3D Printed Custom Surgical Guides for Ameloblastoma Removal and Genu Varam Correction

Though 3D printing has enabled innovations in a multitude of disciplines and industries, it is the advances made by physicians and healthcare providers that can make the most immediate impact in improving people’s lives. 3D printing customized surgical guides can help surgeons understand each patient’s unique anatomy and pathology, helping them analyze risks, plan an approach, and become more familiar with the case before entering the operating room.

Formlabs and our partners’ varied expertise has helped thousands of doctors improve preoperative planning, operation times, and patient outcomes. Through 3D imaging and 3D-printed pre-operative models, surgical guides, and single-use surgical instruments, the power of customization can make patient care easier and more accessible.

The following two cases demonstrate how an accessible 3D printing ecosystem like the Form 3B+ and Formlabs suite of biocompatible resins can enable physicians to successfully treat complex pathologies, all at an affordable cost to the hospital and the patient.

Case Study: Ameloblastoma Surgery

Diagnosis

Dr. Yogesh Bhatt in Aakar Hospital in Vadodara, leveraged the power of accurate, powerful 3D imaging, modeling, and printing to help a 19-year-old man suffering from ameloblastoma.

Ameloblastoma is a rare, noncancerous (benign) tumour that often develops in the jaw near the molars. Tumour growth begins in the cells that form the protective enamel lining of teeth. The most common type of ameloblastoma grows aggressively, forming a large tumour that spreads out from the enamel and into the jawbone (mandible).

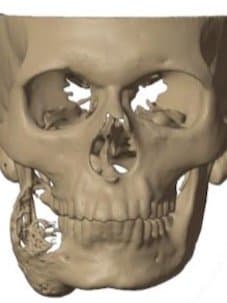

The 3D model of the patient’s skull with the ameloblastoma on the right side of the jaw. Source: Jajal Medical

Side view of the ameloblastoma enabels the surgeons to examine the pathology from different viewpoints. Source: Jajal Medical

Treatment options for ameloblastoma vary depending on size, location, characteristics, and cell type. Surgery is usually performed to remove the tumor, and since the tumor grows into the jawbone, aggressive surgery that removes part of the mandible is performed. Radiation therapy and further supportive care may also be required depending on the extent of the tumor. Though more conservative options exist, due to the high chance of recurrence of the tumor, they are not used extensively.

Preoperative Planning

To treat his patient, Dr. Bhatt started by ordering high-resolution CT scans of the mandibular area from multiple angles. Based on the segmented CT data, Jajal Medical, a biomedical imaging service, created a 3D model of the skull.

Through the visualization of the pathology and the ability to see the pathology from multiple angles, including where its attachment to the mandible, Dr. Bhatt was able to plan out his approach. The procedure would be twofold; first, Dr. Bhatt planned to remove the tumor and compromised parts of the jawbone. Then, he would remove a small section of the fibula, one of the three long bones in the leg, and use it in the reconstruction of the jawbone. This type of mandibular reconstruction using fibula material is common, due to the fibula’s excellent blood supply, lack of load-bearing function, and optimal shape.

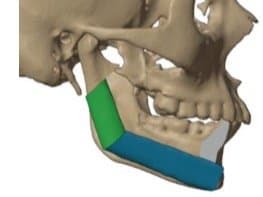

The healthy part of the mandible was mirrored, a technique that involves a digital replication based on the existing data, to facilitate the most optimal reconstruction of the bone and guide Dr. Bhatt in removing only the necessary fragment of bone from the fibula. Then, the team at Jajal Medical designed 3D models of surgical cutting guides customized to fit the anatomical models of both the mandible and fibula.

The blue components bracket the area that will be removed during the surgery. Source: Jajal Medical

The model shows the fibula replacing the removed portion of the mandible. Source: Jajal Medical

3D Prints and Operations Results

Once the models and guides were designed, Jajal Medical 3D printed anatomical models of the jaw and fibula as they would be during pre-op, in-op, and post-op. This allowed Dr. Bhatt to continuously check his progress against a tangible, true-to-life model, and understand what complications could potentially arrive at each stage.

The 3D printed model of the mandible with the ameloblastoma.

The 3D printed model of the skull with the figment of the fibula placed in it post "reconstruction.” Source: Jajal Medical

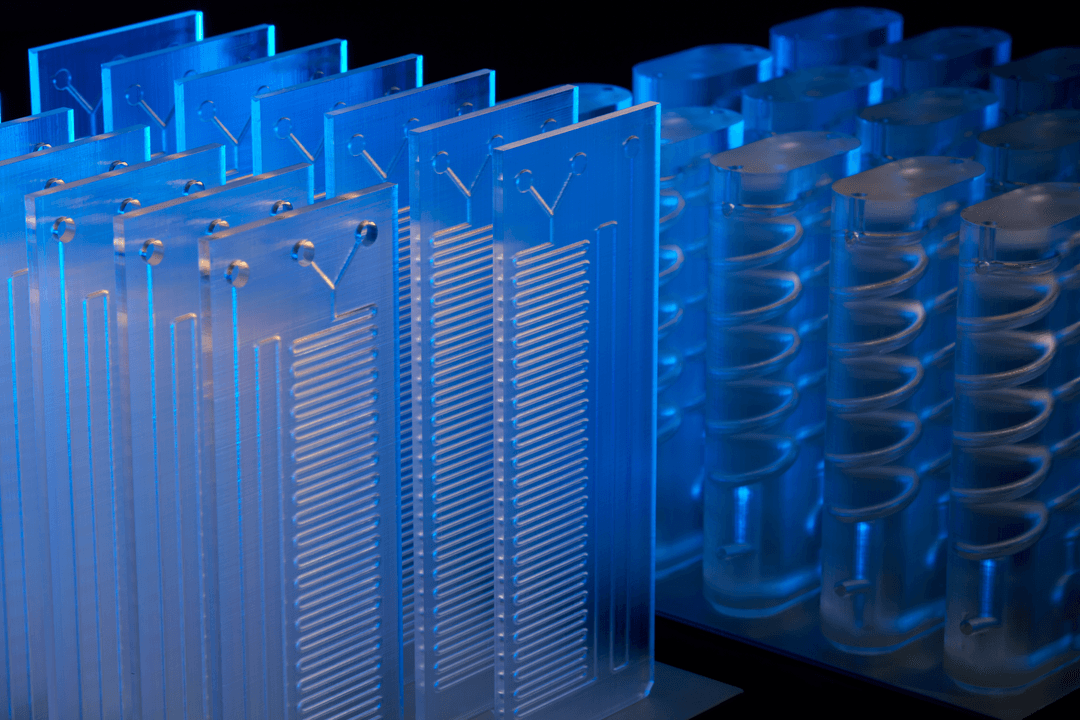

The final patient-specific surgical guides were 3D printed using the Formlabs 3B+ printer in BioMed Amber Resin, and delivered to Dr. Bhatt. The precision of the Form 3B+ printer ensured a perfect fit between the surgical guide and anatomical model, and thus the patient’s unique anatomy during the operation.

The surgical guide for the fibula printed in BioMed Amber Resin using the Formlabs 3B+ printer.

The surgical guide for the mandible printed in BioMed Amber Resin using the Formlabs 3B+ printer. Source: Jajal Medical.

The use of patient-specific 3D models and customized surgical guides enabled Dr. Bhatt to proceed with confidence through a very complex operation. By pre-planning the procedure and ensuring the fit of the guide on the 3D printed model, he reduced operation time, achieved an accurate reconstruction of the jaw, and enabled faster recovery of the patient.

In this particular case, affecting a young man with a visible disfigurement, quick recovery and minimal scarring has an outsized effect. 3D modeling and patient-specific surgical guides are tangible ways to avoid complications and improve the life of the patient.

Case Study: Genu Varam (Bow-Leggedness)

Diagnosis

Dr. Taral Nagda, a pediatric orthopedic surgeon in Thane, India, utilized 3D tools and models to help treat a 14-year-old patient with Genu Varam, colloquially known as bow legs.

Bow legs cause the legs to curve outward at the knee while touching at the feet and ankles — a painful and disabling condition that involves the largest bones in the body as well as intricate connections to the spine and nervous system.

Preoperative Planning

Standard procedures to correct bow-leggedness are based on CT scans which make it hard to visualize the depth and range of the affected bones. The lack of understanding of the patient’s specific anatomy can cause complications or reduce the chance of a fully successful operation.

To better understand the patient’s unique case, Dr. Nagda worked with Imaginarium, a Formlabs value-added partner in India, to design 3D models of the anatomy and surgical tools to help guide him during the surgery. Based on the models, he began to plan the surgery to correct the angle and rotation of the femur and tibia, which rid the patient of difficulties with his gait, stabilize the ligaments, correct patella alignment, and reduce knee discomfort.

These types of procedures are risky as they may lead to neurovascular injury or implant-related complications, Dr. Nagda had to carefully plan and study the models. There are cases in which surgeons may spend hours operating, with only minimal changes to the patient’s condition.

The surgical guide designed for osteotomy of the tibia to correct bow-leggedness. Source: Imaginarium

Once the specifics of the surgery were planned, Imaginarium 3D printed a custom surgical guide using Form3B+ in BioMed Clear Resin. Tolerance, accuracy, and precision were of paramount importance in such a complex procedure. The surgical guides had to account for the patient’s unique anatomy as well as incorporate space for cutting blades, drill bits, and K wires.

The surgical guide that would be used during surgery. Printed in BioMed Clear Resin using Form 3B+. Source: Imaginarium.

Results

Thanks to this patient-centric approach, Dr. Nagda achieved remarkable success, completing the surgery in half the time compared to conventional methods. The young patient is now on the path to recovery, with renewed hope and the opportunity for a brighter future.

Improving Patient Results and Surgical Success Through Digital Techniques

Through the remarkable integration of 3D printing technology and pre-operative planning, the realm of surgical procedures has undergone a paradigm shift. This revolutionary approach ensures enhanced surgical outcomes with high accuracy and efficiency, reduced complications, and accelerated patient recovery

Formlabs, in collaboration with our trusted partners, offers a wide range of solutions for 3D printing biocompatible patient-specific instruments, single-use surgical instruments, medical devices, anatomical study or consent models, and more. The Form 3B+ and Form 3BL biocompatible printers enable a new opportunity for innovators and physicians to improve the quality of their patient care.

If you are seeking patient-specific solutions to optimize surgical outcomes, reach out to our medical sales team to learn more or explore the Form 3B+ and Form 3BL platforms.