Landis Fields has a resume that 3D artists dream of: Star Wars: The Force Awakens, Pacific Rim, and The Fantastic Four, to name a few. He’s currently a lead artist at the legendary design studio Lucasfilm Industrial Light and Magic. We sat down with him to get his insight on the world of digital art and to hear about his path to success in this competitive field.

How did you get into 3D modeling?

Like most professional artists, I always loved to draw when I was a kid. When I got to high school, my art teacher trusted me to essentially hang out in the back room of the library for one hour a day on a computer that had a copy of Adobe Photoshop installed with a 2D scanner. This was a game changer for me — I couldn’t believe that you could get things from the real world into the computer! My family and friends always took notice of my drawings, but I think the whole computer art thing made them all believe I might be able to actually make a career out of it. Later, I ended up going to a nearby community college for graphic design.

Being a crazy young kid, I decided one day that I was going to try something different and join the military. The next thing I know, I'm working on cutting-edge fighter jet avionics systems for the United States Air Force in the middle of the desert. It was an amazing twist of events and a lot to take in through the eyes of an artist. I was still doing my art on the side after work, and my wife was very supportive. My wife helped me get a bunch of art books, some on computer graphics, to take with me in case there were any moments at night in my tent to take my mind off of things.

Among those books were a few on 3D programs that my wife had heard George Lucas and his team at Industrial Light & Magic were using. Every night in the desert I would stay up late in my tent with a sleeping bag covering the light from my laptop not to wake my fellow troops, learning 3D as fighter jets screamed over top. It was clear to me that this is what I was meant to do next in my life.

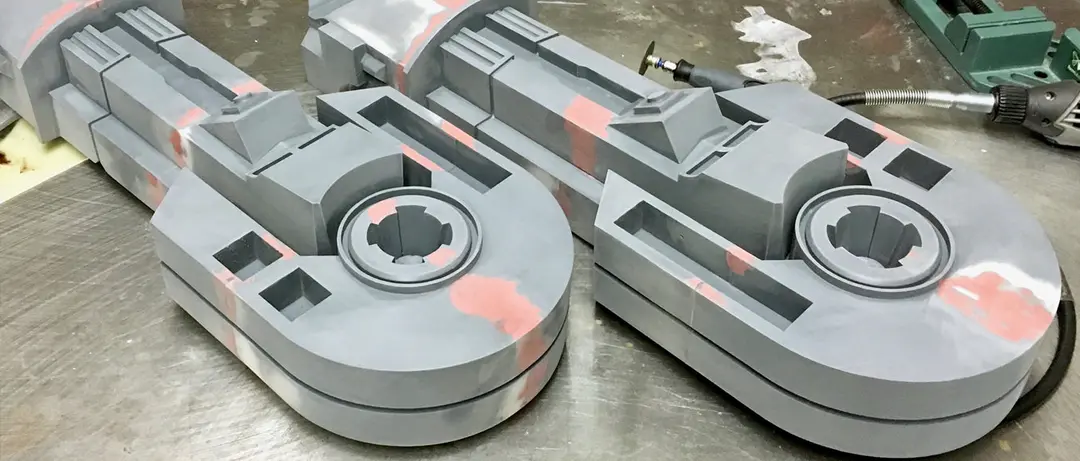

So I completed the remaining time of my enlistment, we moved out to San Francisco to go to the Academy of Art, I worked at many studios, and I finally landed a job for George Lucas at Industrial Light & Magic as a lead 3D Artist/Designer on Star Wars. Not only do I now use scanners to get three-dimensional forms inside of the computer, but I also get my 3D designs out of the computer using 3D printers. Ironically, I often share my creations with a fellow artist I am lucky enough to work for, John Knoll, the man who invented Adobe Photoshop. I never would have guessed that would happen back when I was just a kid learning Photoshop in the back room of a library.

What projects are you working on these days?

I just finished my part on Rogue One: A Star Wars Story and am now forging ahead with an extremely talented team of folks on Dr. Strange. At home I'm learning from my daughter (who also loves to draw and paint, even as a toddler) and my wife as we go through this experience. Becoming a parent changes how you perceive the world which definitely plays a major role in your work as an artist. My time is more precious now, so I've learned to streamline a lot, which is why I need the 3D printer to work almost every time these days. It's not just a matter of a print failing and having it kick off again, but instead the difference is one of my designs making it into the physical world or not. If I hit a snag, I don't have time anymore to troubleshoot, so I personally lean heavily on the reliability that Formlabs products deliver.

I don't have time anymore to troubleshoot, so I personally lean heavily on the reliability that Formlabs products deliver.

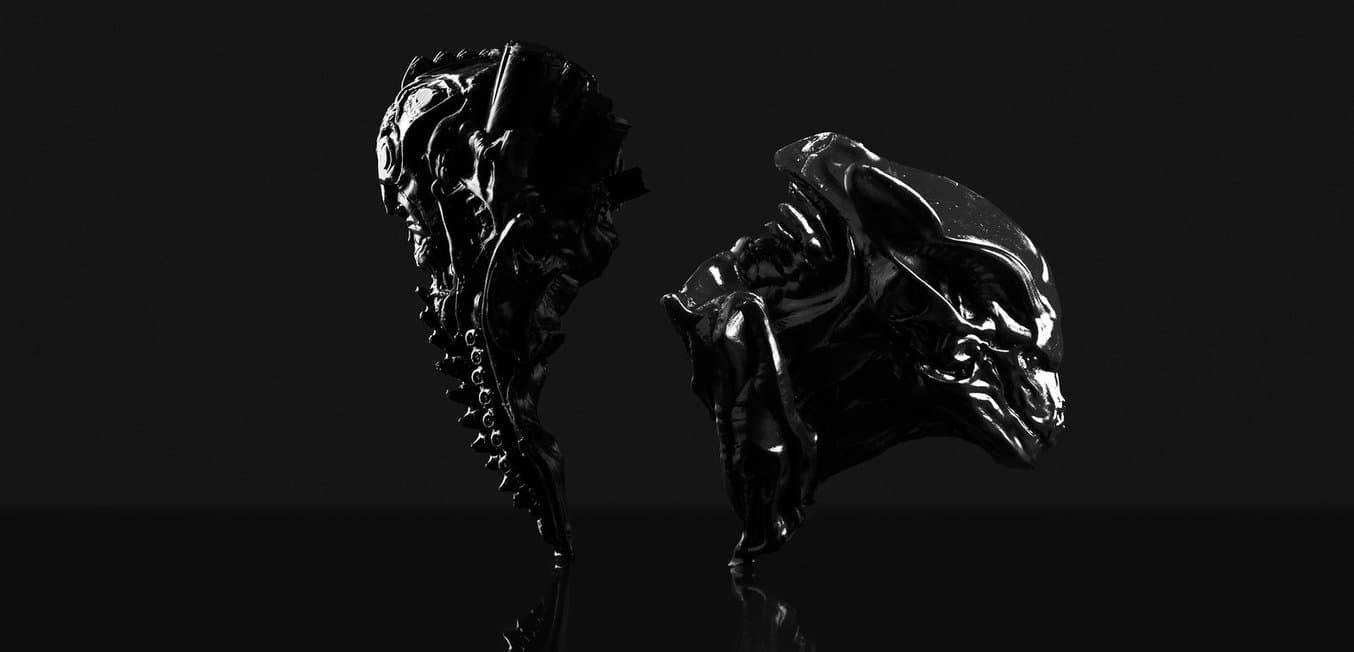

What are you printing with your Formlabs 3D printer?

Anything from cute characters to scary bio-mechanical alien creatures, robots, and spaceships. As with most professional artists, I have to be able to switch styles/genres on the fly for directors/production designers every day, so I'm all over the road. The printer sits right next to me on my desk. That real estate is very coveted to me, and Formlabs has a piece of it. I use it sometimes every day, sometimes once a month, but the important thing is that it's there and I can depend on it when I need it.

What’s your finishing process for the models?

Most people treat this phase as a “make it clean and perfect” kind of step, whereas I actually roll up my sleeves, the power tools come out, and things get ugly. Dremels, saws, glue, wood, bolts, rubber, you name it. Once something is in front of you sitting on the desk or in your hand, something magical happens. It's real. You are interacting with the design because it takes up actual space in the room in front of you. It's then that I start to see the design’s real potential, and the intended footprint or bounding box almost always changes. I often 3D scan this result, bring it back into the computer for more work, and 3D print it again. It's not about efficiency — it's about the story I’m trying to tell.

Once something is in front of you sitting on the desk or in your hand, something magical happens. It's real. You are interacting with the design because it takes up actual space in the room in front of you.

Speaking of story and how it relates to finishing, I always take into consideration how the final piece is going to be viewed and how that relates to its context in the film. For example, if it’s a hero character, and I know the face is of importance, I’m going to try and orient the print where he/she is leaning back; then the face doesn’t require supports. That way, I don't have to worry about any spurs being left behind after removing supports on a surface that the audience is going to be paying close attention to/connecting with emotionally. It's a textbook example of how good finishing practices begin inside of PreForm so that pitfalls later down the line can be avoided.

Every step of the design process is related — defining what areas are hero dictates the orientation, which drives the support structure, which establishes finishing requirements. Finishing starts with the story, is addressed inside of software, and is dealt with when the print is done. Thinking this way saves time and ultimately yields better print results overall.

See more of Landis Fields’ incredible work on his Instagram or his personal site.