs Ambassador, you'll receive unique and exclusive benefits.

Be the first

Gain first access to new Formlabs materials

Get Featured

See your work at in-person and virtual events

Earn more

Earn free materials of your choice

Get recognition

Generate awareness for your business across Formlabs' vast global online reach

Ambassador Directory

Kim Olson

Tool Design Instructor, Moraine Park Technical College

West Bend, WIKim Olson has 13 years of experience teaching professional mold design. He serves as an instructor at Moraine Park Technical College in West Bend, WI for the Tool Design Engineering associate degree program, the Mechanical Design Technology associate degree program, and the Mold Design Certificate Program. His core responsibilities focus on injection mold design related courses, though he also teaches jig and fixture design and metal stamping die design. He is a Certified SolidWorks Professional and teaches CAD to his students. Olson previously spent 15 years as a Zinc Die Cast Tool Designer for Briggs and Stratton Technologies/Strattec Security Corporation in Milwaukee, WI. He primarily worked on products for the automotive lock and small engine markets. Additionally, he managed die designers and injection mold designers for these same products.

Lance Winkel

Educator and Professional Digital Artist

Los Angeles, CALance Winkel is an award winning animated filmmaker, animation educator, and professional artist, whose commercial clients have included Ford, Honda, Nissan, and Warner Brothers. His graduate thesis "Within an Endless Sky" was the first film to be made at Cal Arts using the Maya software package, and it won the first ever "Best Animated Short Film" award at the Newport Beach Film Festival. Recently Lance took assets from this film and brought them into the physical world for the first time using Formlabs printers. As a full time lecturer at the Information Technology Program at USC, he empowers his students to take advantage of 3D Printing technology, and has championed exciting improvements to ITP's 3D Animation Program.

Leah Aegerter

Digital Fabrication Lab Technician, Anderson Ranch Arts Center

Snowmass Village, COLeah Aegerter is an artist and Instructor at Anderson Ranch Arts Center. Leah uses digital fabrication as part of an interdisciplinary practice, and she believes that the most successful and exciting outcomes happen when 3D printing is used in combination with other processes, including traditional hand-crafting techniques. Leah incorporates many SLA materials including Draft and Clear Resins into her workflow for 3D design courses. Her students include instructors at other institutions who want to learn about the latest available tools and processes.

Lindsey Zindroski

CEO, SNL Creative

Los Angeles, CALindsey Zindroski is an Additive Manufacturing Entrepreneur and Los Angeles Ambassador for Women in 3D Printing. In 2008, she founded SNL Creative, where she works in design, development, and manufacturing of goods for luxury brands, toys and art collectables, fine art, consumer products, automotive, themed entertainment and film. She is a client focused business leader with a commitment to building trusted partnerships with her clients and within Industry.

Luiz Maracaja

Associate Professor, Wake Forest Baptist Health

Winston-Salem, NCLuiz specializes in cardiac surgery and now serves as both founder and medical advisor to VIDA Medical Devices. In both his commerical and clinical work, he devises creative engineering solutions to imrpoving patient experience. His Formlabs printer helps him with rapid prototyping, and having the printer in house allows him to have a one-day design cycle. He 3D prints every night, tests his prototypes during the day and does design revisions in the afternoon. This cycle has allowed Luiz to take the next step from intellectual property to proof of concept and preclinical testing.

Maarten Verhoeven

Founder, We Are Grim

Antwerp, BelgiumMaarten has been a freelance digital sculptor for 10 years and considers himself lucky enough to win the ZBrush sculptoff in 2018, where the prize was a Form 2 printer. He had already been considering 3D printing his creations for some time, so it was a no brainer to fire up the machine! He now finds that by bringing his digital creations into the physical realm, he’s playing a completely different game...getting closer to being a real sculptor.

Marco De Rossi

Research Fellow, Universitat Politècnica de València

Valencia, SpainMarco is an industrial designer and researcher specializing in digital fabrication at the Universitat Politècnica de València in Spain. His everyday work involves quickly developing prototypes for lab tests and experimental equipment for research projects at the university. In addition, lots of people from many industries reach out to Marco in search of advice to solve design and manufacturing problems. Because of this, he has had the opportunity to implement 3D printing for many types of clients, from toy and chocolate manufacturers to hospitals.

Marc Moir

Owner, American Outlaw Design

Moodus, CTMarc Moir has been working as a CNC manufacturing engineer for the past 10+ years, and has a side passion for creating artistic jewelry pieces for his fellow motorcyclists. Mark was quickly drawn into the endless possibilities of 3D printing with the availability and affordability of desktop printers, and makes extensive use of both Castable Wax resin and Formlabs Engineering Resins in his work.

Mark Chester

Innovation Development Manager, Manchester PrintCity

Manchester, UKWith a background in product design, Mark is responsible for designing and delivering prototypes for a range of clients. Specialising in additive manufacturing, Mark provides design consultation for additive and technical services within PrintCity and helps customers develop their ideas further and turn them into reality. Mark additionally has a strong background in the application of generative design and other industry 4.0 technologies. He also supports and consults clients on how to improve their current processes through new technologies. Mark’s role at PrintCity is also partially funded by the Manchester Business Growth Hub, which enables businesses to grow through a broad range of services.

Matias Ezequiel Biancucci

CEO and Co-Founder, Mirai3D

Buenos Aires, ArgentinaCo-Founder MIRAI 3D. Surgical Planning & Simulation Business Development.

In college, while I was studying biomedical engineering, me and two friends built a RepRap 3D printer. We got to know the tech by building it, but quickly started growing, so we acquired a Form 2 printer in 2017 to meet the industry´s demand for precise models. Today, Formlabs printers help us meet demand of surgical planning models, but also enables us to rapidly prototype and manufacture surgical simulators.

Matt Moseman

Founder, Node U Design

Spring Green, WIMatt Moseman is the co-founder of Node U Design, a startup creating programmable industrial nodes for localized manufacturing. Matt is passionate about helping small businesses scale by vertically integrating design to manufacturing. While his company leverages many manufacturing processes including CNC equipment, the Formlabs solutions became a must-have. Being able to ideate and create low fidelity prototypes in less than a day at an affordable cost allows Node U Design to stay competitive in a fast-paced industry.

Matt Schmotzer

Founder, Print My Ride

Detroit, MIMatt is a Product Development Engineer at Ford and roller coaster enthusiast. Matt uses both FDM printers and Formlabs SLA printers to create working 3D printed replicas of roller coasters around the world. So far he’s made three full working models, containing tracks and highly detailed train assemblies. Matt leverages both FDM and SLA, leveraging the strengths of each technology, and ultimately creating a more functional model as a result. Recently he’s been taking the roller coasters on the road, giving presentations at schools to inspire future engineering students.