3D Printing Applications

3D printing is a versatile solution for a wide range of applications, from high-resolution models to rapid prototyping, rapid tooling for traditional production processes, manufacturing aids, and even end-use parts in manufacturing.

Rapid Prototyping

Bring Products to Market Faster With In-House Rapid Prototyping

Rapid prototyping with affordable in-house desktop 3D printers empowers you to create prototypes within a day and carry out multiple iterations of design, size, shape, or assembly based on results of real-life testing and analysis, helping you to bring better products to market faster.

Rapid Tooling

Supercharge Your Manufacturing Tools With 3D Printed Rapid Tooling

Accelerate product development, iterate quickly, and bring better products to market by incorporating 3D printed rapid tooling into your development process. 3D printed rapid tooling enables you to validate your design and material choice prior to transitioning to mass production, or alternatively provides an affordable means to produce custom or limited series of end-use parts.

Production Volumes

Affordable, Scalable Production for End-Use Parts

Bring production in-house and reduce cost per part with a proven, scalable, and accessible SLS ecosystem. Formlabs’ Fuse Series is the #1 SLS 3D printing platform that has helped thousands of customers bring new products to the market and achieve their lowest cost per part, ever.

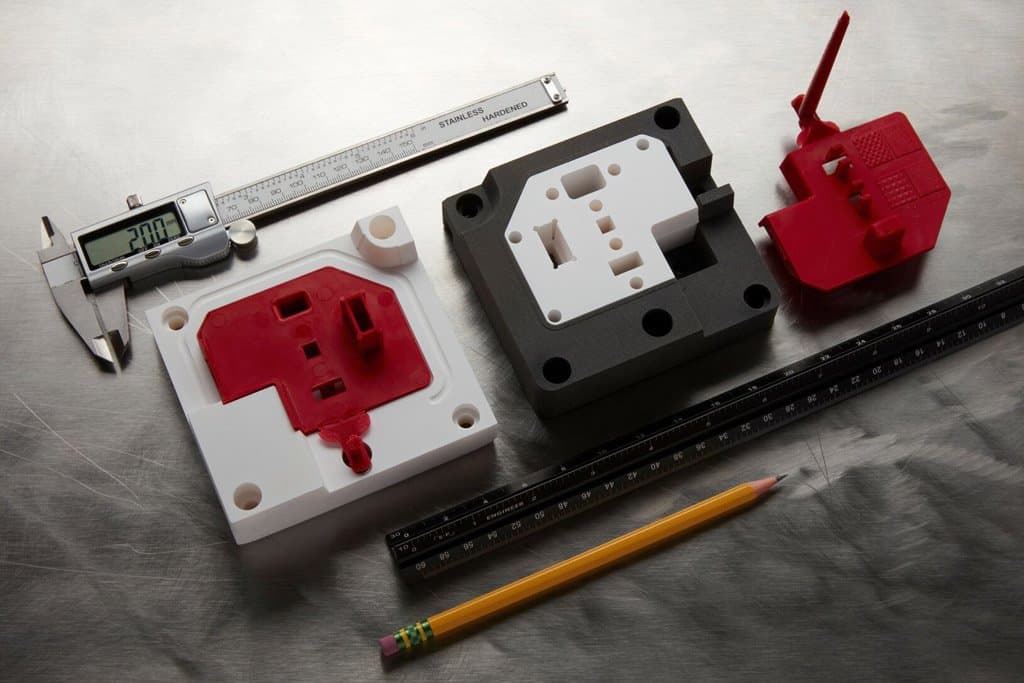

Injection Molding

An Efficient and Affordable Means for Bridge Tooling

Accelerate product development, reduce costs and lead times, and bring better products to market by incorporating 3D printing and short-run injection molding into your development process. Use 3D printed injection molds with both benchtop and industrial machines to efficiently and affordably produce hundreds to thousands of functional prototypes, parts for pilot production, or end-use parts.

End-Use Parts

Manufacture Custom End-Use Parts and Complex Designs

An end-use part is a good that is sold as a product, used as a sub-assembly in a product, or used as a component in a product. With 3D printing, you can create end-use parts without tooling, making it possible to create custom parts and complex designs in a cost-efficient manner.

Manufacturing Aids

Improve Efficiency With 3D Printed Manufacturing Aids

3D printed manufacturing aids are vital tools for addressing common problems that arise during the manufacturing process. This includes the need for custom jigs, fixtures, tools, and replacement parts. Use in-house 3D printing to improve the efficiency of the manufacturing process, reducing costs and improving production.

Silicone & Rubber Parts Production

Flexible and Affordable Means to Produce Limited Quantities of Silicone and Rubber Parts

Low-volume production of soft or flexible parts can be technically challenging, costly, and slow. Many professionals use 3D printing to manufacture rapid tooling for molding and casting silicone parts, or to directly 3D print flexible parts. Desktop 3D printers offer many benefits, including design flexibility within CAD software, high accuracy, easy iterations, and quick turnaround times.

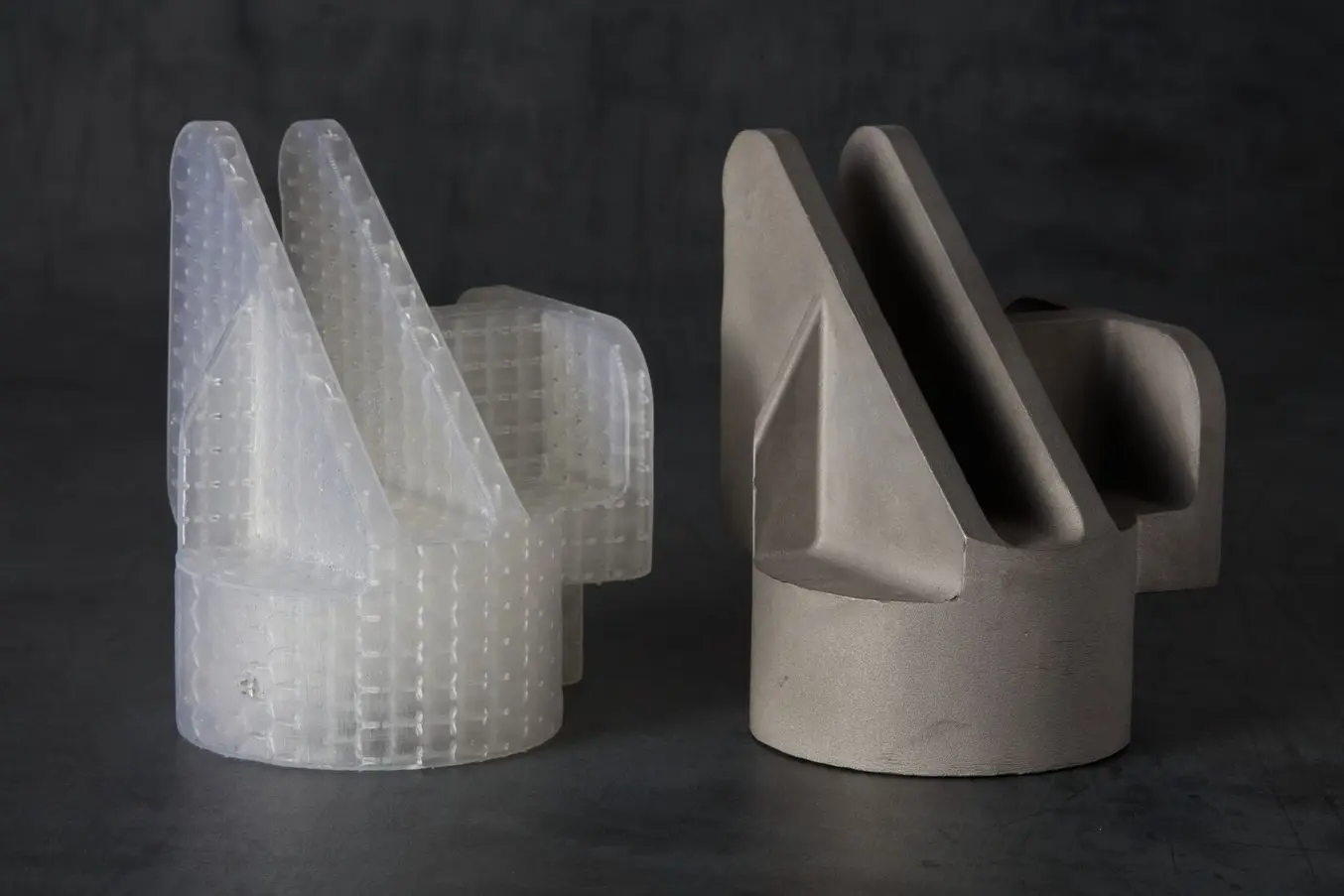

Investment Casting

3D Print Accurate, Low Ash Patterns for Investment Castings Directly in House

Formlabs stereolithography (SLA) 3D printers and Clear Cast Resin enable direct production of industrial investment casting patterns in-house. This workflow reduces costs, decreases turnaround times, and improves flexibility for prototyping as well as the production of small to medium batches and complex geometries.

Models and Props

3D Print High-Definition Models and Props

Bypass time-consuming traditional model and prop processes. Accurately 3D print models with fine surface detail, saving time and costs.

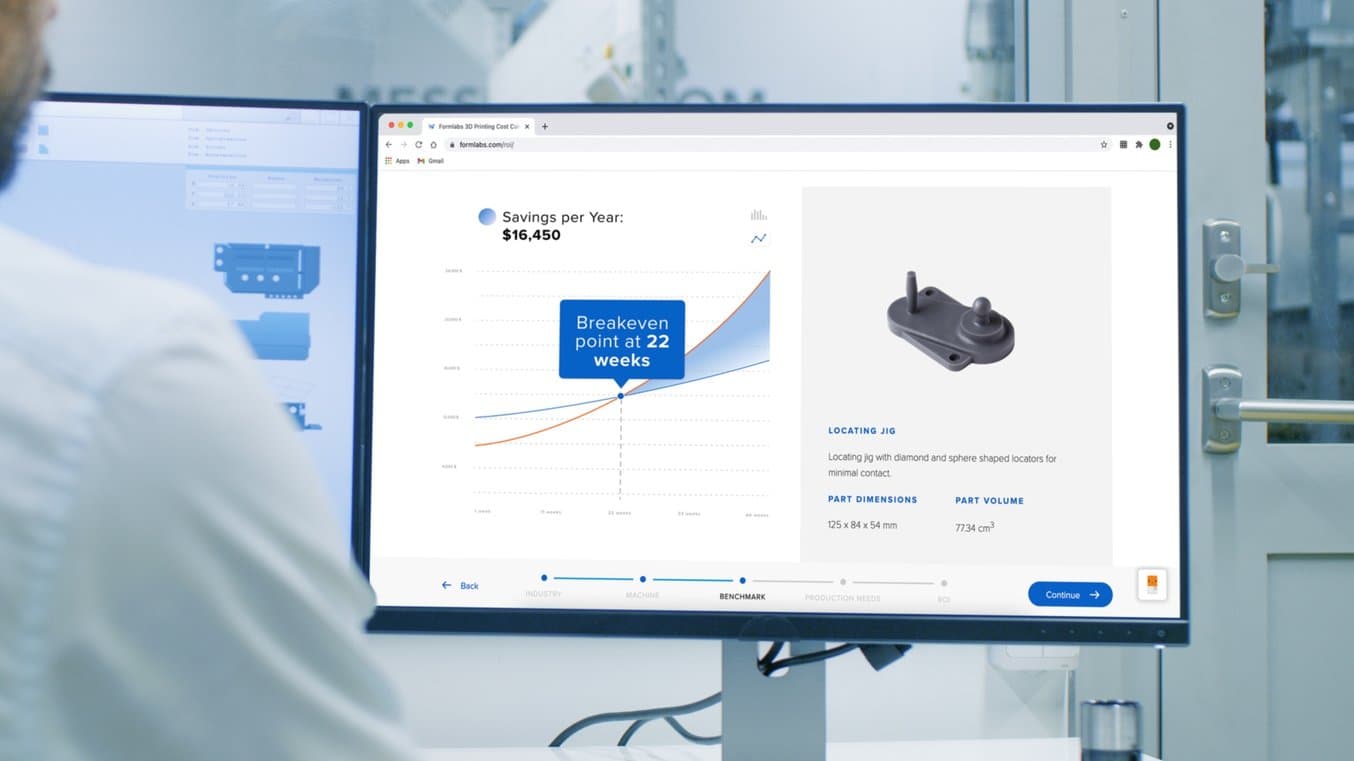

Calculate Your Time and Cost Savings

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

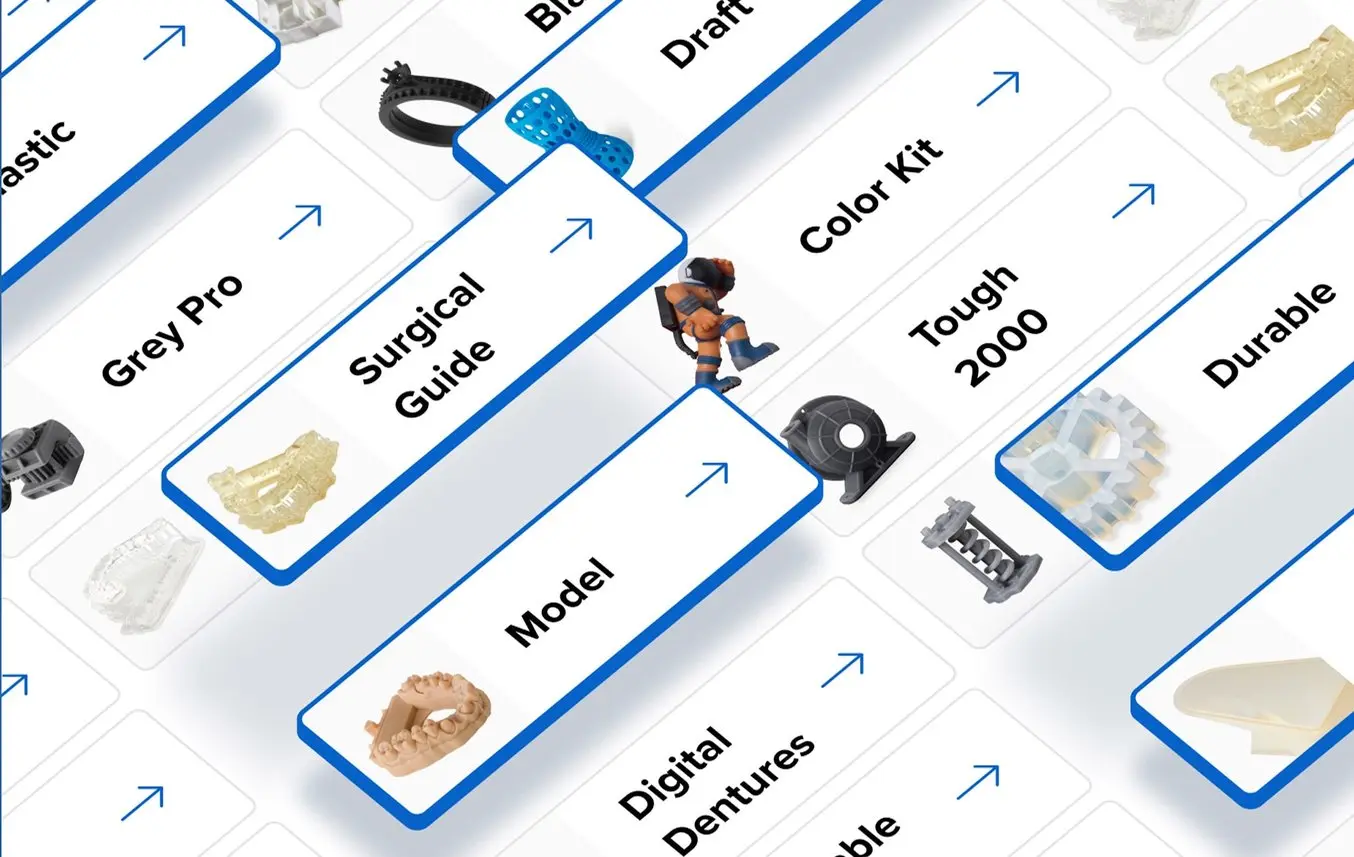

Find the Right Material for Your Application

Our interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.