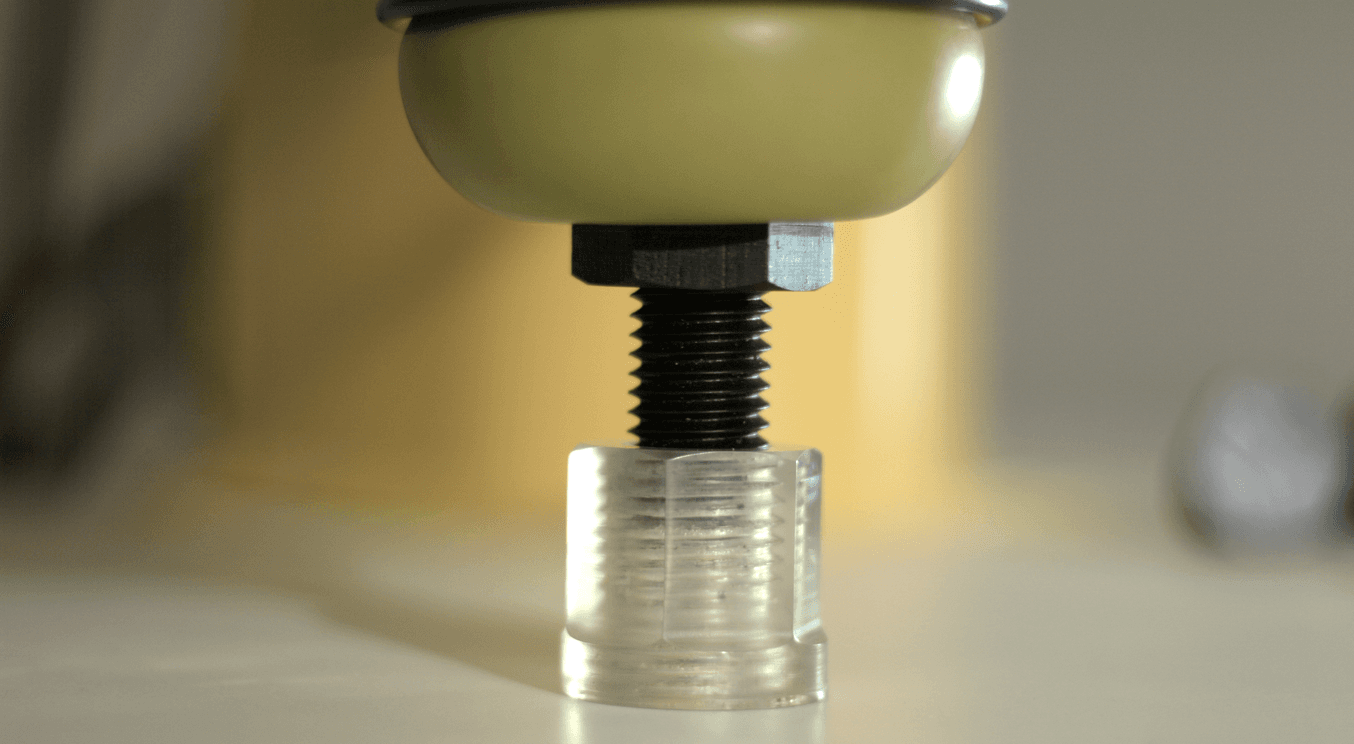

Mechanical engineer John Amend co-founded Empire Robotics in Boston to give robots a better grip. Their Versaball picks up non-uniform objects using innovative granular jamming technology, allowing a soft surface to conform to irregular shapes.

“3D printing is part of our everyday prototyping process, we use 3D printers like other engineering tools–like a drill press or other high-end tool,“ Amend said.

The Form 1+ has proved to be the perfect tool to continue their fast-paced development process.

“Every mechanical engineer should have a Form 1+ on their desk. To be able to design something, print it, and in the morning, test it,” Amend said.

In the company’s early days, Empire Robotics used expensive and slow service bureaus. The Form 1+ has sped up their development process and dramatically reduced the cost of prototyping.

Experience SLA technology firsthand: Request a free sample of our Standard or Engineering Resins.