3D Printing to Support COVID-19 Response Efforts

Formlabs launched its COVID-19 response efforts in March of 2020, determined to help the medical community use 3D printing to address the pandemic and associated supply chain shortages. In the following months, we worked with dozens of healthcare providers and government agencies around the world on various projects spanning COVID-19 testing, PPE, and medical equipment.

On this page you can find information on currently available applications for medical professionals and non-clinical use. You will also find stories highlighting how Formlabs users overcame local challenges and shortages to help fight the pandemic.

Success Stories

Hear from users around the world that pivoted to 3D print during the COVID-19 pandemic.

Ultimate Guide to Engineering From Home

Do you need to work from home due to COVID-19 restrictions? With the right home setup and workflow, desktop 3D printing can help you maintain productivity and adapt quickly while working remotely. Ultimately, this agility will help you keep the edge on your competitors and maintain tight deadlines, even through a crisis.

3D Printing Applications

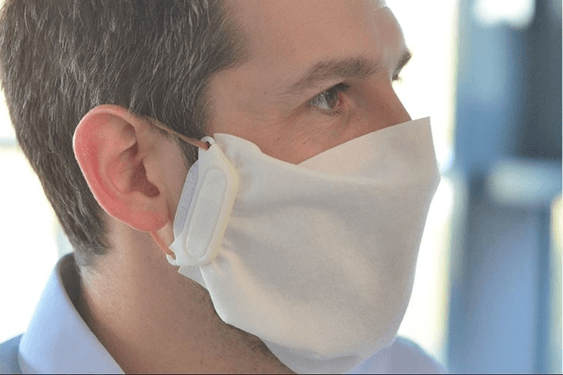

Formlabs has made available 3D prints for both clinical and nonclinical users.

Below, find content for medical professionals such as information on NP swabs and BiPaP adaptors. These are select clinical projects that Formlabs and our clinical innovation partners have pioneered around the world and have been using in the field.

For non-medical users who do not have specialized manufacturing environments which meet regulatory requirements to produce medical-grade parts, we’ve put together a library of impactful solutions that are ready to be printed and used by anyone.

Medical

Applications for hospitals, medical device firms, healthcare providers, and the clinical community.

Latest News

Since the start of the pandemic, 3D printing has been generating headlines. From the race to produce test swabs, to new FDA approved devices addressing supply chain shortages, 3D printing stepped up to help fight COVID-19. Here is a collection of some of the biggest stories you may have missed.

Formlabs Recognition

Since the start of the pandemic, hundreds of companies, nonprofits, and government agencies have contributed to reducing the impact of COVID-19. Below, you will find awards given to Formlabs by various media publications.

Frequently Asked Questions

Formlabs has received thousands of inquiries regarding how 3D printing can help the current crisis. Here are answers to some of the most common questions we have received.

Interested in learning more about 3D Printing for Healthcare?

Join our monthly newsletter to stay updated on how 3D printing is transforming the healthcare industry.

New to 3D printing? Explore our healthcare resources to learn how 3D printing is helping to deliver treatments and devices customized to better serve each unique individual and saving time and costs from the lab to the operating room.